Large vertical grinder

A vertical grinding machine, large-scale technology, applied in the direction of grinding machines, machine tools suitable for grinding workpiece planes, grinding/polishing equipment, etc., can solve the problems of decreased work efficiency, increased peripheral sag, and unequal worktables, and achieves savings Energy consumption, the effect of eliminating the increase in resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

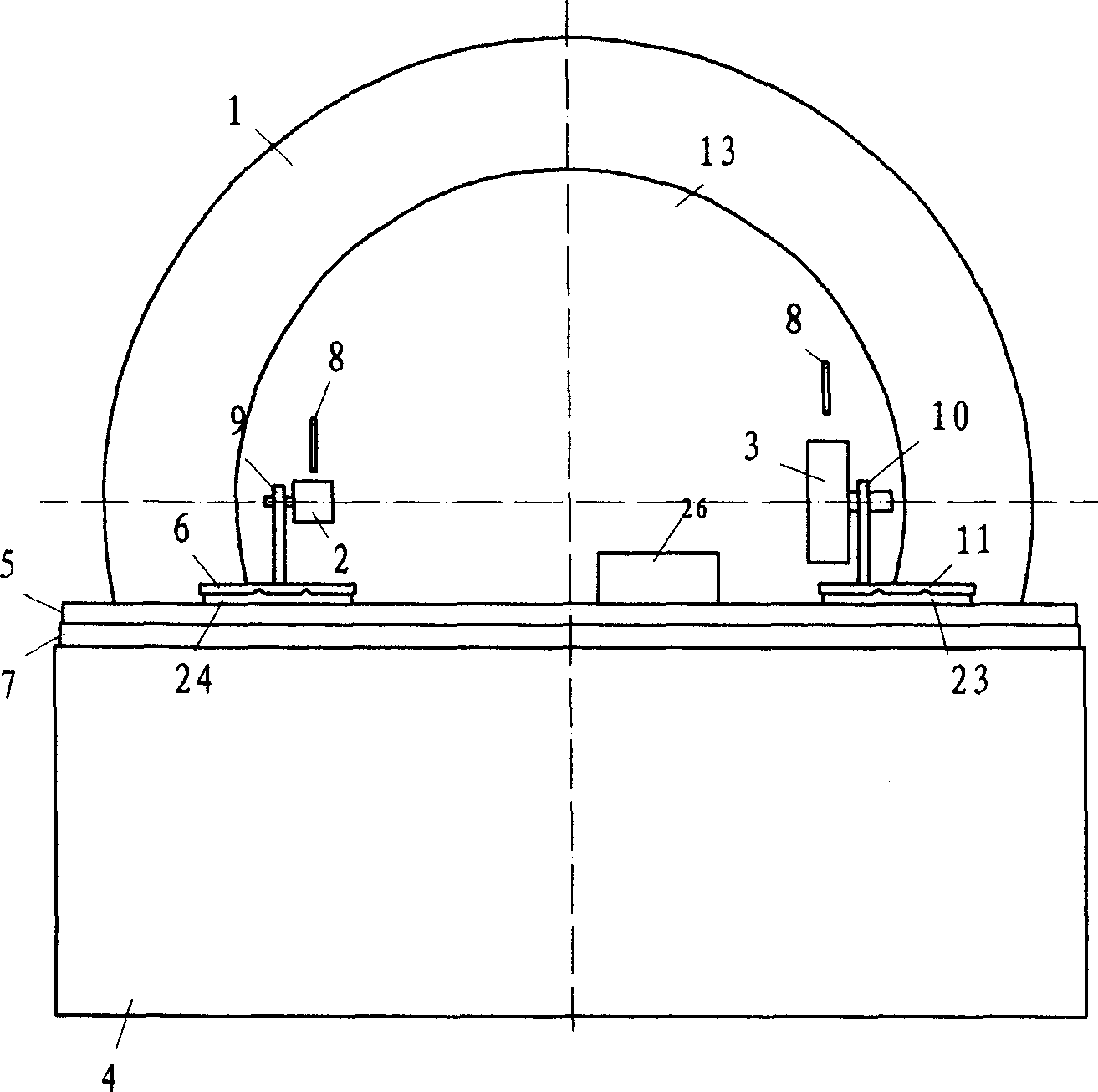

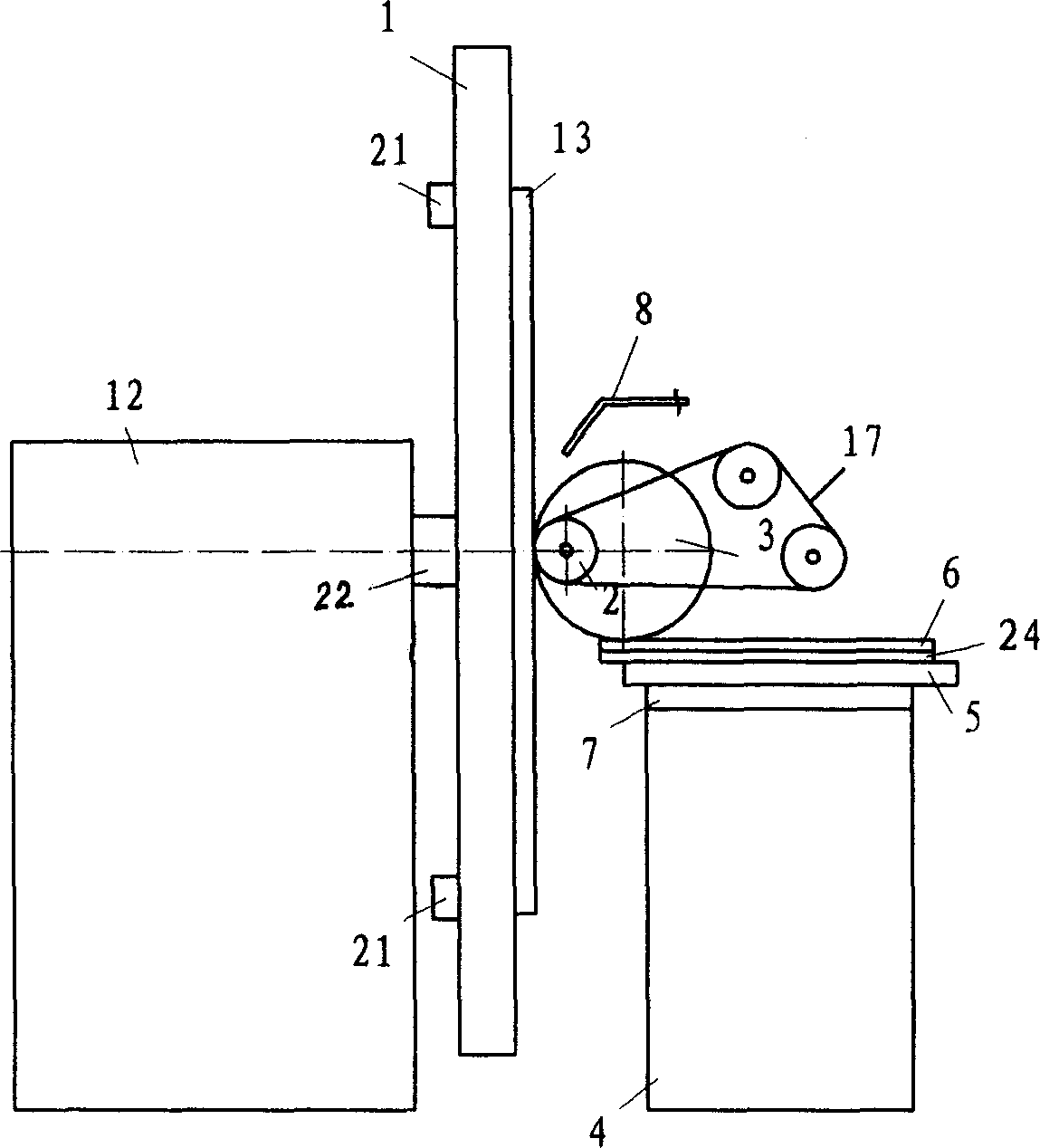

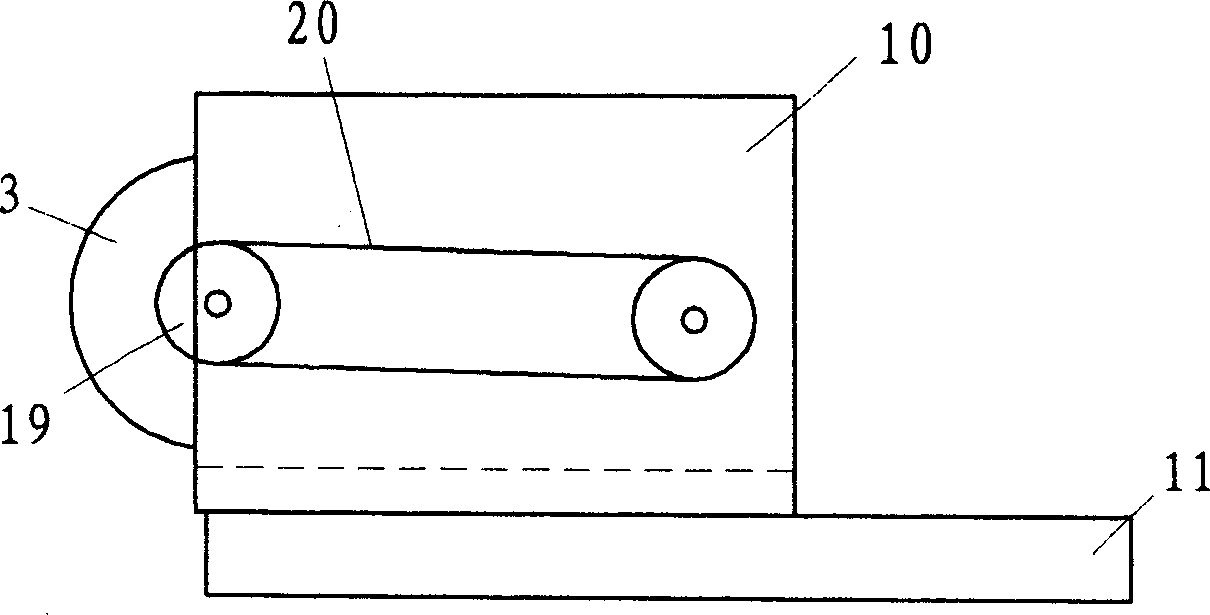

[0023] Depend on figure 1 , 2 It can be seen that the large vertical grinding machine of the present invention consists of workbench 1, power and transmission device 12, guide rail base 4, transverse guide rail 7, transverse guide plate platform 5, longitudinal guide rail (23,24), longitudinal guide plate (6,11), The grinding tool 3 and the transmission device, the polishing wheel 2 and the transmission device are composed. The workbench 1 is vertical, and is assembled on the power and transmission device 12 through the rotating shaft 20. The power and transmission device 12 is fixed on the foundation. The guide rail base 4 stands opposite to the workbench 1 and is fixed on the foundation near the workbench. Above, the transverse guide rail 7 is fixed on the guide rail base 4 , and the transverse guide plate platform 5 is sleeved on the transverse guide rail 7 . The transverse guide plate platform 5 can move back and forth in the transverse direction along the transverse gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com