Composite inner component for gas-solid fluidized bed

A technology of internal components and fluidized bed, applied in chemical instruments and methods, chemical/physical process, chemical/physical/physical-chemical process, etc., can solve the problems of grid layer cannot be installed, inconvenient installation, etc., to achieve the best use effect , convenient installation, flexible layout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

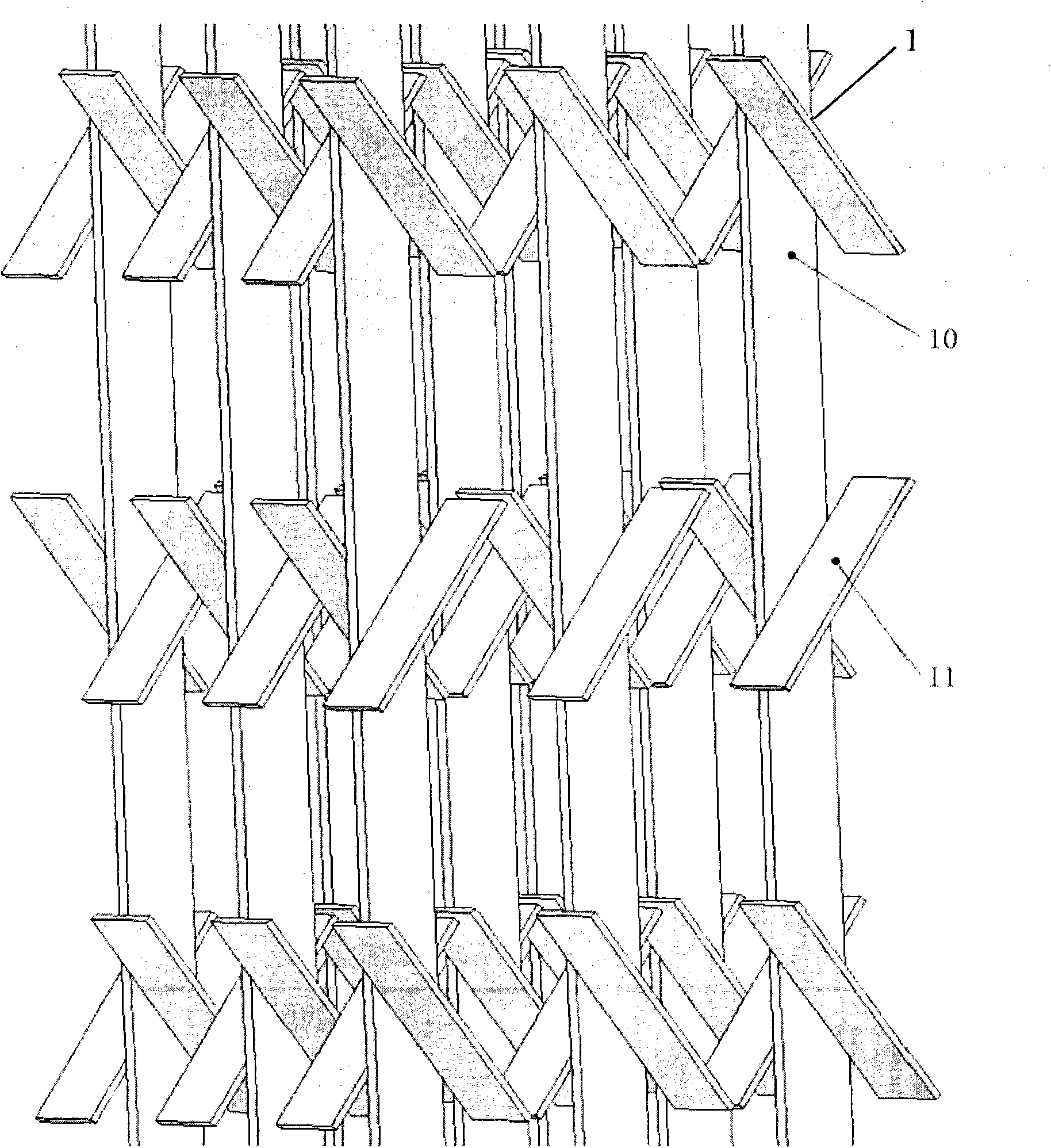

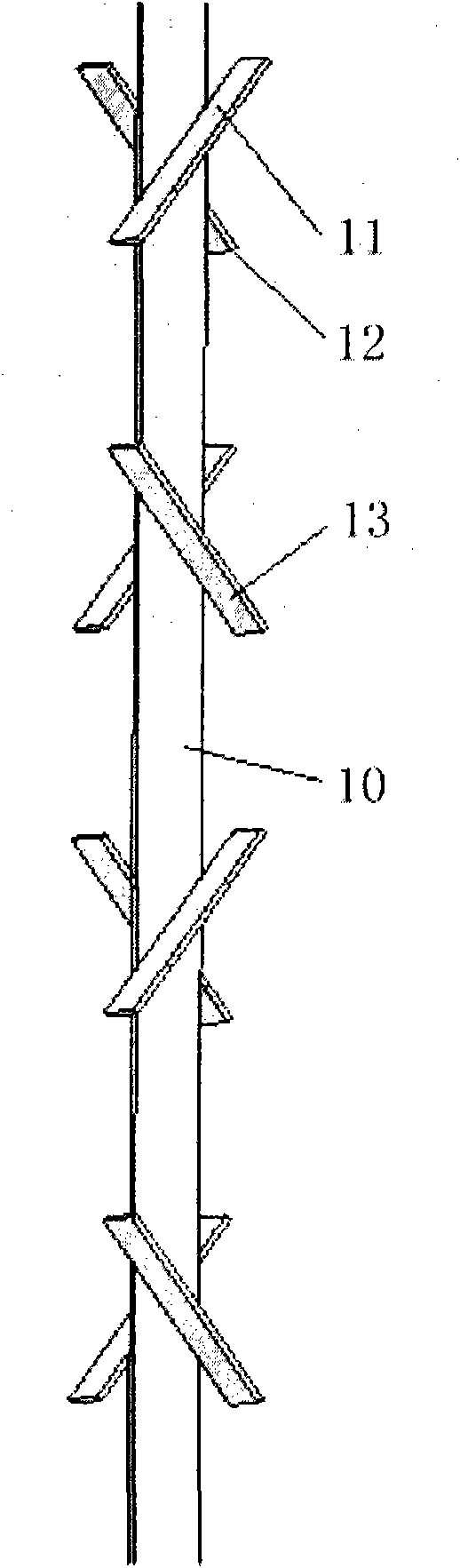

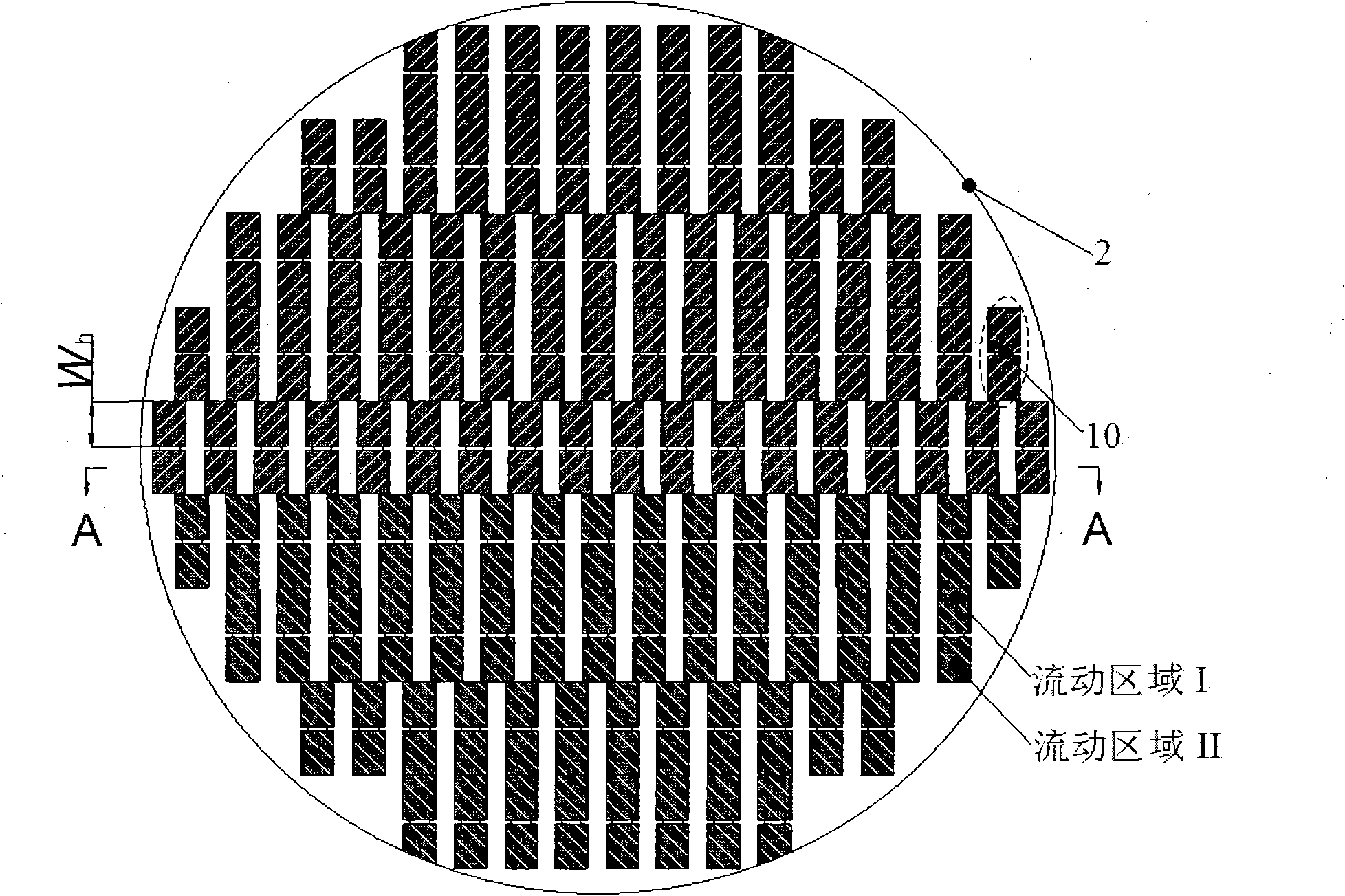

[0037] Seefigure 1 As shown, the specific structure of the fluidized bed composite internal member of the present embodiment is shown, and the internal member is composed of a plurality of vertically parallel arranged component group units 1 (please refer to figure 2 As shown), each component group unit 1 is composed of a vertical support plate 10 and a plurality of guide vanes 11, 12, 13..., and the plurality of guide vanes are connected with the support through appropriate connection methods, such as welding, etc. The plates are connected together and distributed on both sides of the guide vanes, and are arranged at an oblique angle to the height direction of the vertical support plate. Such as figure 2 As shown, the guide vanes 11 and 13 are two guide vanes adjacent to each other up and down on the same side. The guide vanes on the same side of the plate form a "zigzag" flow to improve the gas-solid contact efficiency.

[0038] In the internal member of this embodiment,...

Embodiment 2

[0045] This embodiment provides another form of component group unit, its structure please refer to Figure 6A shown, with figure 1 The component group unit of the illustrated embodiment is different. The component group unit of this embodiment is directly processed from a steel plate, so that the problem of guide vanes falling off during operation due to welding defects can be eliminated. When processing this form of component group unit of the present embodiment, it is necessary to punch or cut a piece such as Figure 6B As shown in the steel plate, components such as support rods, guide vanes, and connecting ribs connecting the support rods and guide vanes have been preliminarily formed on the steel plate. clear as Figure 6A The component group unit shown.

Embodiment 3

[0047] This embodiment provides another form of component group unit, its structure please refer to Figure 7 As shown, the overall structure of the component group unit is basically the same as that of the first and second embodiments, but the support structure is a tubular support rod, and the guide vanes are directly welded on the support rod. The composite internal member composed of multiple component group units in this embodiment is especially suitable for some fluidized beds that need to be provided with heat exchange tubes, and the heat exchange tubes are used as the support rods of the internal components of the present invention, so that it does not affect the fluidized bed. The heat exchange can achieve the purpose of improving the gas-solid phase mass transfer effect and suppressing the gas-solid phase back mixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com