Method and system for recycling residual heat of ash and slag of liquid slag-tapping boiler

A technology of liquid slag discharge and boiler ash, which is applied in the field of waste heat recovery and utilization of liquid slag discharge boiler ash and slag, which can solve the problems of large physical heat loss of liquid slag discharge boiler ash and slag, improve thermal buoyancy and diffusion capacity, and weaken corrosion , the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

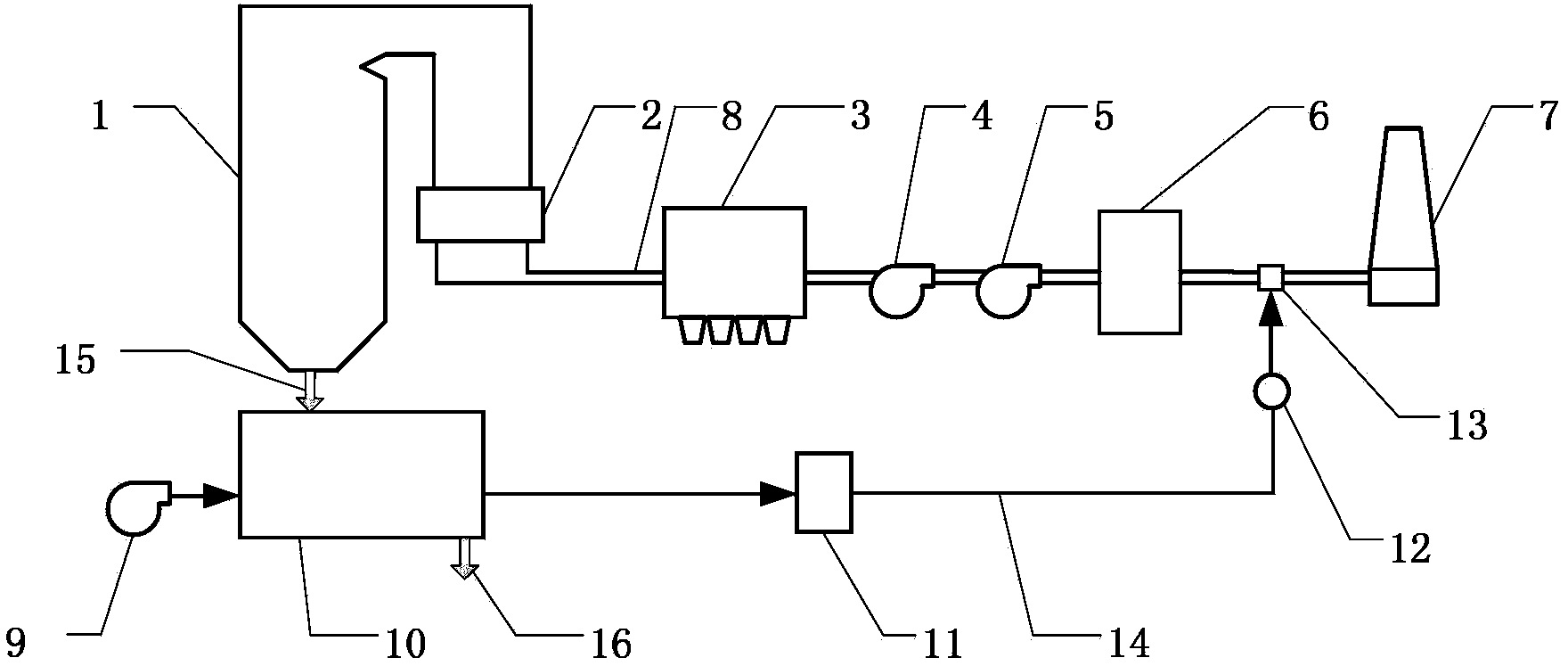

[0027] Embodiment 1: see figure 1 , this embodiment includes a conventional liquid slag discharge boiler, a smoke exhaust system and a liquid slag waste heat recovery and utilization system. Conventional liquid slagging boiler and smoke exhaust system are composed of liquid slagging boiler 1, air preheater 2, dust collector 3, induced draft fan 4, booster fan 5, wet desulfurization equipment 6, chimney 7 and flue 8. The liquid slagging boiler 1 is connected to the flue gas inlet of the air preheater 2 through the flue 8, the flue gas outlet of the air preheater 2 is connected to the flue gas inlet of the dust collector 3, and the flue gas outlet of the dust collector 3 passes through the flue 8 The induced draft fan 4 and the booster fan 5 are connected in sequence, the outlet of the booster fan 5 is connected to the inlet of the wet flue gas desulfurization equipment 6 , and the outlet of the wet flue gas desulfurization equipment 6 is connected to the chimney 7 through the f...

Embodiment 2

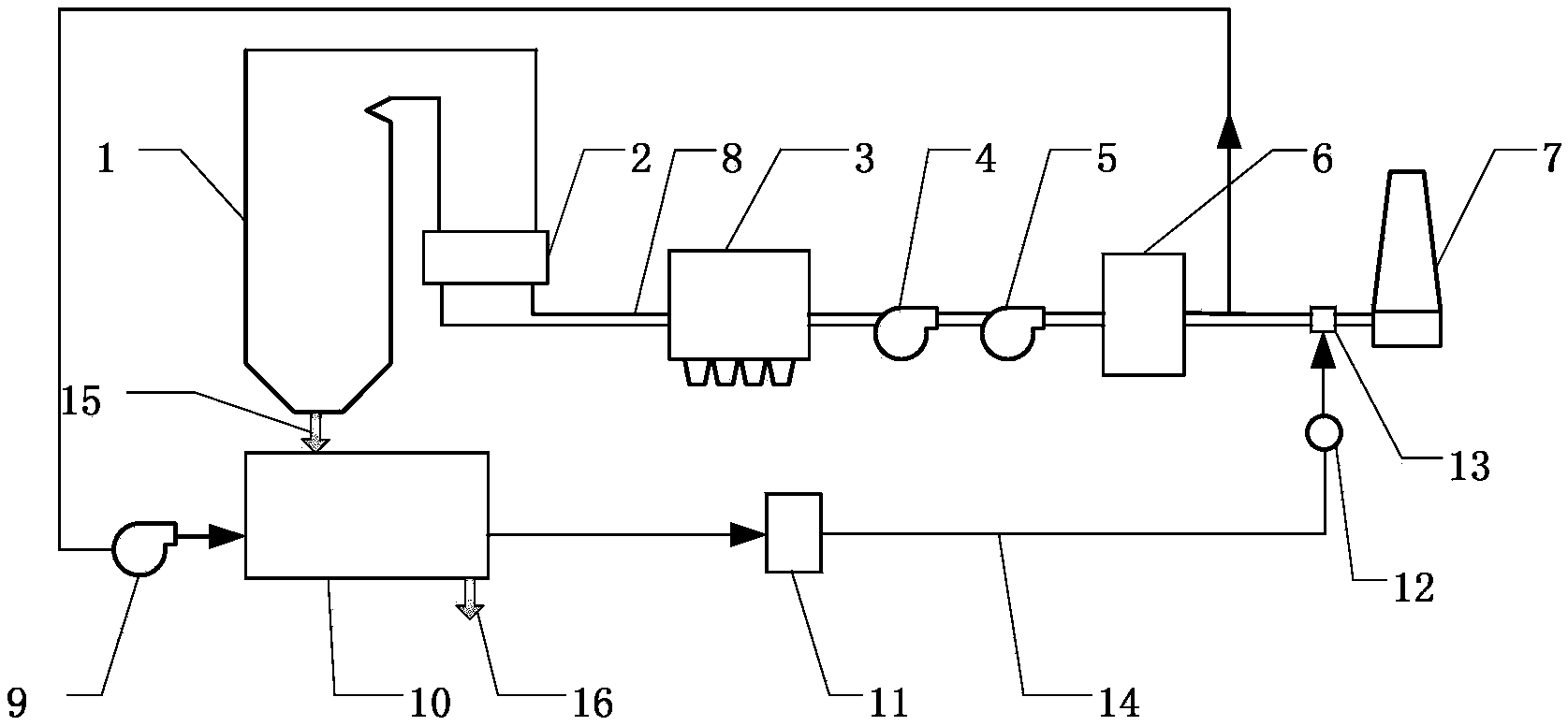

[0029] Example 2: see figure 2, this embodiment includes a conventional liquid slag discharge boiler, a smoke exhaust system and a liquid slag waste heat recovery and utilization system. Conventional liquid slagging boiler and smoke exhaust system are composed of liquid slagging boiler 1, air preheater 2, dust collector 3, induced draft fan 4, booster fan 5, wet desulfurization equipment 6, chimney 7 and flue 8. The flue 8 of the liquid slagging boiler 1 is connected to the flue gas inlet of the air preheater 2 through each heating surface, the flue gas outlet of the air preheater 2 is connected to the flue gas inlet of the dust collector 3, and the flue gas outlet of the dust collector 3 The induced draft fan 4 and the booster fan 5 are sequentially connected through the flue 8 , the outlet of the booster fan 5 is connected to the inlet of the wet flue gas desulfurization device 6 , and the outlet of the wet flue gas desulfurization device 6 is connected to the chimney 7 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com