Fatigue test device taking coupling effect of steel bridge decking and pavement layer into consideration

A steel bridge deck, fatigue test technology, applied in the direction of measuring device, elasticity test, machine/structural component test, etc., can solve the problems of high cost and inability to consider the influence of the pavement layer, so as to reduce the test cost and improve the efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

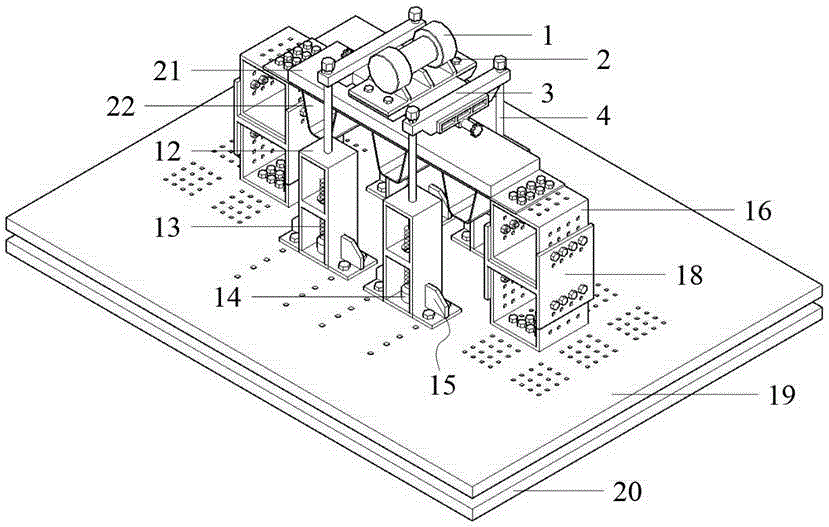

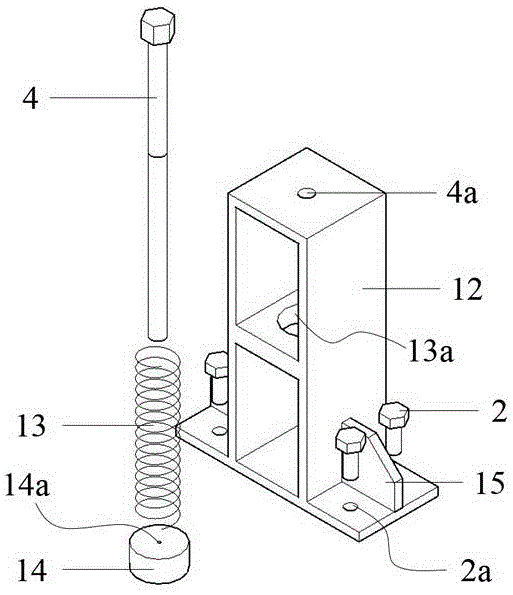

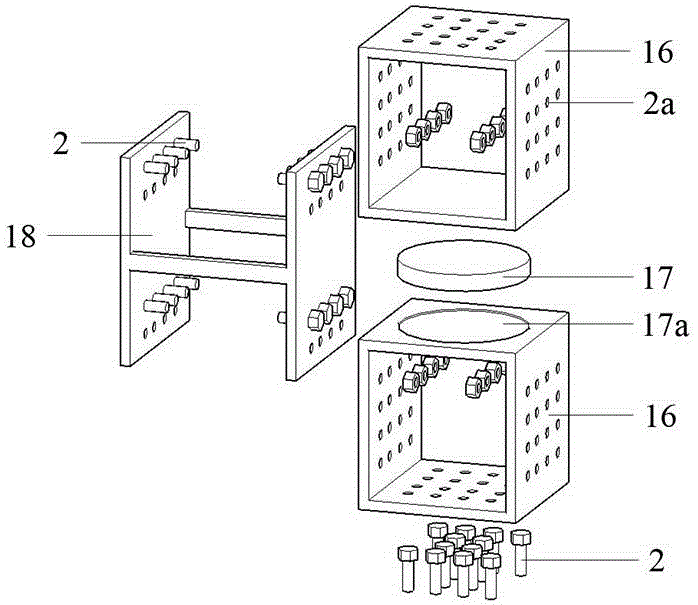

[0040] Take the fatigue test of three U-rib specimens with pavement as an example, such as figure 1 , figure 2 , image 3 , Figure 5 , Figure 6 , Figure 10 , Figure 11 , Figure 12 As shown, the fatigue testing device includes a fatigue testing machine 1, a high-strength bolt 2, a high-strength bolt hole 2a, a fixed base 3 for the fatigue testing machine, a longitudinal stiffener 3a, a transverse stiffener 3b, a threaded vertical rod 4, and a threaded vertical rod through the hole 4a , vertical rod connecting bearing 4b, bearing placement hole 4c, spring connection hole 4d, limit scale gauge 5, limit scale gauge placement hole 5a, limit spring 6, horizontal limit screw rod 7, actuating head placement chute 7a, Auxiliary positioning round rod 8, actuating head fixed end 9, actuating head fixing bolt 10, actuating head bolt through hole 10a, rubber actuating head 11, rubber actuating head rectangular bottom surface 11a, testing machine base fixing frame 12, connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com