High-bearing gear-type pump motor

A gear type, pump motor technology, applied in the motor field, can solve the problems affecting the service life of the gear motor, reduce the stability of the gears, and reduce the contact surface surface, and achieve the advantages of improving the service life, reducing the stability and improving the wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

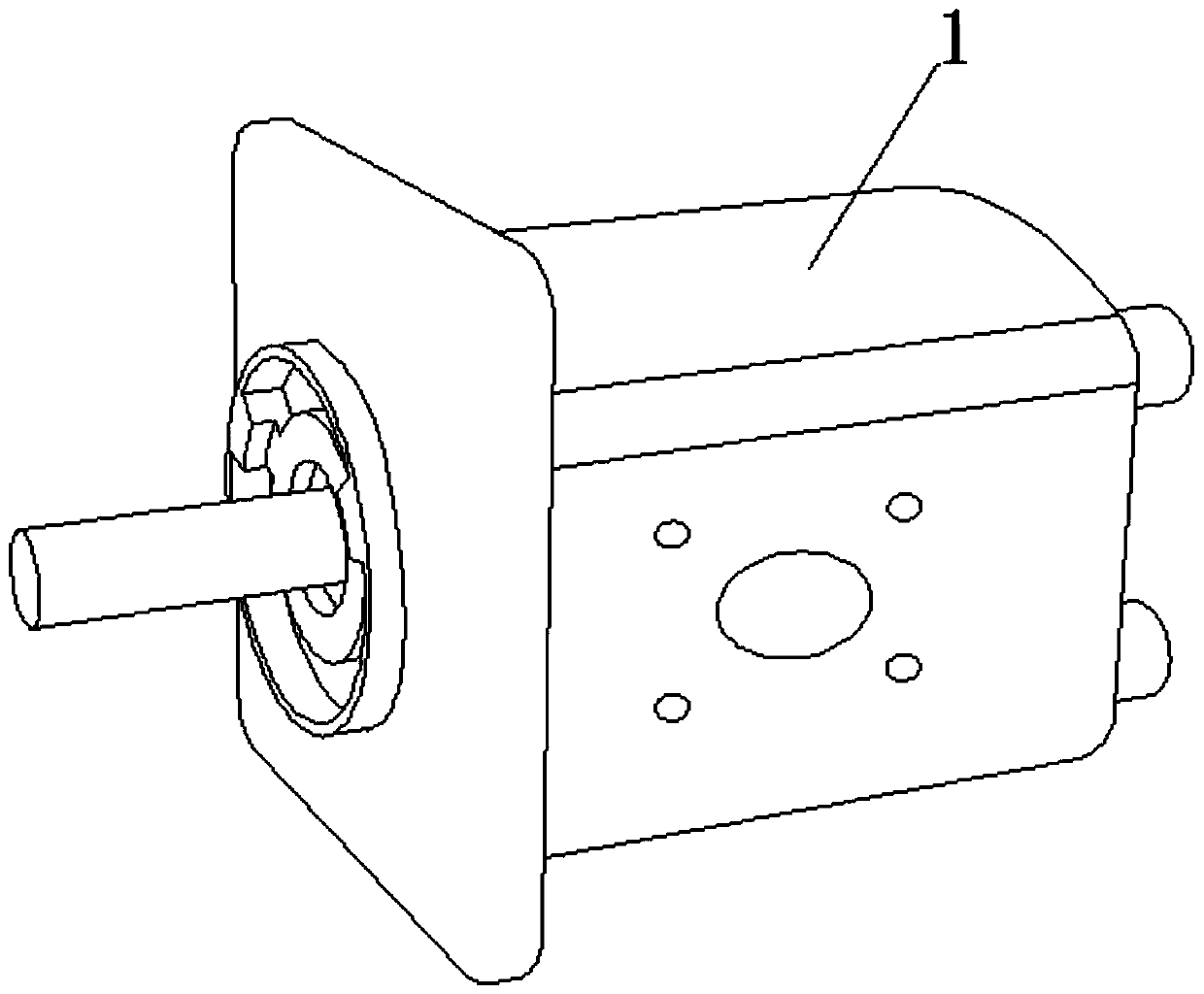

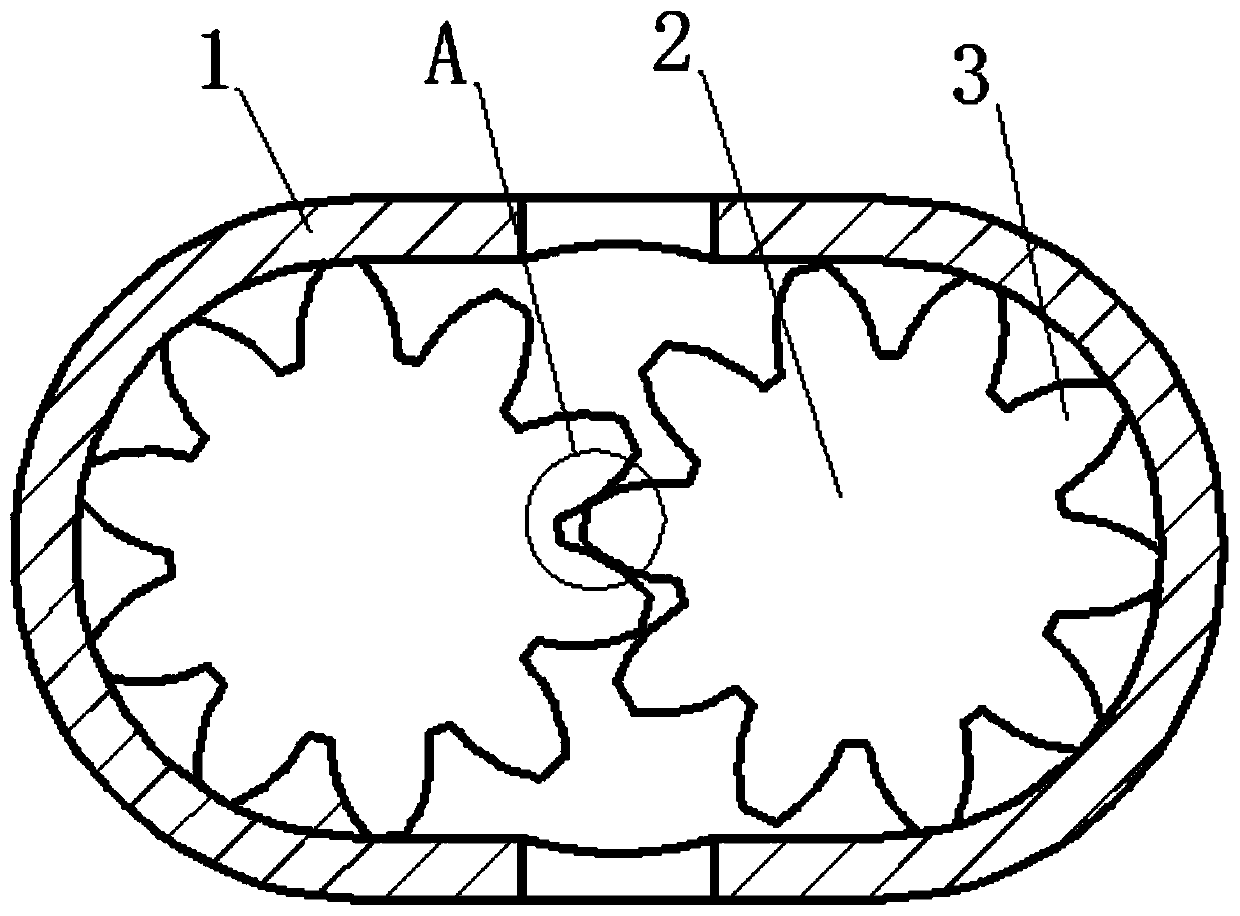

[0041] see Figure 1-2 , a high-load gear pump motor, including a gear pump body 1, two gears 2 are installed inside the gear pump body 1, and a plurality of uniformly distributed teeth 3 are fixedly connected to the outer ends of the two gears 2, and the two gears 2 is connected by teeth 3 meshing.

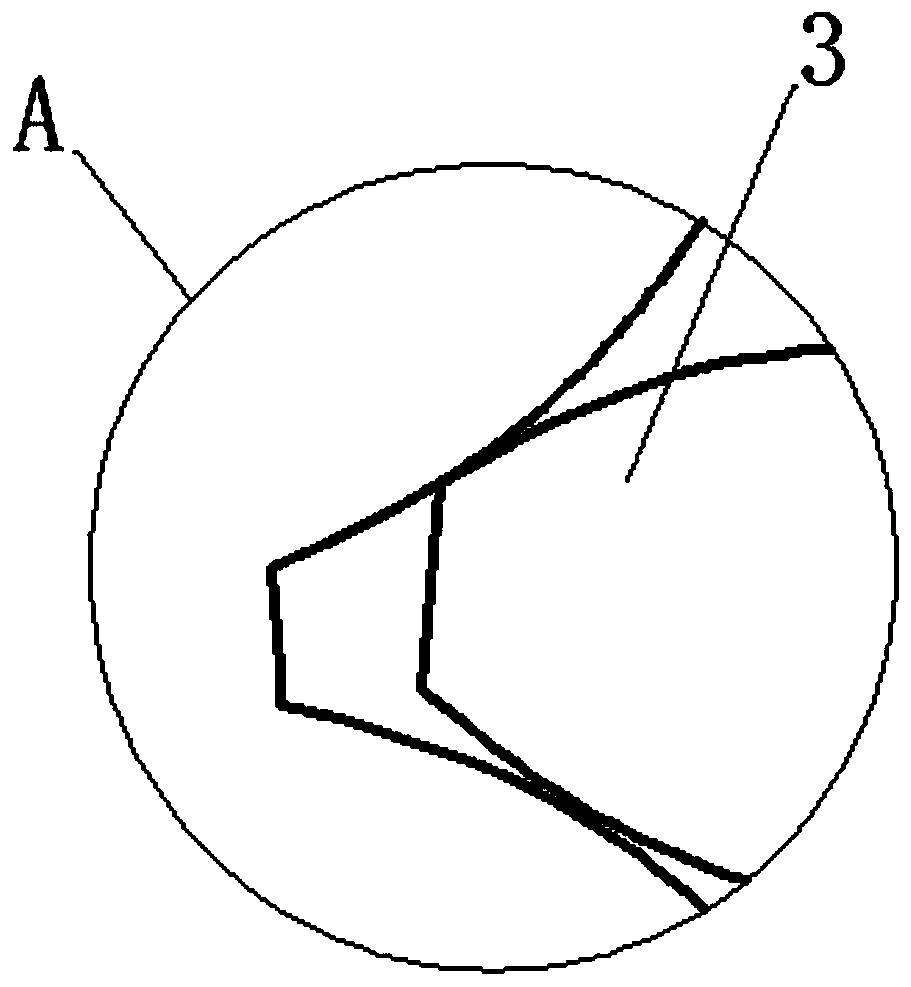

[0042] see Figure 4-5 There is an inverted U-shaped cavity 5 excavated inside the tooth 3, and a plurality of reinforcing balls 4 are placed at the left and right inner ends of the inverted U-shaped cavity 5. Every two adjacent reinforcing balls 4 are in contact with each other, and the inverted U-shaped An eight-shaped storage bag 6 is placed at the inner end of the cavity 5, and the eight-shaped storage bag 6 is located in the middle of the inverted U-shaped cavity 5, and the left and right ends of the eight-shaped storage bag 6 are in contact with the adjacent reinforcing ball 4, The reinforcing ball 4 and the eight-shaped storage bag 6 are extruded and contacted with each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com