Secondary grouting construction method of machine setting

A secondary grouting and machine tool installation technology, which is applied in infrastructure engineering, construction, etc., can solve problems such as poor flatness, affecting the accuracy and stability of machine tools, and the incomplete contact between the foundation and the adjustable pad iron, so as to ensure long-lasting stability , to prevent the effect of false contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

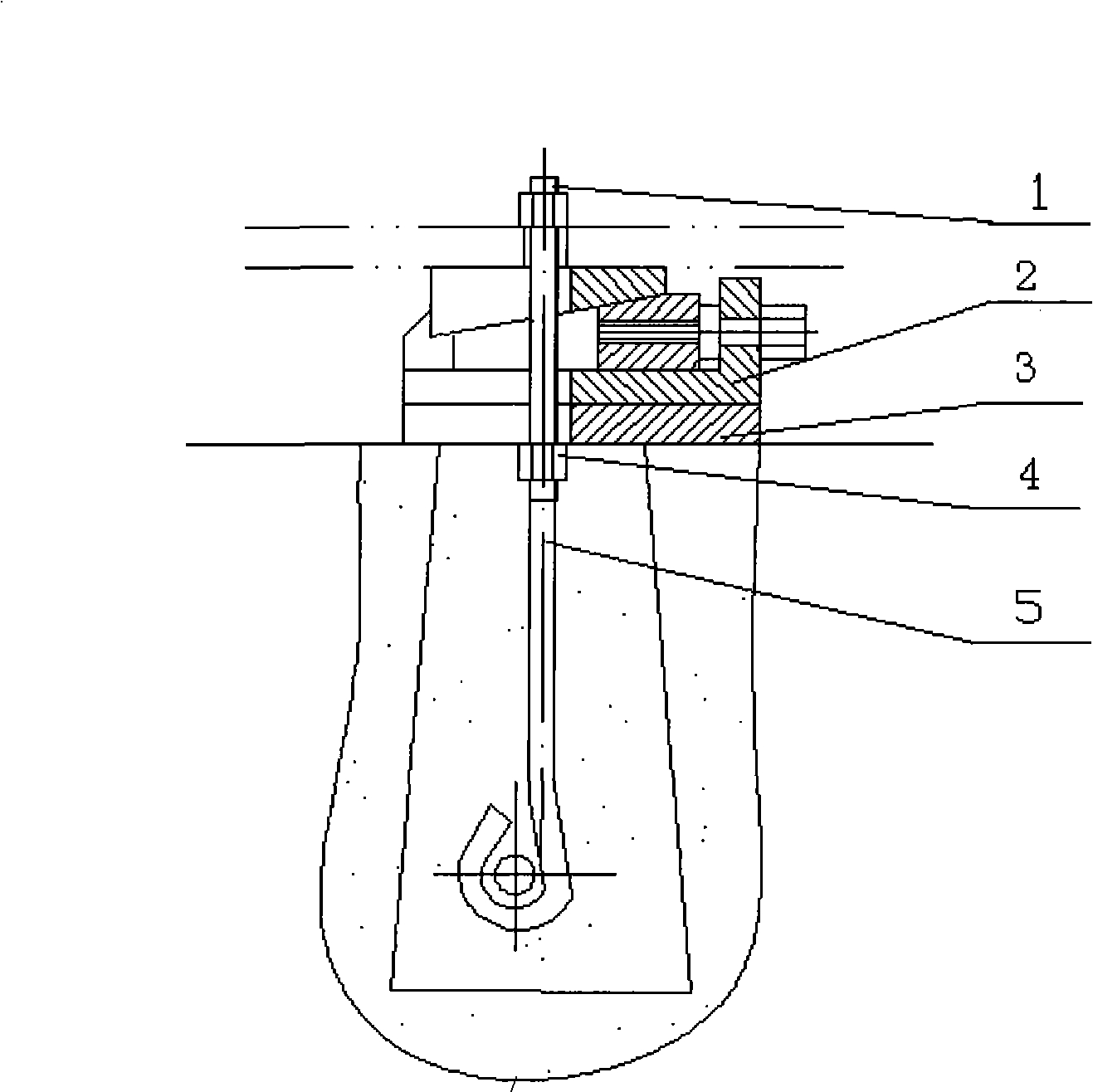

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation. A secondary grouting method for machine tool installation, which is carried out according to the following steps:

[0021] 1) Preparation

[0022] ①Three days before the second grouting, fill the foundation hole where the anchor bolts (5) are placed with water, and pump out the water on the day of the second grouting;

[0023] ②Adjust the adjustable shim (2) to the middle position through the adjusting bolt;

[0024] ③ Screw the nut (4) to the appropriate position of the anchor bolt (5), and ensure that the nut (1) has 7-15mm adjustment space;

[0025] 2) Secondary grouting

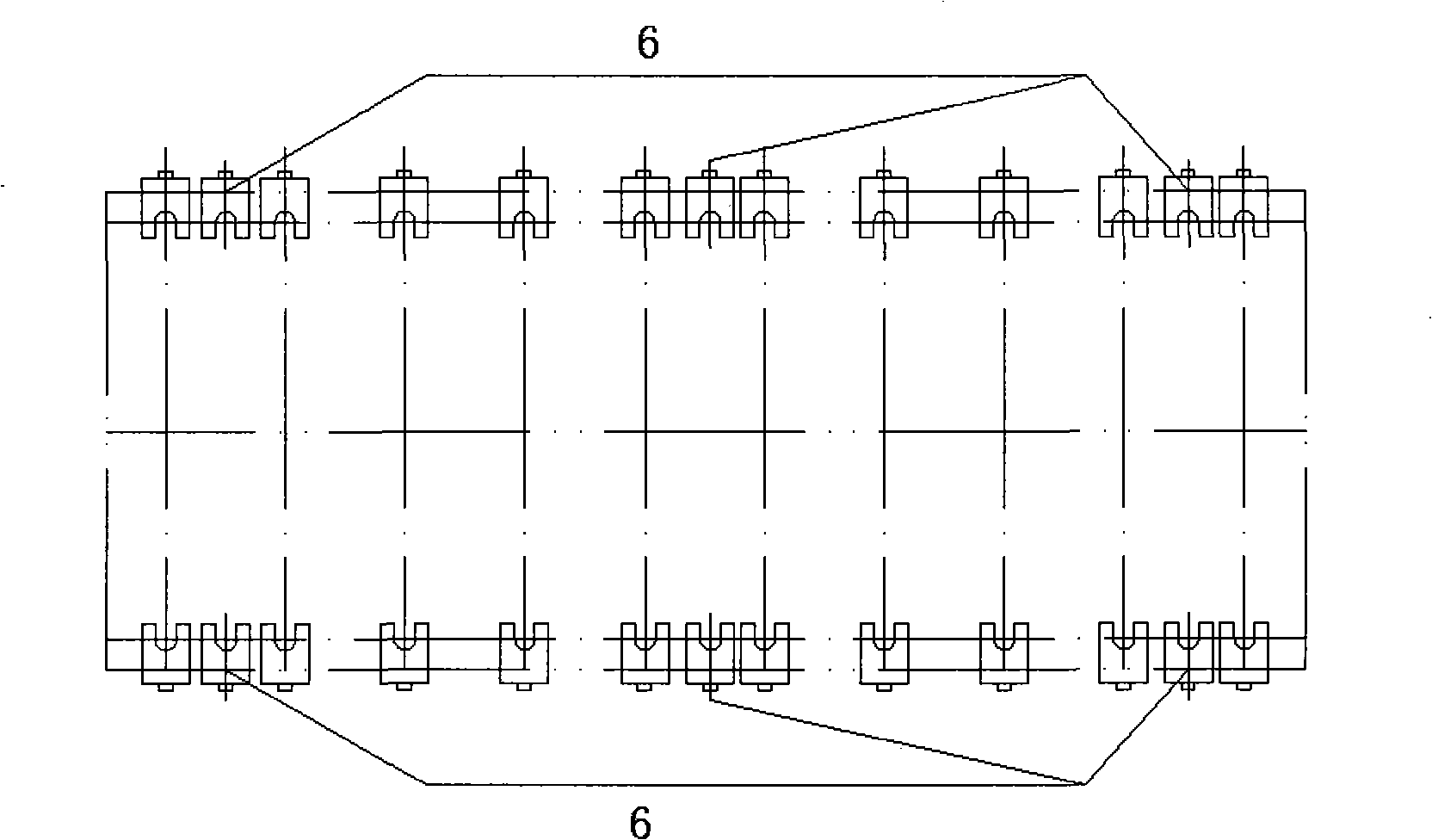

[0026] ① Lift the base of the machine tool, such as figure 1 Install the anchor bolts (5) as shown, and fix the anchor bolts (5), adjustable pad iron (2) and backing plate (3) on the machine tool base with nuts (1) and nuts (4), as shown in figure 2 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com