Axial-flow ultrashort contact cyclone reactor

A reactor and axial-flow technology, applied in the field of axial-flow ultra-short contact cyclone reactor, can solve the problem that it is difficult to make breakthroughs in residual oil catalytic cracking, and improve the contact efficiency of catalyst oil and inhibit Secondary reaction, coking, and time-shortening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical characteristics of the present invention will be described in detail below in conjunction with specific embodiments.

[0026] In the actual implementation of this technology, the technical route of the present invention is realized through the following operations:

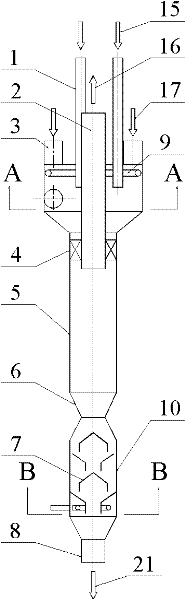

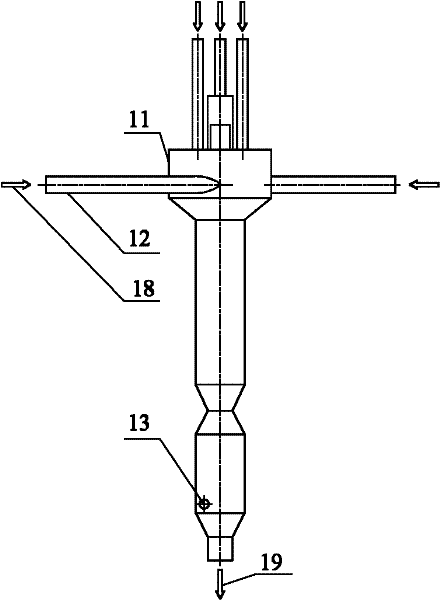

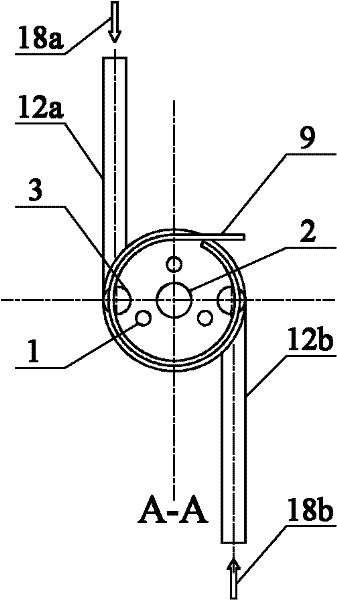

[0027] Figure 1~5 An axial flow ultrashort contact cyclone reactor according to a first embodiment of the present invention is shown.

[0028] Such as figure 1 ,2 As shown, the swirl reactor of the first embodiment includes a mixing chamber 11, which provides a mixing space for raw materials and catalysts for the axial flow swirl reactor of the present invention. Multiple catalyst feed pipes are installed on the top of the mixing chamber, and the same number of fresh raw material introduction devices are installed on the side of the mixing chamber. In order to ensure a high contact efficiency of agent and oil, it is necessary to ensure that the catalyst falls to the conical transition zone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com