Subminiature radial glass packaging thermistor and manufacturing method thereof

A thermistor and glass encapsulation technology, applied in the direction of resistors with negative temperature coefficients, etc., can solve problems such as the reduction of the electrical gap between the two leads, the reduction of external force resistance, and the risk of product quality, so as to avoid the thinning of the glass layer and reduce the risk of product quality. Small internal stress, good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of glass paste in S4 is:

[0041] S41. Weigh 200-230g of glass powder, 2-3g of sodium hexametaphosphate, 76-78g of binder, and 60-63g of organic solvent, and mix evenly. The organic solvent is a mixture of n-propyl acetate and isobutanol;

[0042] S42. Put the mixed material in S41 in a container and add zirconium balls of 1 / 3-1 / 2 volume of the container, then seal it and use a ball mill to stir and mix evenly, and then use a 200-mesh gauze to sieve to separate the zirconium balls and glass slurry.

[0043] Glass powder is used as the main raw material in the glass paste raw material, and a small amount of binder is added to ensure that the glass paste can be better adsorbed on the surface after spraying on the surface of the ultra-small glass-encapsulated NTC thermistor. At the same time, adding sodium hexametaphosphate can The glass powder is fully and uniformly dispersed in the solvent, which not only ensures the flatness of the glass layer on ...

Embodiment 1

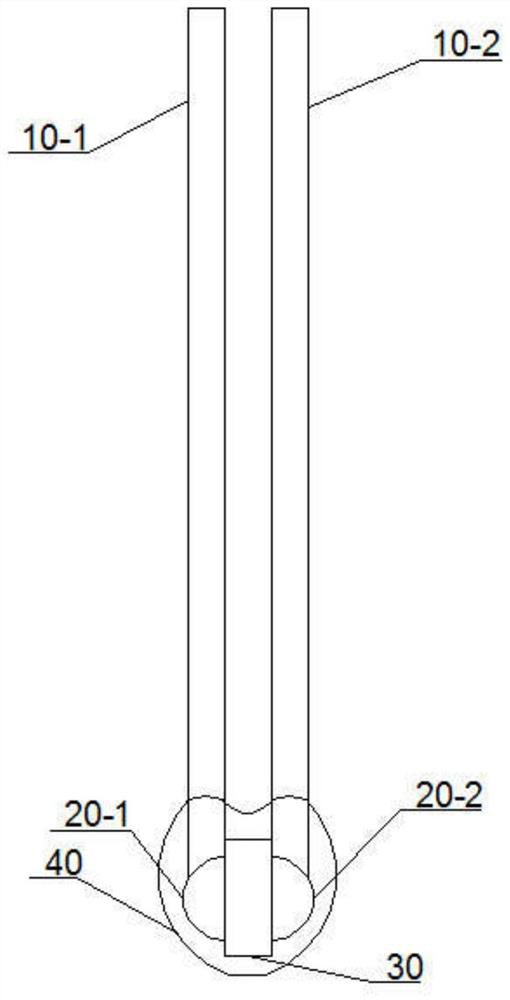

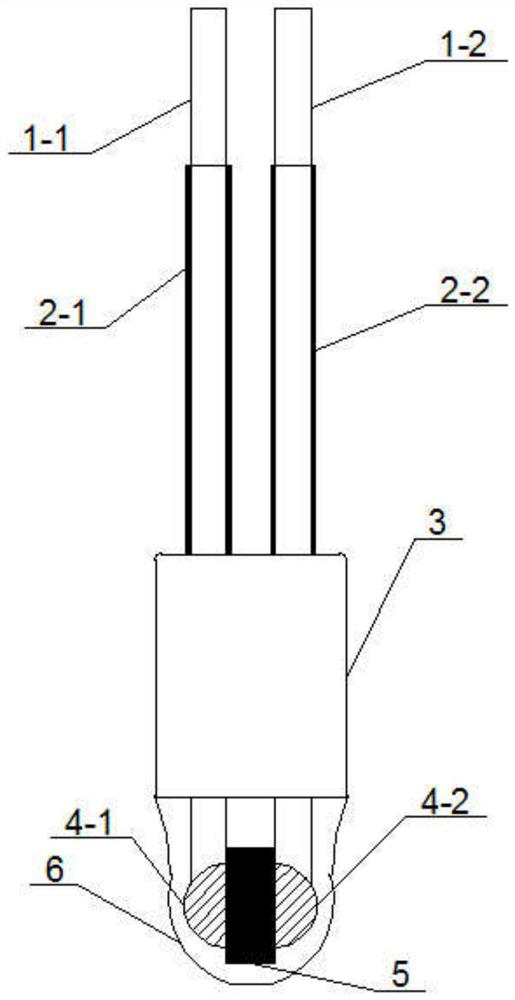

[0052] S1. Thread two Dumagnesian wires into the cylindrical alumina ceramic column. The heads of the two Dumagnesian wires are flush and expose the outer length of the ceramic column by 1mm;

[0053] S2. Expose two Du magnesium wires to the end of the porcelain column and dip it in silver paste;

[0054] S3. Fill the thermosensitive chip between the two Du magnesium wires, connect the two electrode terminals of the thermistor with the silver-coated ends of the two Du magnesium wires, and form a semi-finished product after sintering at a high temperature of 100°C;

[0055] S4, preparing glass paste, and coating the glass paste on the surface of the semi-finished product in S3;

[0056] Wherein the glass slurry preparation process:

[0057] S41, 200g glass powder is mixed with 2g sodium hexametaphosphate and 76g binding agent with 60g solvent (n-propyl acetate and isobutanol mixture);

[0058] S42. Put the mixed material in S41 in a container and add zirconium balls of 1 / 3-1 / ...

Embodiment 2

[0063] S1. Thread two Dumagnesian wires into the cylindrical alumina ceramic column. The heads of the two Dumagnesian wires are flush and expose the outer length of the ceramic column by 1mm;

[0064] S2. Expose two Du magnesium wires to the end of the porcelain column and dip it in silver paste;

[0065] S3. Fill the thermosensitive chip between the two Du magnesium wires, connect the two electrode terminals of the thermistor with the silver-coated ends of the two Du magnesium wires, and form a semi-finished product after sintering at a high temperature of 100°C;

[0066] S4, preparing glass paste, and coating the glass paste on the surface of the semi-finished product in S3;

[0067] Wherein the glass slurry preparation process:

[0068] S41, 210g glass powder is mixed with 2.3g sodium hexametaphosphate and 77g binder with 61g solvent (n-propyl acetate and isobutanol mixture);

[0069] S42. Put the mixed material in S41 in a container and add zirconium balls of 1 / 3-1 / 2 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com