Normally closed micro-mechanical inertia electrical switch

A mechanical inertia and micro-mechanical technology, applied in the direction of electric switches, circuits, electrical components, etc., can solve the problems of circuit false contact, mass electrode without boundary protection, device damage, etc., to prevent false contact, improve contact effect, The effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

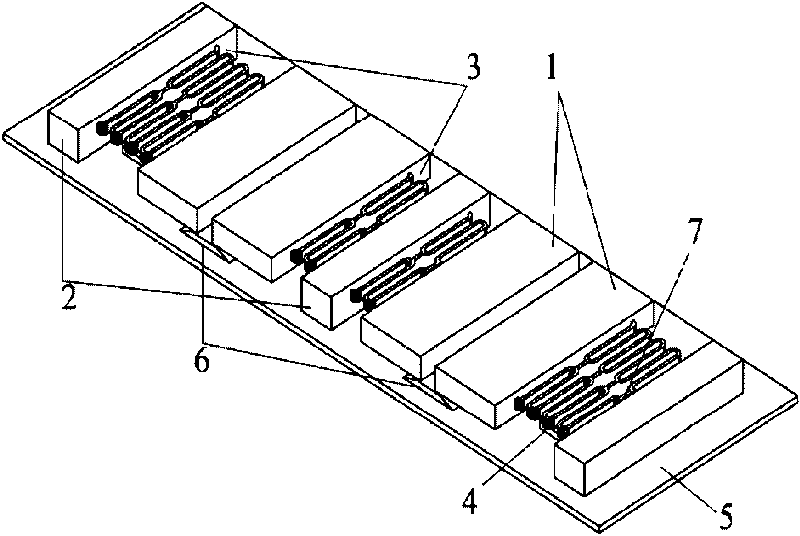

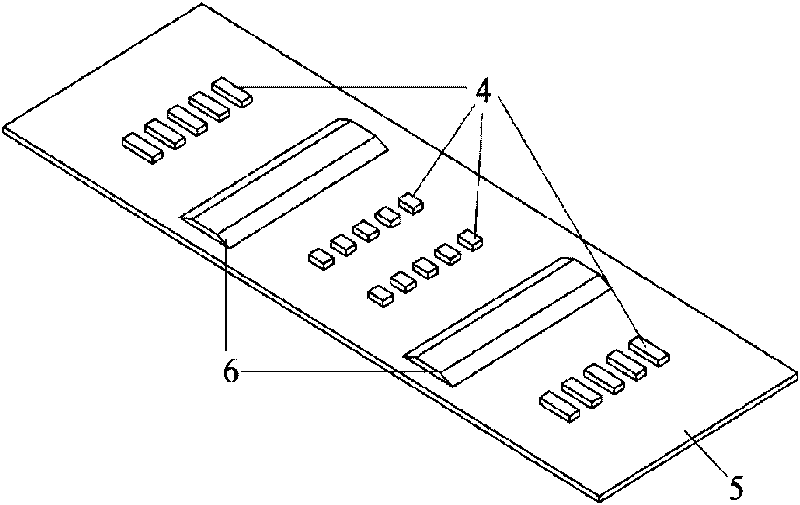

[0027] Such as figure 1 As shown, this embodiment includes: two pairs of mass electrodes 1, three spring support seats 2, four pairs of multi-turn conjoined serpentine springs 3, two support layers 4, an insulating substrate 5, and two fixed contact electrodes 6 and twelve springs connecting body 7, wherein: the fixed contact electrode 6 and the support layer 4 are fixed on the insulating substrate 5; the support layer 4 is located on both sides of the fixed contact electrode 6; the mass electrode 1 is located above the fixed contact electrode 6 , in contact with the fixed contact electrode 6; the spring support seat 2 is fixed on the insulating substrate 5, and is located on both sides of the support layer 4; The other end is connected to the electrode 1 of the mass block; the connecting body 7 between the springs is located in the middle of the connecting snake spring 3, and is connected to the connecting snake spring 3 on both sides respectively

[0028] Such as figure 2...

Embodiment 2

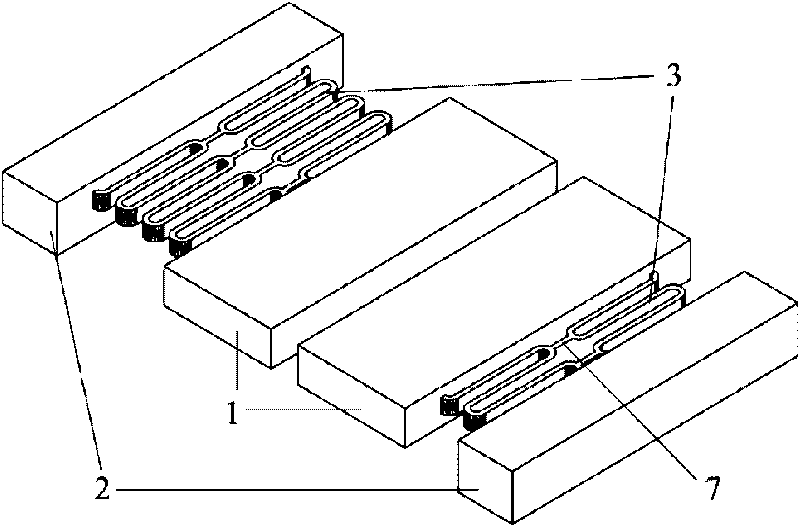

[0034] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the number of turns of the one-piece serpentine spring 3 is one turn, and the number of corresponding spring-connected bodies 7 is four.

[0035] This embodiment effectively improves the contact effect between the mass electrode 1 and the fixed contact electrode 6, and prevents the false contact phenomenon of the circuit; Under external impact acceleration, there will be no violent collision with the spring support seat 2, which effectively prevents damage to the device.

Embodiment 3

[0037] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that each mass electrode 1 includes a 4×8 square hole array, the square holes have a length of 40 microns, a width of 30 microns, and a height of 75 microns.

[0038] This embodiment effectively improves the contact effect between the mass electrode 1 and the fixed contact electrode 6, and prevents the false contact phenomenon of the circuit; Under external impact acceleration, there will be no violent collision with the spring support seat 2, which effectively prevents damage to the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com