A built-in fuel manifold for dual-circuit fuel delivery and atomization

A fuel main pipe, built-in technology, applied in the direction of combustion chamber, combustion method, combustion equipment, etc., can solve the problems of impact, influence of external channel airflow, instability of fuel flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

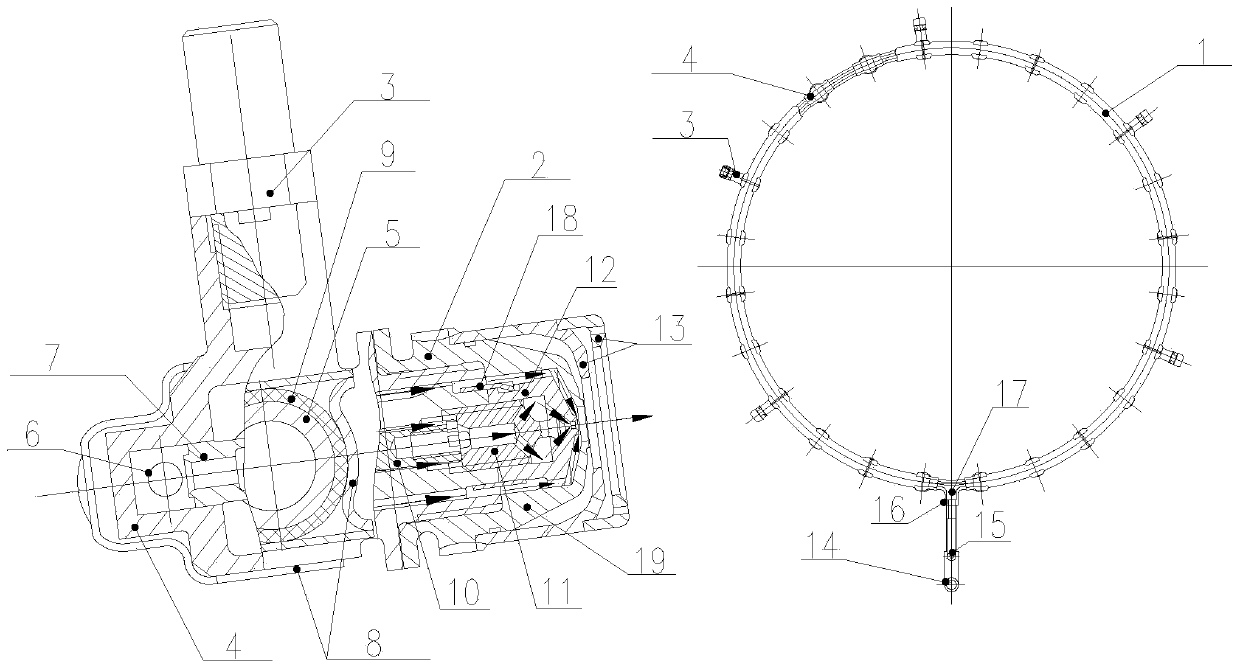

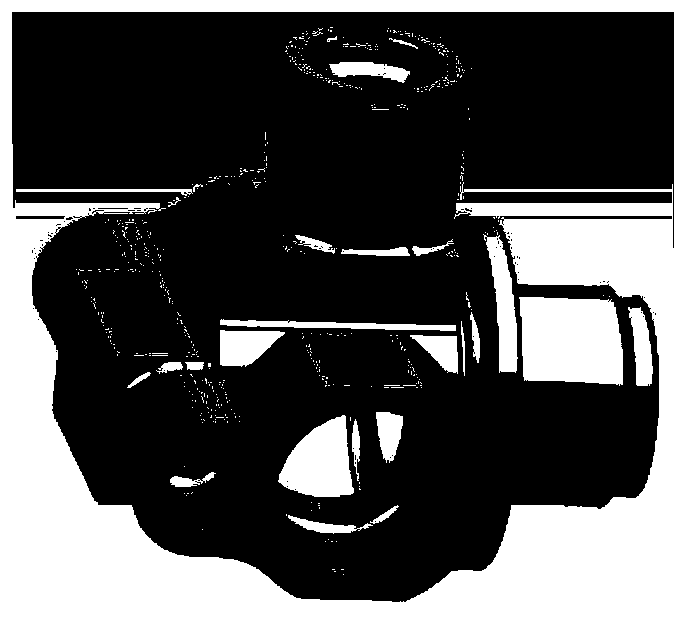

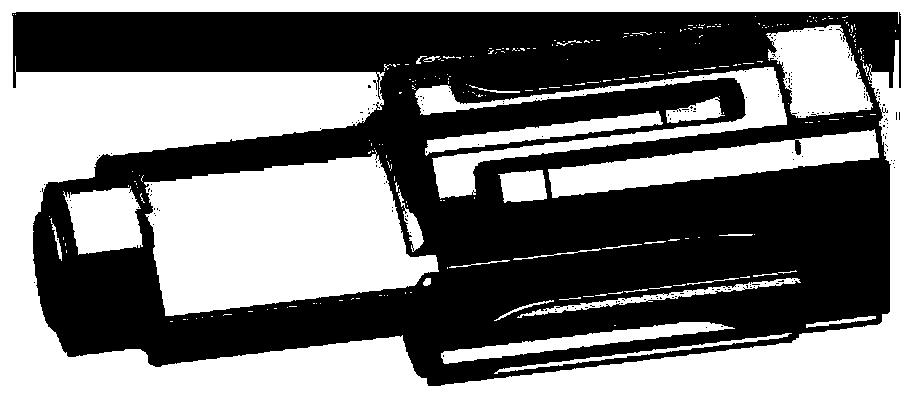

[0017] Such as figure 1 As shown, the built-in fuel main pipe of the present invention is mainly composed of a pillar with a sphere, a nozzle housing, a main oil supply pipe, an auxiliary oil supply pipe, an outer cover, a heat insulation layer, a bushing with a threaded oil filter, an auxiliary Oil filter, swirler, nozzle swirler, lock ring, main oil nozzle, gas cover, main oil elbow joint, auxiliary oil elbow joint, main oil tee pipe joint and auxiliary oil tee Composition of pipe joints.

[0018] The built-in fuel main pipe is fixed outside the equipment through the interference fit between the positioning pin and the ball in the pillar with the ball, because the ball in the pillar with the ball can rotate freely in the pillar, but the closing of the end face of the pillar can prevent the ball from falling off , this structure facilitates the fixed installation of the fuel main pipe; the main oil supply pipe and the auxiliary oil supply pipe are connected with the nozzle h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com