Production of diphenyl carbonate by triphosgene or solid phosgene

A technology of diphenyl carbonate and solid phosgene, applied in the preparation of organic carbonate, organic chemistry and other directions, can solve the problems of low yield of diphenyl carbonate, damage to catalyst activity, long process flow, etc., and achieves process environmental protection, The effect of reducing equipment and installation manufacturing costs and increasing space-time efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0016] Organic phase: 20 kg of solid phosgene in 100 liters

[0017] Water phase: 100 liters contains 38 kg of phenol, 16.5 kg of sodium hydroxide (100%), and an appropriate amount of catalyst.

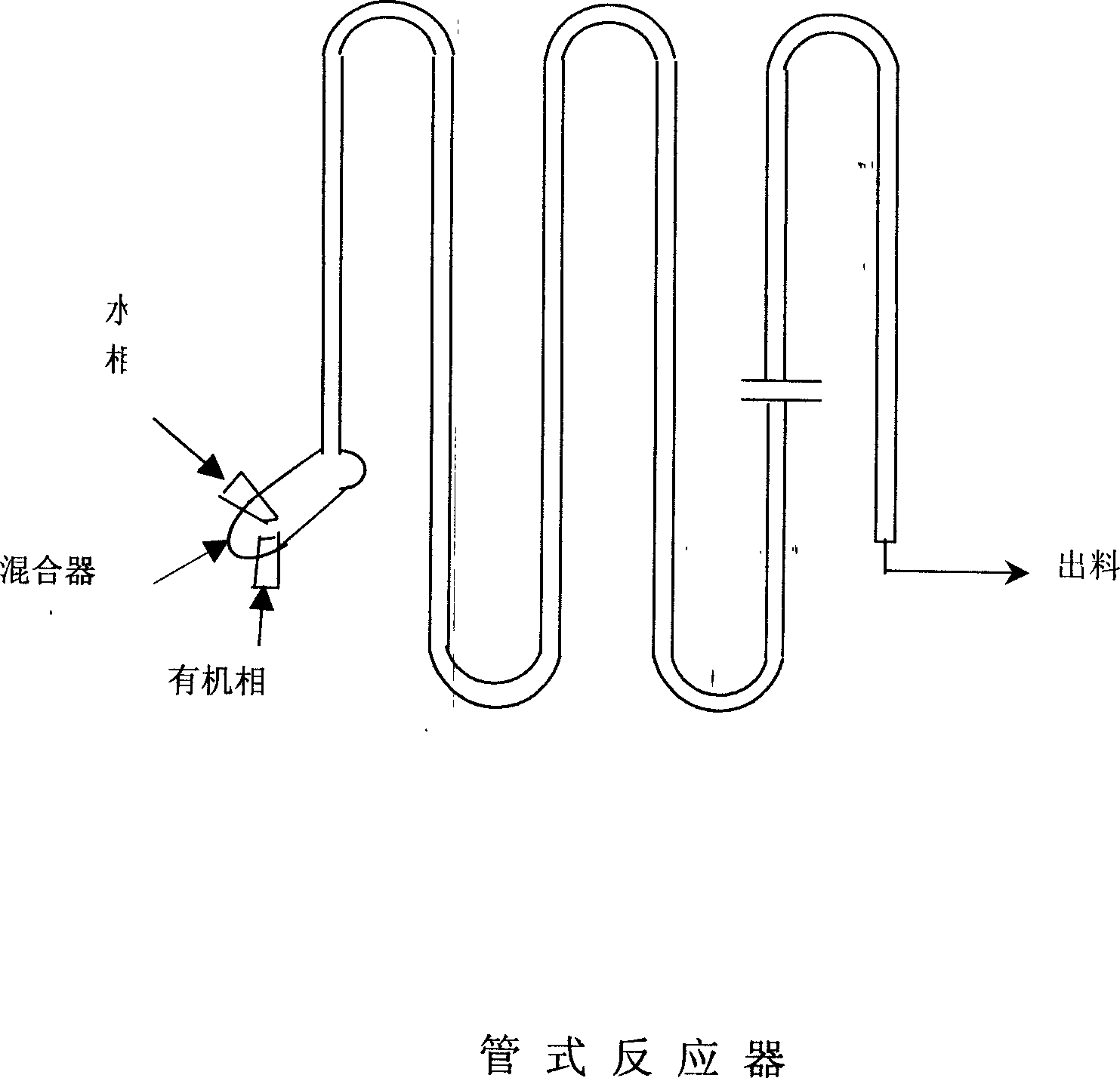

[0018] Reactor: The structure is as above, see attached drawing. The mixer added at the front end has a throttling mixer with back-mixing and dispersing functions. The main body of the tubular reactor is a serpentine tube with an inner diameter of 8mm, and the length of the tube is 200 meters. .5, 5 intervals are connected in series with tapered sharp-hole pipe fittings with an inner diameter of 1.5mm to achieve the purpose of fully mixing two-phase materials. The total volume of the pipe system is only 10 liters, and the annual production capacity can reach 150 tons of diphenyl carbonate. The space-time efficiency is 15 tons / M 3 .Hour.

[0019] Synthesis: The above-mentioned materials are dosed according to the volume flow ratio of 1:1, continuously input into the reactor under th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com