Nano-liter spraying device

A technology of nano-liter spray and spray head, applied in the field of mass spectrometry, which can solve the problems of unsatisfactory spray stability, short service life and difficult operation of the spray head, and achieve the effect of simple production, convenient operation and easy spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further described by the following examples, but not limited to the examples.

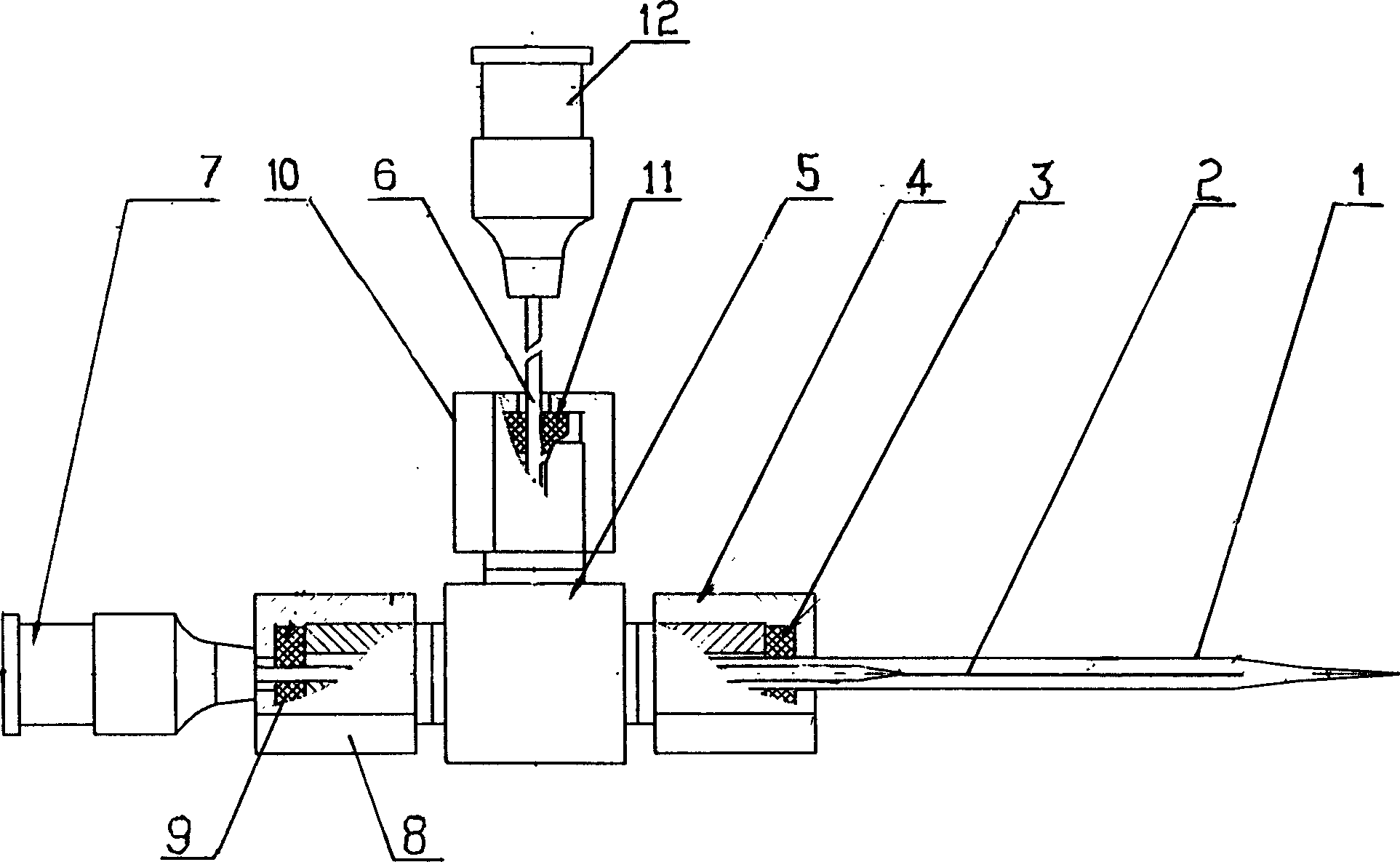

[0017] according to figure 2 As shown, the main body of the nanoliter spray device is a three-way, made of stainless steel, and the glass spray head 1 is drawn from a glass capillary of Φ1.4 on a multifunctional glass microelectrode controller. Finished spray head tip is in closed state, is 36mm, and injection needle 7 and 12 all use No. 7 medical needles (also available No. 6 or No. 8). The diameter of the molybdenum wire 2 is 30-100 μm (50 μm diameter is usually available), and the length is 18 mm. One end of the molybdenum wire 2 is mechanically welded on the tip of the needle 7, and then passes from one end of the stainless steel tee 5 to the other end; the glass spray head 1 The port of the tee 5 is sealed and connected through the silicone rubber ring 3 and the nut 4, and the molybdenum wire 2 is inserted therein; the third port of the tee 5 is the gas passag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com