Dynamic rotary rotational flow plate device for strengthening transmission

A technology of dynamic rotation and swirling plates, applied in chemical instruments and methods, chemical/physical/physicochemical fixed reactors, dispersed particle separation, etc., can solve problems affecting mass transfer effects and achieve enhanced gas-liquid mass transfer process, volume reduction, and the effect of improving absorption and separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

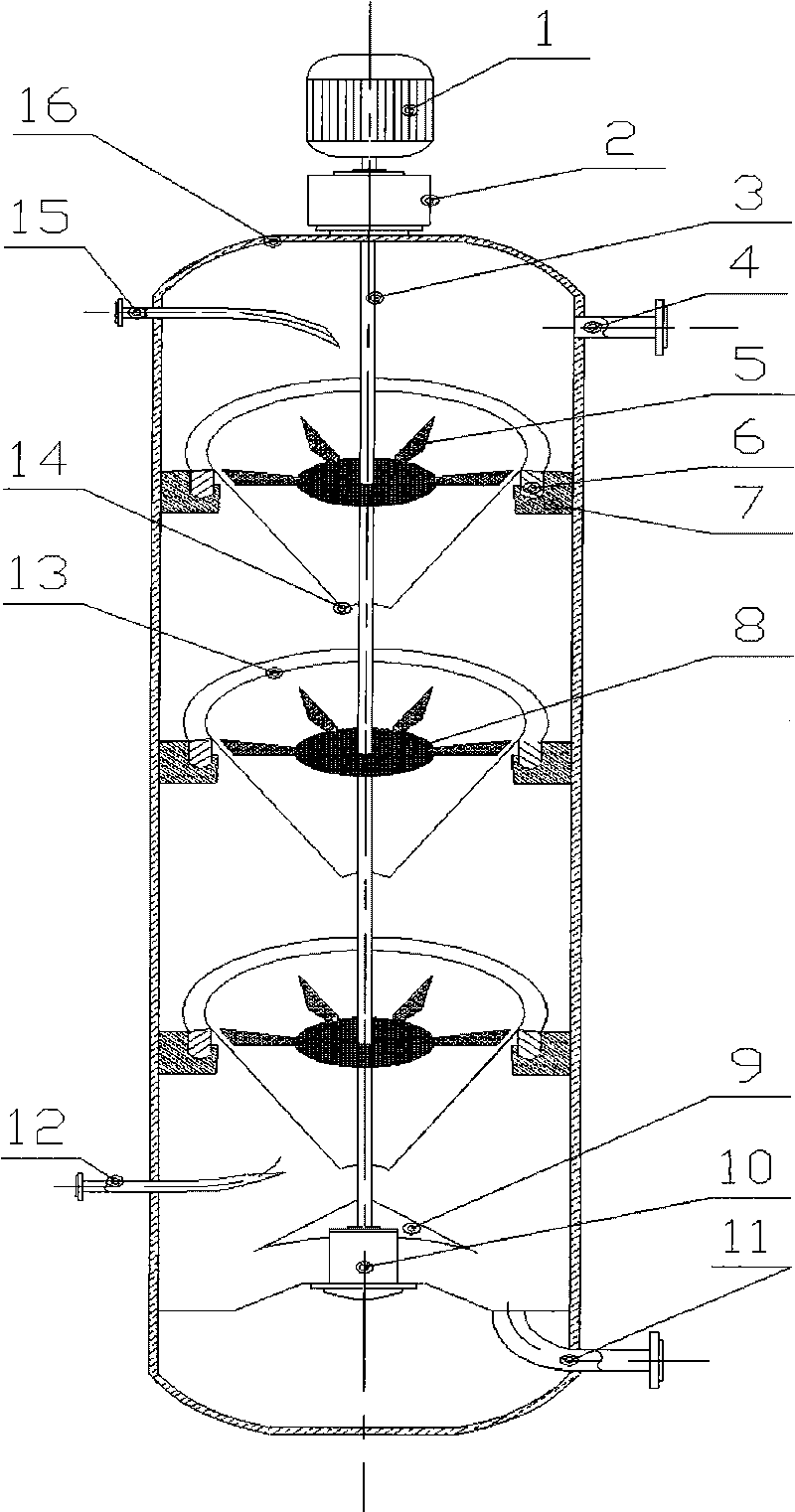

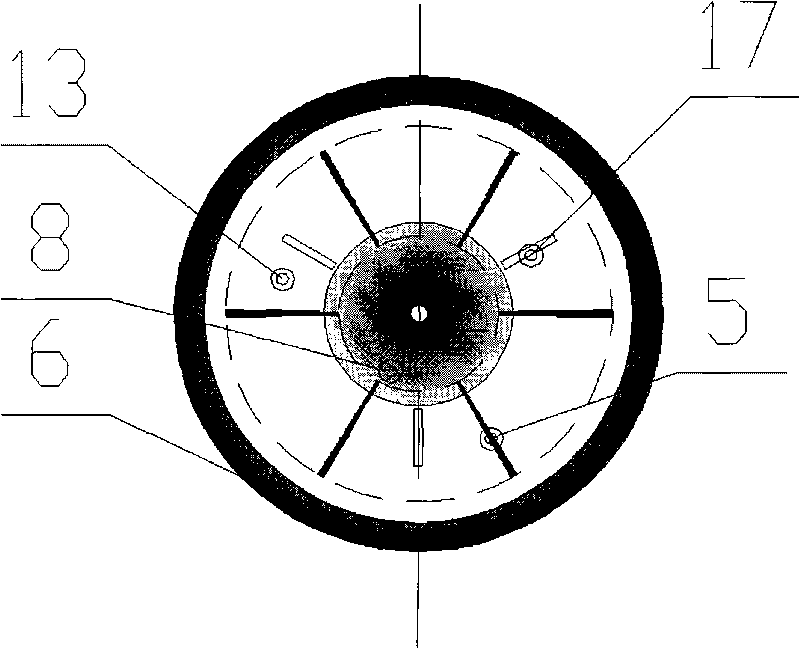

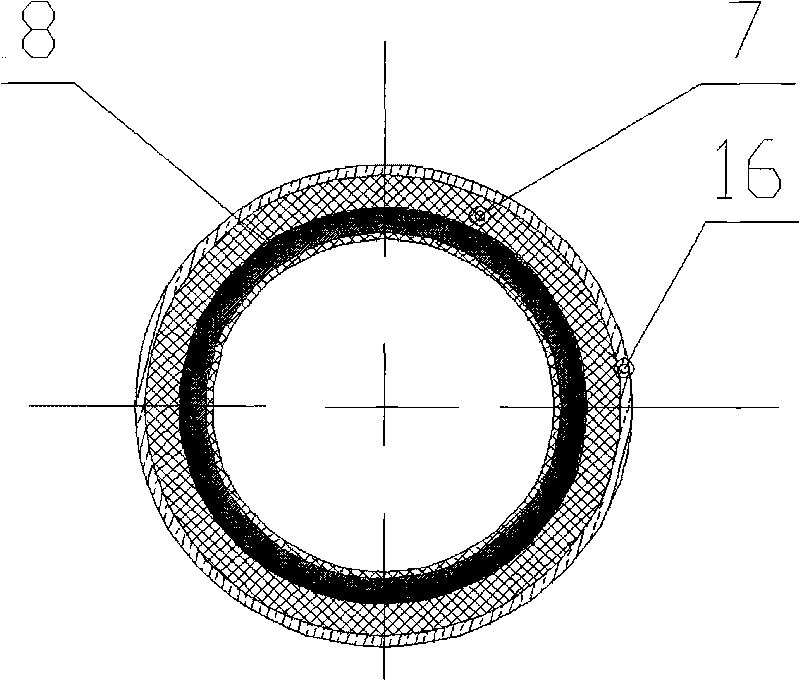

[0014] In order to better achieve the purpose of the present invention, the designer of the present invention installs blades in the swirl plate, the blades are fixed between the swirl plate and the blind plate, and fixed to the stirring shaft through the blind plate, the swirl plate and the tower body Between them, the seal is connected by a labyrinth sealing member, and the structure of a fixed stirring shaft is installed at the bottom of the equipment, which reduces the defect of swinging caused by the excessive length of the stirring shaft. The deposited solids increase the resistance, and on the other hand, the liquid can be thrown onto the tower wall, making it easier to flow out from the liquid outlet.

[0015] The content of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] The specific structure of the present invention is as figure 1 As shown, it mainly includes two parts, namely the tower body and the dy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com