Method and system for biogas desulfurization using electrolysis and air flotation to treat biogas slurry

A biogas desulfurization and biogas slurry technology, which is applied in chemical instruments and methods, flotation water/sewage treatment, sedimentation treatment, etc., can solve the problems of cumbersome operation, high desulfurization cost, and poor control, and achieve simple process and desulfurization effect Obvious, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

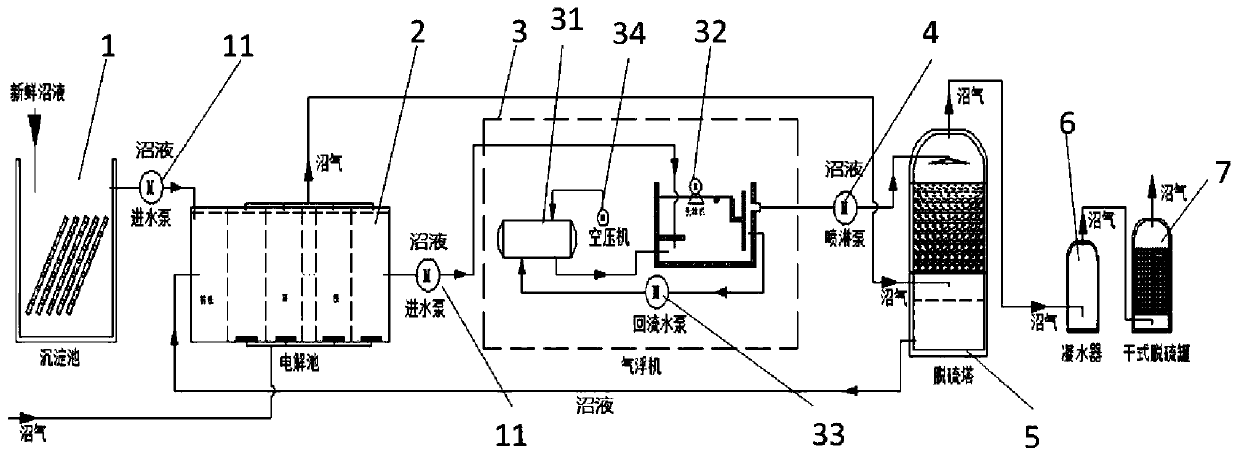

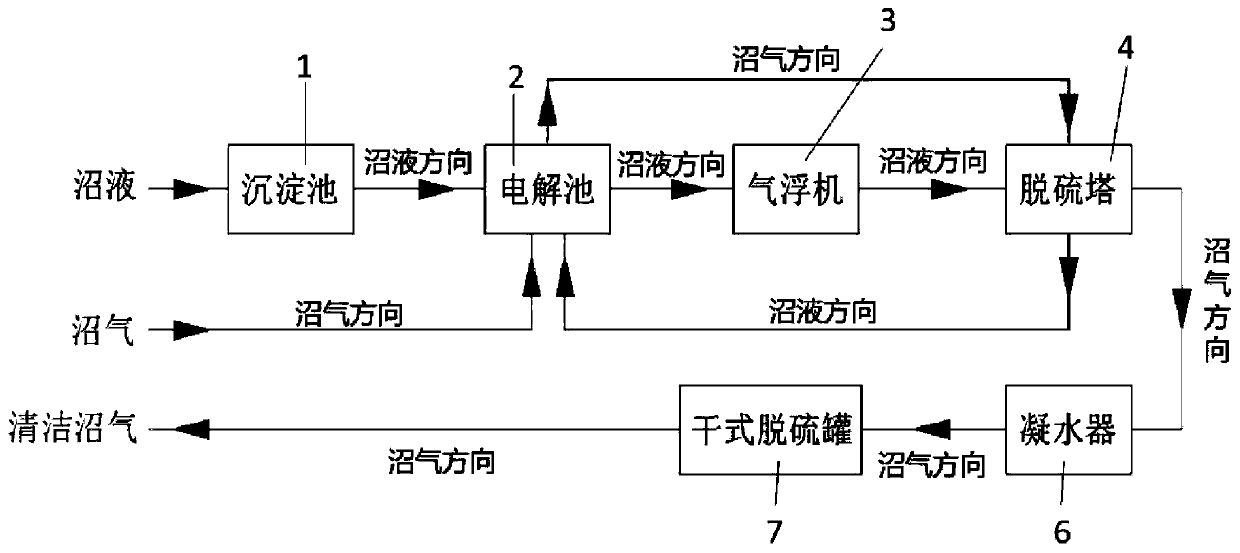

[0051] Example 1 A system for biogas desulfurization using electrolysis and air flotation to treat biogas slurry

[0052] A biogas desulfurization system using electrolysis and air flotation to treat biogas slurry, which includes a sedimentation tank 1, an electrolytic cell 2, an air flotation machine 3, a desulfurization tower 5, a water condenser 6, and a dry desulfurization tank 7; it is characterized in that the Sedimentation tank 1 has a biogas slurry inlet and a biogas slurry outlet; electrolytic tank 2 includes 2 biogas slurry inlets and a biogas slurry outlet, a biogas inlet and a biogas outlet, and the air flotation machine 3 includes a biogas slurry inlet and a biogas slurry outlet; the desulfurization tower 5 includes a biogas inlet and a biogas outlet, a biogas inlet and a biogas outlet; the condenser 6 includes a biogas inlet and a biogas outlet; the dry desulfurization tank 7 includes a biogas inlet and a biogas outlet The biogas slurry inlet of the sedimentation...

Embodiment 2

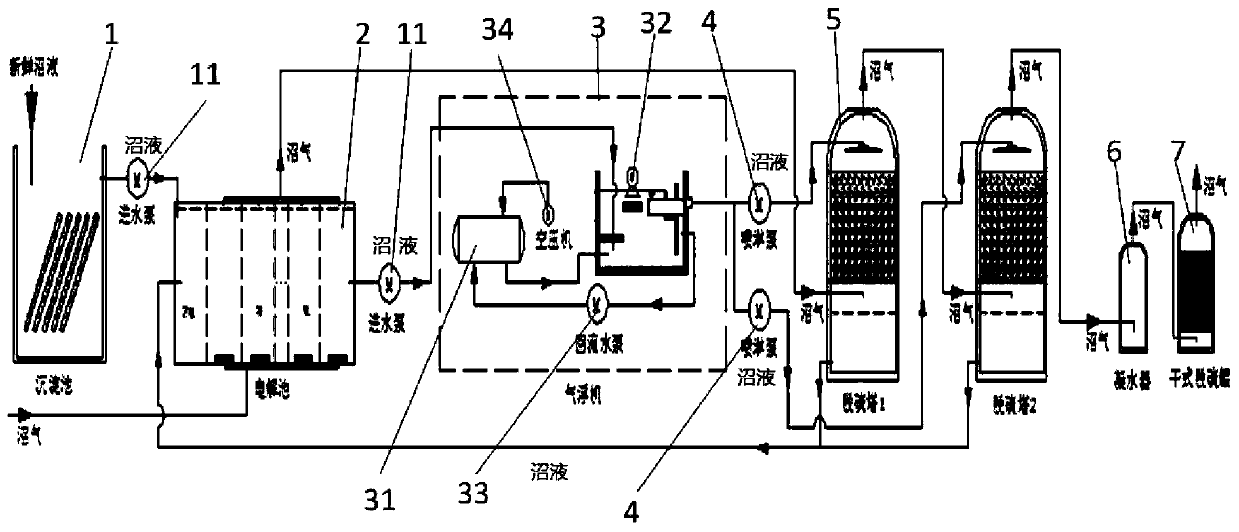

[0053] Example 2 A system for biogas desulfurization using electrolysis and air flotation to treat biogas slurry

[0054] A biogas desulfurization system using electrolysis and air flotation to treat biogas slurry, which includes a sedimentation tank 1, an electrolytic cell 2, an air flotation machine 3, a desulfurization tower 5, a water condenser 6, and a dry desulfurization tank 7; it is characterized in that the Sedimentation tank 1 has a biogas slurry inlet and a biogas slurry outlet; electrolytic tank 2 includes 2 biogas slurry inlets and a biogas slurry outlet, a biogas inlet and a biogas outlet, and the air flotation machine 3 includes a biogas slurry inlet and a biogas slurry outlet; the desulfurization tower 5 includes a biogas inlet and a biogas outlet, a biogas inlet and a biogas outlet; the condenser 6 includes a biogas inlet and a biogas outlet; the dry desulfurization tank 7 includes a biogas inlet and a biogas outlet The biogas slurry inlet of the sedimentation...

Embodiment 3

[0059] Example 3 A method of biogas desulfurization using electrolysis and air flotation to treat biogas slurry

[0060] A method of biogas desulfurization using electrolysis and air flotation to treat biogas slurry is as follows:

[0061] (1) The fresh biogas slurry discharged from the anaerobic fermentation tank first enters the sedimentation tank 1 through the biogas slurry transportation pipeline through the biogas slurry delivery pump, and settles for 24 hours, which is used for preliminary precipitation to remove large particles of impurities in the biogas slurry.

[0062] (2) The biogas slurry comes from the sedimentation tank 1 when it is used for the first time, and then the biogas slurry is recycled. The electrolytic cell 2 is equipped with an anode and a negative electrode made of metal materials. There are multiple anodes, usually 2 to 6. The metal ions in the biogas slurry gather at the anode when the electricity is applied. The electrolytic cell 2 is a closed ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com