Plug and socket combining device of illuminating bus slot

A combined device and busway technology, applied in lighting devices, components of lighting devices, coupling devices, etc., can solve problems such as potential safety hazards, poor contact effect, difficult insulation protection level of branch units, etc., and achieve high protection level, The effect of improving firmness and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

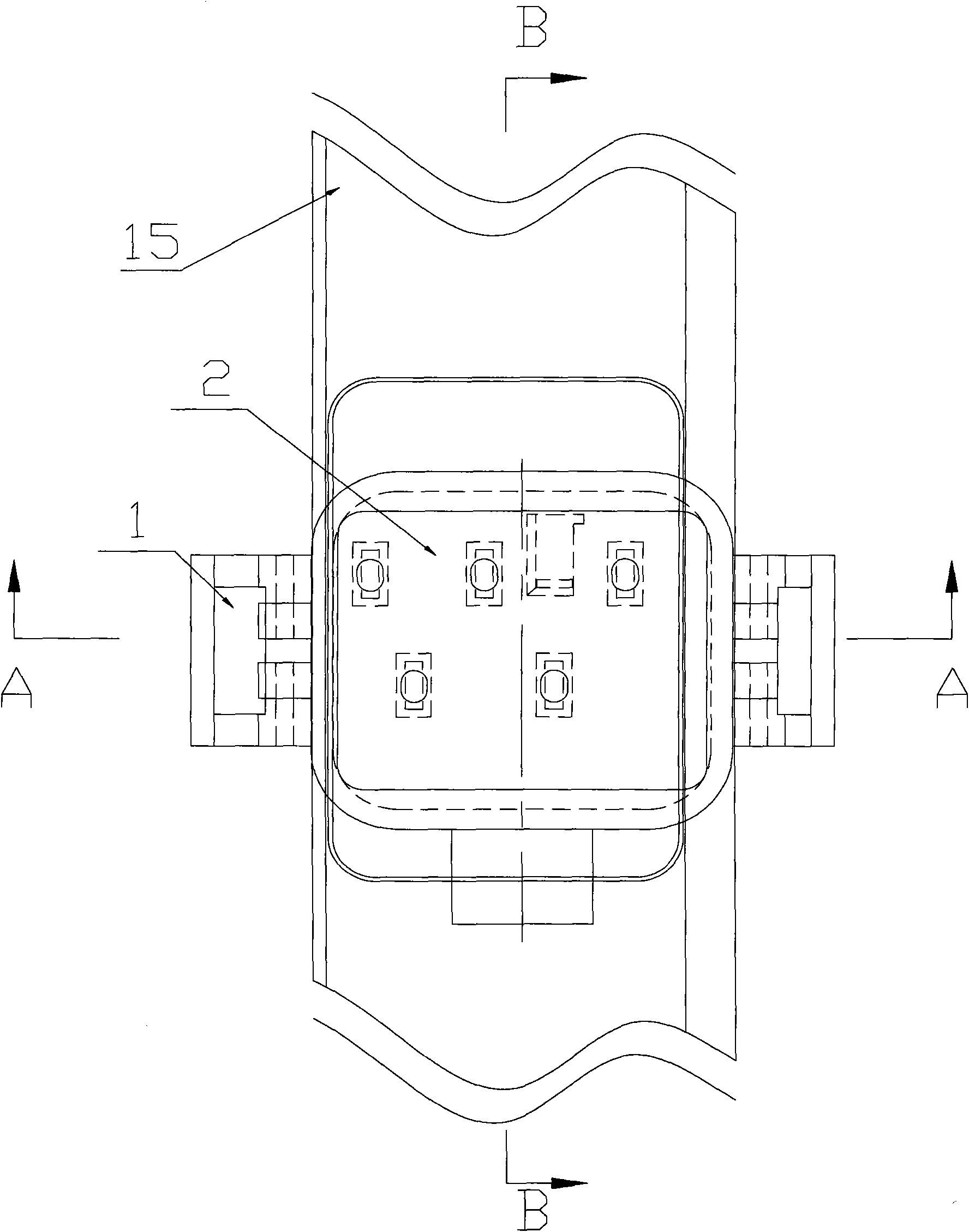

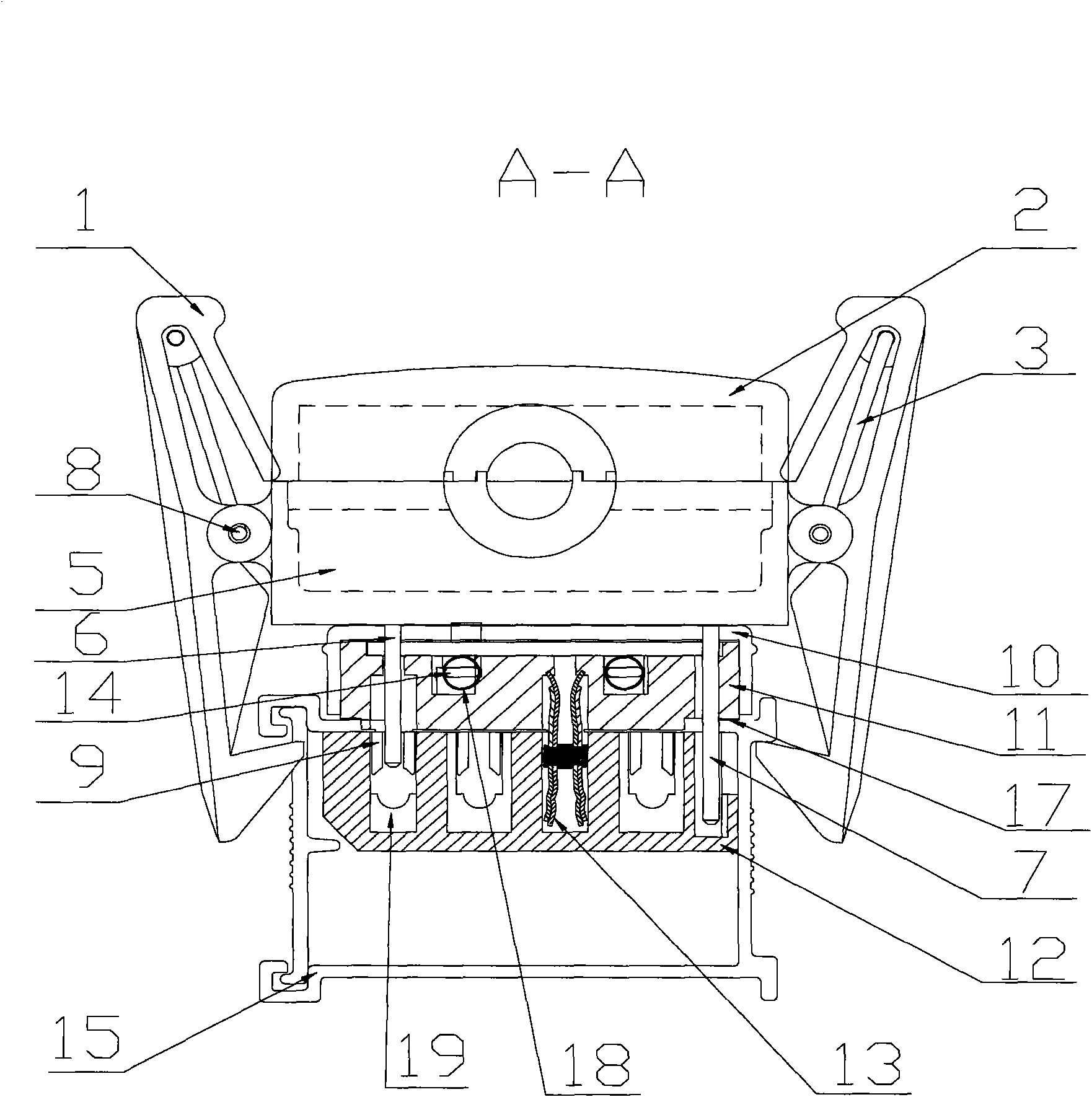

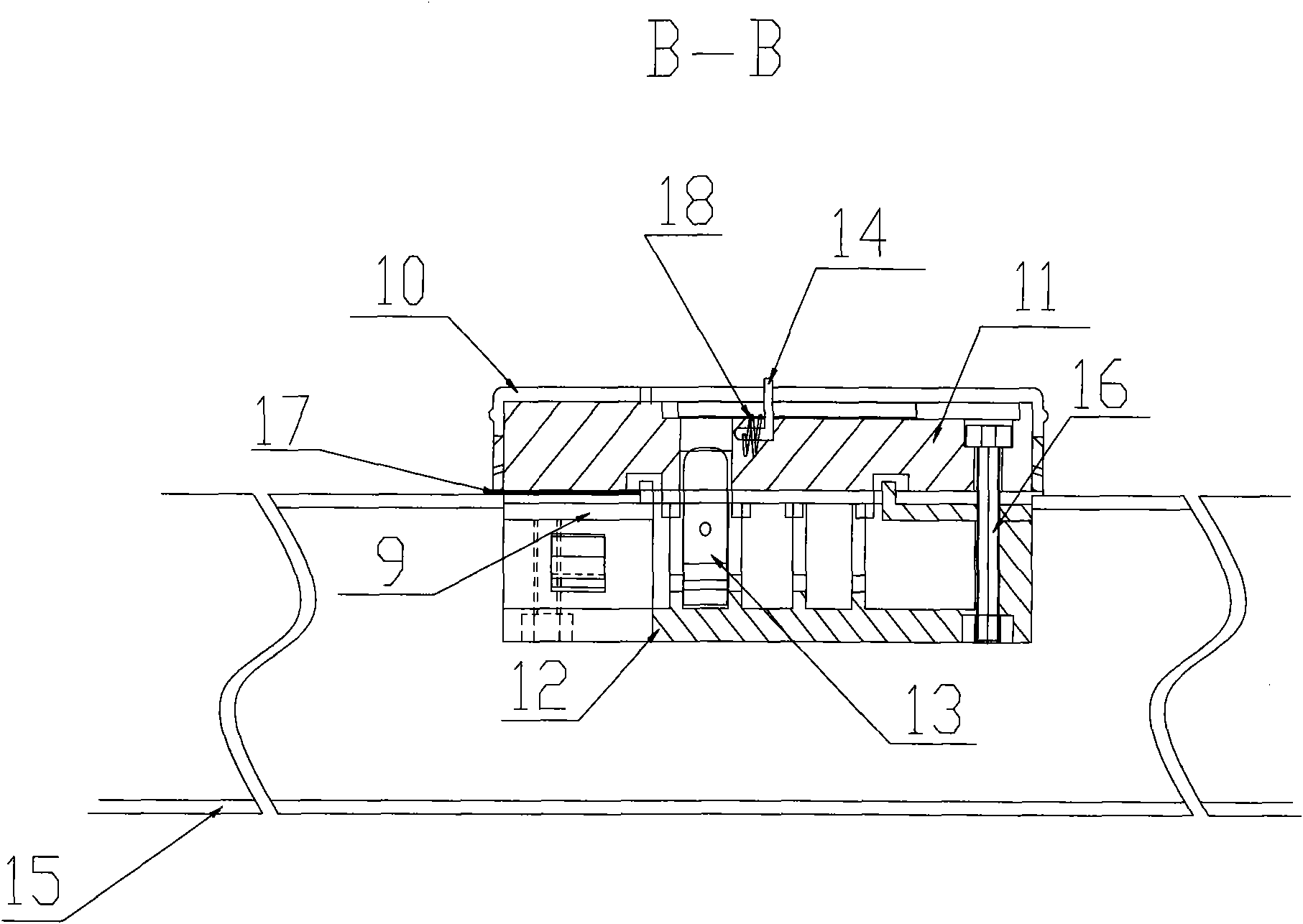

[0012] like Figure 1-3 As shown, the structure of the socket device for the lighting bus duct is as follows: an insulating socket seat 12 is fixed in the slot body 15, and a plurality of wire slots 19 are longitudinally arranged in the socket seat 12 from top to bottom, which can facilitate the positioning of the wires. The riveting piece 13 is fixedly installed in the line groove 19, and the sliding door seat 11 is arranged on the upper surface of the groove body 15, and the bolt 16 passes through the corresponding hole from top to bottom to fix the sliding door seat 11 and the socket seat 12 on the groove body 15, A fixing device is formed, which can effectively ensure the tight fit between the socket seat 12 and the sliding door seat 11, and greatly improve the safety performance. At the same time, the distance between the bus bars is separated by the socket seat 12 and the sliding door seat 11, and the socket The elastic copper riveting sheet 13 in the mouth seat 12 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com