Sintering smoke wet method sulphur removing and dust removing technology

A technology for sintering flue gas and wet desulfurization, which is applied in the field of wet desulfurization and dust removal technology, can solve the problems of deterioration of GGH working conditions, complex composition of sintering flue gas, and low dust removal efficiency, so as to improve resource utilization and alleviate chlorine pollution. Corrosion problems, effects of mitigating enrichment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

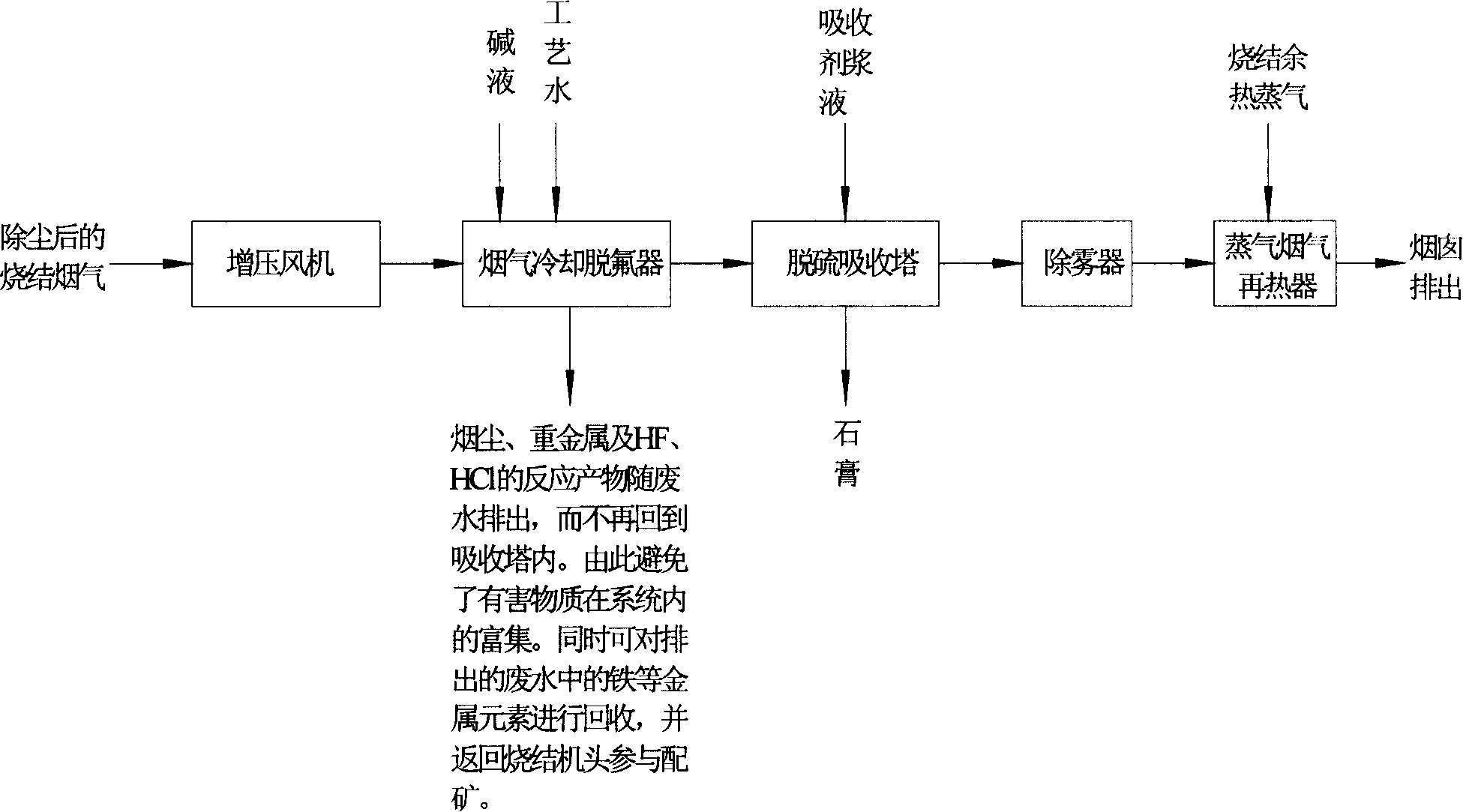

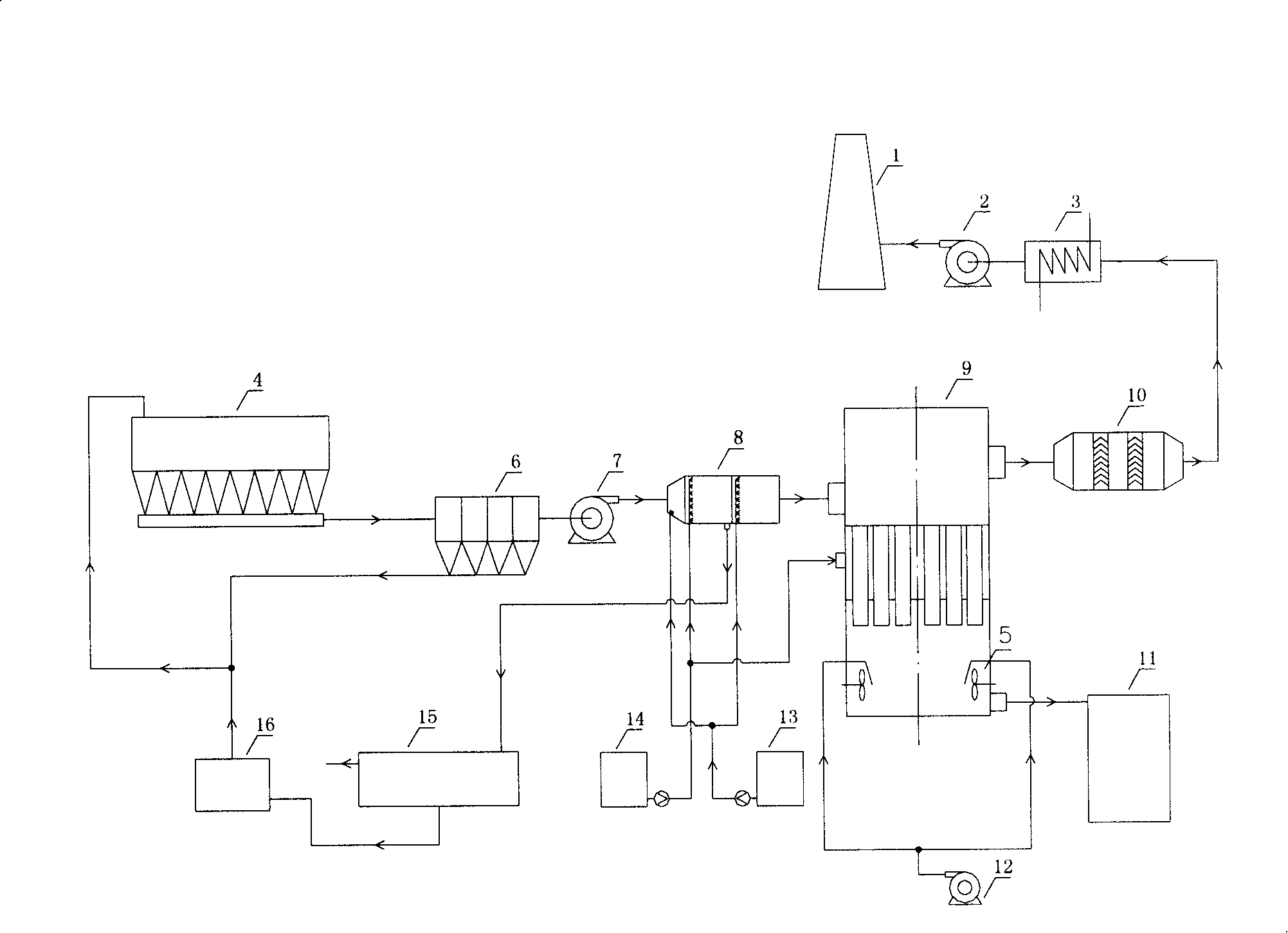

[0040] Depend on Figure 1 to Figure 2 It can be seen that the sintering flue gas to be treated from the electrostatic precipitator 6 is first boosted by the booster fan 7, and then enters the cooling defluorination device 8 located at the front of the desulfurization absorption tower 9 for defluorination and cooling. At this stage, after the flue gas reacts with the fresh lye sprayed into the cooling defluorination device 8 from the limestone slurry tank 14, and is washed by the process water sprayed into the process water tank 13, the HF gas in the sintering flue gas can be basically removed, At the same time, the temperature of the flue gas is reduced to below 80°C, which provides the best reaction conditions for the subsequent desulfurization and ensures the thermal safety of the absorption tower. Since the HCl gas in the flue gas also has a very high solubility, most of the HCl can be removed during cooling and defluorination, and large particles of soot can be removed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com