Shrapnel-type wire connector of auxiliary terminal of intelligent electric energy meter

A technology for smart energy meters and connectors, which is applied to instruments, measuring electrical variables, measuring devices, etc., can solve the problems of increased positioning difficulty, high positioning requirements, long positioning time, and poor contact wire insertion, etc., to avoid poor contact or The effect of virtual connection, low transformation cost and saving transformation funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

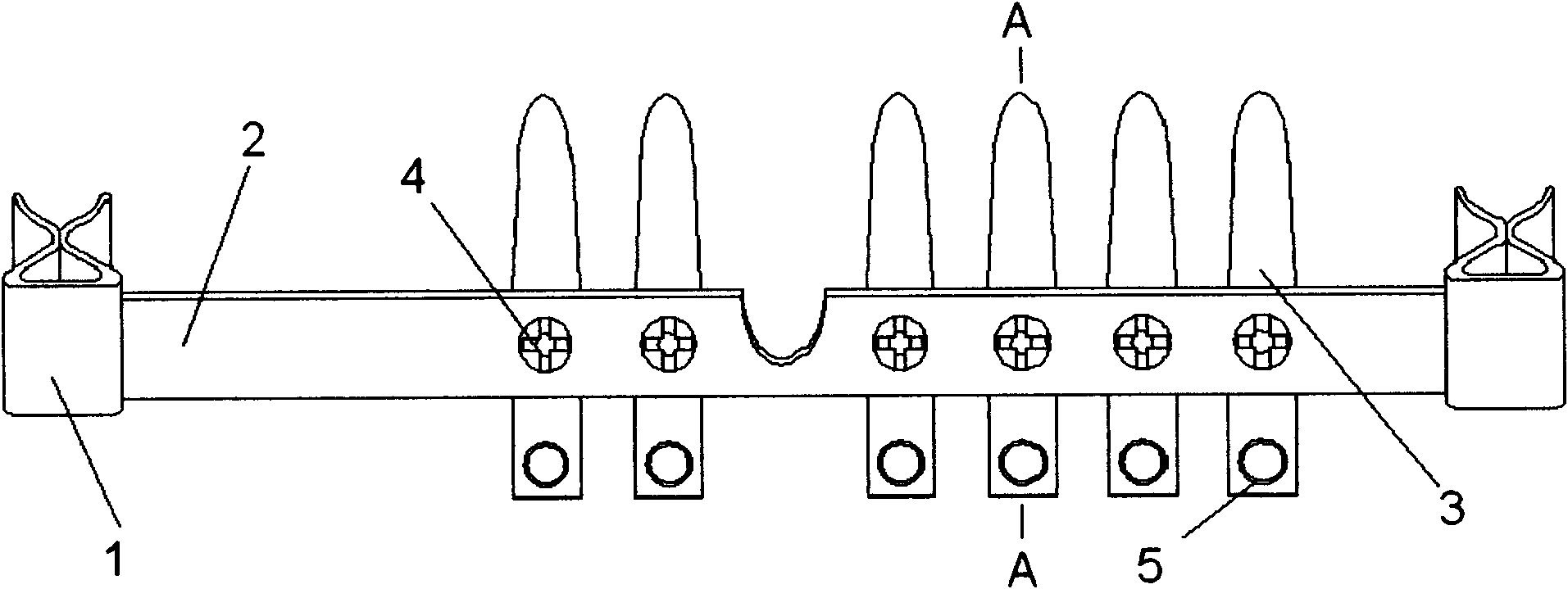

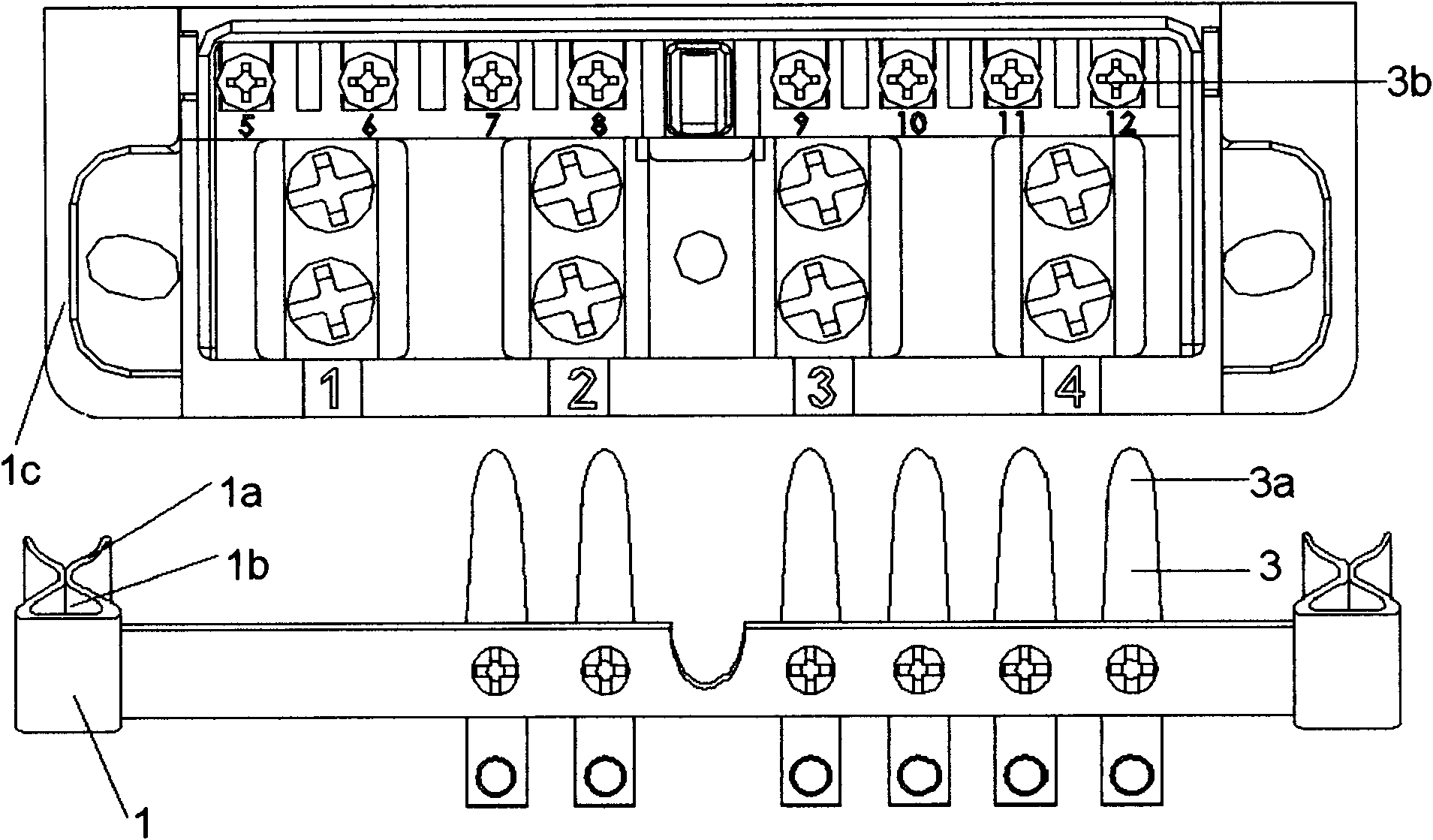

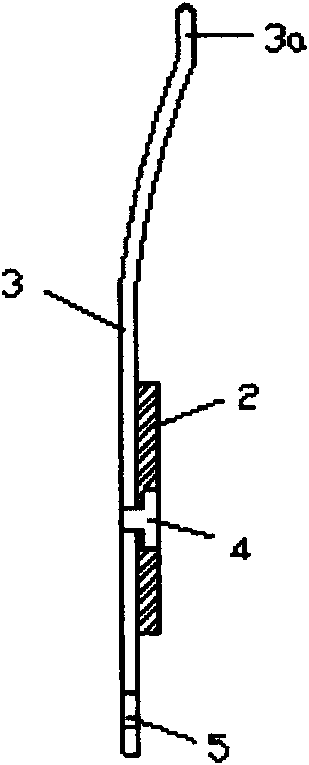

[0020] The shrapnel type connector for the auxiliary terminal of the intelligent electric energy meter in this embodiment, such as figure 1 As shown, a V-shaped opening fastening clip 1 and a metal shrapnel 3 are fixed on the fixing plate 2; the metal shrapnel 3 has a welding port 5 for welding wires and a screw 4 for connection; the screw 4 fixes the shrapnel 3 on the fixing plate 2 on. Of course, other fixing methods such as welding can also be used to fix the metal shrapnel 3 on the fixing plate 2 .

[0021] The part of the metal dome 3 above the fixed plate 2 has an inward angle of about 20 degrees. Setting the inclination angle facilitates reliable contact between the metal shrapnel and the screw head 3b of the auxiliary terminal of the electric energy meter. Of course, the present invention does not limit the angle of the inclination angle, and the angle of the inclination angle can be changed according to, for example, the size of the shrapnel.

[0022] Preferably, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com