Pumping unit polish rod centralized connecting device

A connection device and pumping unit technology, which is applied in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve problems such as unbalanced pumping unit, complex structure, and reduced service life of packing, and achieve Reduce the labor intensity of employees, solve environmental pollution problems, and reduce the effect of material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

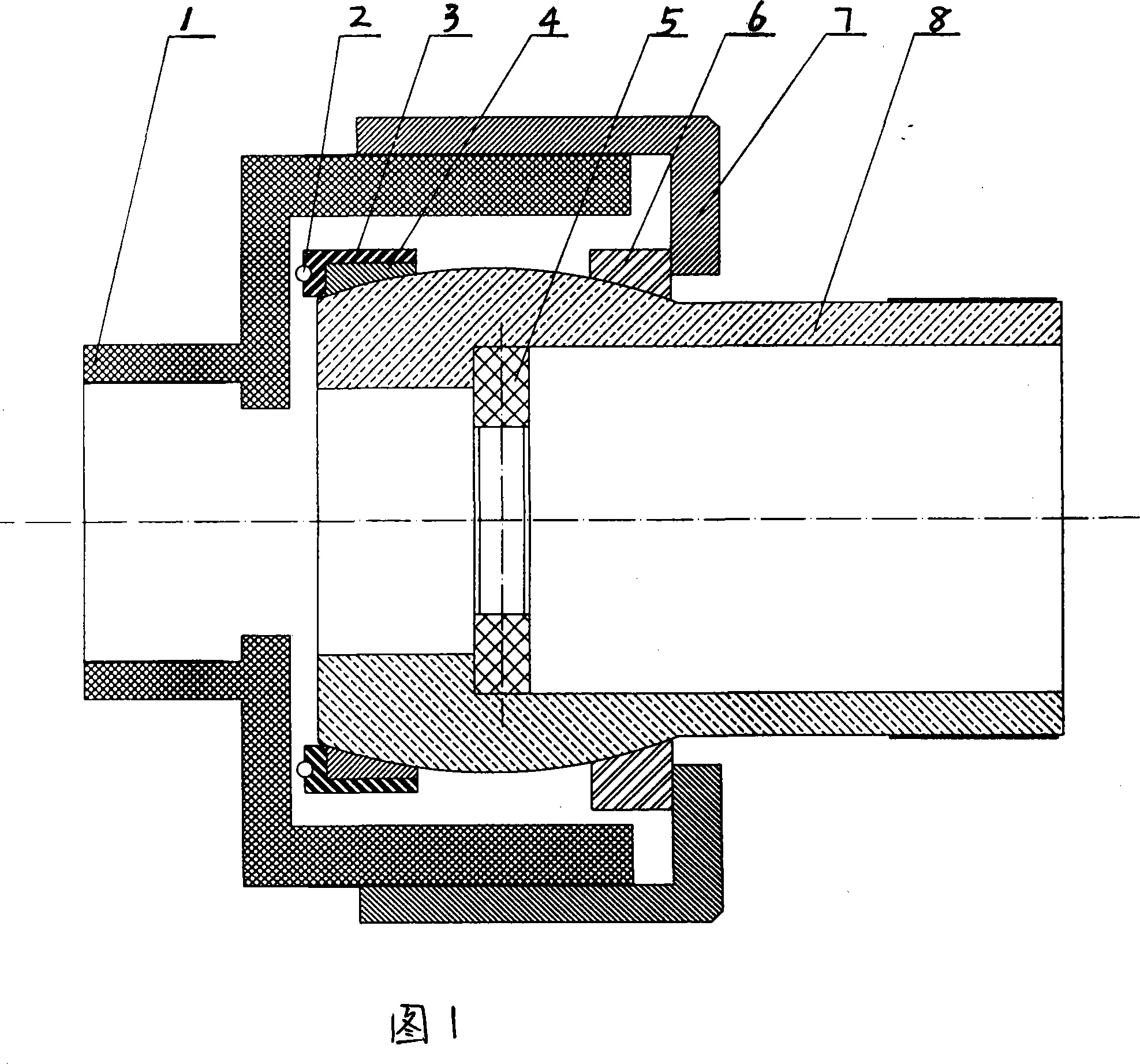

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0009] As shown in the figure, a centering connection device for a polished rod of a pumping unit is composed of a wellhead tee connection cavity 1, a translational movable ball seat 3, a movable ball joint 8, a nylon bush 5, and a ball pressure cap 7 , the translational movable ball seat 3 is located in the wellhead tee connection cavity 1, an O-shaped sealing ring 2 is installed at the bottom, and a sealing ring 4 is installed between the translational movable ball seat 3 and the movable ball joint body 8, The movable ball joint 8 sits in the translational movable ball seat 3, the nylon bushing 5 is sleeved inside the movable ball joint 8, the upper part of the movable ball joint 8 is covered with an oval gasket 6, and the ball head presses the cap 7 is threadedly connected with the wellhead tee connection chamber 1.

[0010] When in use, the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com