Negative pressure generating device, method and ink-jet printer

A technology of negative pressure generating and adjusting devices, which is applied in the fields of negative pressure generating devices and inkjet printing machines, and can solve problems such as low negative pressure anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

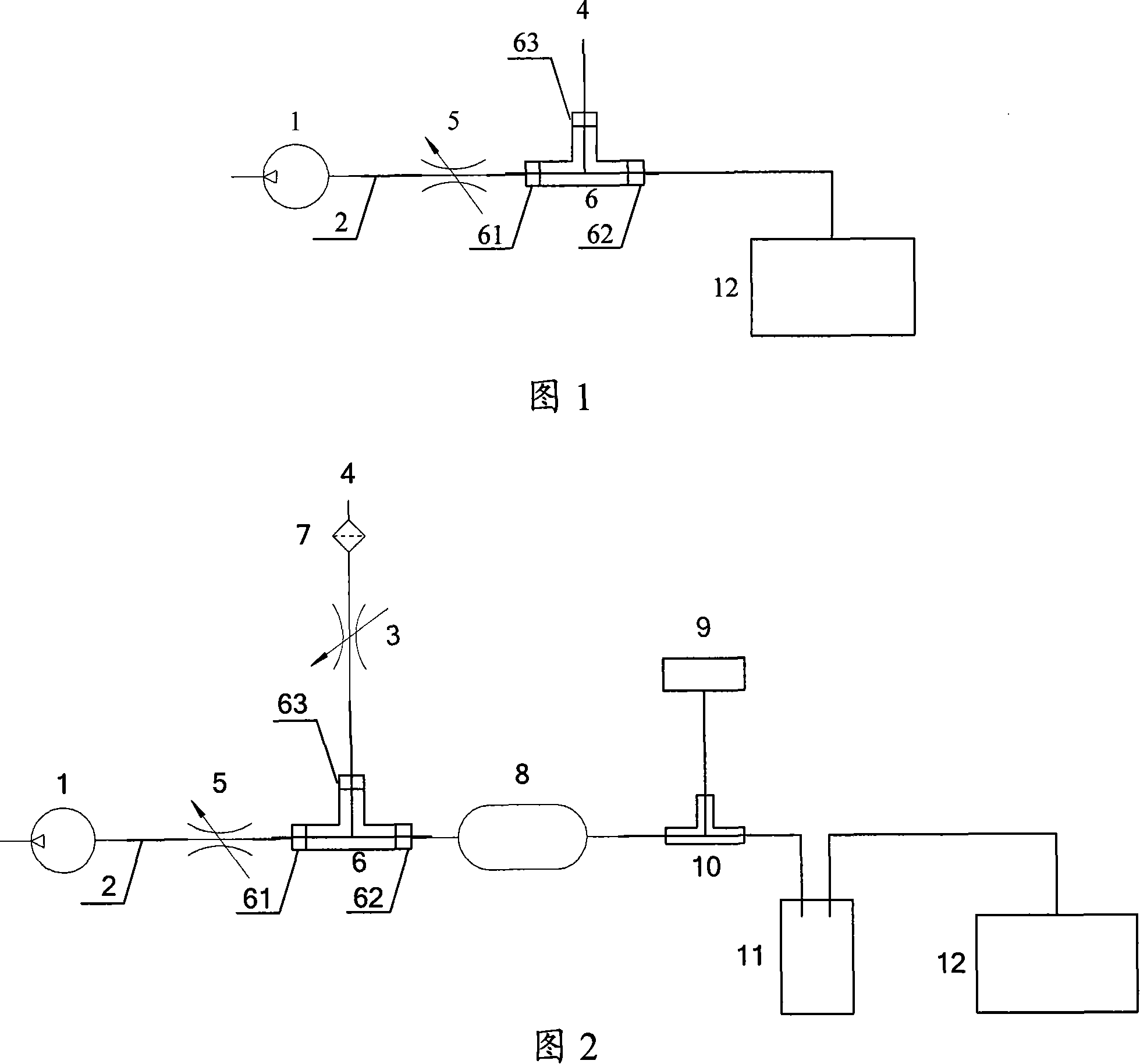

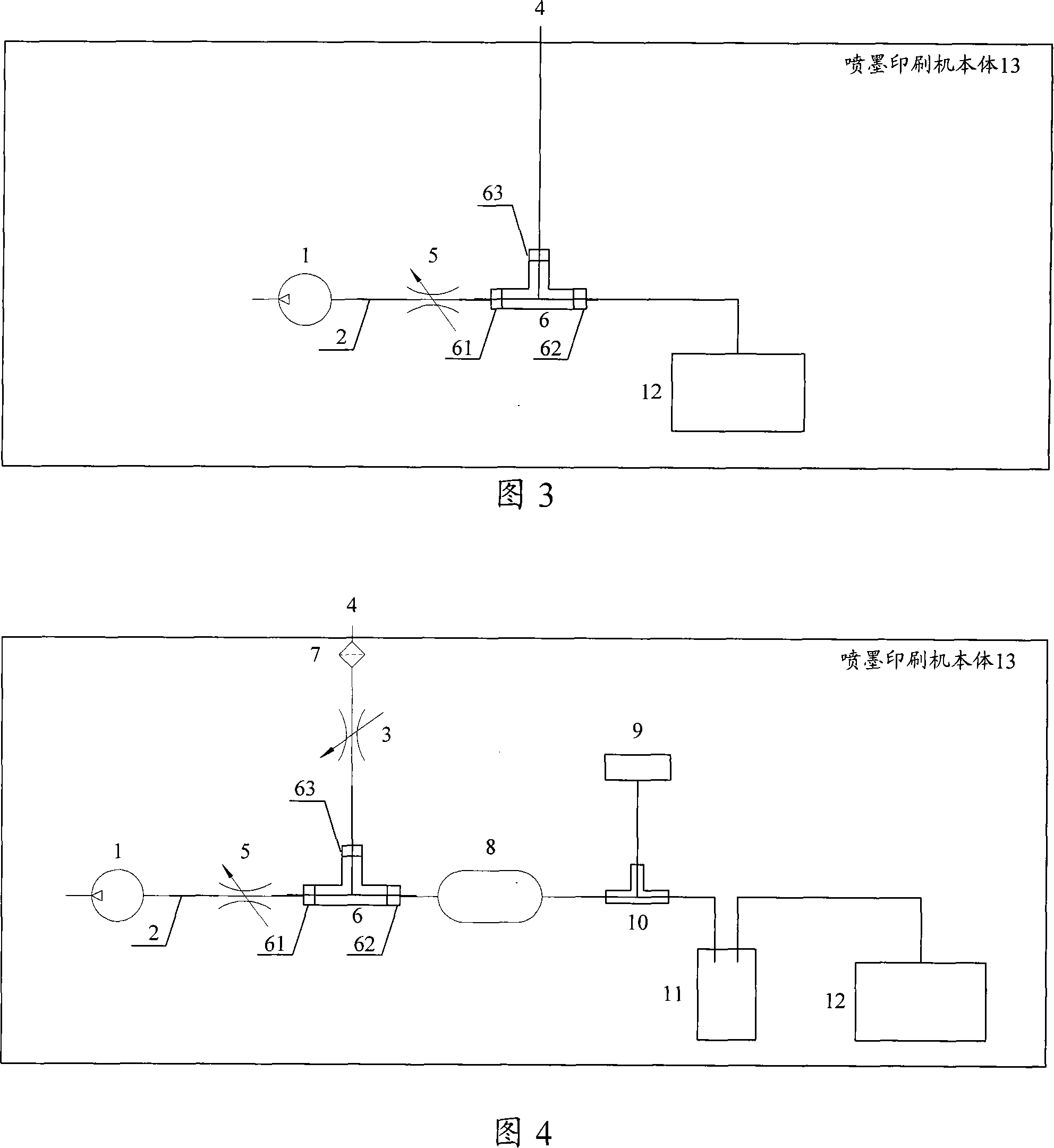

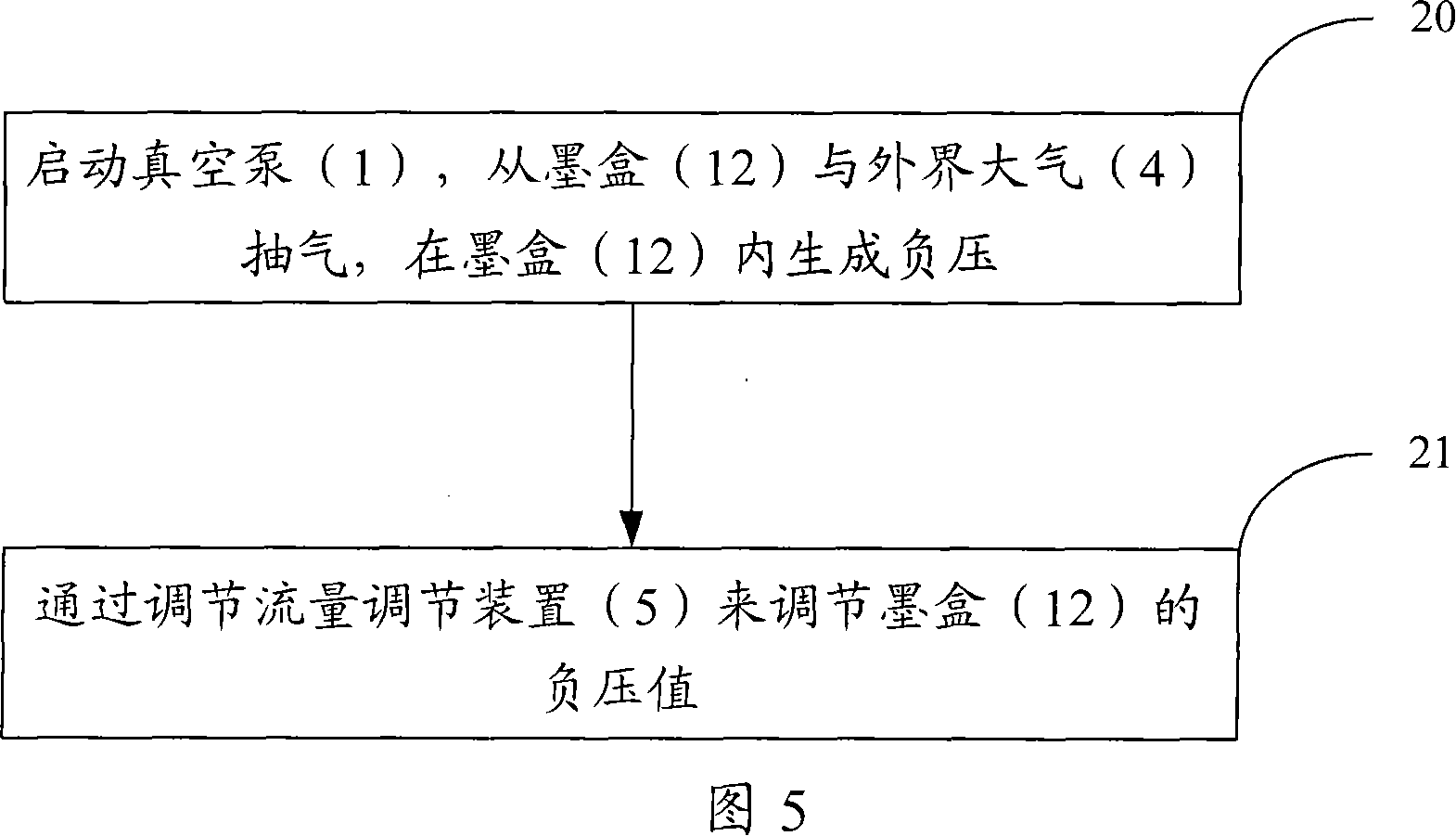

[0022] An embodiment of the present invention provides a negative pressure generating device, and the structural diagram of the device is shown in FIG. 1 .

[0023] A pneumatic device flow regulating device 5 capable of throttling is connected to the suction end of the vacuum pump 1 . The other end of the flow regulating device 5 is connected with the outlet port 61 of a three-way joint 6, and simultaneously draws air from the outside atmosphere 4 and the ink cartridge 12, wherein the port 62 is connected with the ink cartridge 12, and the inlet port 63 is connected to the atmosphere 4, and by adjusting the The first flow regulating device 5 regulates the negative pressure of the ink cartridge 12. The individual components can be connected via lines 2 . The flow regulating device 5 has a certain inhibitory effect on the fluctuation of the pumping rate of the vacuum pump 1, and the pumping effect of the outlet port 61 in the tee joint 6 and the air intake effect of the inlet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com