3D printout surface sand blasting processing machine

A technology of surface sandblasting and 3D printing, which is applied in the direction of abrasive jetting machine tools, used abrasive processing devices, abrasives, etc. It can solve problems such as difficult internal and external surfaces, poor surface roughness, and complex shapes of finished products, and achieve consistent smoothness Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

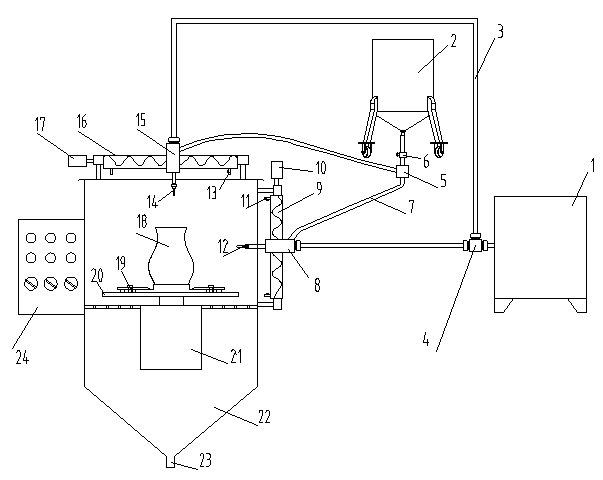

[0007] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0008] Such as figure 1 As shown, the present invention includes an ultra-high pressure generator 1 for producing high-pressure water, a sand storage tank 2, a sand feeding hose 7 connected between the sand storage tank 2 and the mixing chamber, and a solenoid valve installed on the sand feeding hose 7 6. The sand outlet tee 5 installed under the electromagnetic valve 6, the high-pressure water pipe 3 connected between the high-pressure generator 1 and the mixing chamber, and the high-pressure tee 4 installed on the high-pressure water pipe 3. There are two mixing chambers, respectively It is the mixing chamber A 8 and the mixing chamber B 15. The bottom of the mixing chamber A is connected to the nozzle A 12, and the bottom of the mixing chamber B is connected to the nozzle B 14. The Z-direction screw rod 9 is installed on the right side of the sandblasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com