Heat-conducting plate with wick supporting structures and method for manufacturing same

The technology of a support structure and manufacturing method is applied in the field of heat conduction plate with capillary support structure and its production, which can solve the problems of long return path, lack of capillary structure, and influence on heat transfer effect of heat conduction plate, so as to achieve enhanced heat transfer effect, The effect of shortening the return path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to enable those skilled in the art to further understand the characteristics and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. However, the accompanying drawings are provided for reference and illustration only, and are not intended to limit the present invention. .

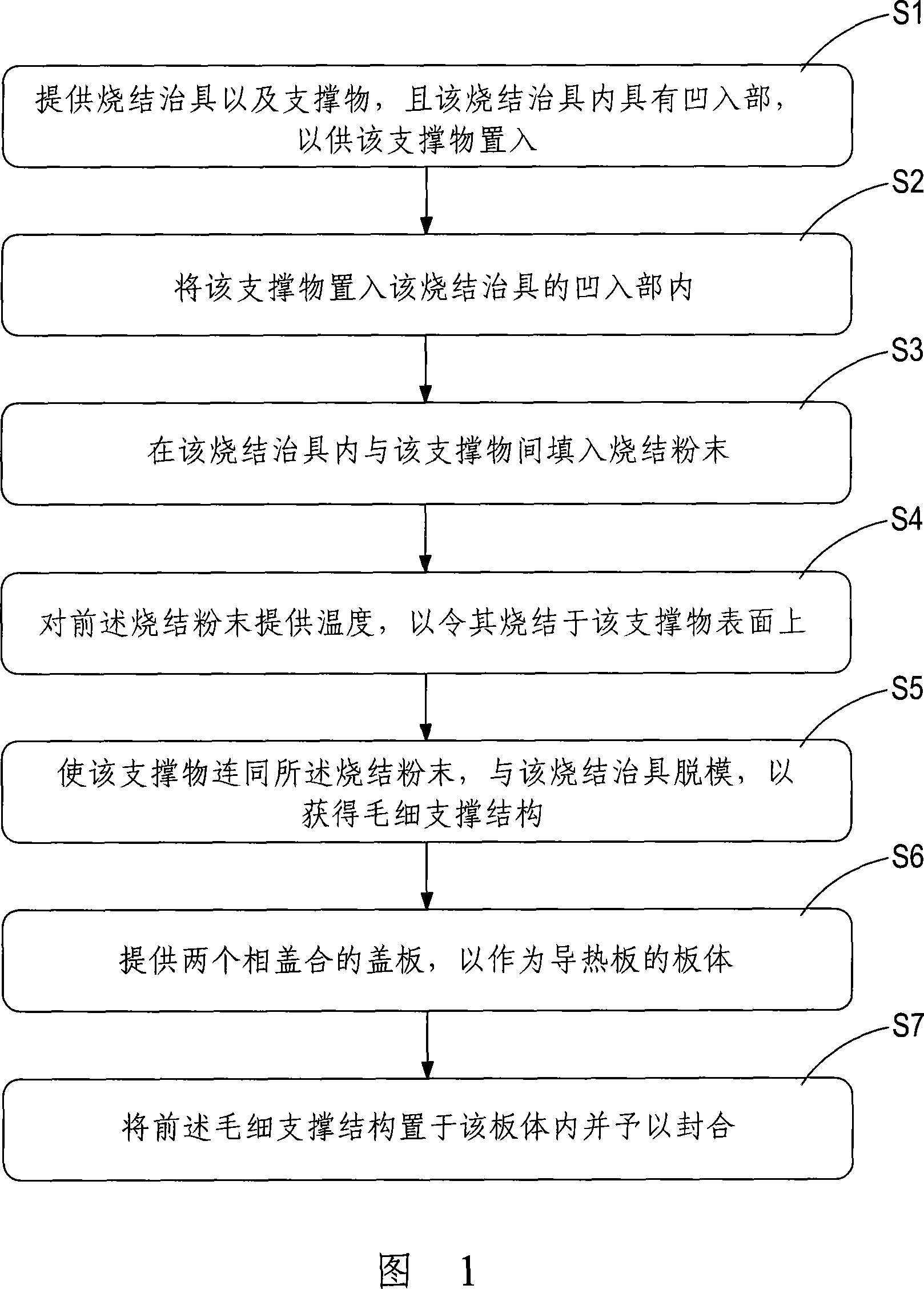

[0041] see figure 1 Shown is the flow of steps of the manufacturing method of the present invention. The invention provides a heat conducting plate with a capillary support structure and a manufacturing method thereof. The manufacturing method steps are as follows:

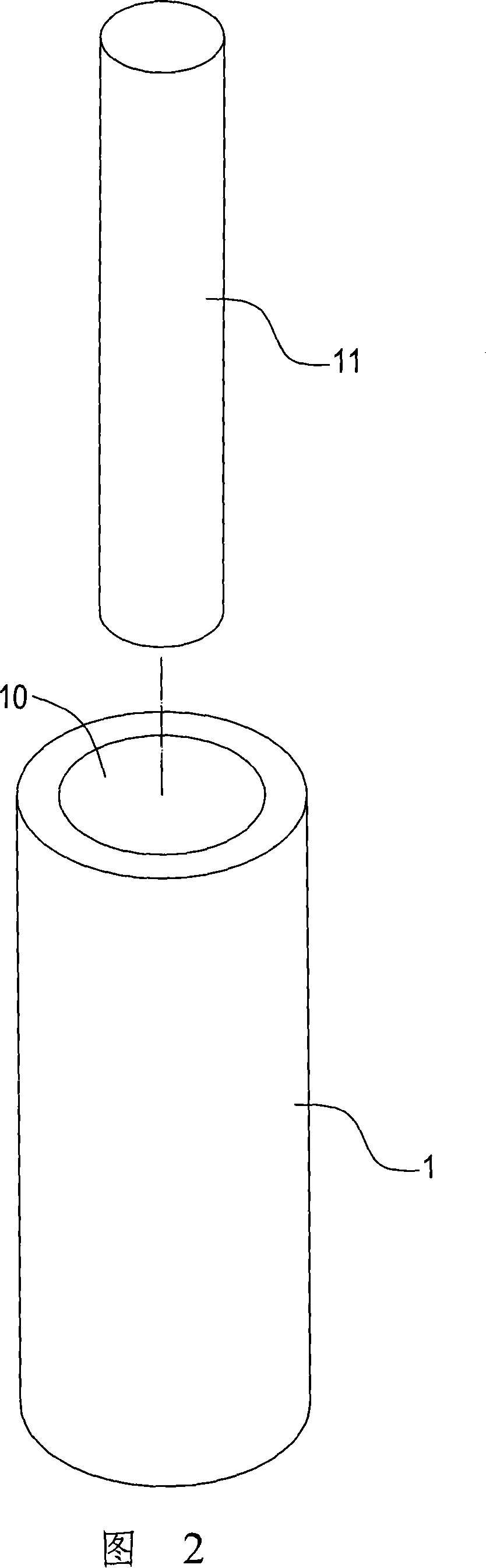

[0042] Step S1: providing a sintering jig and a support, and the sintering jig has a concave part for the support to be placed in;

[0043] Step S2: placing the support into the concave portion of the sintering jig;

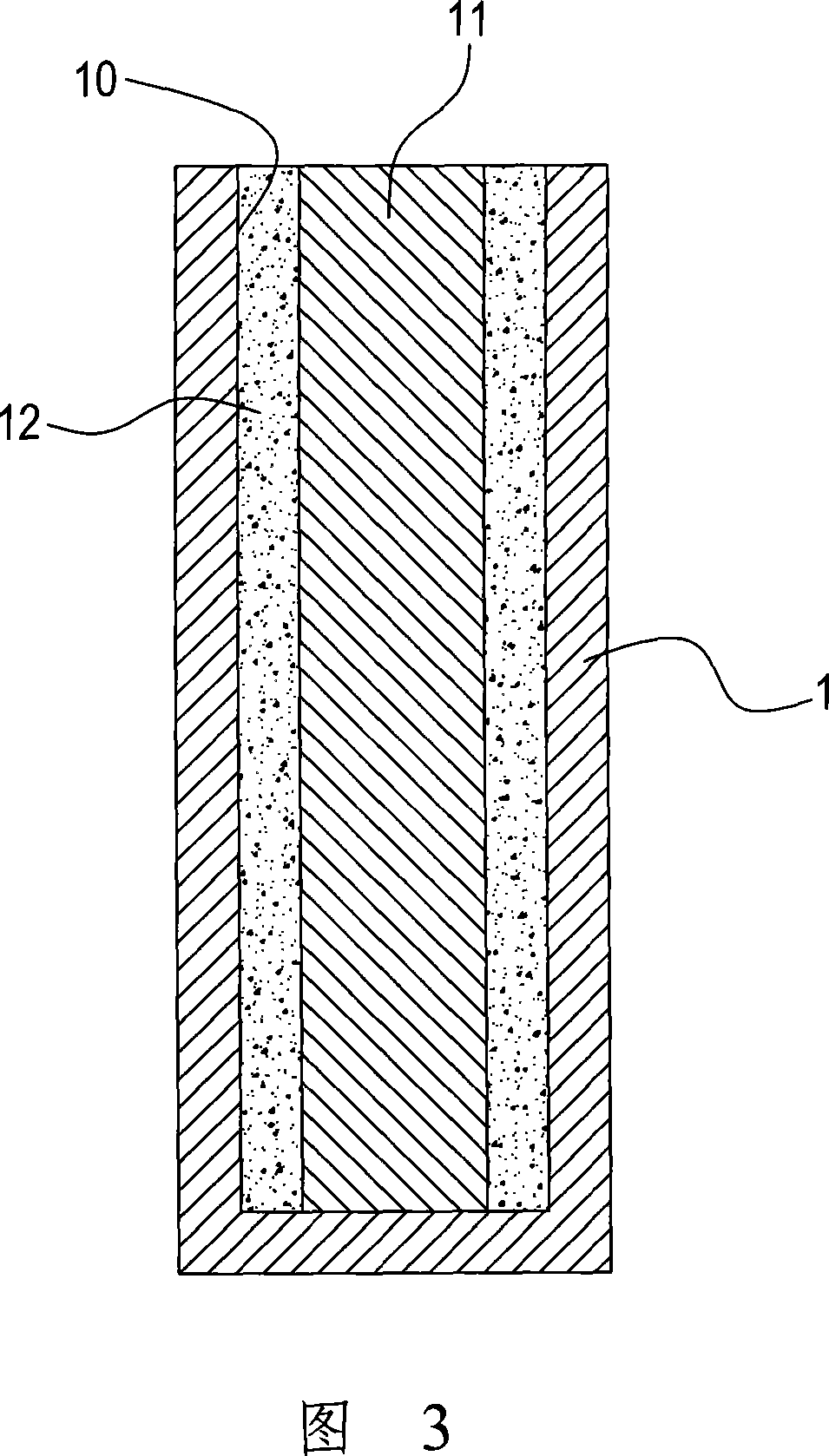

[0044] Step S3: Filling sintering powder between the sintering fixture and the support;

[0045] Step S4: providing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com