Top air-injection gravity auxiliary driving oil-extraction two-dimensional physical simulation experiment system

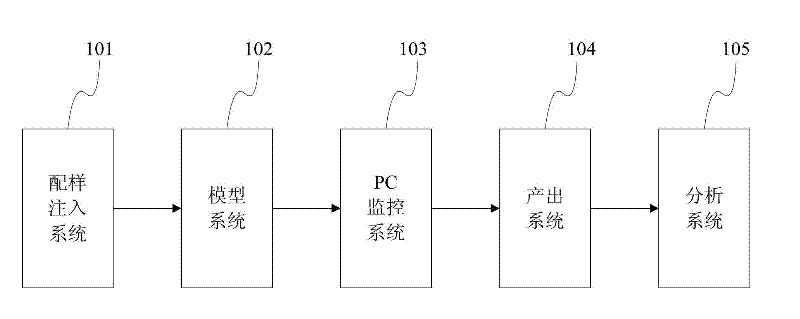

An experimental system and physical simulation technology, applied in the field of two-dimensional physical simulation experimental system of top air injection gravity assisted flooding oil recovery, can solve the problems of not considering the safety of mixed gas output, easy gas channeling, and inability to simulate formation dip, etc. Achieve the effect of ensuring the consistency of crude oil, improving real-time performance, and authentic and reliable experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

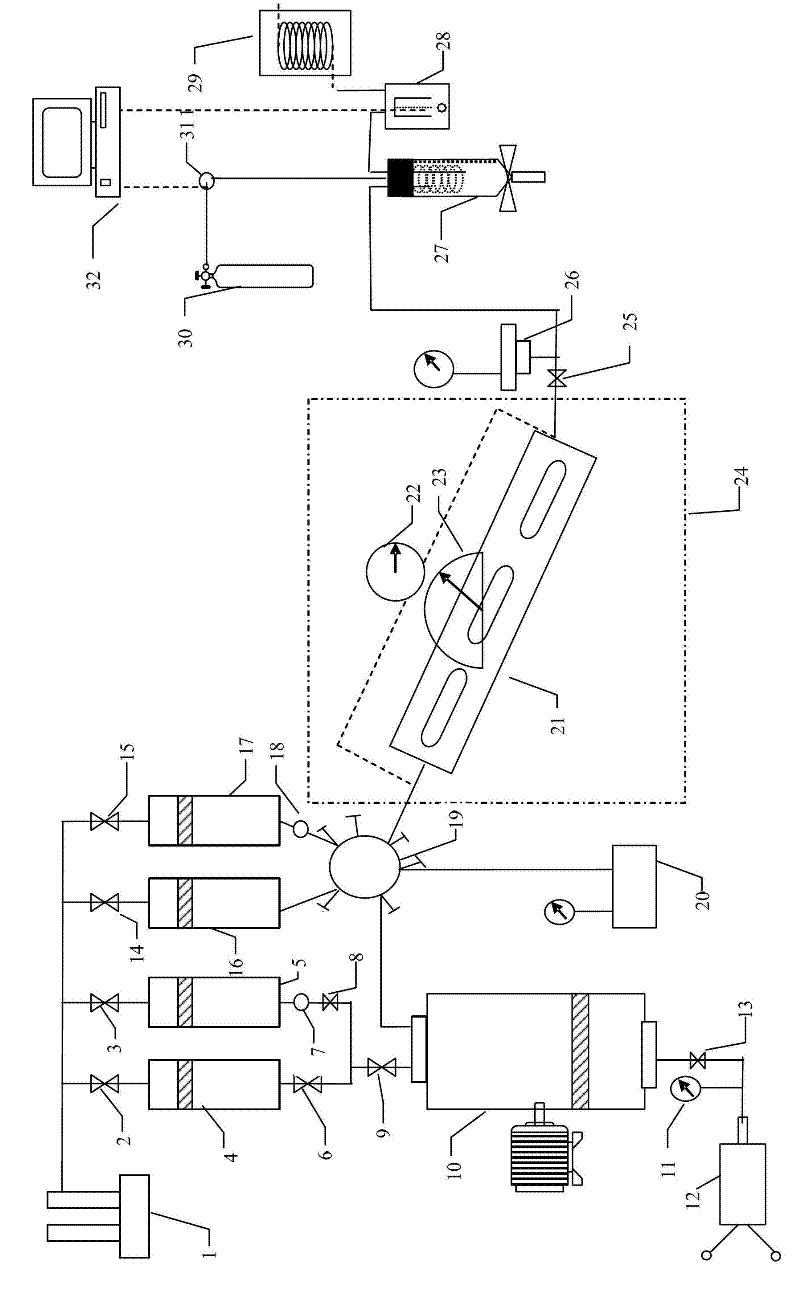

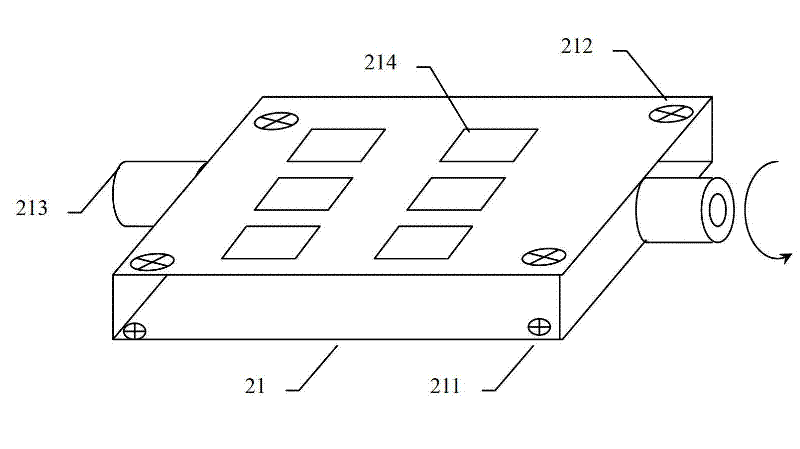

[0055] The detailed implementation is as follows:

[0056] The sample injection system consists of ISCO high-precision metering pump 1, valve 2, valve 3, dead oil piston container 4, natural gas piston container 5, gas mass flow meter 7, valve 8, valve 9, sample dispenser 10, and pressure gauge 11 , Hand pump 12, valve 13 composition.

[0057] The dead oil piston container 4 is connected to the upper inlet of the ISCO high-precision metering pump 1 and the sample dispenser 10 through the valve 2 and the valve 6 respectively, and the natural gas piston container 5 and the gas mass flow meter 7 are connected in series to the ISCO high-precision metering pump 1 and the sample dispenser respectively. The upper end inlet of the device 10 is connected, the manual pump 12 is connected with the lower end inlet of the sampler, and the outlet of the sampler is connected with the six-way valve 18 through a pipeline.

[0058] The model system consists of ISCO high-precision metering pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com