Unloading and liquid adding device for skid-type liquid adding station and unloading and liquid adding method

A liquid filling device and liquid filling station technology, which is applied in the field of unloading and liquid filling devices of skid-mounted liquid filling stations, can solve problems such as waste, pipeline pressure rise, and local pipeline rupture, so as to avoid explosion hazards and enhance use Life and safety improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

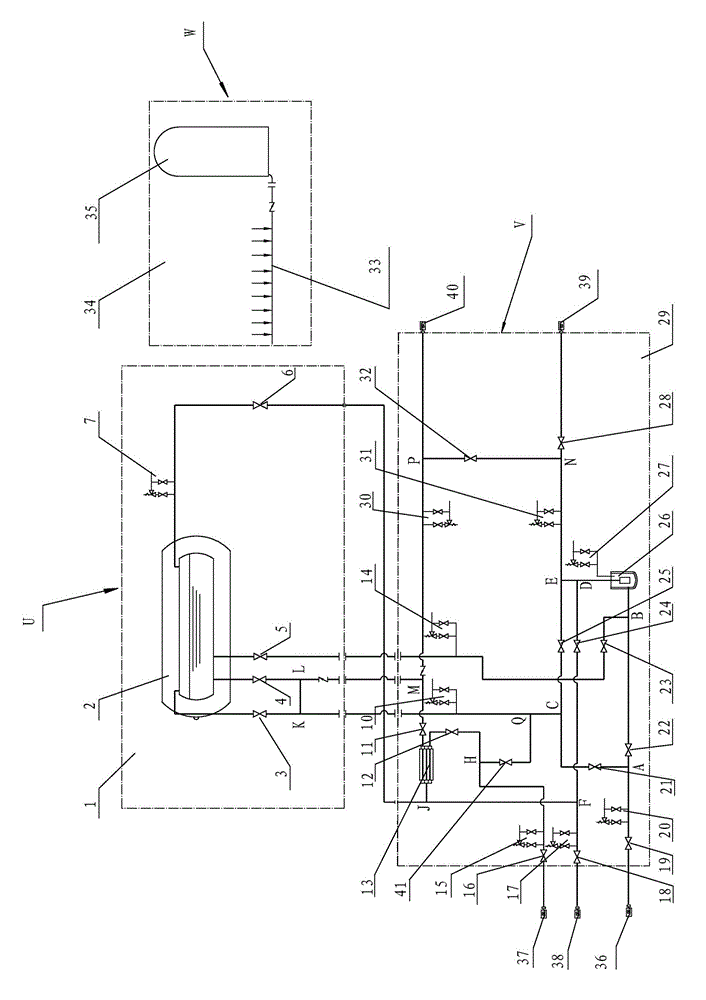

[0015] The embodiment of the present invention discloses a skid-mounted liquid filling station unloading and liquid filling device, including: a storage tank skid, a liquid filling skid and a gas collection skid, and the storage tank skid includes: a storage tank skid The base, the liquefied natural gas storage tank, the heat preservation pipeline, and several stop valves and safety relief valves arranged on the heat preservation pipeline. And several shut-off valves and several safety relief valves arranged on the insulation pipeline, the gas collection skid includes a gas collection skid base, a gaseous natural gas storage tank and an insulation pipeline.

[0016] Correspondingly, the present invention also discloses a method for unloading and adding liquid of a skid-mounted liquid filling station. When unloading the truck, firstly, pre-cool the unloading pipeline, that is, let the liquefied natural gas of the tank car enter the submersible pump and be fed by the submersible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com