Process method for preventing end pieces of large-scale motor stator core from escaping

A stator core and large-scale motor technology, applied in the direction of motors, manufacturing stator/rotor bodies, electric vehicles, etc., can solve problems such as inability to synchronize thermal expansion and cold contraction, poor bonding effect of end pieces, uneven stress distribution of stators, etc. To achieve the effect of ensuring lasting stability, being easy for enterprises and technical personnel to master, and easy to promote

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The invention relates to a process method for preventing end pieces from escaping from a stator core of a large motor. The technical solution includes the following steps:

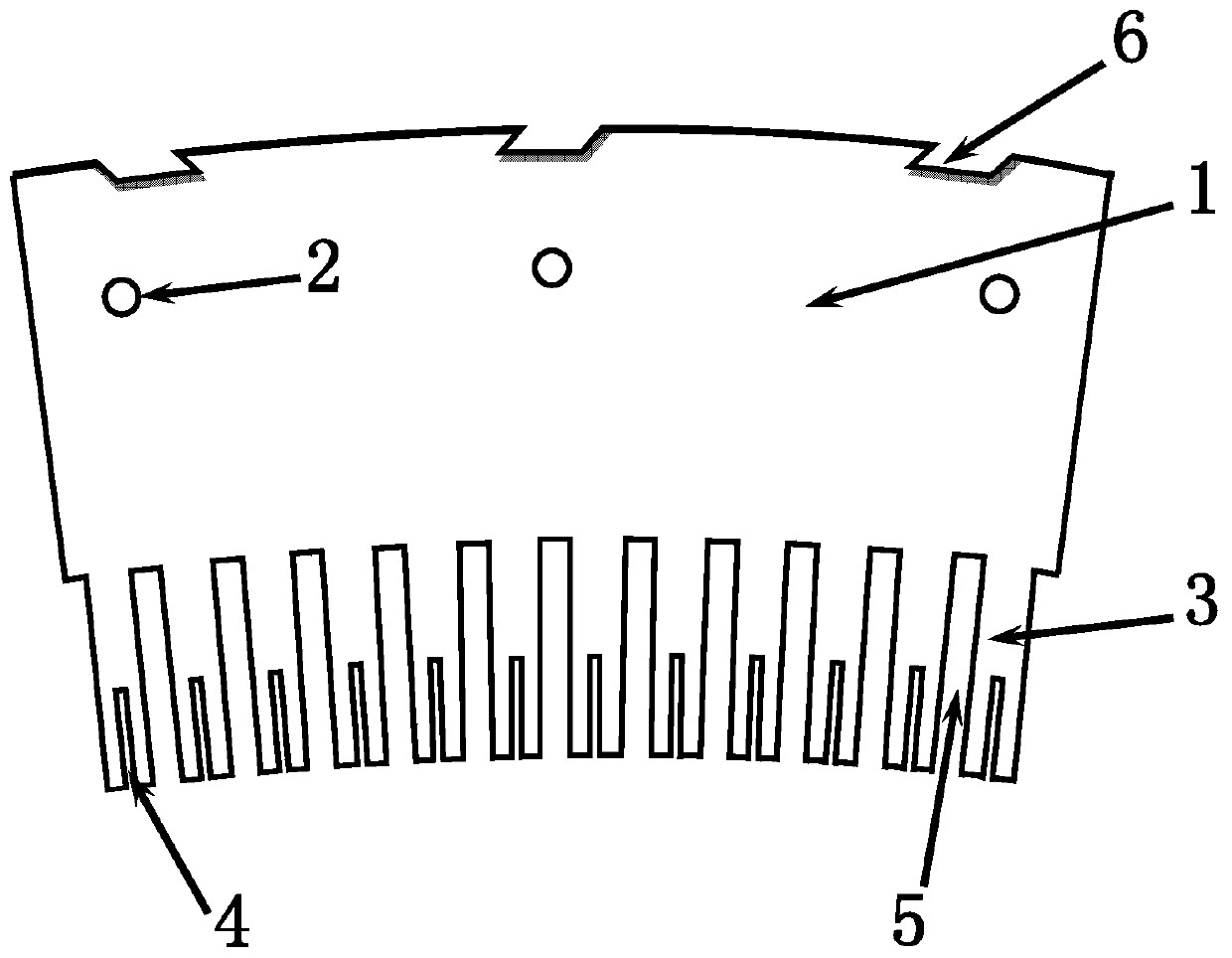

[0033] 1) Auxiliary fixing hole slots and slot size enlargement are added to the end pieces of the stator core: such as figure 1 The stamping piece of the stator core end piece shown in the illustration selects 0.5 mm thick non-oriented silicon steel sheet as the manufacturing material, punches two insulating pin positioning holes 2 with a diameter of 12 mm on the yoke part 1 of the end piece on the punching machine, and punches two insulating pin positioning holes 2 with a diameter of 12 mm for the end piece. Each tooth part 3 is punched with a vertical rib plug groove 4 with a width of 5 mm and a depth of 100 mm. After the end pieces are bonded into a whole, the size of the groove 5 becomes smaller due to the influence of the adhesive film. When processing the size of the groove 5, it is necessary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com