Preparation method of graphene microsheets with controllable size

A graphene micro-chip size technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems that graphene micro-chips cannot be controlled in size and cannot be mass-produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0030] The invention discloses a method for preparing a size-controllable graphene microsheet, the specific steps of which are as follows:

[0031] Step 1. High-temperature expanded acidified graphite: use acidified graphite with high expansion ratio as raw material, expand it at high temperature to prepare expanded graphite; the acidified graphite raw material size used here can be 1-8000 μm, preferably graphite raw material size ≥ 150 μm; the expansion temperature used can be 100-1500°C, preferably the expansion temperature is ≥800°C.

[0032] Step 2. Organic matter intercalation expanded graphite: use organic matter as intercalation matter and adopt a certain blending method to prepare expanded graphite / organic matter composite material; this organic matter is intercalated, combustible and can make the expanded graphite form before entering the pulverizer block, when a mixture is used, the mixing ratio of each component in the mixture is any ratio; one or more of saturated ...

Embodiment 1

[0037] The large-scale preparation of size-controllable graphene by combustion method is realized through the following steps:

[0038] Step 1. High-temperature expanded acidified graphite: using 180 μm acidified graphite as raw material, expand it at 800° C. to prepare expanded graphite;

[0039] Step 2, organic intercalation expanded graphite: using polystyrene as an intercalation material, adopting a melt blending method to prepare expanded graphite / polystyrene composite material;

[0040] Step 3, the pulverizer refines the composite material: using an ultrafine pulverizer, the expanded graphite / polystyrene composite material is pulverized into a 40 μm expanded graphite / organic fine powder;

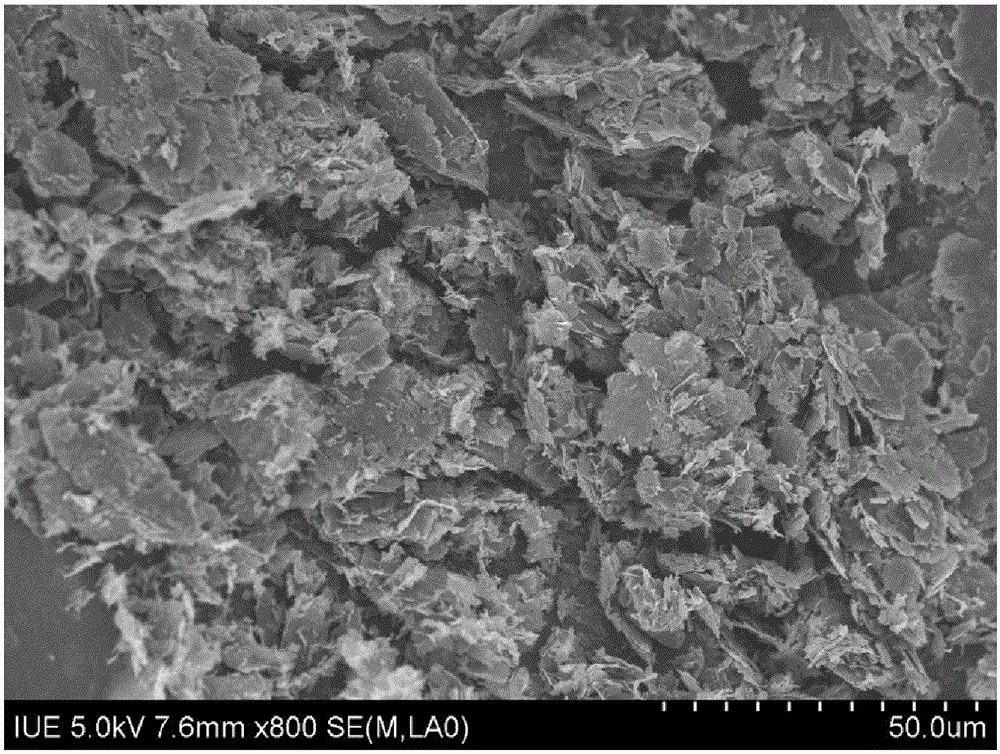

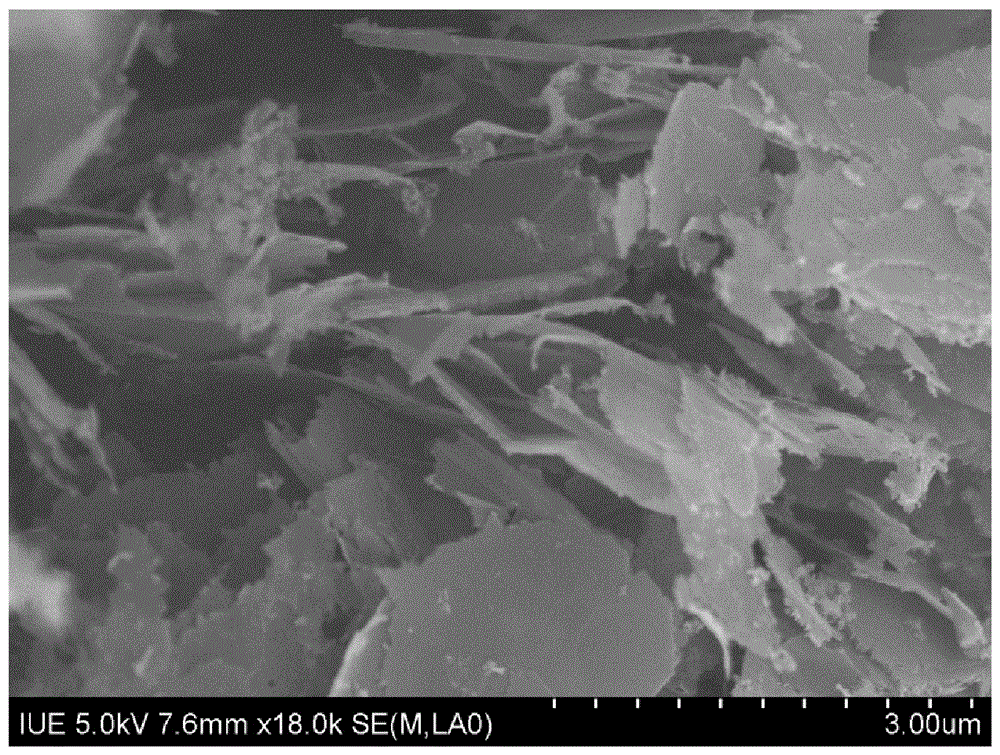

[0041] Step 4. Combustion of expanded graphite / organic fine powder: In an air atmosphere and at a temperature of 800°C, polystyrene is burned to generate a large amount of energy, and the expanded graphite is exfoliated into a graphene micro-sheet powder of ≤40 μm.

Embodiment 2

[0043] The large-scale preparation of size-controllable graphene by combustion method is realized through the following steps:

[0044] Step 1. High-temperature expanded acidified graphite: using 300 μm acidified graphite as raw material, expand it at a temperature of 1000° C. to prepare expanded graphite;

[0045] Step 2, organic matter intercalation expanded graphite: using nylon 6 as the intercalation material, adopting a melt blending method to prepare expanded graphite / nylon 6 composite material;

[0046] Step 3, the pulverizer refines the composite material: using an ultrafine pulverizer, pulverize the solid blend into 10 μm expanded graphite / nylon 6 fine powder;

[0047]Step 4. Combustion of expanded graphite / nylon 6 fine powder: In an air atmosphere and at a temperature of 800°C, nylon 6 is burned at a high temperature to generate a large amount of energy, and the expanded graphite is exfoliated into graphene microflake powder of ≤10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com