Reticular porous lithium-manganese-rich-based positive electrode material for lithium ion cell and preparation method of material

A lithium-rich manganese-based lithium ion battery technology, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc., can solve problems such as poor conductivity, bottlenecks in rate performance, and decreased lattice order. Achieve long service life, simplify the preparation process, and improve the effect of rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

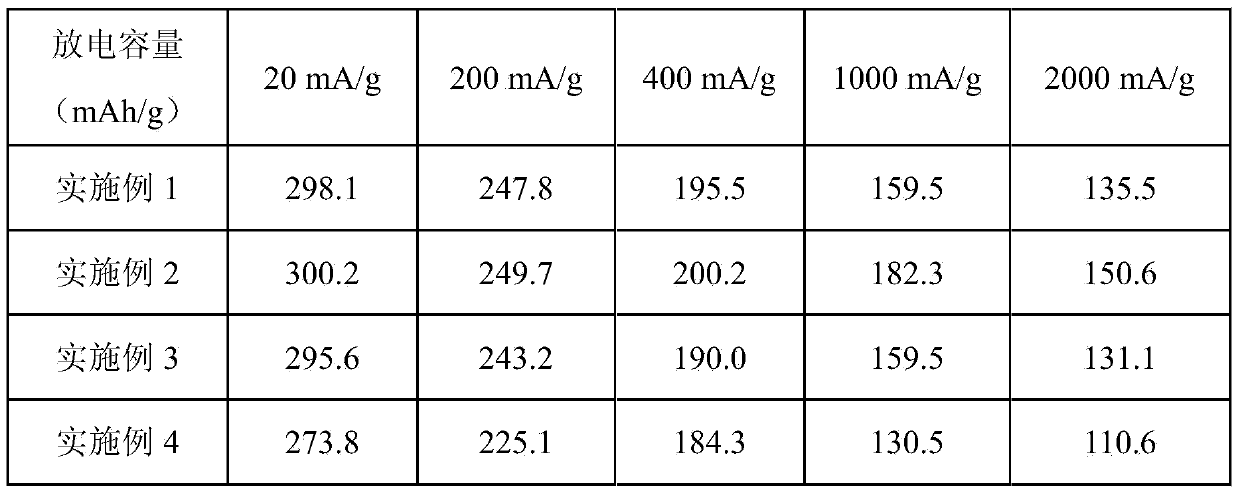

Embodiment 1

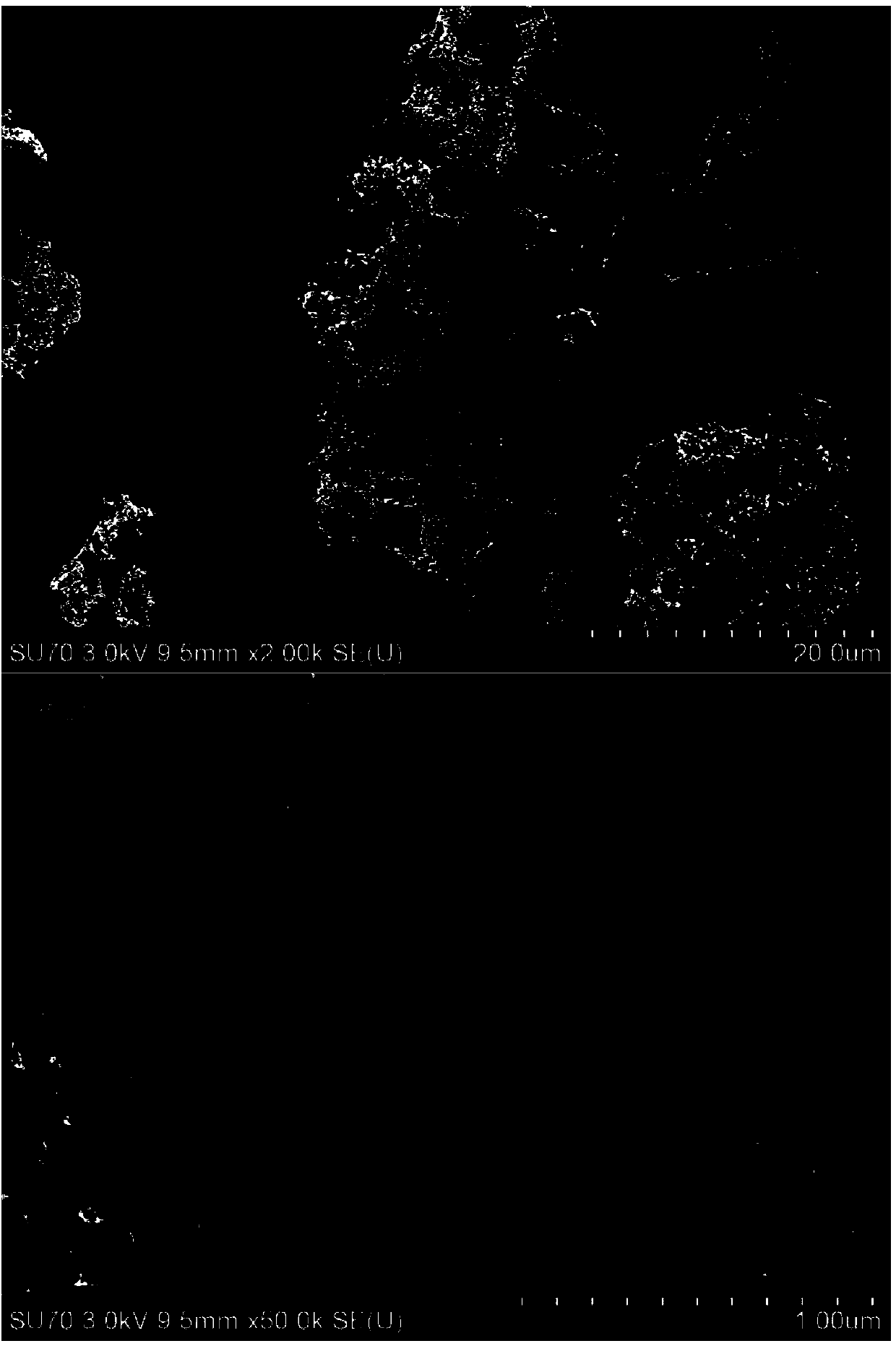

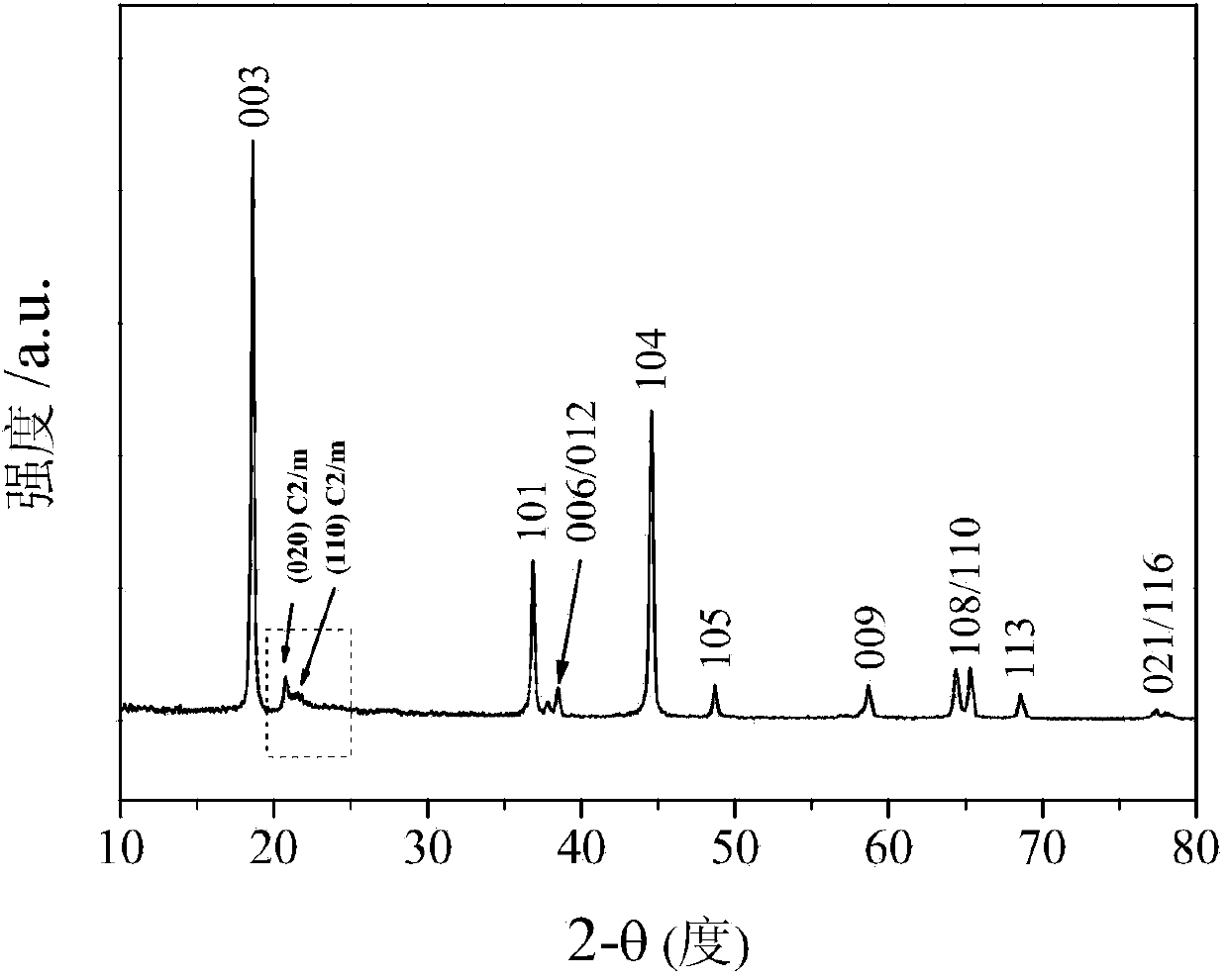

[0030] 1) According to the molar ratio of 1.236:0.56:0.16:0.08, the raw material LiNO 3 , Mn(NO 3 ) 2 ·6H 2 O, Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 O was dissolved in deionized water (an excess of 3% lithium salt was added to offset the loss of lithium at high temperature) to form a transparent solution, and then sucrose with a total metal salt molar weight of 15% was added to the transparent solution, and Stir continuously until the solution becomes transparent again, then heat the solution to 80°C, and continuously evaporate to remove the water in the solution, first to obtain a sol, and finally to obtain a gel.

[0031] 2) Put the gel into a box-type furnace, heat up to 500°C at a rate of 10°C / min in an air atmosphere, heat-preserve and calcinate for 2 hours to remove organic components, and then cool to room temperature 25°C with the furnace to obtain a preliminary product. Grind the obtained preliminary product, and finally heat up to 800°C at a heating rate...

Embodiment 2

[0038] 1) According to the molar ratio of 1.236:0.54:0.13:0.13, the raw material LiNO 3 , Mn(NO 3 ) 2 ·6H 2 O, Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 O was dissolved in deionized water (an excess of 3% lithium salt was added to offset the loss of lithium at high temperature) to form a transparent solution, and then 20% sucrose was added to the transparent solution, and Stir continuously until the solution becomes transparent again, then heat the solution to 80°C, and continuously evaporate to remove the water in the solution, first to obtain a sol, and finally to obtain a gel.

[0039] 2) Put the gel into a box-type furnace, heat up to 500°C at a rate of 10°C / min in an air atmosphere, heat-preserve and calcinate for 2 hours to remove organic components, and then cool to room temperature 25°C with the furnace to obtain a preliminary product. Grind the obtained preliminary product, and finally heat up to 800°C at a heating rate of 10°C / min for the second calcination....

Embodiment 3

[0046] 1) According to the molar ratio of 1.236:0.56:0.16:0.08, the raw material LiNO 3 and LiCH 3 COO·2H 2 Mixed lithium salts of O, Ni(NO 3 ) 2 ·6H 2 O and Ni(CH 3 COO) 2 4H 2 Mixed nickel salts of O, Mn(NO 3 ) 2 ·6H 2 O and Mn(CH 3 COO) 2 4H 2 Mixed manganese salts of O, Co(NO 3 ) 2 ·6H 2 O and Co(CH 3 COO) 2 4H 2 Mixed cobalt salts of O (in which nitrate accounts for 50% in each mixed salt) were dissolved in deionized water (to which an excess of 3% lithium salt was added to offset the loss of lithium at high temperature) to form a transparent solution, and then Add 10% sucrose with a molar mass of total metal salts to the transparent solution, and keep stirring until the solution becomes transparent again, then heat the solution to 80°C, and continuously evaporate to remove the water in the solution, first to obtain a sol, and finally to obtain a gel.

[0047] 2) Put the gel into a box-type furnace, heat up to 500°C at a rate of 10°C / min in an air atmos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com