Double-cock ball throwing device and ball throwing method

A technology of ball-throwing device and double cock, which is applied in the direction of wellbore/well valve device, earthwork drilling and production, wellbore/well parts, etc. It can solve the problems of difficult installation process, time-wasting, difficult operation, etc., and achieve high work efficiency , Strong operability and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

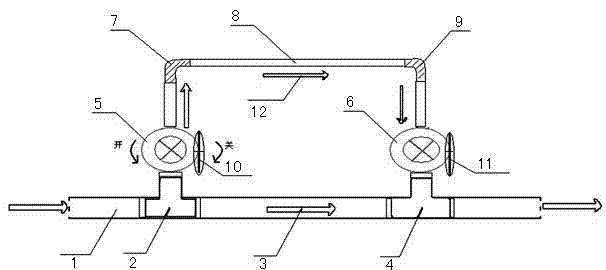

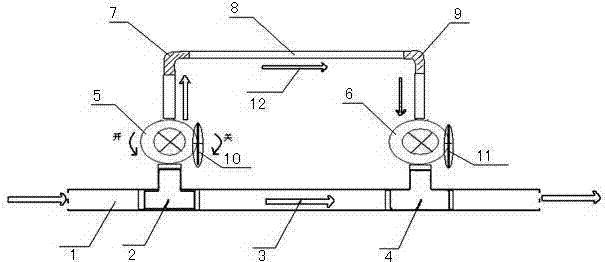

[0079] see figure 1 , the assembly, disassembly process and working principle of the present invention are as follows:

[0080] (1) When assembling the present invention, first install the left and right T-shaped high-pressure tees 2 and 4 on the high-voltage main line 1, check the stability of the high-pressure main line 1 and the connection at the oil pan, and ensure that the connection does not puncture No leakage (that is, there is no leakage at the connection of the pipeline, so as to ensure that the entire pipeline is well sealed); then connect the left and right cocks 5 and 6 with oil nonels (referring to a conventional connection method, the female port is a non-oil ring , the male port is threaded, and the oil ring is connected when it reaches the threaded place) to the T-shaped high-pressure tee 2, 4 on the left and right sides, and then put the left and right cock handles 10, 11 in the closed position; The left and right cocks 5 and 6 are connected by using the hig...

Embodiment 2

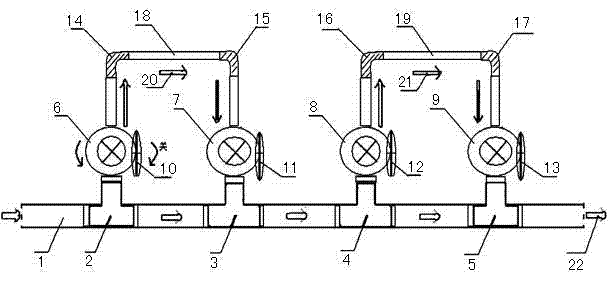

[0084] see figure 2 , the assembly, disassembly process and working principle of the present invention are as follows:

[0085] (1) When assembling the present invention, first install the T-shaped high-pressure tee 2, 3, 4, and 5 on the high-pressure main line 1, and sequentially connect the cocks 6, 7, 8, and 9 to the T-shaped high-voltage On the tee 2, 3, 4, 5; connect the left two cocks 6, 7 with the high-pressure elbow 14, 15 and the high-pressure pipeline 18 connected to the left elbow, and the right two cocks 8, 9 The high-pressure elbows 16, 17 and the high-pressure pipeline 19 connected to the right elbow are used for connection, and different types of balls are respectively loaded into the high-pressure pipeline 18 connected to the left elbow and the high-pressure pipeline 19 connected to the right elbow according to the construction design requirements. High-pressure pipeline 19; when starting fracturing, the cock handles 10, 11, 12, and 13 are respectively in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com