Concrete pump truck

A concrete pump truck and car body technology, which is applied in the direction of concrete transportation, etc., can solve the problems that hinder the expansion of the model of the movable concrete pump, the size of the width direction cannot be changed, the cost of licensing fees, insurance fees, etc., so as to expand the applicability of the product and improve Mobility, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

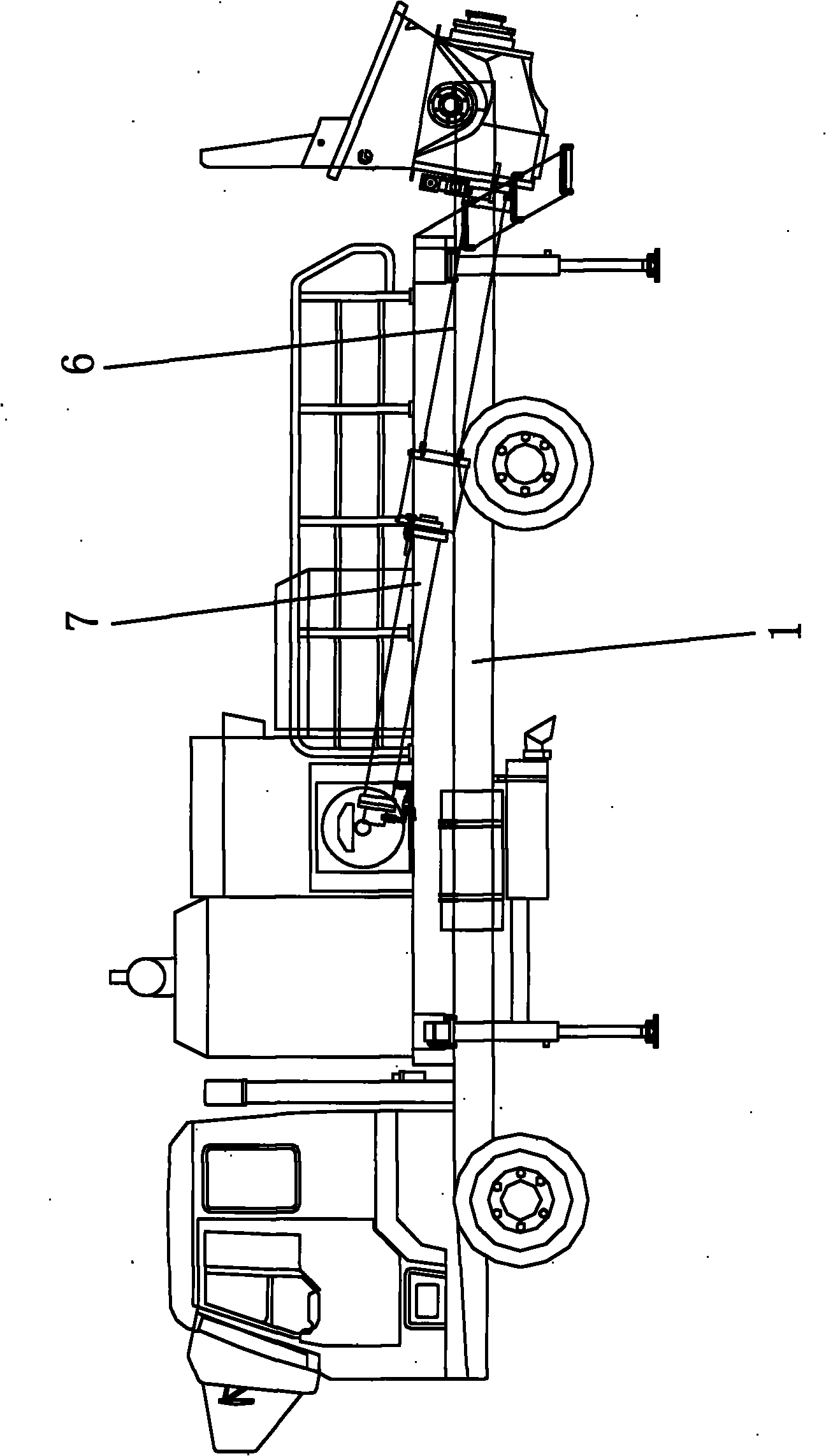

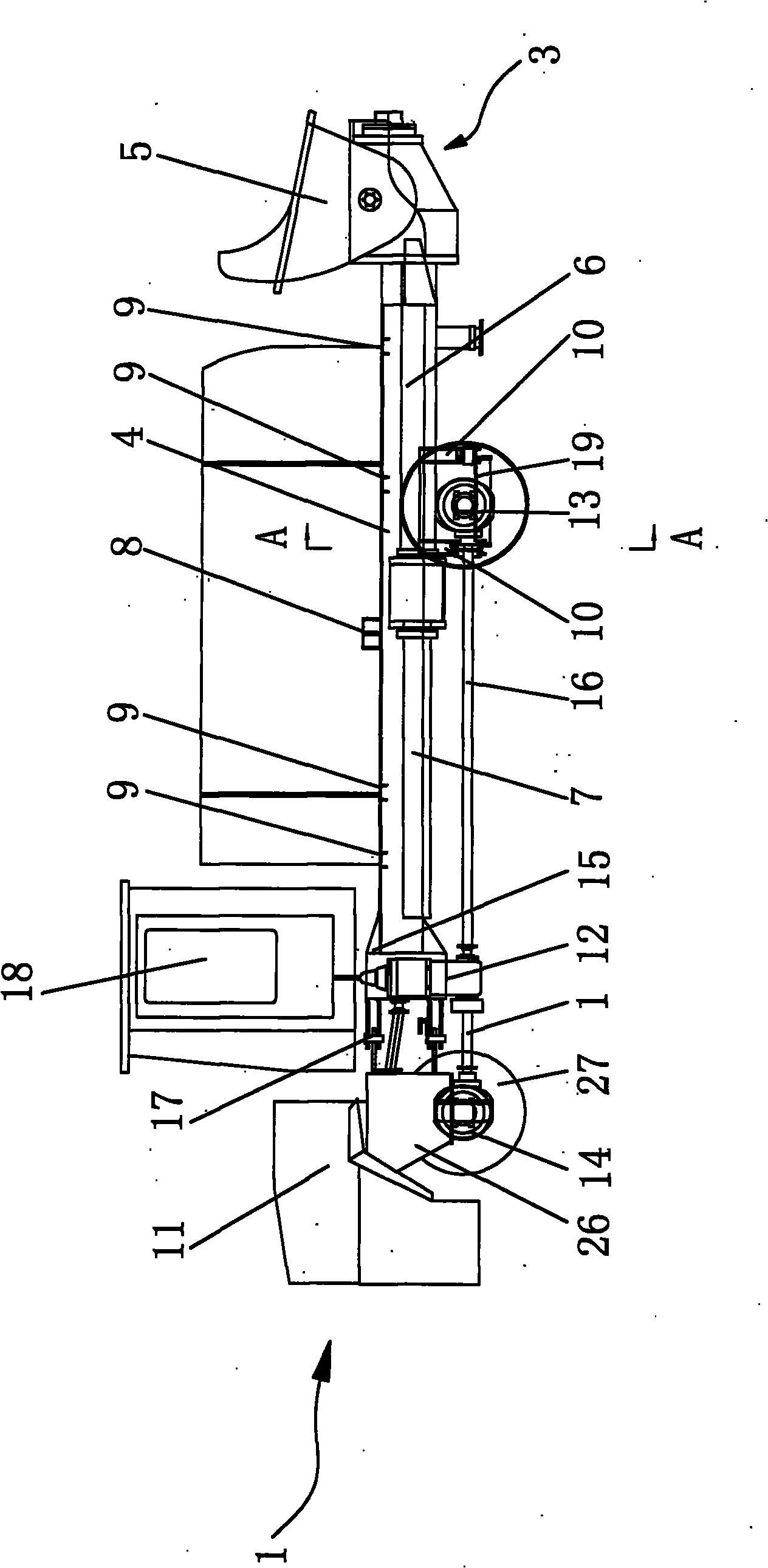

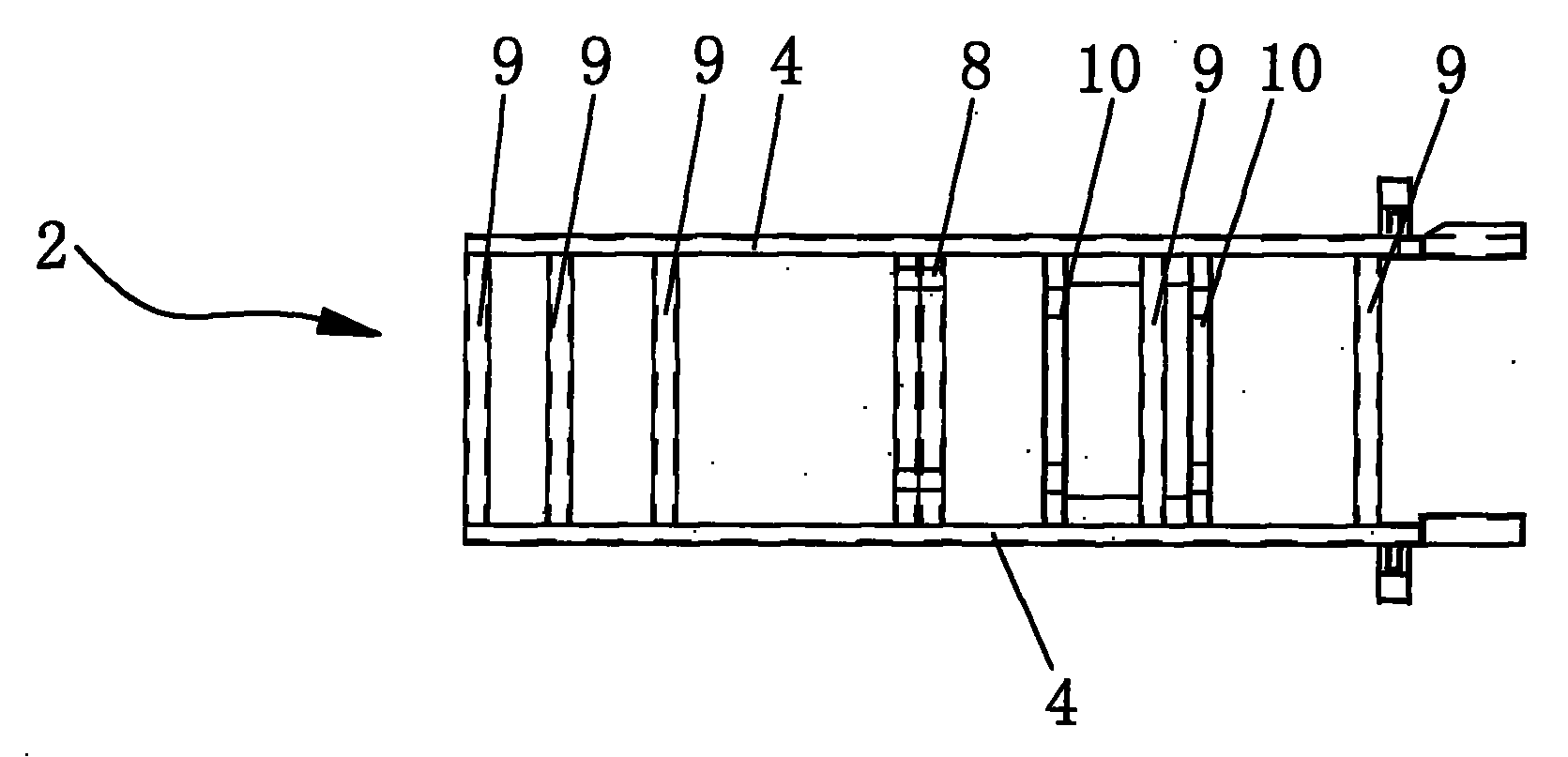

[0033] Such as figure 2 , 4 The shown concrete pump truck includes a car body 1, a frame 2 horizontally arranged on the car body 1, a pumping mechanism 3 installed on the frame 2, a power mechanism and a steering mechanism. The frame 2 includes two horizontally arranged U-shaped beams 4 , and the openings of the two U-shaped beams 4 are arranged opposite to each other, and a beam assembly straddling between the two U-shaped beams 4 . The pumping mechanism 3 generally includes: a hopper 5 , a concrete cylinder 6 connected to the hopper 5 , and a main oil cylinder 7 connected to the concrete cylinder 6 .

[0034] Such as image 3 As shown, the crossbeam assembly includes a first crossbeam 8, a second crossbeam 9 and a third crossbeam 10, wherein: the centerline of the first crossbeam 8 is located above the horizontal plane where the U-shaped beam 4 is located, and the centerline of the second crossbeam 9 is located at the U-shaped On the horizontal plane where the girder 4 i...

Embodiment 2

[0039] Such as Figure 5As shown, the difference from Embodiment 1 is that a gearbox 12 is directly installed on the front end of the U-shaped girder 4, the input end of the gearbox 12 is connected with the walking engine 11 through a belt 20, and the output end of the gearbox 12 is driven by a universal joint. The shaft 16 is connected to the drive rear axle 13 . The front steering bridge 14 is installed under the second beam 9, and the piston rod of the steering oil cylinder is connected with the front steering wheel 27 to drive the rotation of the unpowered front steering wheel 27.

Embodiment 3

[0041] Such as Figure 6 , 7 As shown, the difference from Embodiment 1 is that the two third beams 10 lower than the U-shaped beam 4 are also fixed supports for driving the rear axle 13. The third beam 10 is equipped with a leaf spring hinge seat 21, and the leaf spring is hinged. Seat 21 is equipped with shock-absorbing leaf spring 22, and driving rear axle 13 is elastically connected on the shock-absorbing leaf spring 22 by a U-shaped bolt, and driving rear axle 13 adapts to uneven road surface by the elasticity of shock-absorbing leaf spring 22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com