Environment-friendly treatment equipment for industrial toxic waste gas emission

A technology for waste gas emission and environmental protection treatment, which is used in the separation of dispersed particles, chemical instruments and methods, and combined devices, etc., which can solve the problem of reduced exhaust gas passing effect, reduced waste gas harmless treatment effect, and impact on the contact effect between waste gas and chemical agent coating. and other problems, to avoid the decrease of the contact effect and the decrease of the exhaust gas passing rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

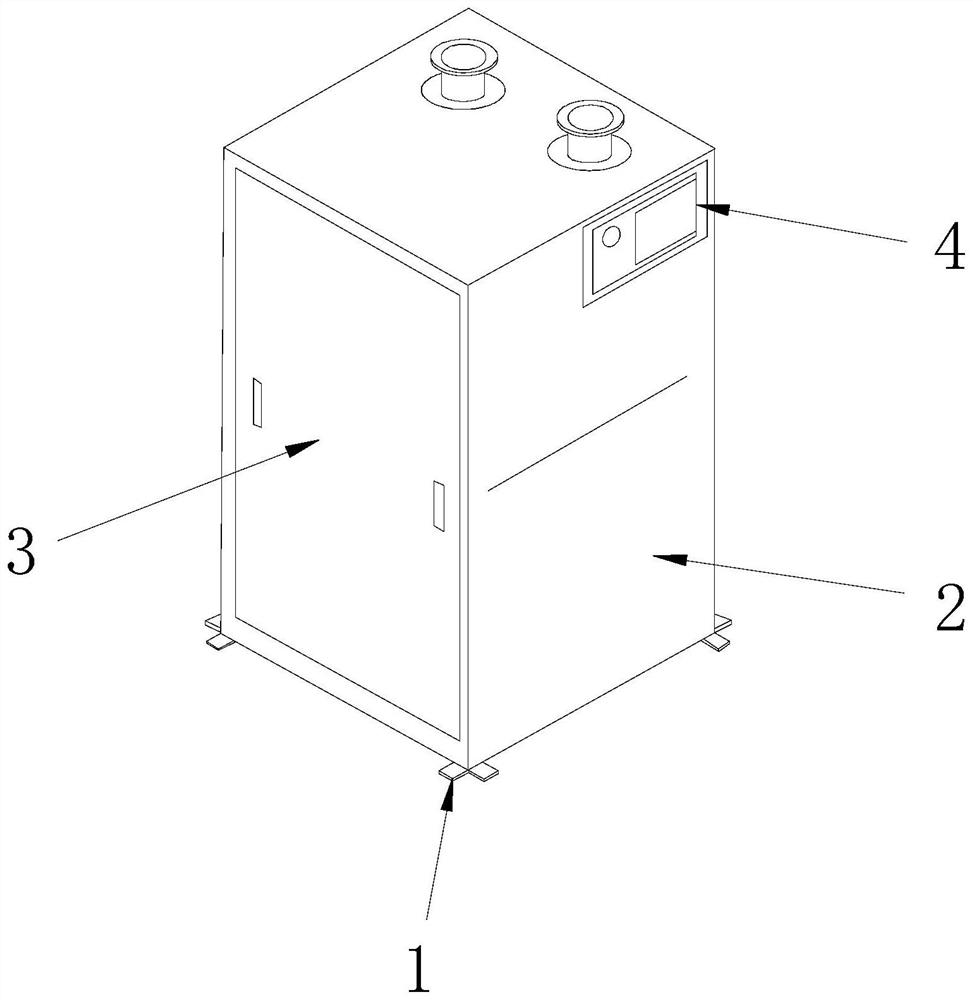

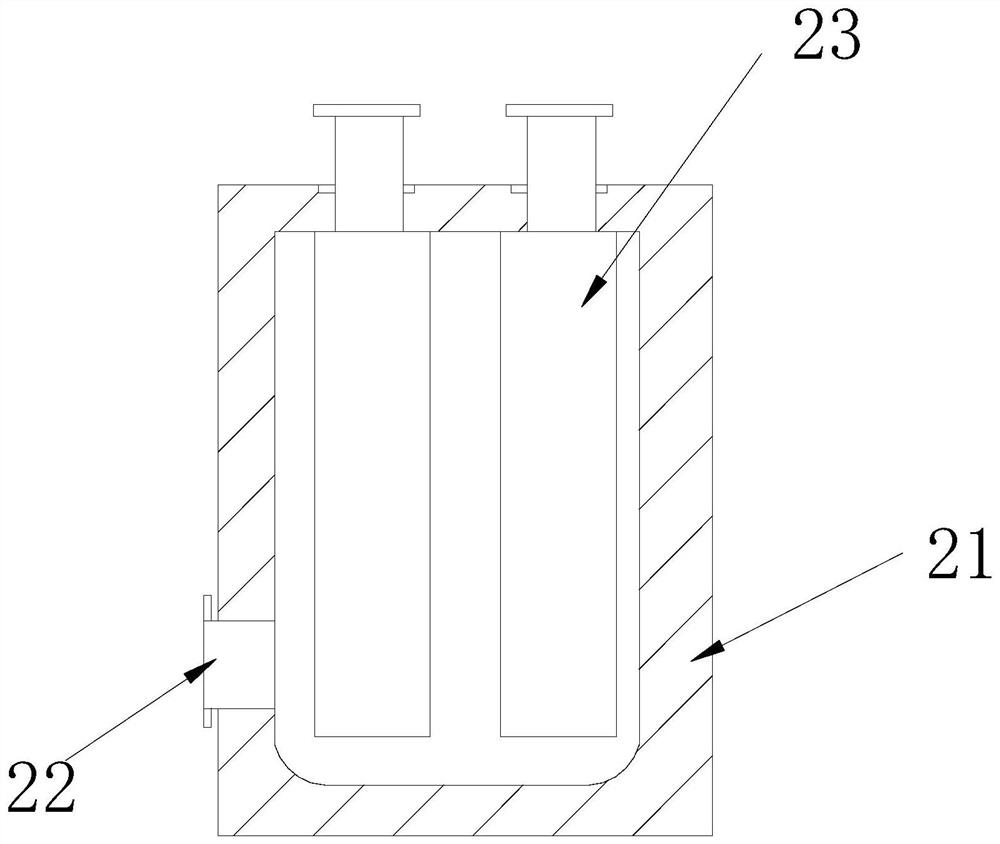

[0029] see Figure 1-Figure 6 , the specific embodiments of the present invention are as follows: an industrial toxic waste gas emission environmental protection treatment equipment, its structure includes a base 1, a body 2, an inspection door 3, a control panel 4, the top surface of the base 1 is welded to the bottom surface of the body 2, the The right side of the inspection door 3 is hingedly connected with the front of the body 2, and the control panel 4 is embedded in the right side of the body 2; The sides are connected with each other and connected by electric welding. The processing cylinder 23 is embedded in the top surface of the shell 21. There are two processing cylinders 23, and the two processing cylinders 23 are evenly embedded in the top surface of the shell 21, which is conducive to speeding up the processing. speed.

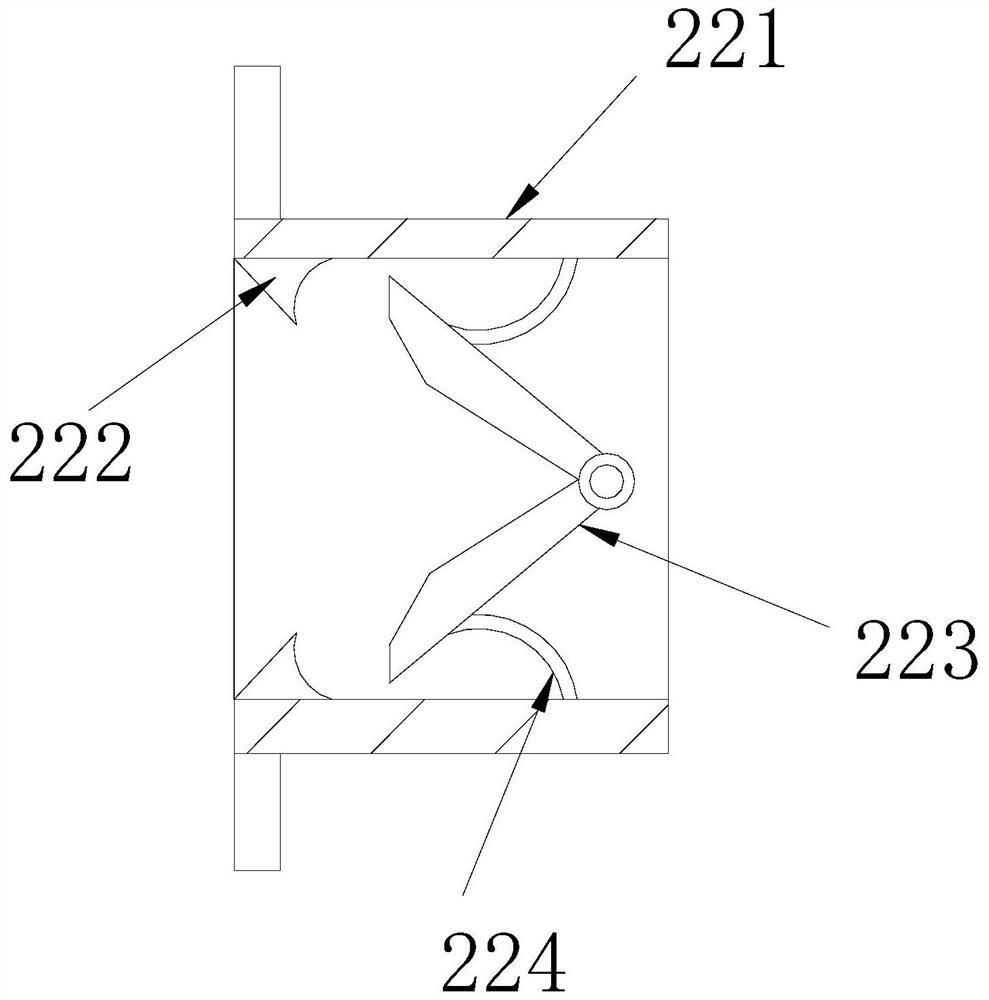

[0030] Wherein, the air intake pipe 22 includes an outer wall 221, a guide head 222, a separation plate 223, and a pressing piece 224. Movab...

Embodiment 2

[0036] see Figure 1-Figure 2 , Figure 7-Figure 9 , the specific embodiments of the present invention are as follows: an industrial toxic waste gas emission environmental protection treatment equipment, its structure includes a base 1, a body 2, an inspection door 3, a control panel 4, the top surface of the base 1 is welded to the bottom surface of the body 2, the The right side of the inspection door 3 is hingedly connected with the front of the body 2, and the control panel 4 is embedded in the right side of the body 2; The sides are connected with each other and connected by electric welding. The processing cylinder 23 is embedded in the top surface of the shell 21. There are two processing cylinders 23, and the two processing cylinders 23 are evenly embedded in the top surface of the shell 21, which is conducive to speeding up the processing. speed.

[0037] Wherein, the processing cylinder 23 includes a discharge pipe 231, a reaction cover 232, an inner shaft 233, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com