Patents

Literature

53results about How to "Prevent invagination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot wall type heat exchanger

PendingCN107388861AImprove compactnessEase of design optimizationIndirect heat exchangersEngineeringLiquid phase

The invention discloses a hot wall type heat exchanger. Each hot wall of the hot wall type heat exchanger comprises an inner supporting device and a heat exchange partition wall wrapping the inner supporting device. Each inner supporting device comprises a middle section allowing phase change fluid to circulate up and down and upper and lower ends allowing the phase change fluid to circulate left and right. The hot walls are rectangular, and a plurality of hot walls of the uniform size are arranged in parallel to form a cluster, or the hot walls are annular, and a plurality of hot walls of varying sizes are nested layer by layer to form a cluster. A channel allowing fluid to pass through or a fin is arranged between every two adjacent hot walls. The fluid sides of the channels outside all the hot walls or the fluid sides of the fins outside all the hot walls are divided into a plurality of regions. Heat exchange of heat exchange fluid is realized through the phase change fluid in the hot walls. The hot wall type heat exchanger provided by the invention has higher compactness than that of existing heat pipes and can be suitable for more heat exchange fields. The hot wall type heat exchanger enables the circulation speed of the phase change fluid to be increased without resistance existing between gas phase fluid and liquid phase fluid or liquid phase resistance caused by tension of capillary pipes, and the heat exchange efficiency is improved.

Owner:HUNAN CHUANGHUA LOW CARBON ENVIRONMENTAL PROTECTION TECH

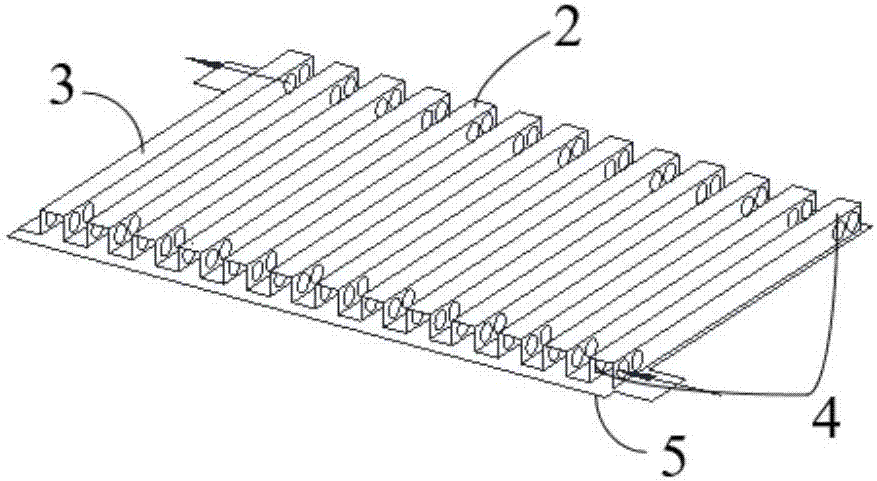

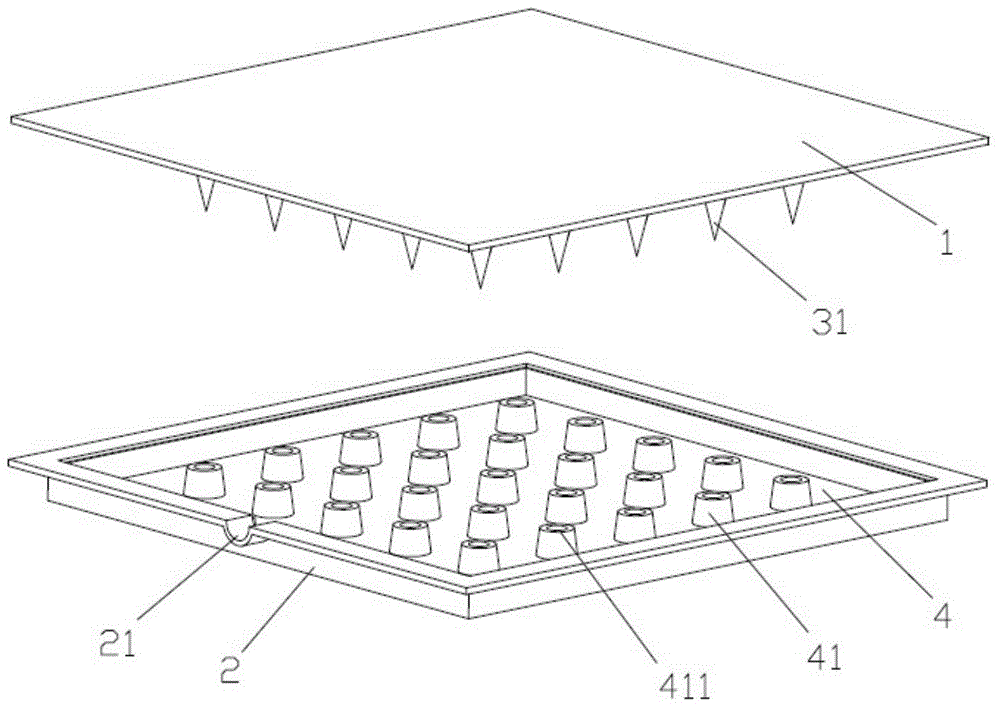

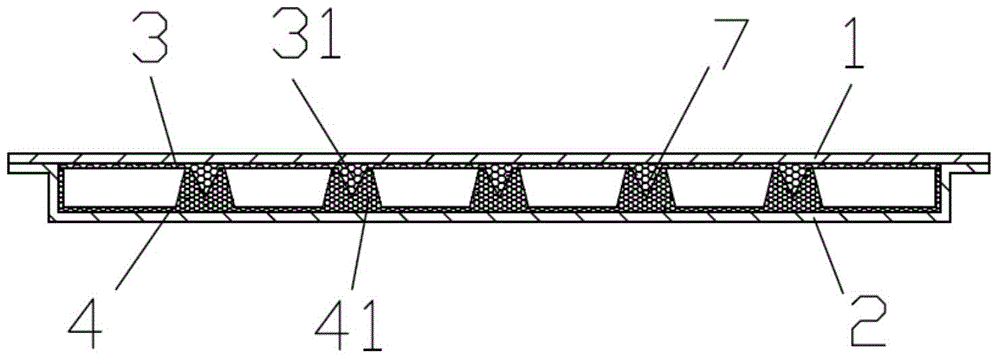

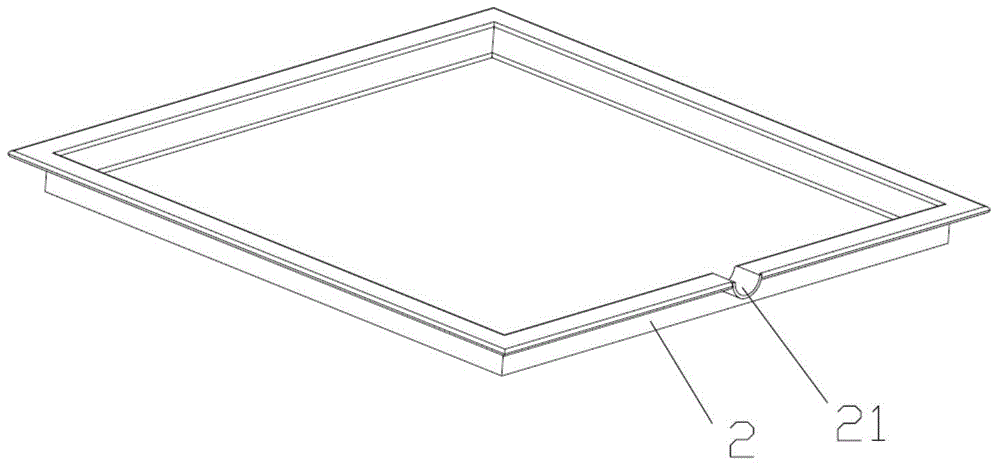

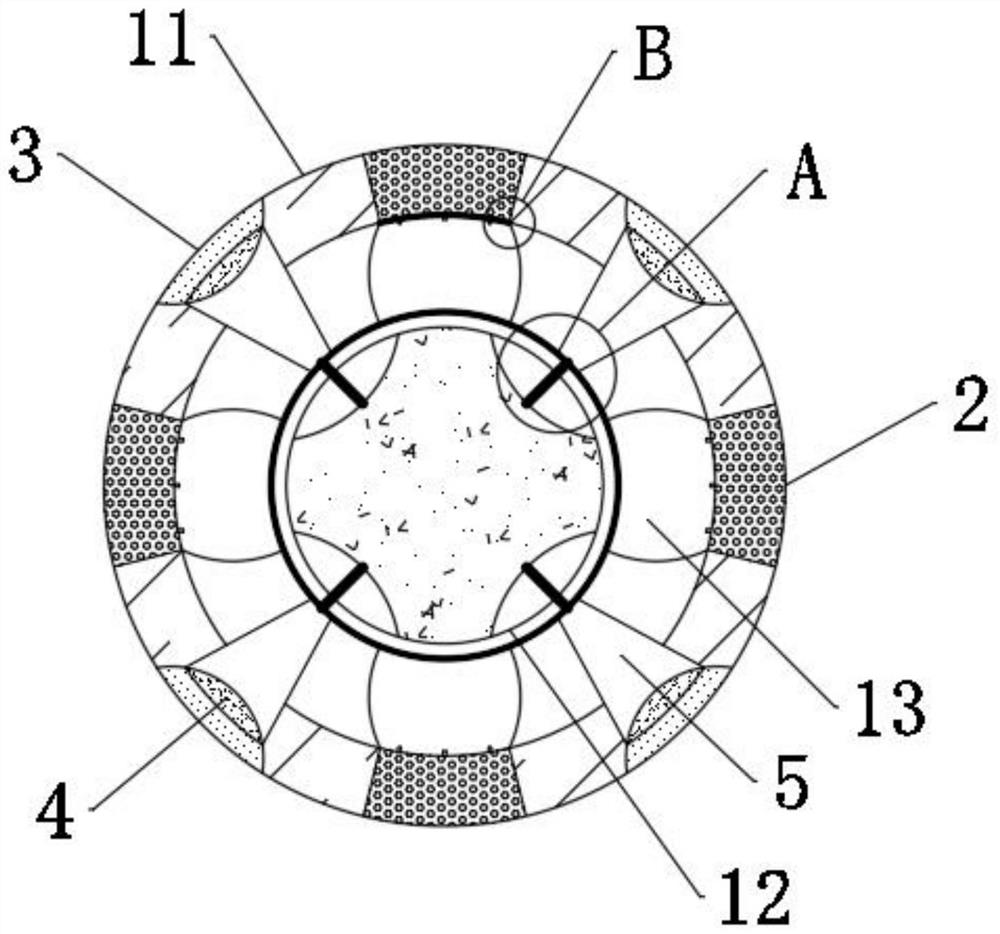

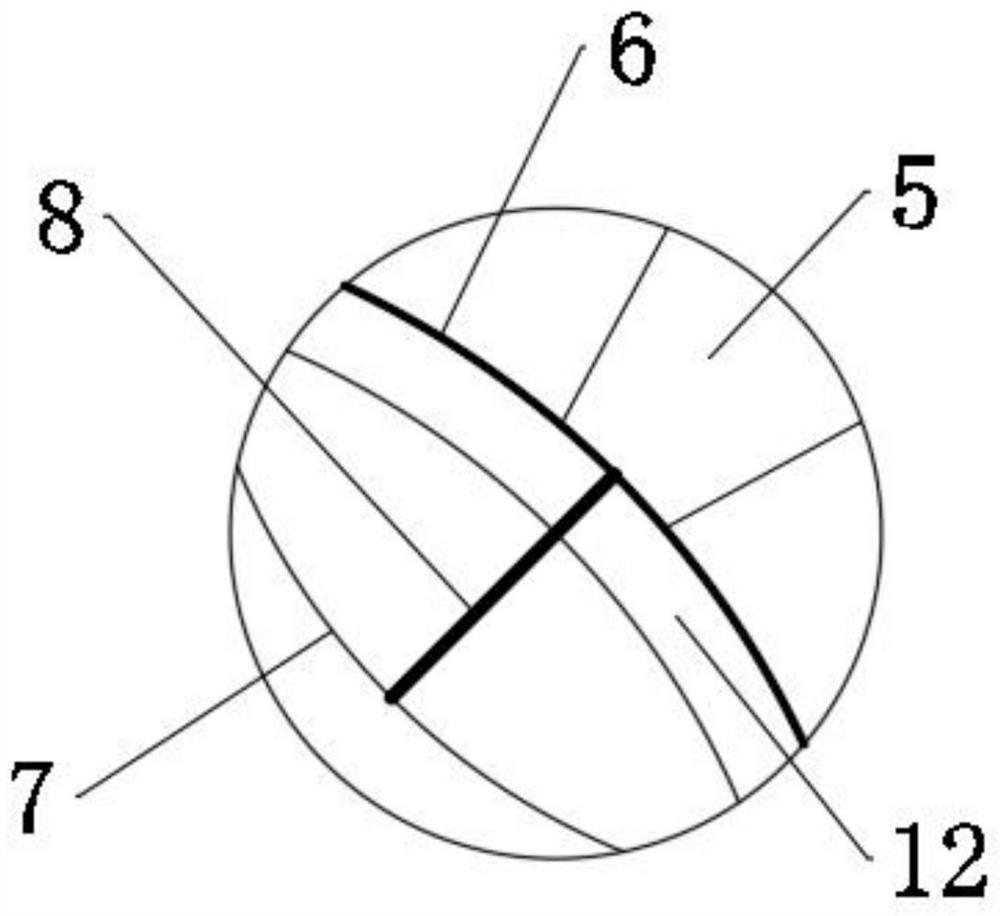

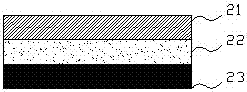

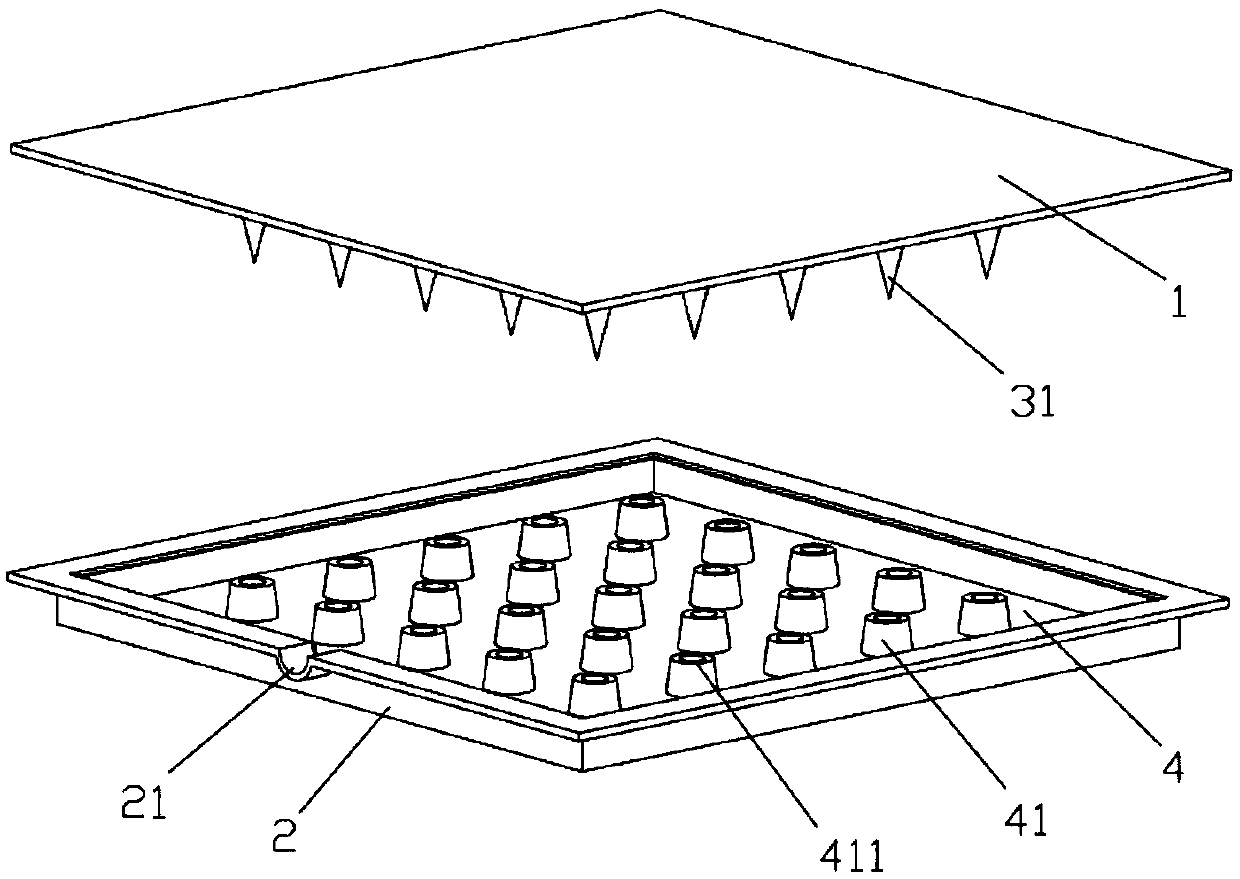

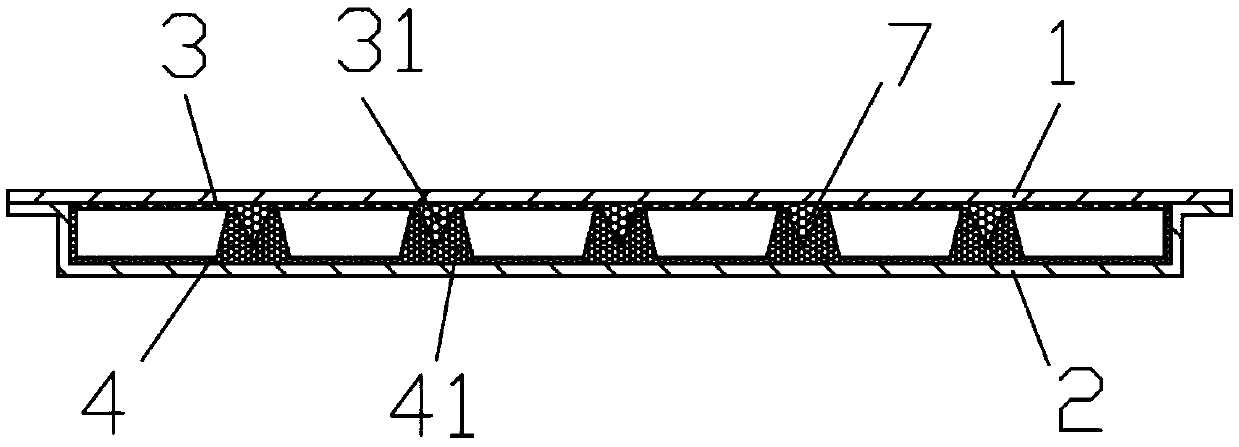

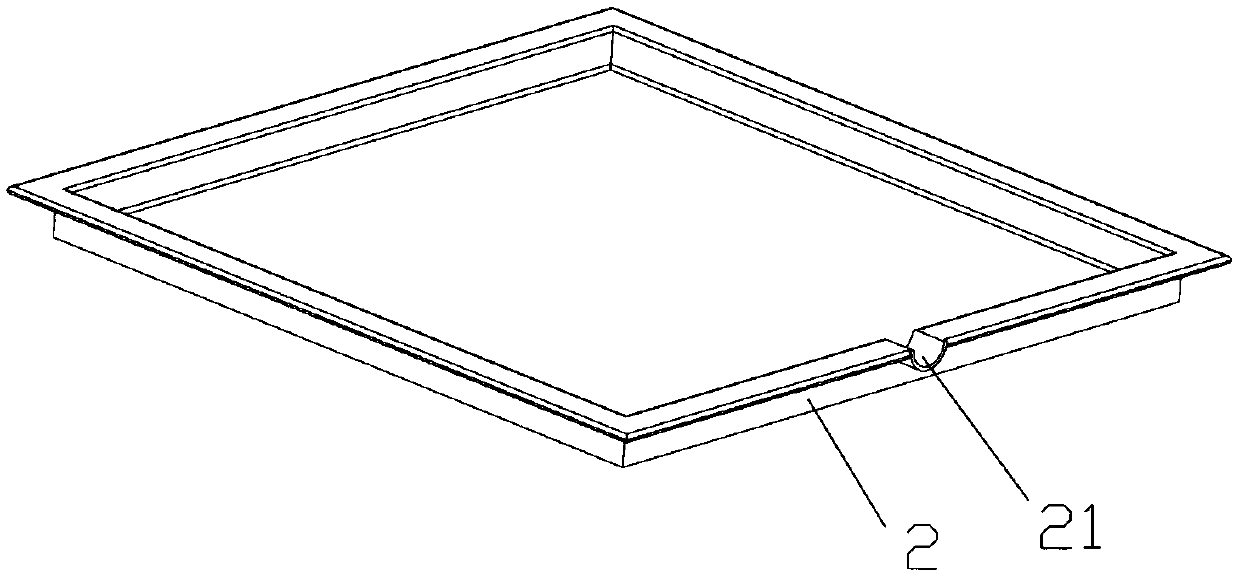

Panel heat pipe with embedded porous wick and manufacturing method thereof

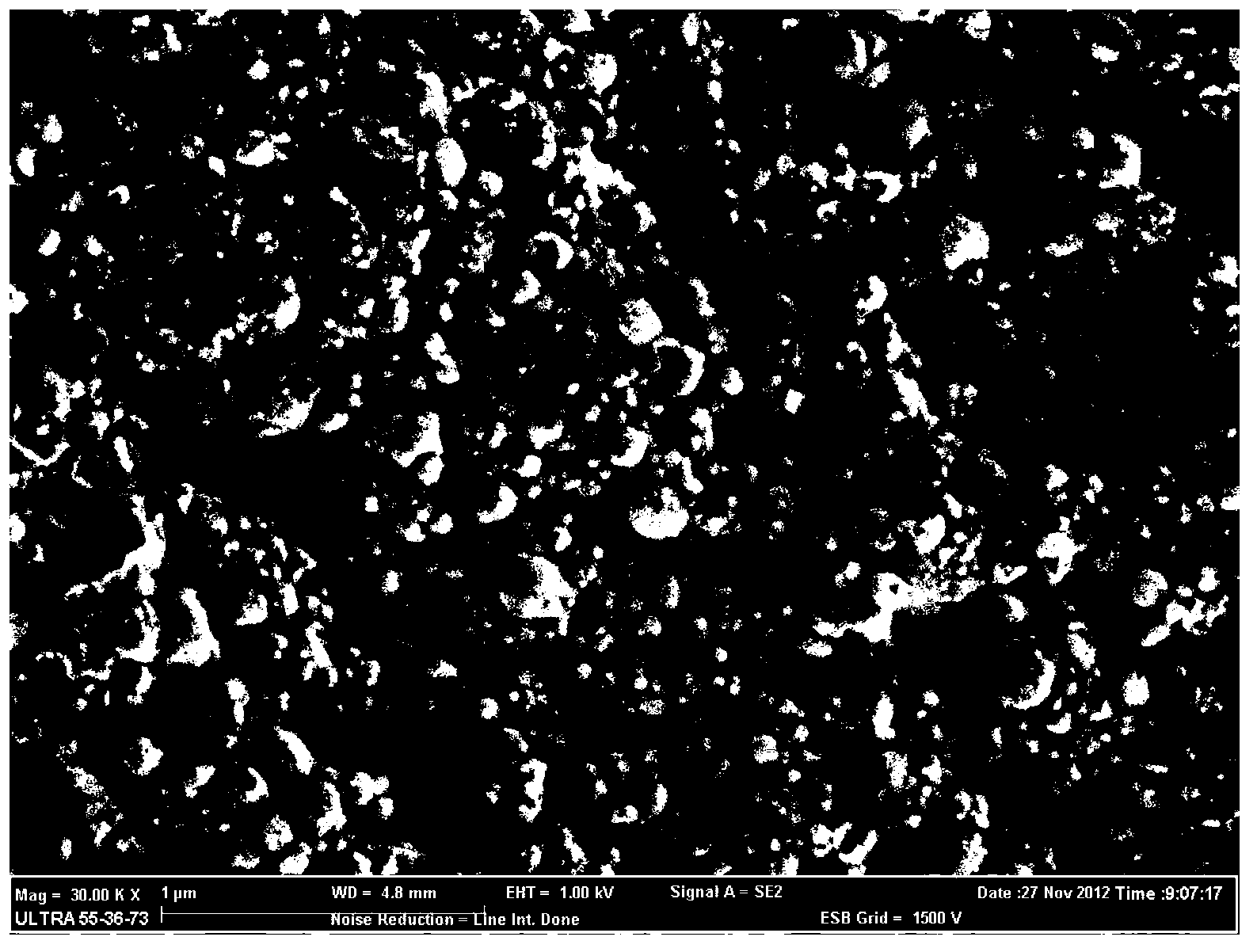

InactiveCN104534906ARaise the capillary limitShorten return pathIndirect heat exchangersVapor liquidCapillary pressure

The invention provides a panel heat pipe with an embedded porous wick and a manufacturing method thereof. The panel heat pipe comprises an upper metal cover plate, a lower metal cover plate, and a closed cavity is formed between the upper metal cover plate and the lower metal cover plate in a welded and sealed mode. The cavity is filled with liquid working media. The inner surface of the cavity is divided into an evaporation face and a condensation face. The condensation face and the evaporation face are paved with a thin-layer porous wick structure formed by sintering metal powder particles. Sintering porous columns with inner grooves which are distributed in an array mode are machined on the evaporation face. Porous protrusions matched with the inner grooves are machined in the condensation face. The sintering porous columns and the porous protrusions are in close fit to form an embedded porous structure column. A working medium backflow channel is formed in the embedded porous structure column. According to the panel heat pipe, the capillary pressure is improved, the working medium backflow speed is remarkably increased, vapor-liquid two-phase separation is achieved, and the heat transfer performance is greatly improved; meanwhile, the embedded wick plays a supporting column role, and panel heat pipe inward sinking or crack deformation or other problems are effectively avoided.

Owner:XIAMEN UNIV

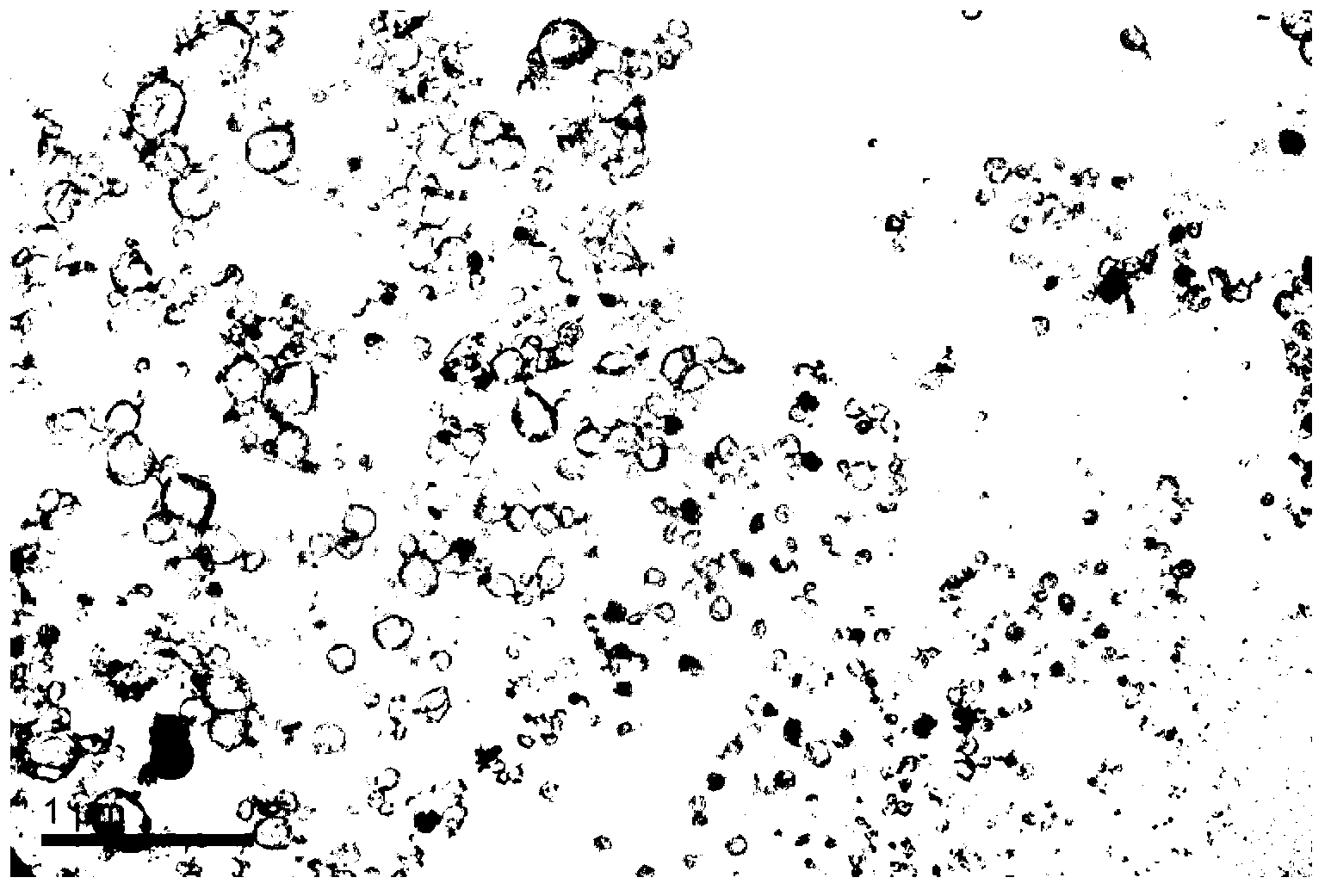

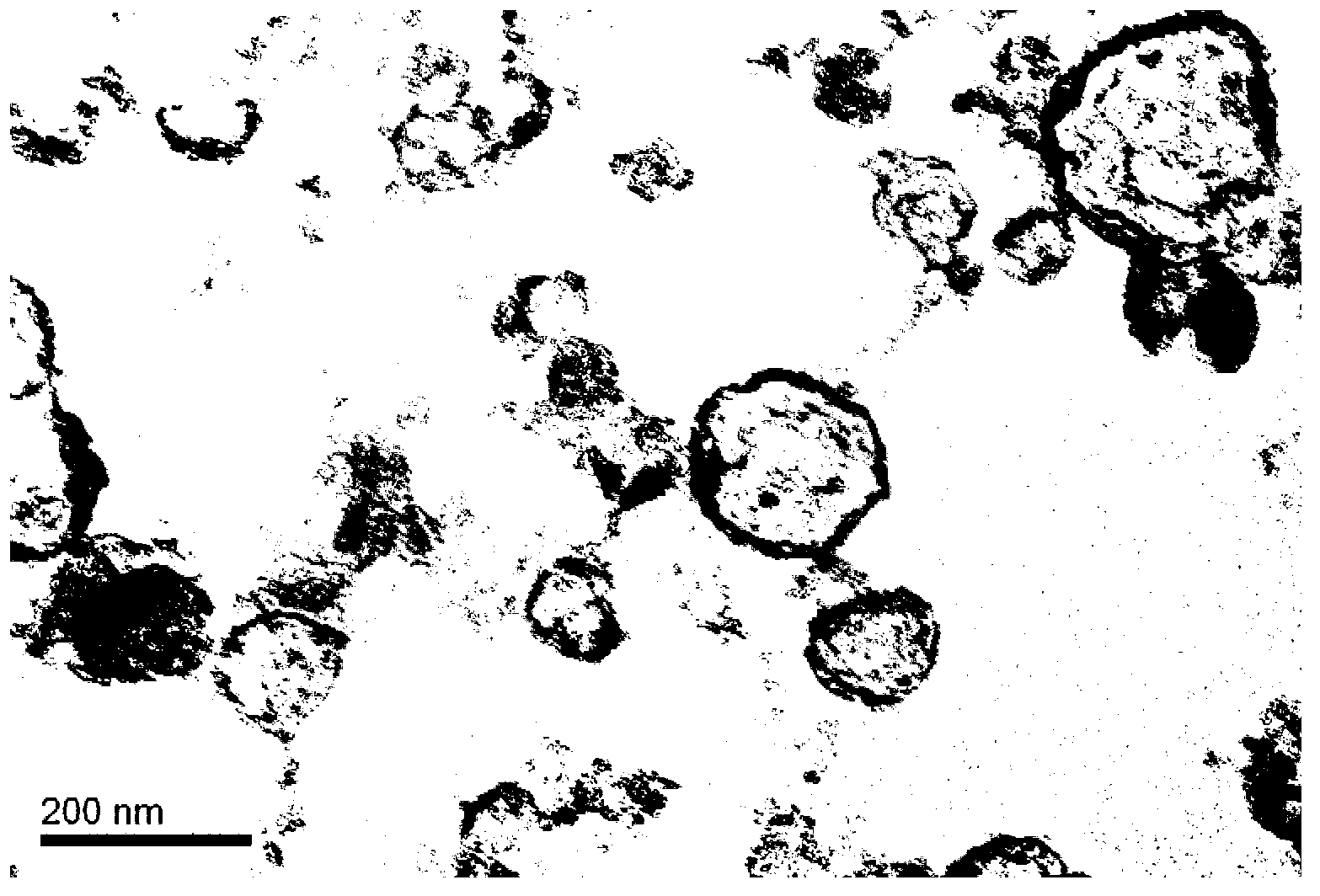

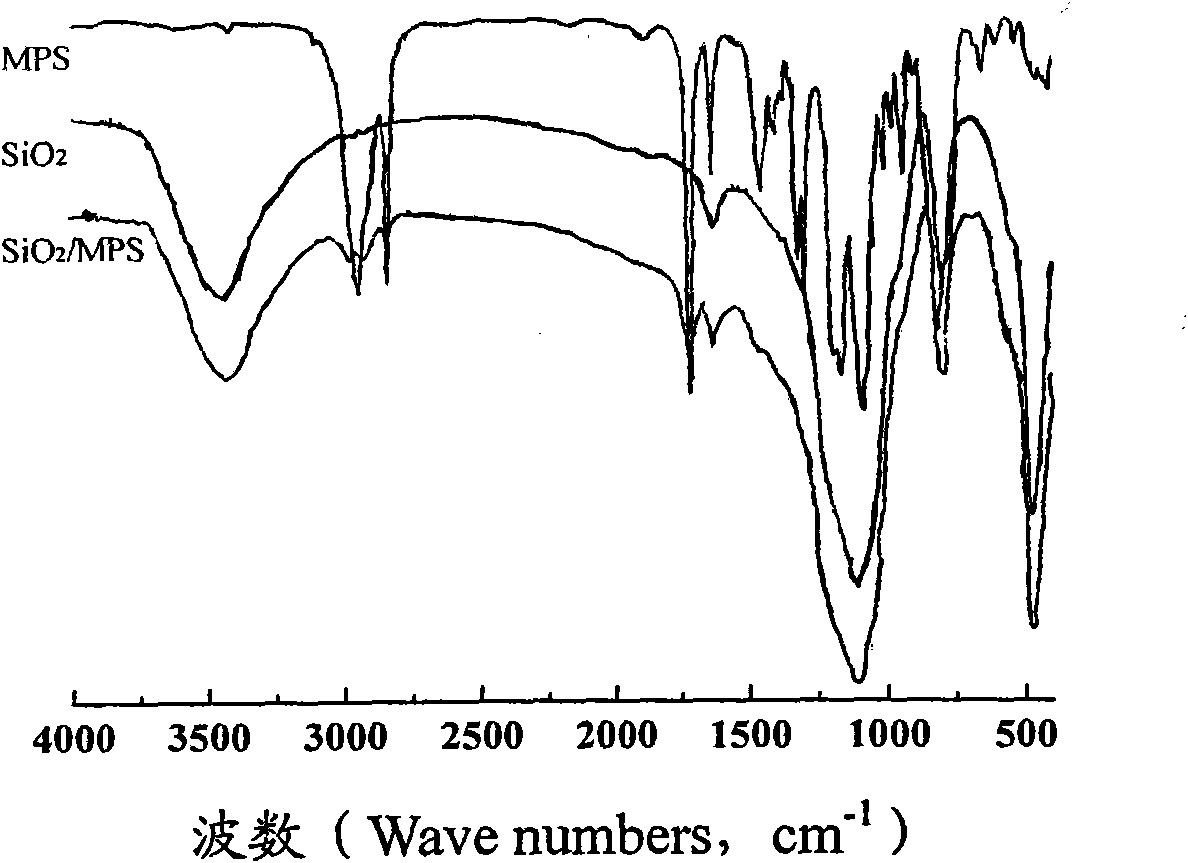

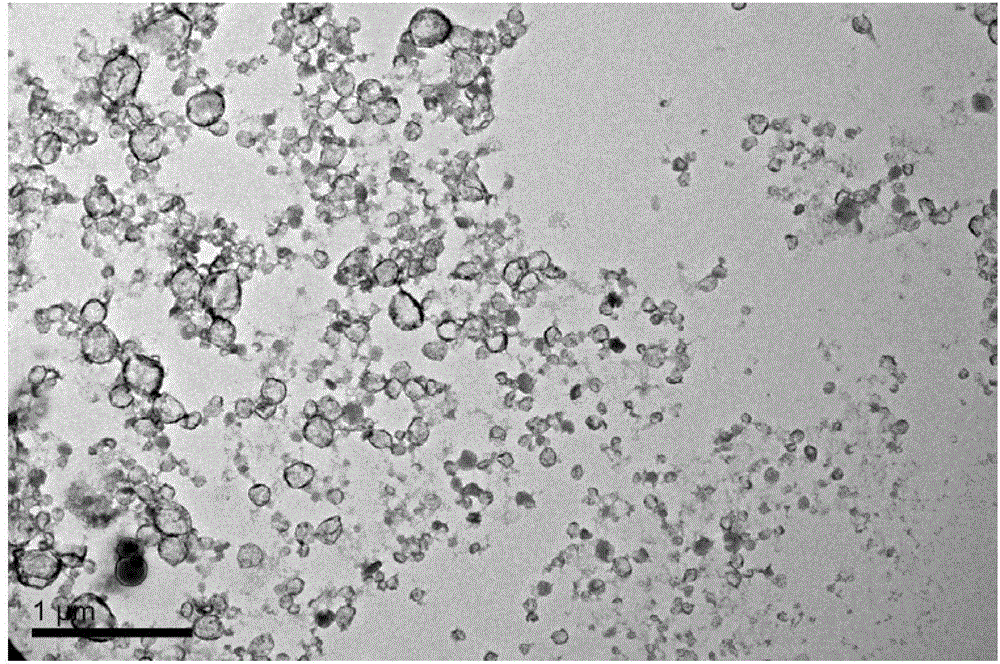

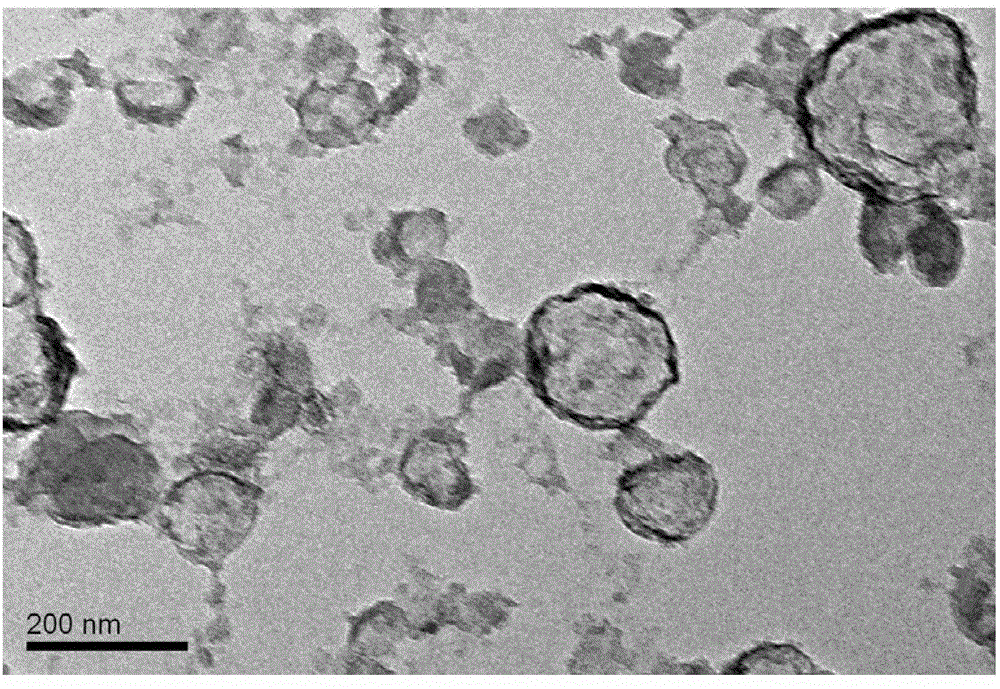

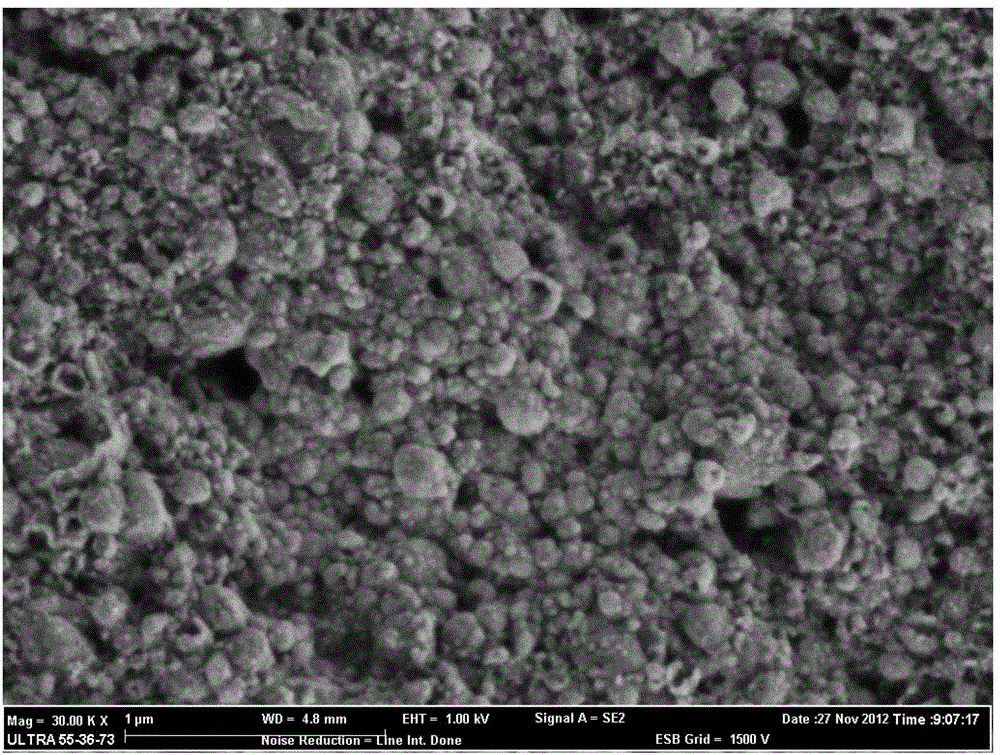

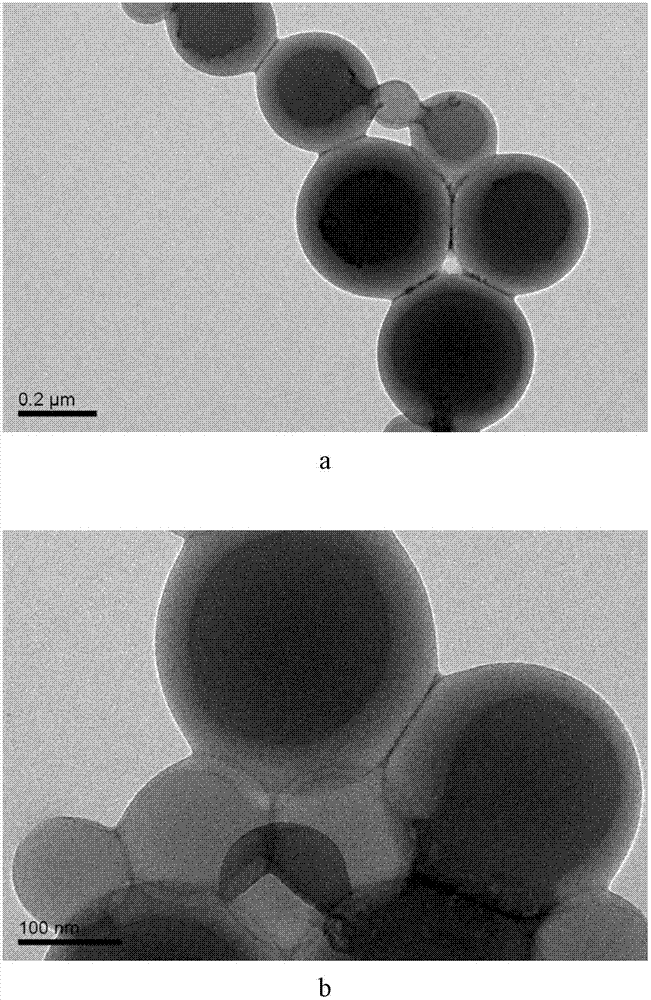

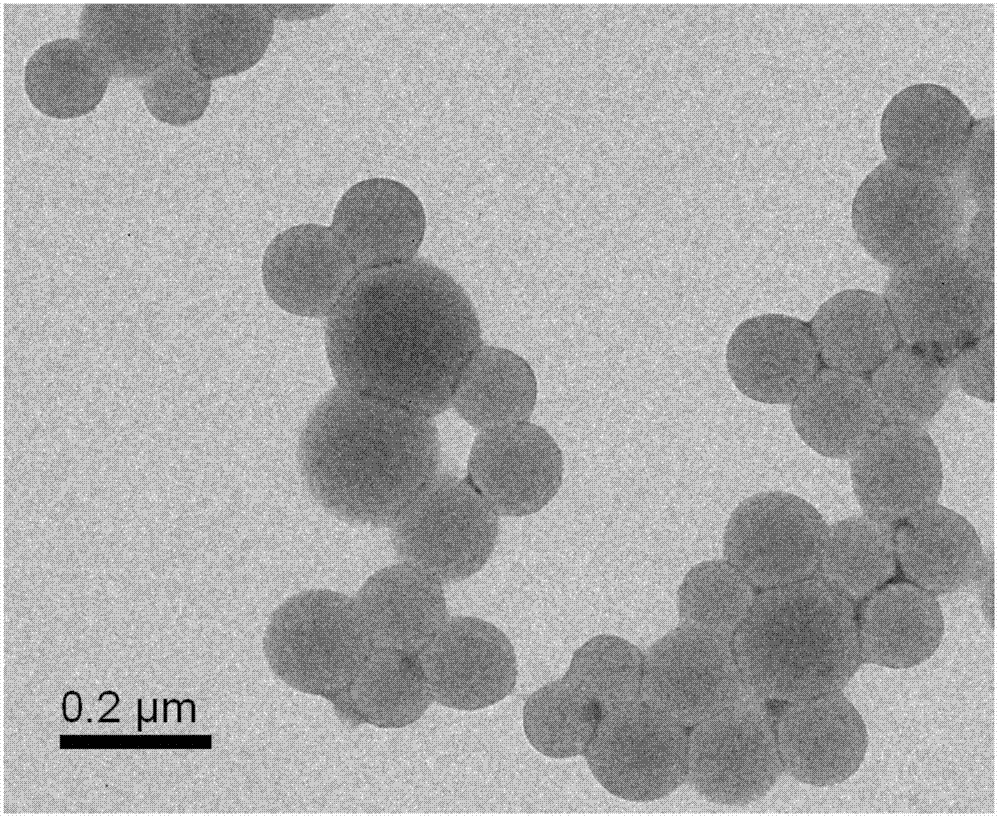

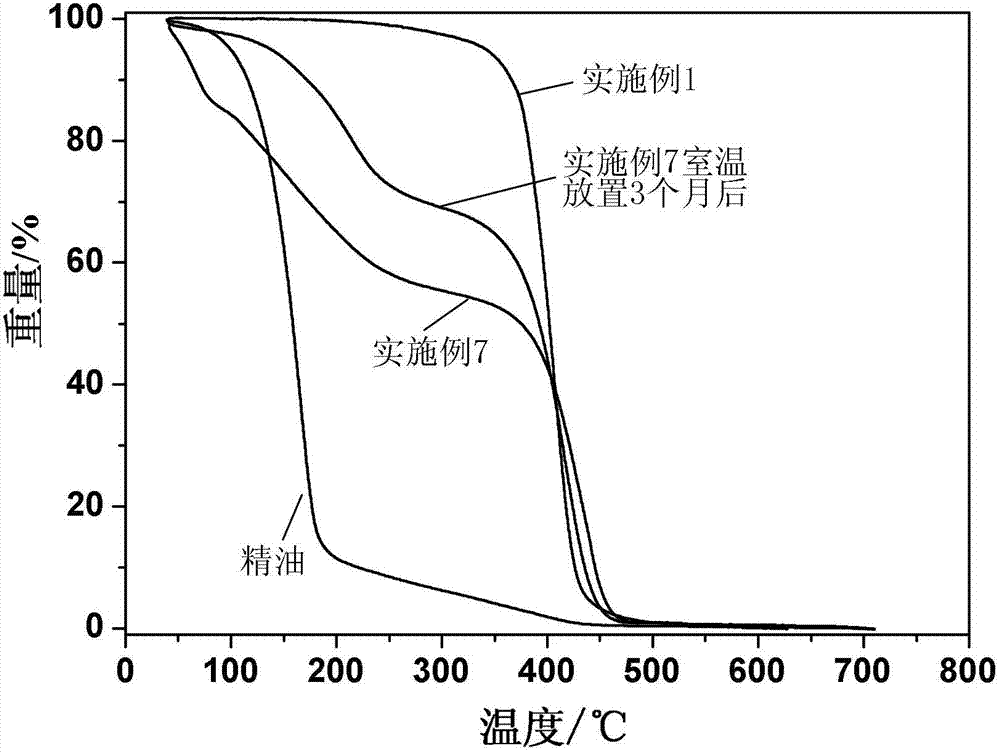

Preparation method of essential oil-contained silicon dioxide microcapsule

ActiveCN103263877ASmall particle sizeImprove structural strengthMicroballoon preparationMicrocapsule preparationOil phaseColloid

The invention discloses a preparation method of an essential oil-contained silicon dioxide microcapsule, which comprises the following steps: evenly mixing essential oil, a silicon dioxide precursor and co-emulsifier to obtain an oil phase mixed solution; adding acid into a silicon dioxide water dispersion solution until the pH value is regulated to 4.5-5.7, mixing with the oil phase mixed solution, and performing ultrasonic dispersion to obtain a fine emulsion; and performing closed reaction on the fine emulsion at 10-60 DEG C for 1-6 hours to obtain a colloid emulsion of the essential oil-contained silicon dioxide microcapsule. According to the invention, the liquid essential oil is contained in a hard shell of silicon dioxide; the preparation process is quick, convenient, clean and pollution-free; the essential oil-contained silicon dioxide microcapsule is small in particle size, high in structural strength and favorable in water-phase dispersibility; and the release performance adjustable range of the essential oil contained in the microcapsule is large. The preparation method disclosed by the invention is suitable for industrial large-scale production.

Owner:义乌市中力工贸有限公司

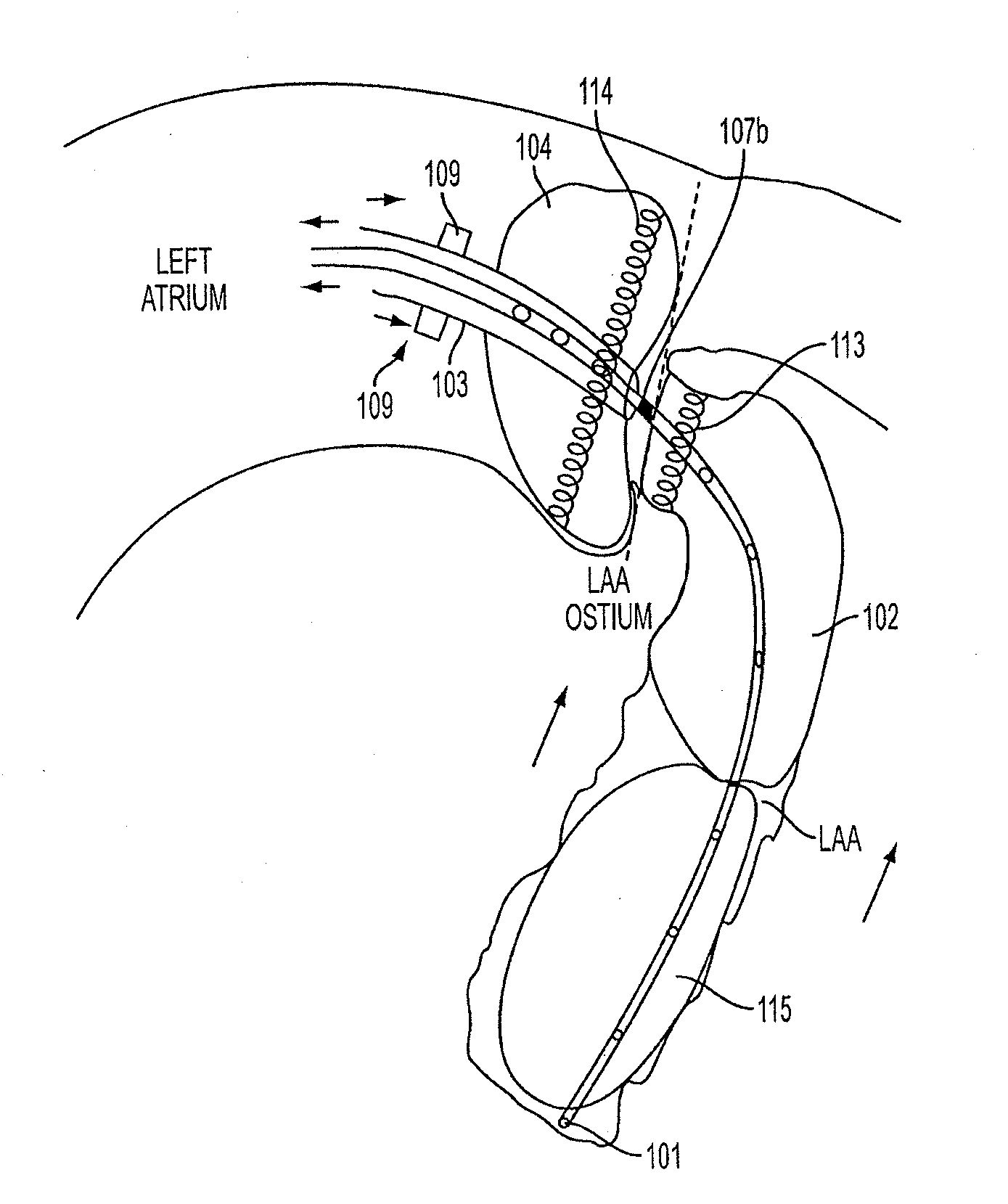

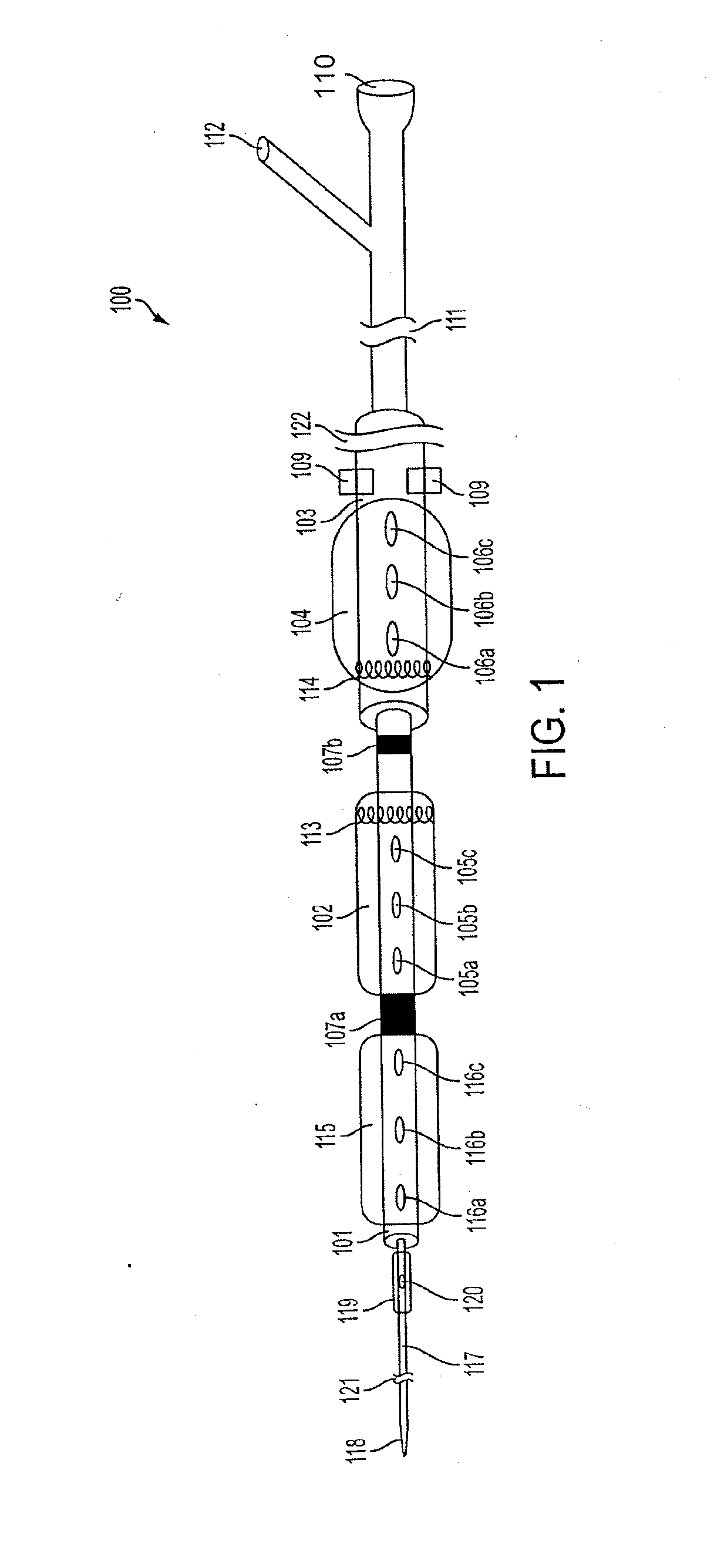

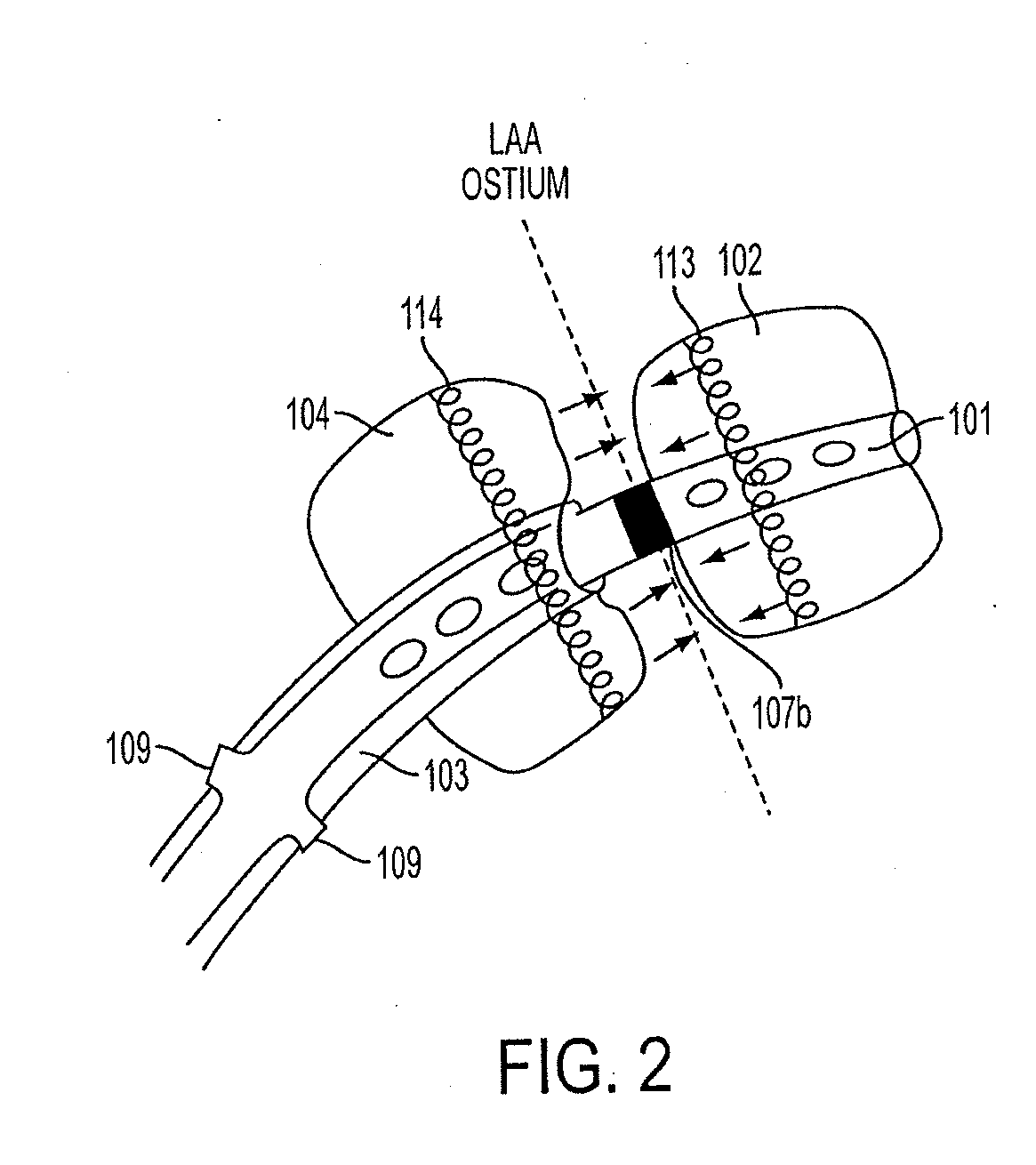

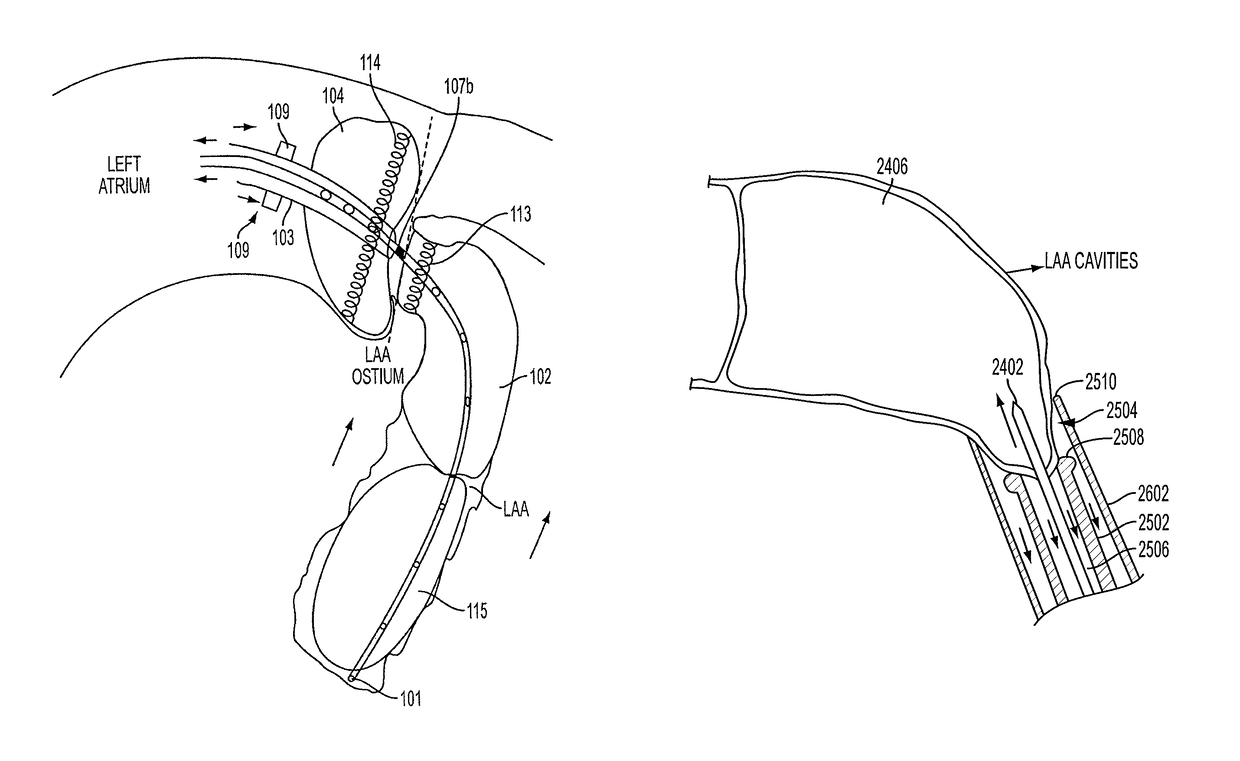

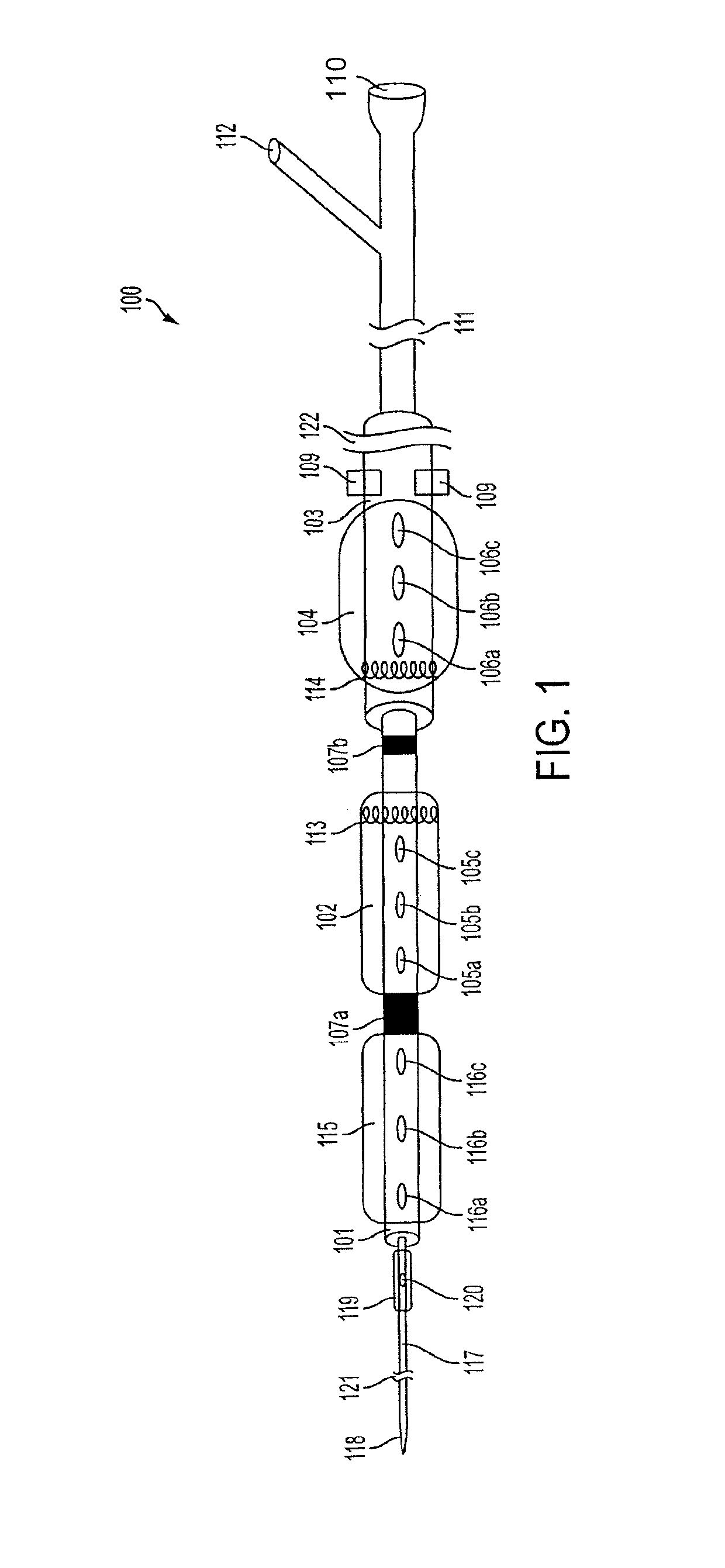

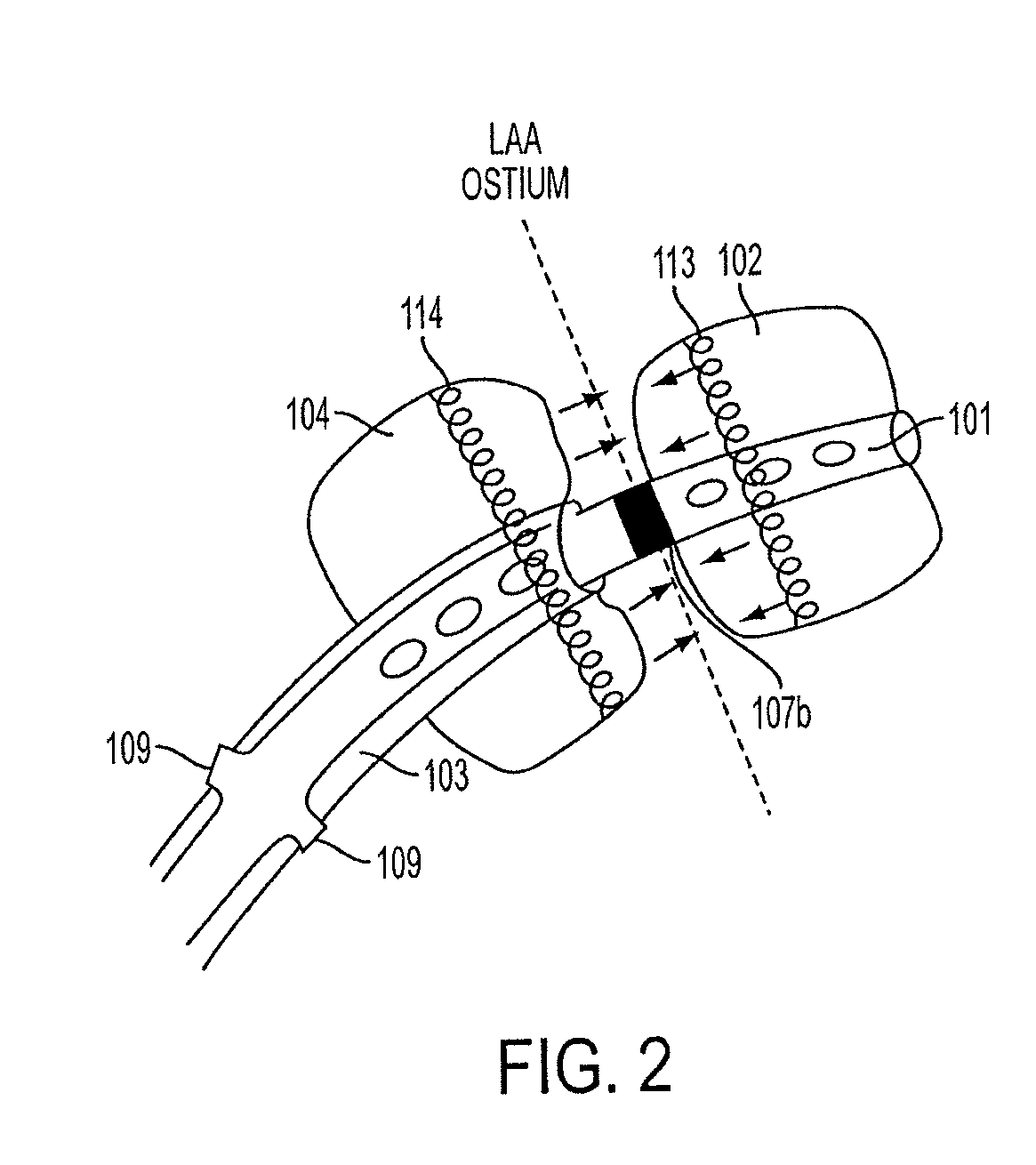

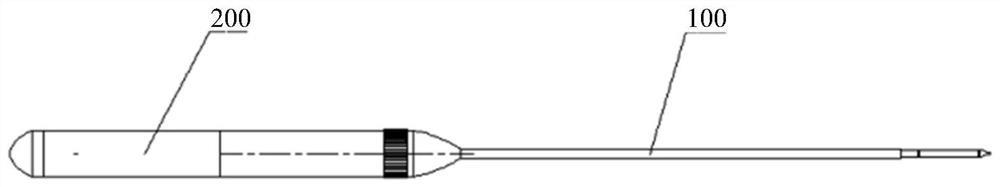

Methods and systems for preventing bleeding from the left atrial appendage

ActiveUS20160166242A1Improve sealingPrevent invaginationSuture equipmentsUltrasound therapyPresent methodSuction force

The disclosure presents methods and systems for applying a suction force to a surface of a left atrial appendage (LAA) with a plurality of tubes. A method may include puncturing the surface of the LAA using a tissue-penetrating tip while the suction force is applied to the surface. The disclosure also presents methods and systems for inflating a first inflatable balloon within a cavity of a left atrial appendage (LAA). A method may include applying a suction force with at least one tube coupled to the first inflatable balloon to attract the first inflatable balloon to an interior surface of the LAA or to a second inflatable balloon.

Owner:KRISHNAN SUBRAMANIAM CHITOOR

Methods and systems for preventing bleeding from the left atrial appendage

ActiveUS10052168B2Improve sealingPrevent invaginationSuture equipmentsUltrasound therapyPresent methodSuction force

The disclosure presents methods and systems for applying a suction force to a surface of a left atrial appendage (LAA) with a plurality of tubes. A method may include puncturing the surface of the LAA using a tissue-penetrating tip while the suction force is applied to the surface. The disclosure also presents methods and systems for inflating a first inflatable balloon within a cavity of a left atrial appendage (LAA). A method may include applying a suction force with at least one tube coupled to the first inflatable balloon to attract the first inflatable balloon to an interior surface of the LAA or to a second inflatable balloon.

Owner:KRISHNAN SUBRAMANIAM CHITOOR

Preparation method of microcapsule

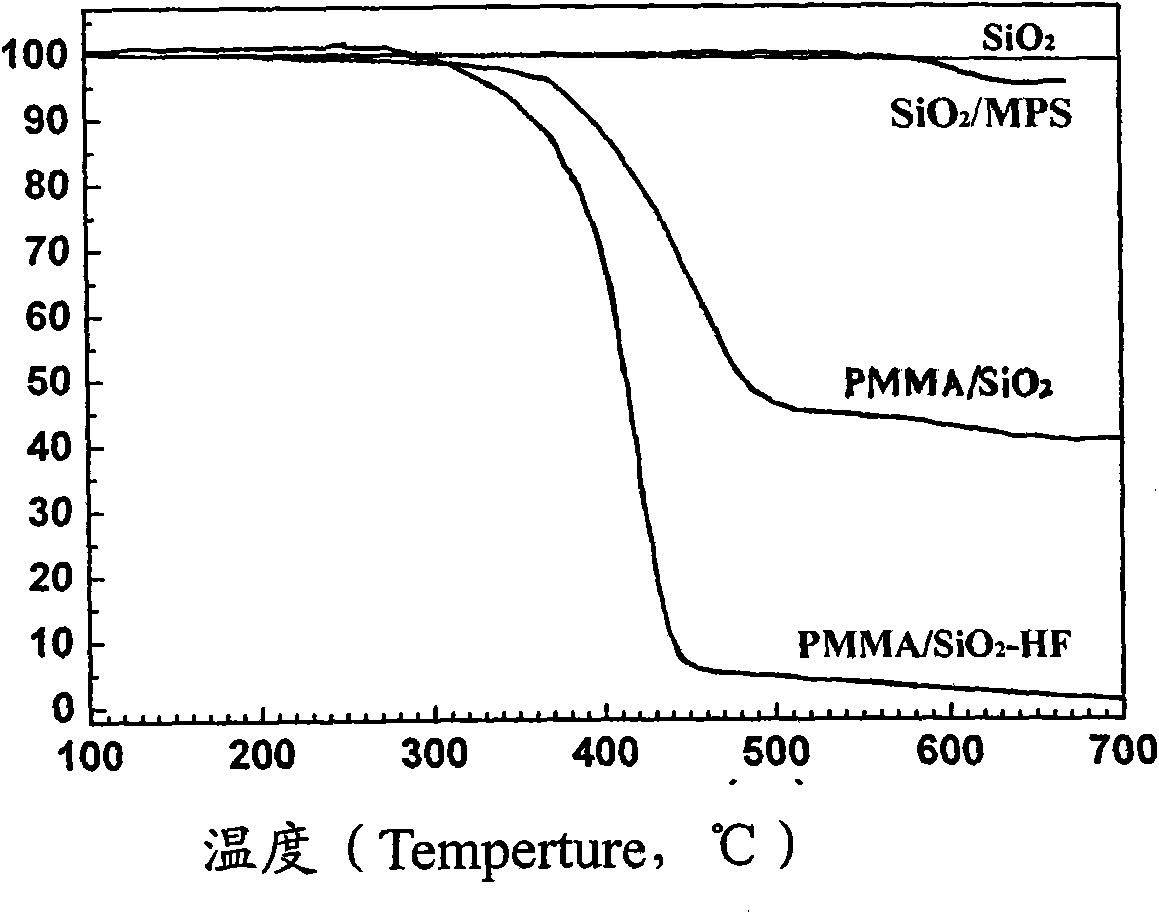

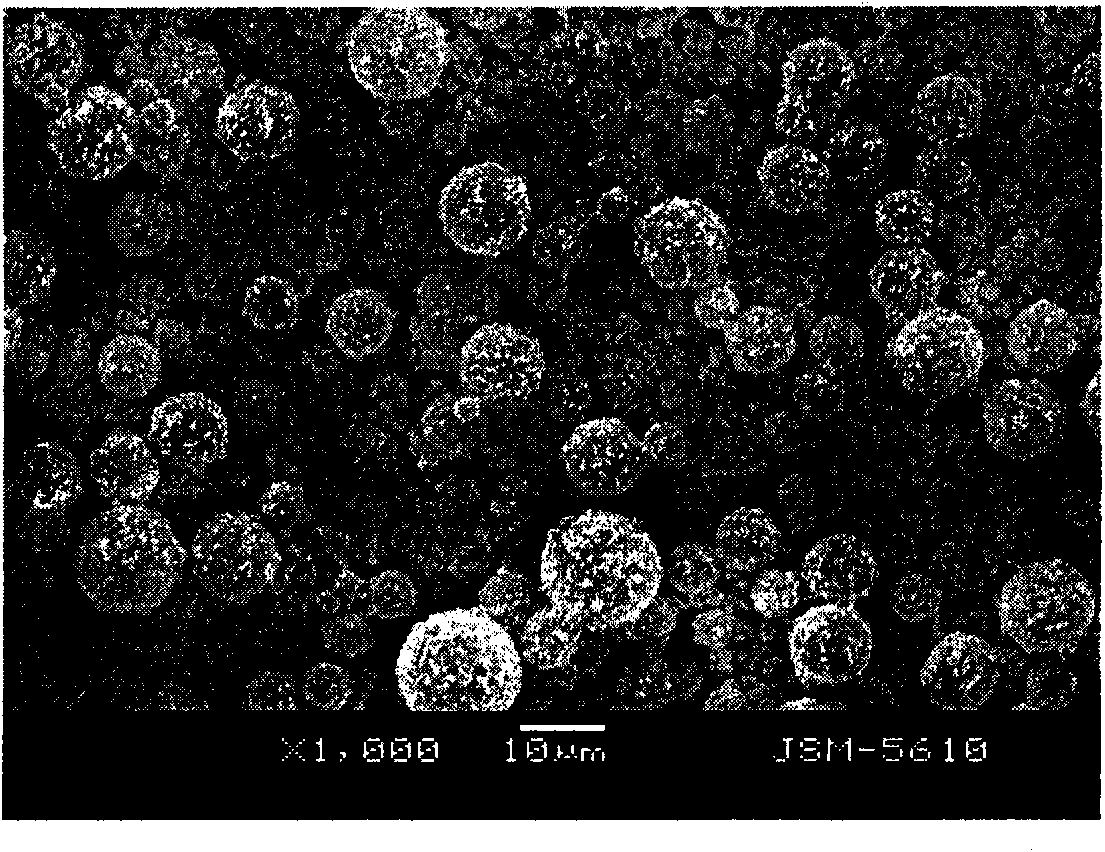

InactiveCN101564668AImprove structural strengthPrevent invaginationMicroballoon preparationMicrocapsule preparationCross linkerDouble bond

The invention discloses a preparation method of a microcapsule, which comprises the steps of: uniformly mixing silicon dioxide particles, monomer provided with ethylene and silane coupling agent with double bonds, stirring and reacting for 1 to 24 hours under a closed state at the temperature between 40 and 70 DEG C, then adding an oil-soluble cross linker and an oil-soluble initiator, stirring uniformly and then adding a dispersant and de-ionized water to prepare a suspension system, polymerizing for 2 to 6 hours in a nitrogen atmosphere at the temperature between 60 and 80 DEG C with rotating speed of 50-300 rpm, then raising the temperature to 95 DEG C and curing for 1 hour, then carrying out cooling and acid cleaning to obtain composite particles, adding hydrofluoric acid, dipping to remove the silicon dioxide inside the composite particles, then preparing the microcapsule with multi-cavities through neutralizing, washing and drying. The preparation method is easy to obtain materials, has simple technique, has good controllability on the morphostructure of the microcapsule, does not relate to organic solvents and is suitable for industrial production. Moreover, the prepared microcapsule has the advantages of high structure strength, multi-empty cavities and good controllability on the slow-release effect.

Owner:ZHEJIANG SCI-TECH UNIV

Shoemaking stamping machine with adjustable height

InactiveCN109691747AImprove applicabilityPrevent invaginationShoemaking devicesDecorative surface effectsHot stampingControl switch

The invention discloses a shoemaking stamping machine with adjustable height. The shoemaking stamping machine comprises an operation board, wherein an electric telescopic rod is mounted at the rear end of the operation board through a support frame, an electric heating box is mounted at a telescopic end of the electric telescopic rod, a hot stamping board is fixed on the lower surface of the electric heating box, a constant-pressure air compressor is fixed on the rear side of the upper surface of the operation board, an air outlet of the constant-pressure air compressor is communicated with anair inlet of a control valve through a guide pipe, an air outlet of the control valve is communicated with an air inlet of an air bag through a guide pipe, the right end of the air bag is fixedly connected with the left side surface of an insert block, a control switch is fixed on the upper surface of the operation board, and support units are fixed at left and right ends of the lower surface ofthe operation board. Before hot stamping by the shoemaking stamping machine with adjustable height, shoes are filled with a support article to be prevented from sinking in the hot stamping process, and stamping precision is guaranteed.

Owner:阜阳金马鞋业有限公司

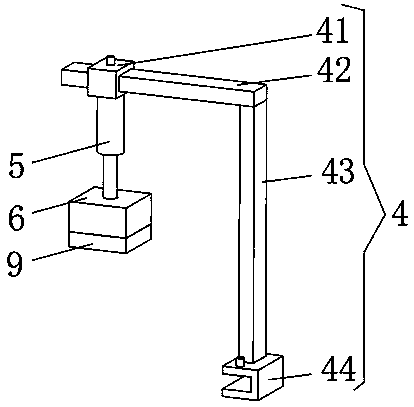

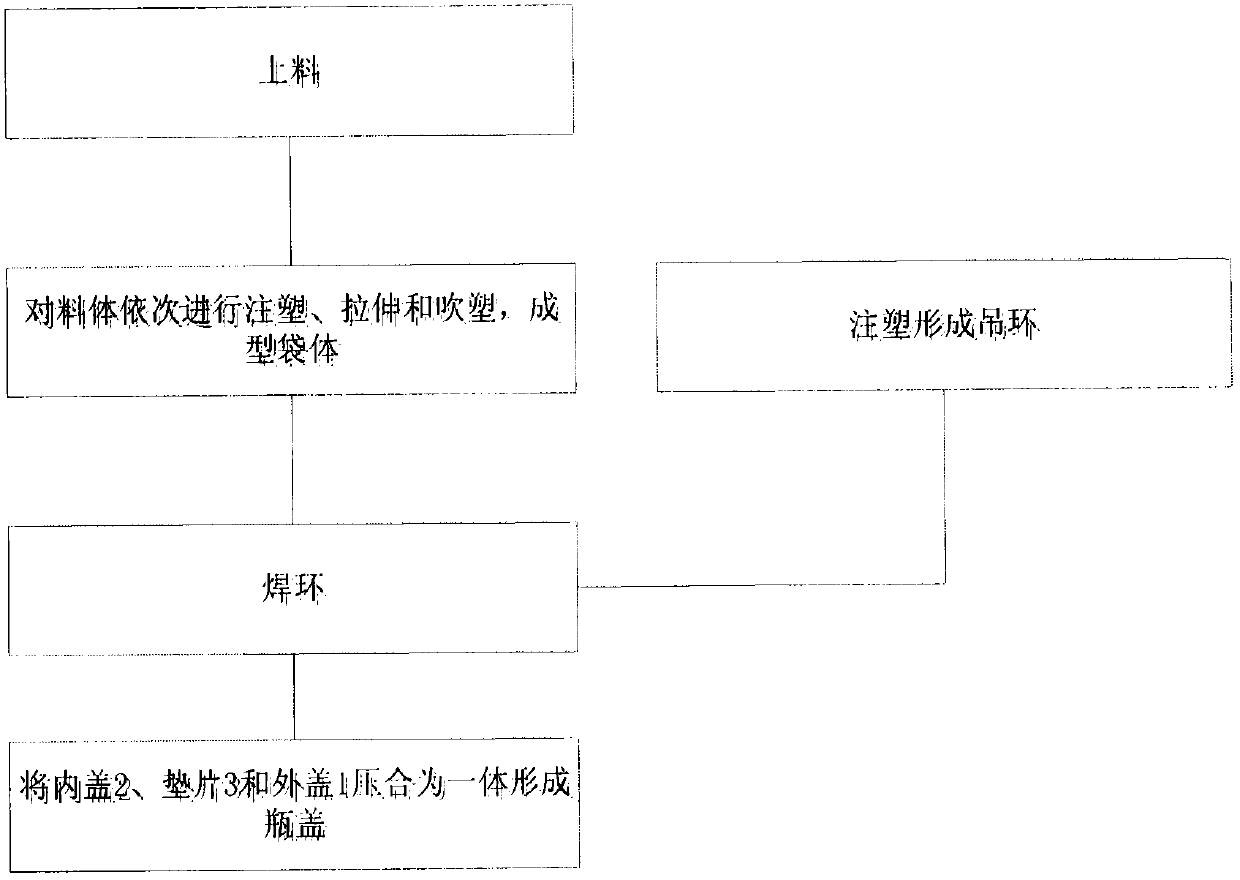

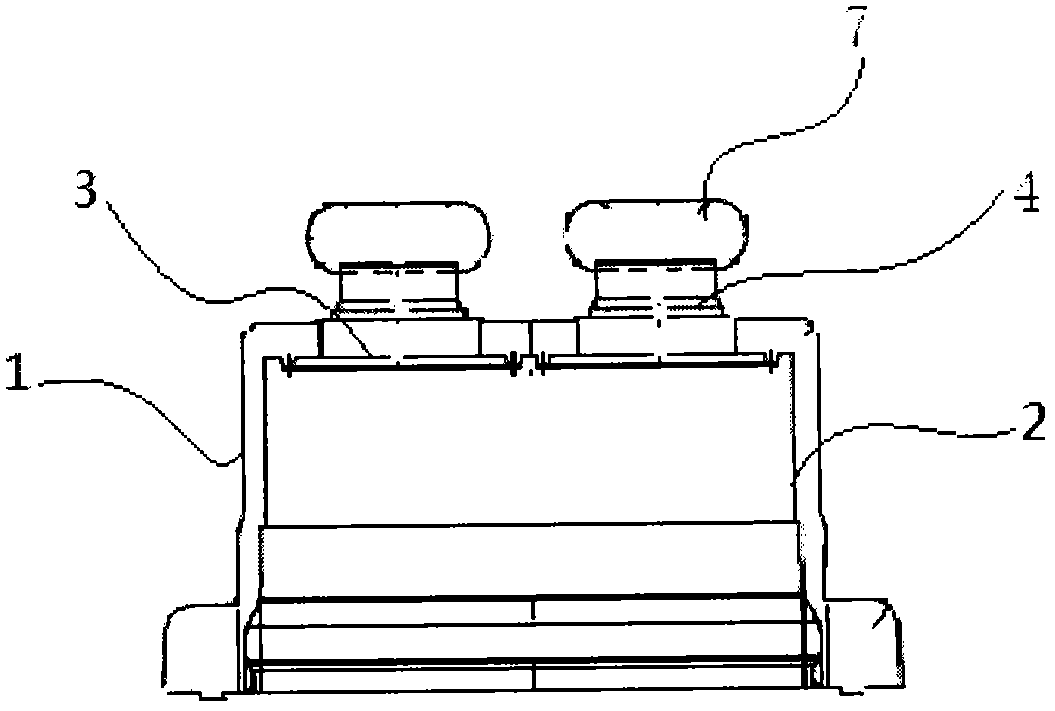

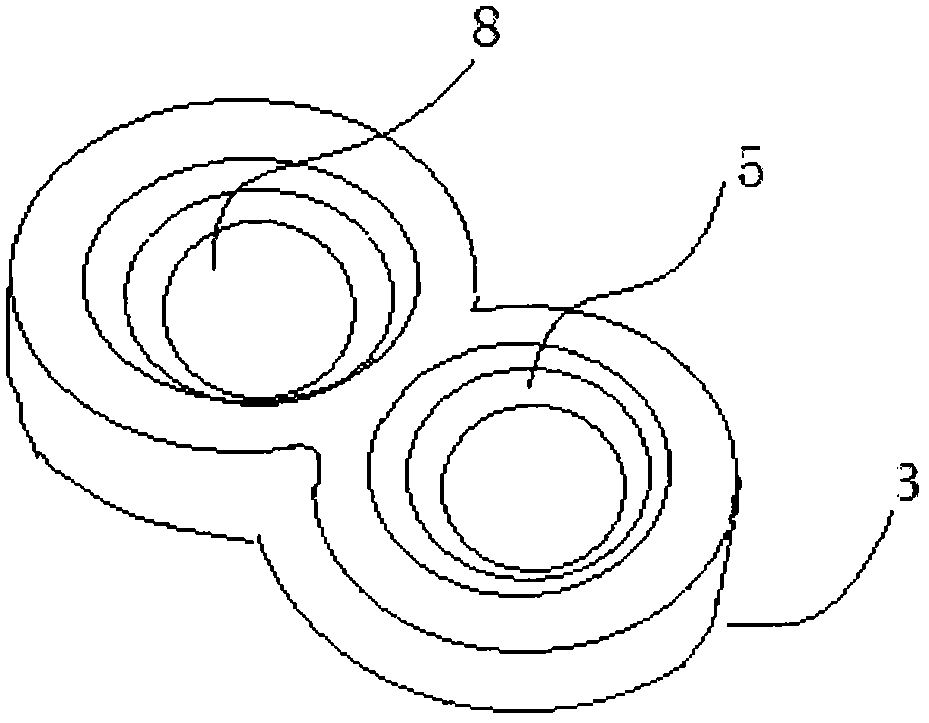

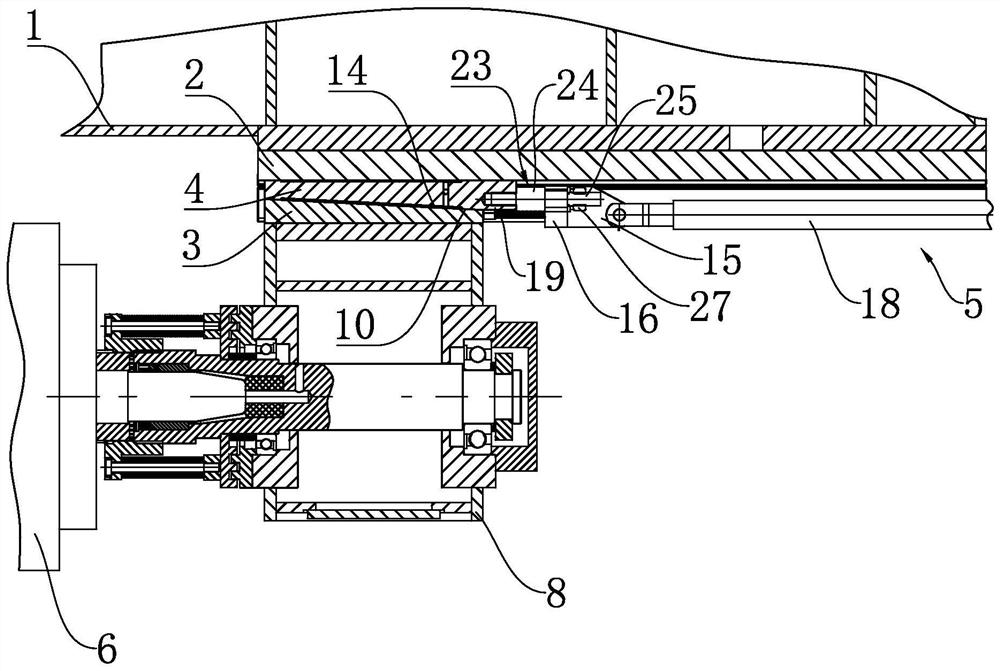

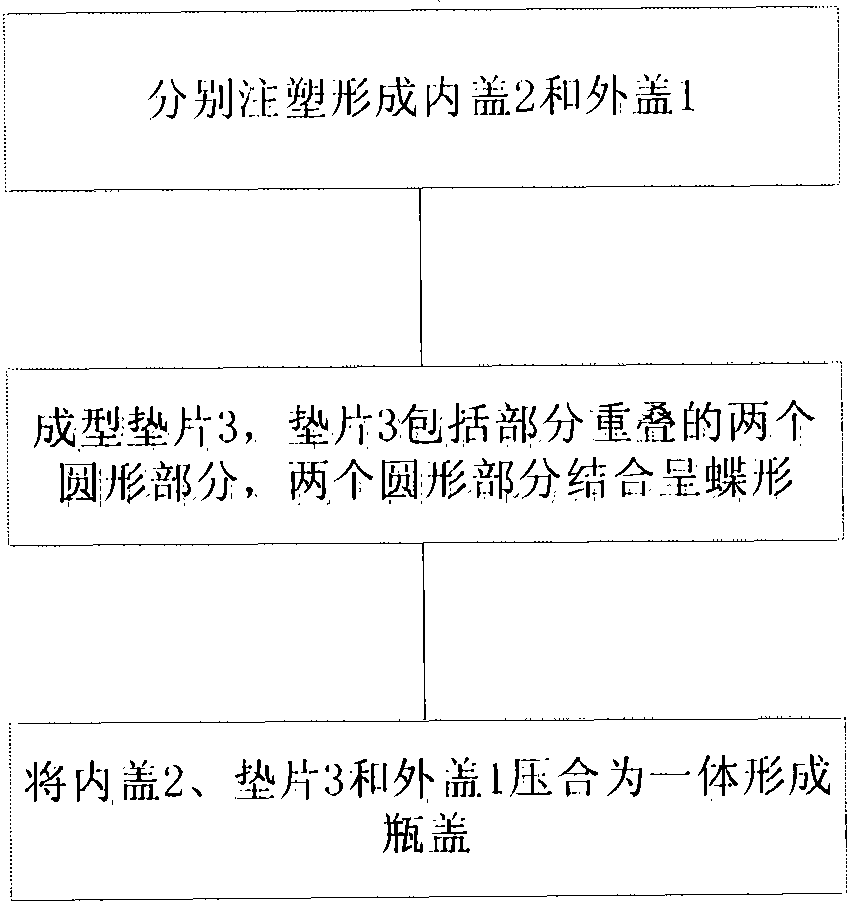

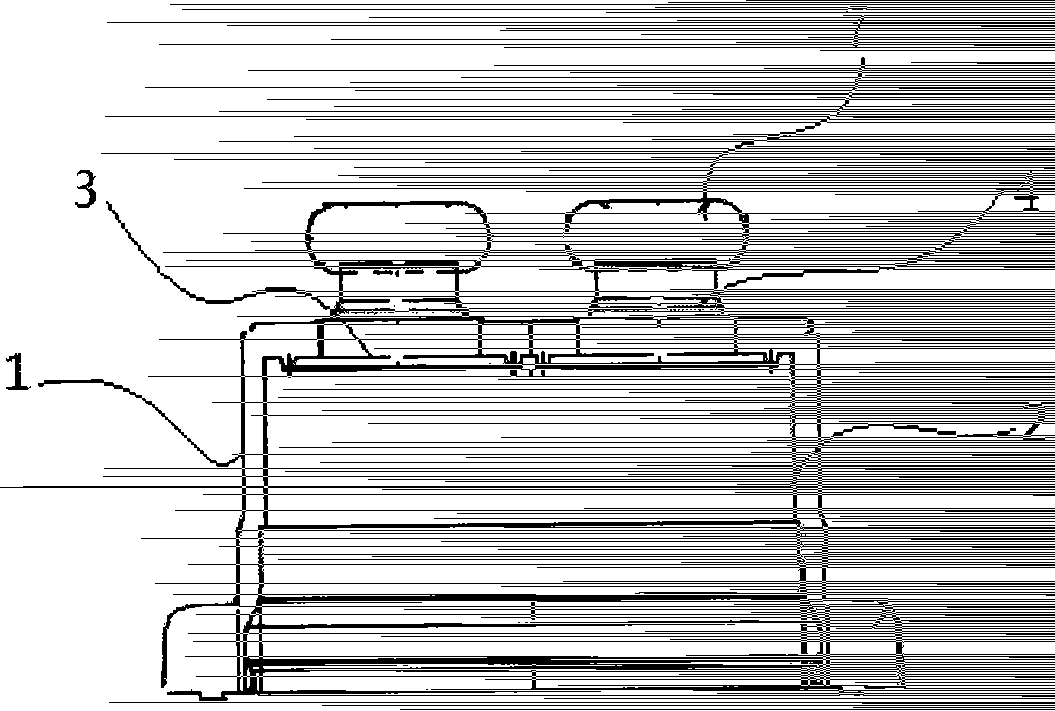

Combined cover, double-valve vertical infusion bag and manufacturing method thereof

ActiveCN104287965ALarge retraction forcePrevent slidingPharmaceutical containersMedical packagingColloidEngineering

The invention provides a combined cover, a double-valve vertical infusion bag and a manufacturing method thereof. The combined cover comprises an outer cover (1), an inner cover (2) and a gasket (3) arranged between the inner cover (2) and the outer cover (1), the gasket (3) is designed integrally and comprises two round portions which are overlapped partly, the round portions are combined to be butterfly-shaped, opening bosses (4) are arranged at the top of the outer cover (1), and clamping grooves in clamped fit with the gasket (3) are formed in the inner sides of the opening bosses (4). According to the combined cover, the gasket can provide bigger retraction force to enable a colloid of the gasket to tightly hold a syringe needle without liquid leakage; the combined cover is reasonable in design, safe and reliable. The double-valve vertical infusion bag is controlled through a medicine adding valve and an infusion passage valve, so that sterilization and pollution can be reduced; automatic contraction can be realized without air incoming during infusion, so that secondary pollution can be avoided, and more convenience is brought to medicine adding.

Owner:SHIJIAZHUANG NO 4 PHARMA +1

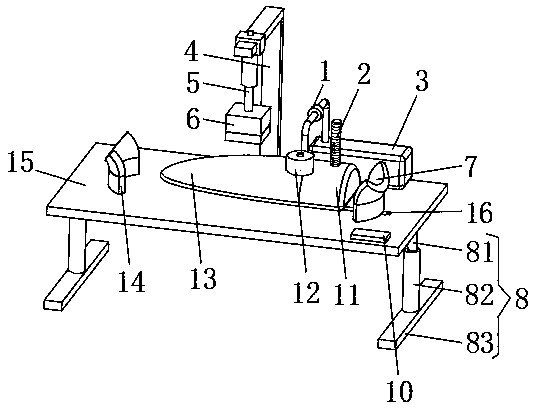

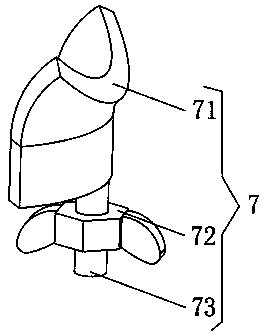

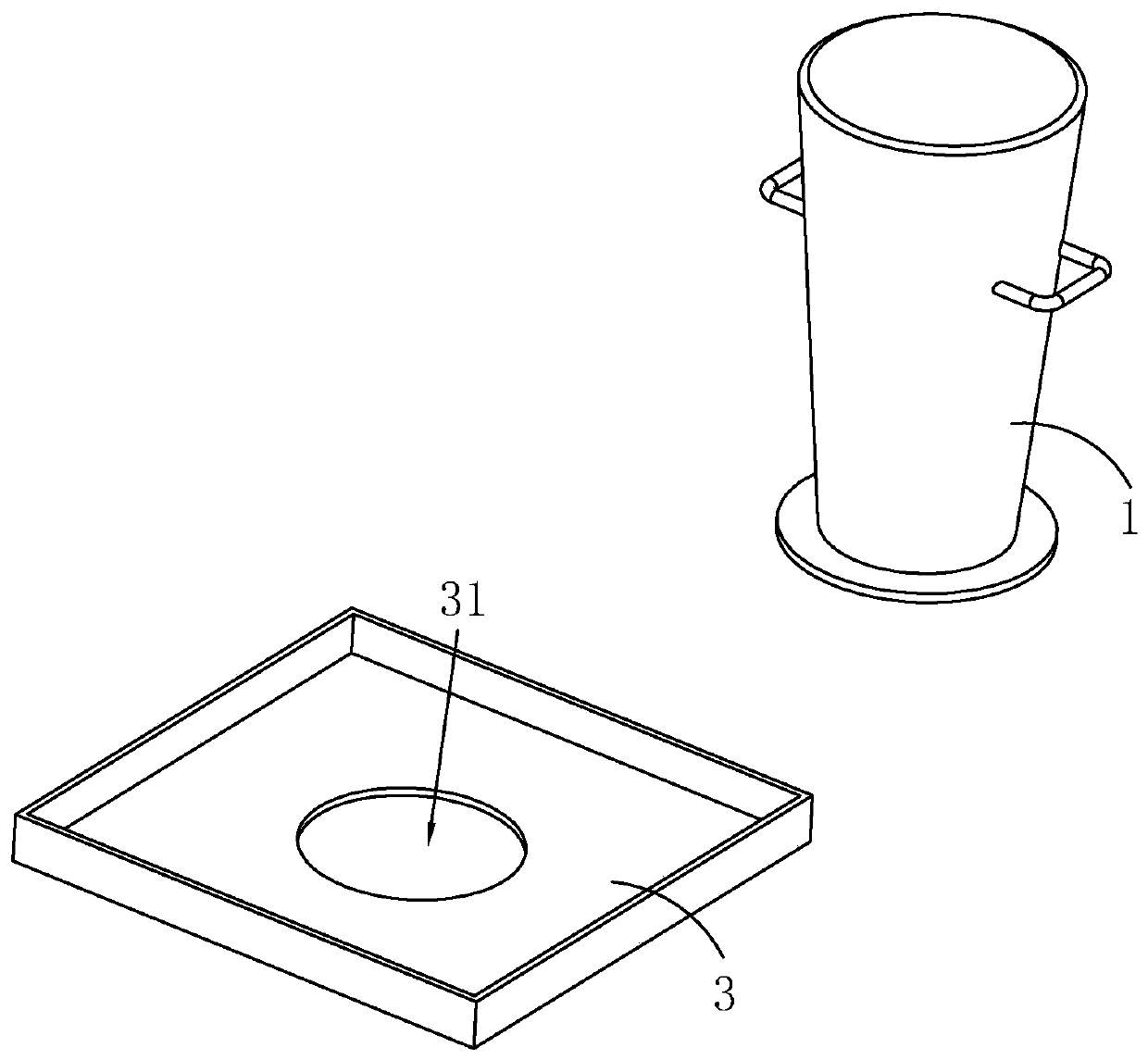

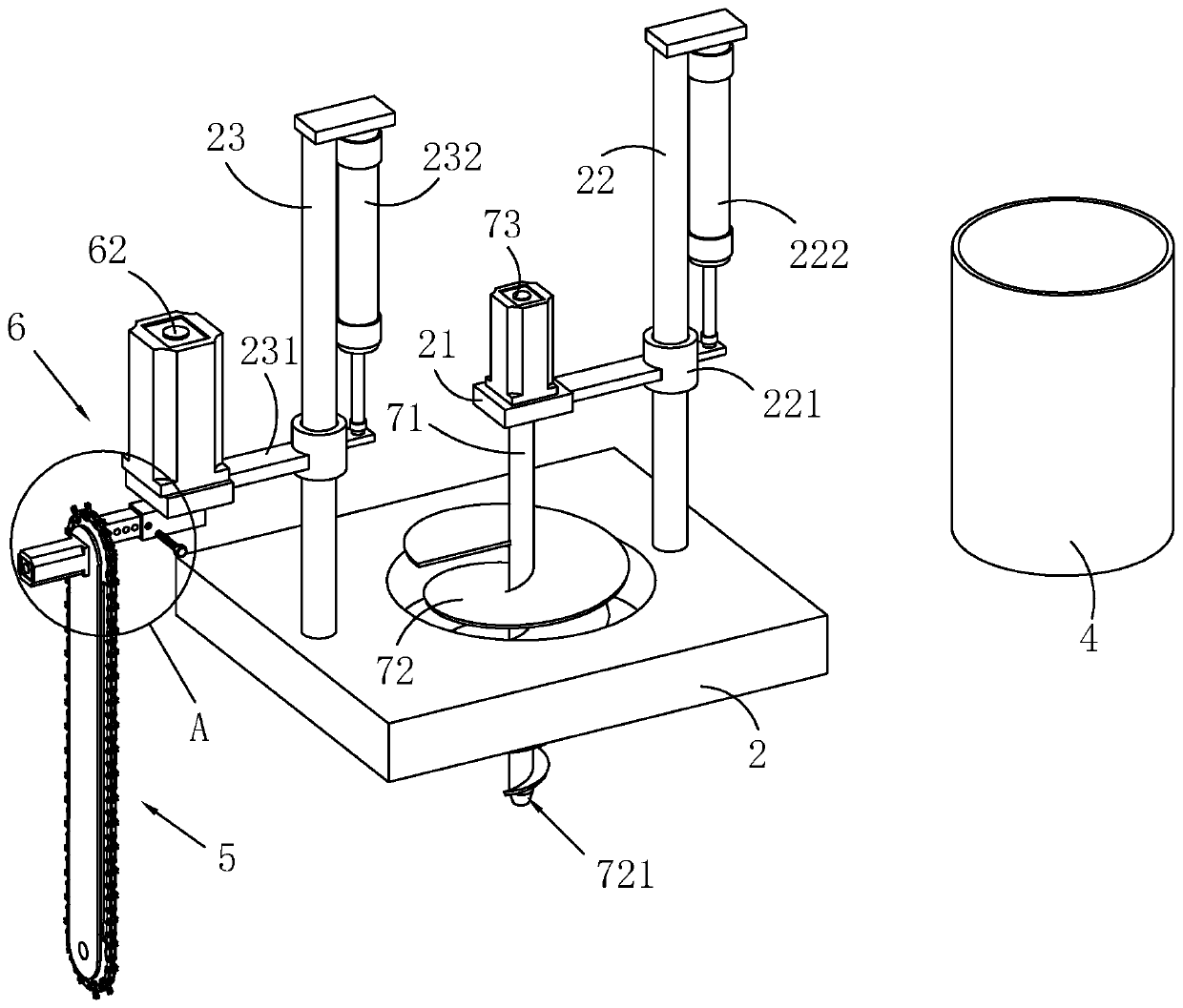

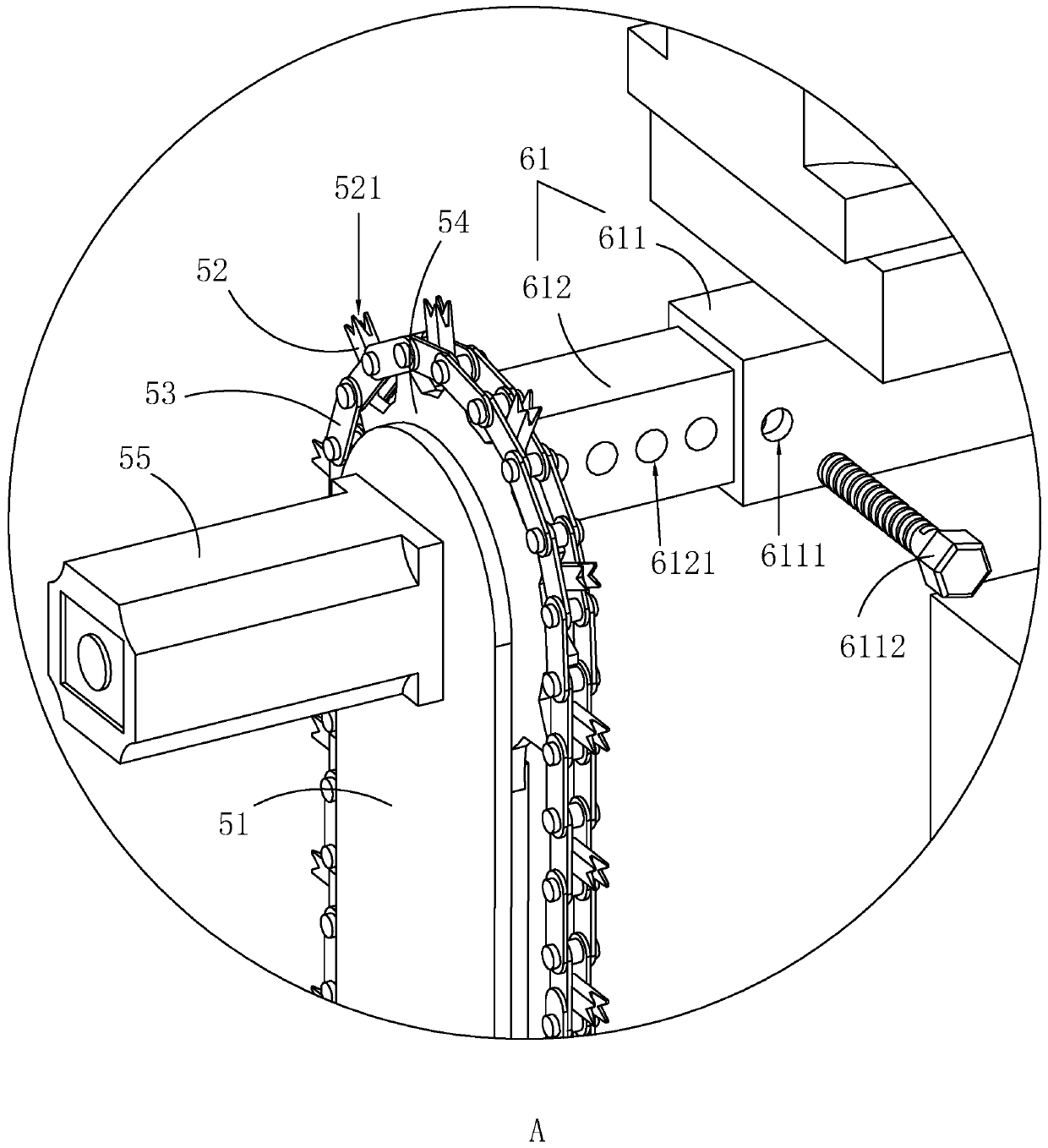

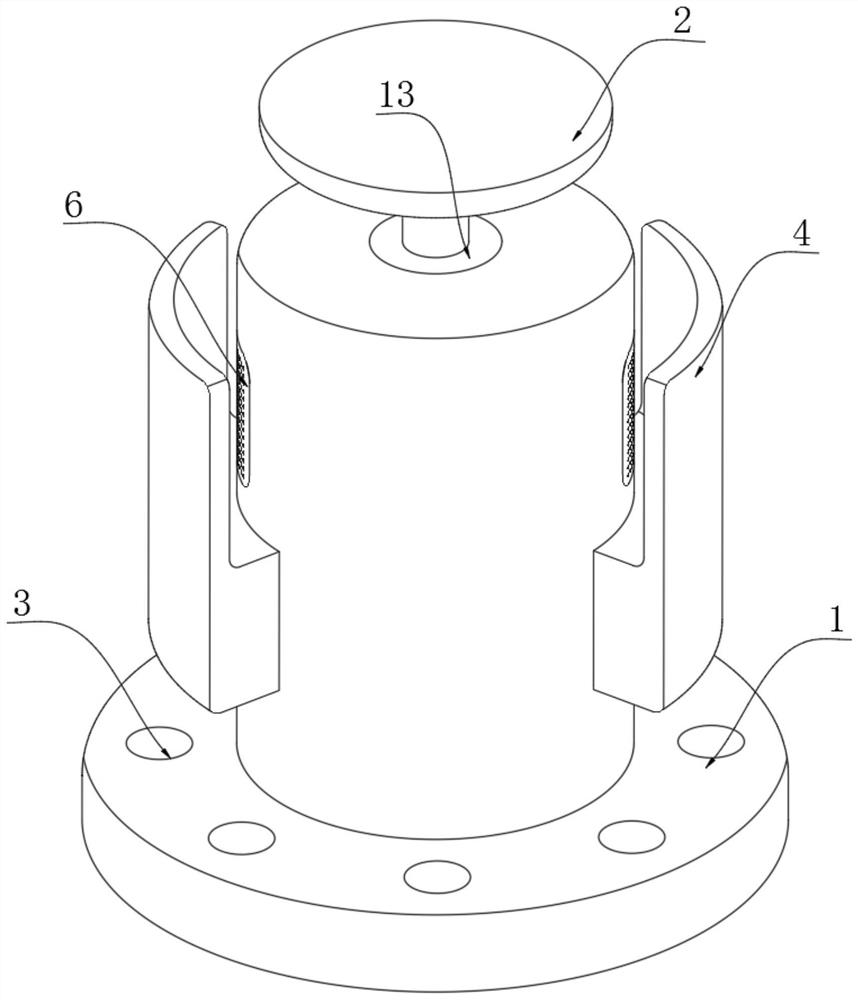

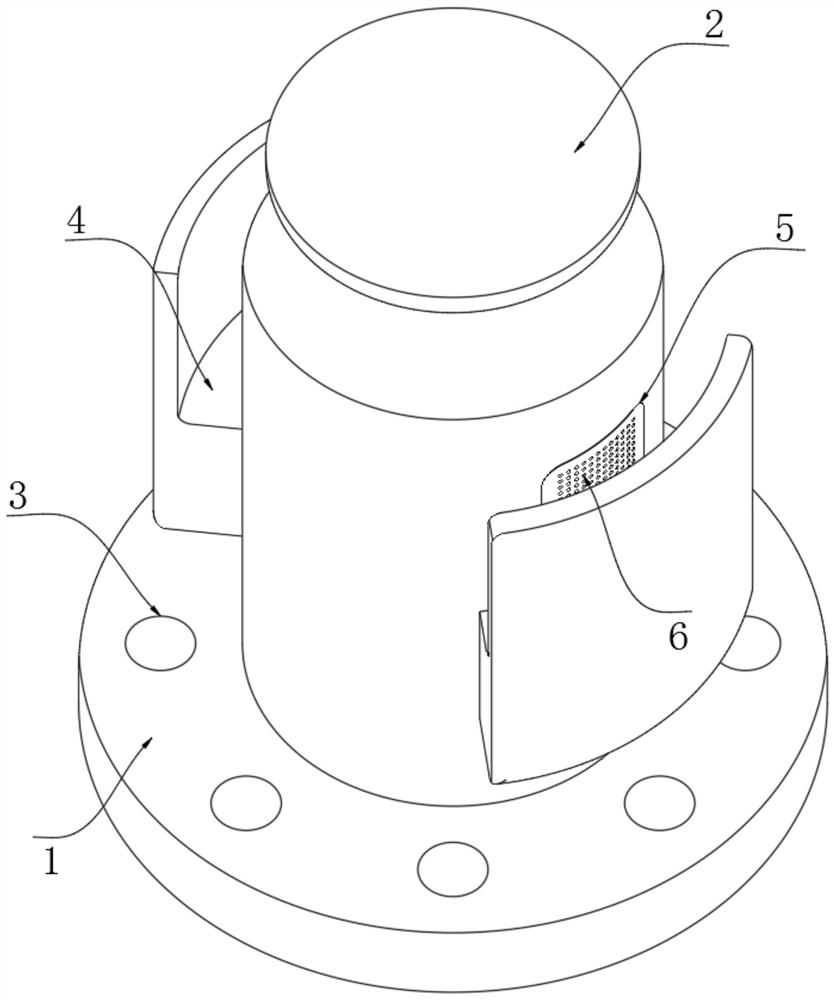

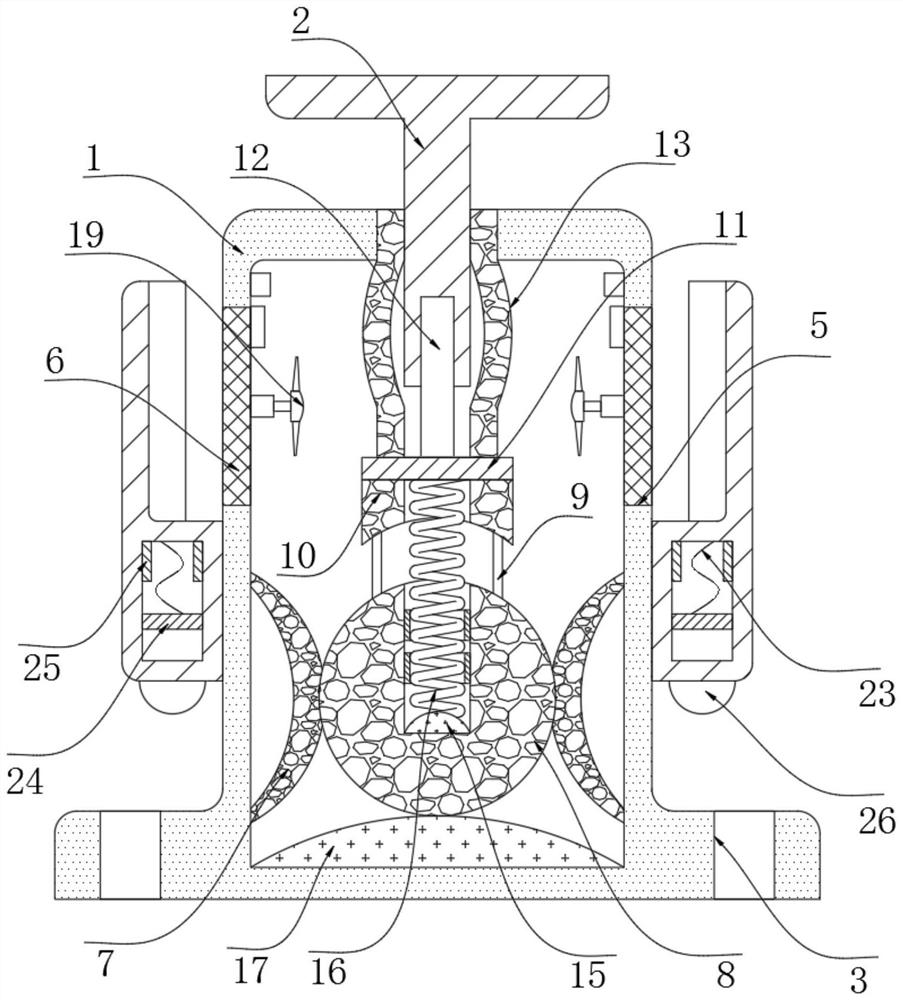

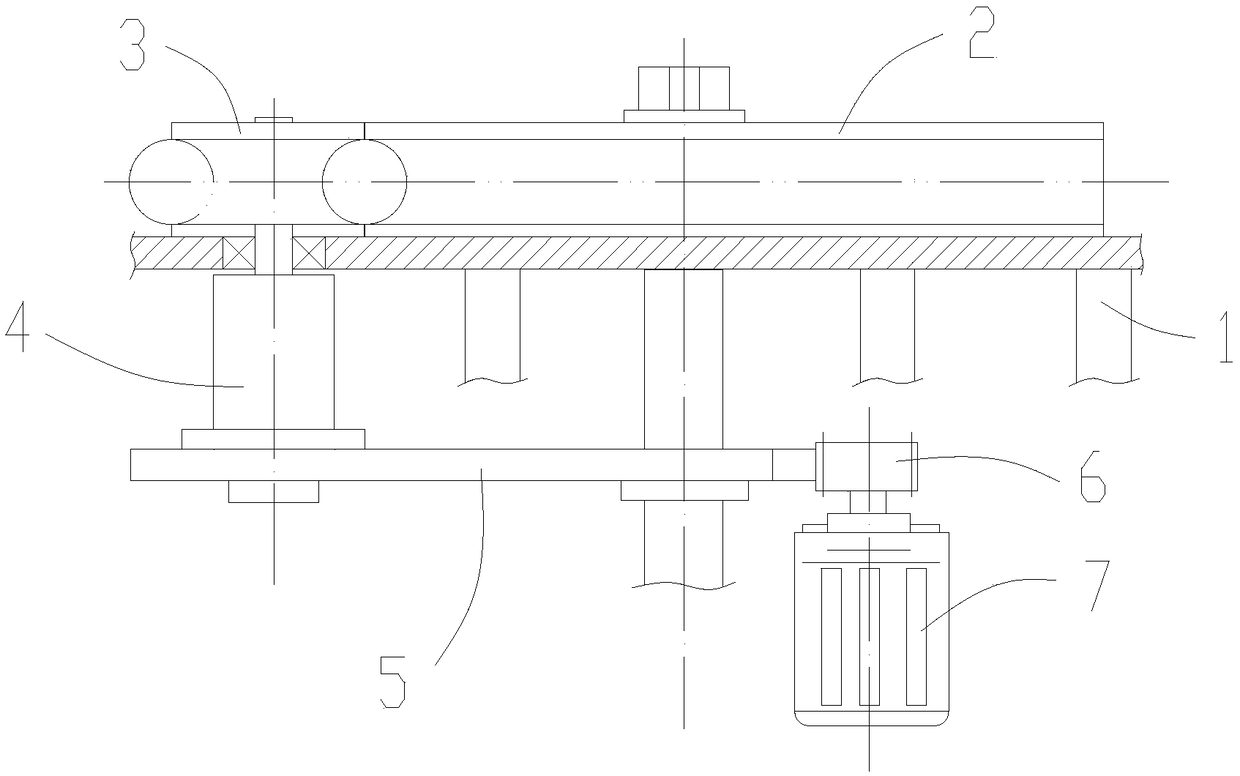

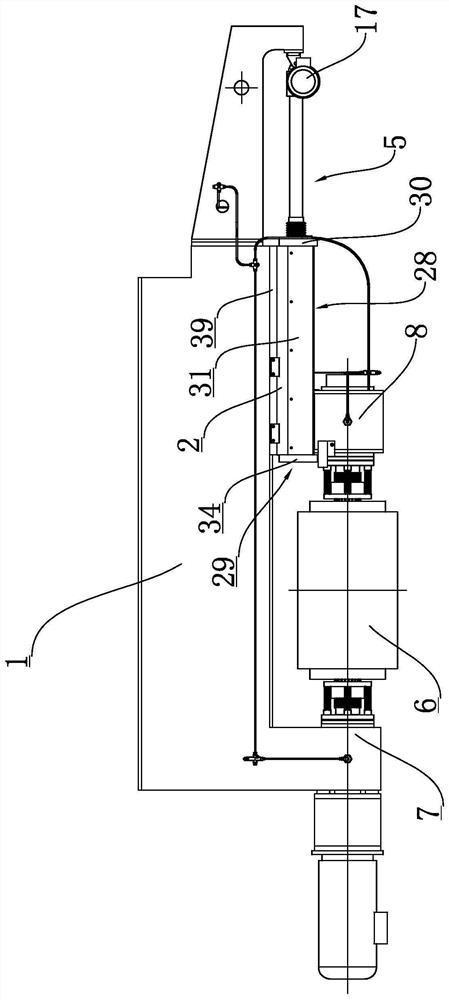

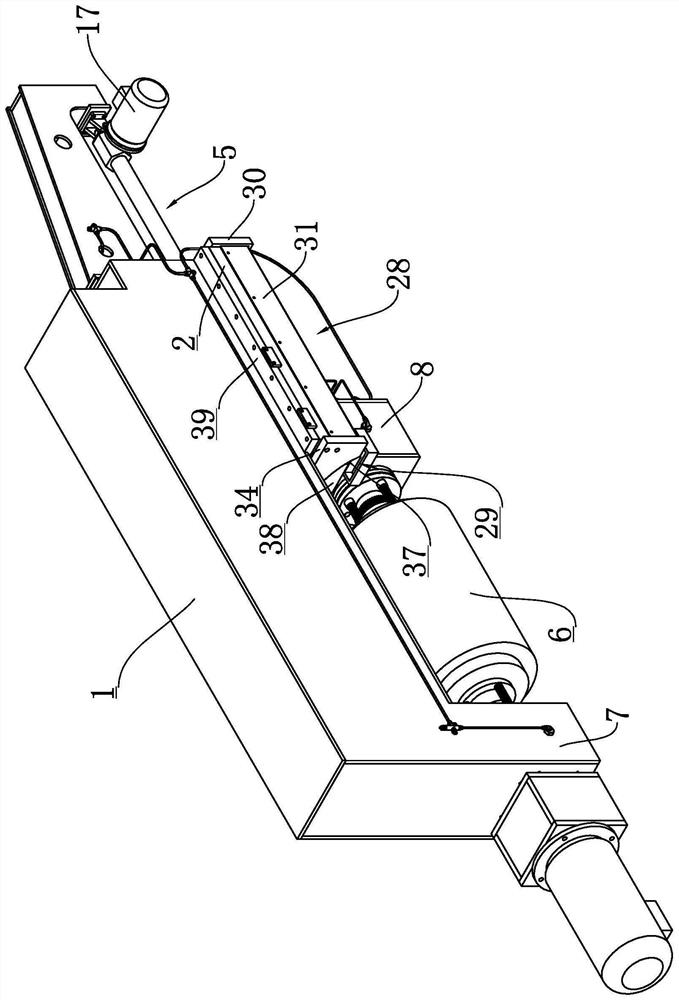

Sand filling method compaction detection system and detection method

ActiveCN110346242AImprove digging efficiencyEasy to insertSpecific gravity measurementEngineeringCircular motion

The invention relates to a sand filling method compaction detection system, and belongs to the technical field of road compaction detection. The sand filling method compaction detection system comprises a sand filling cylinder, a pedestal, a soil collection box and a protection cylinder with two opening ends; a round hole is formed in the middle of the soil collection box; the pedestal is providedwith a cutting component used for cutting the ground, and a driving component used for driving the cutting component to make circular motion is arranged on the pedestal; a moving base is arranged onthe pedestal along a vertical direction in a sliding manner, and a driving source is arranged on the pedestal; and a soil excavation component used for hole digging is arranged on the moving base. A cylindrical cutting slot is cut in the foundation via the cutting component; and then the protection cylinder is pressed into the cutting slot, and the pedestal position is moved, so that the soil excavation component right faces the protection cylinder, and then excavates soil in the protection cylinder out via the soil excavation component. The soil excavation efficiency is effectively improved,meanwhile, the soil around the cutting slot is separated via the protection cylinder, the soil around the soil excavation component is prevented from being excavated to cause excessive excavation, andthe measurement accuracy is improved.

Owner:深圳市实瑞建筑技术有限公司

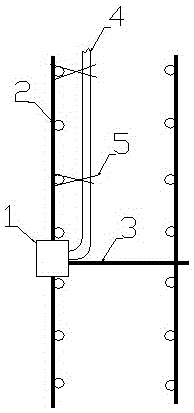

Junction box concealed burying accurate positioning method

InactiveCN105071302AAvoid misalignmentPrevent invaginationApparatus for laying cablesEngineeringRebar

The invention discloses a junction box concealed burying accurate positioning method. The positioning method comprises the following steps: 1) measurement line laying, 2) installation and fixing of a threading pipe, 3) processing and manufacturing of a positioning reinforcing steel bar, 4) primary positioning and installation of a junction box, 5) auxiliary fixing of the positioning reinforcing steel bar and accurate positioning of the junction box, and 6) dimension repetition measurement. A position deviation and invagination of the junction box can be effectively prevented; the junction box can be prevented from tilting to the left and the right, and construction quality is improved; and secondary reworking cost generated by scraping and beating at a later stage can be effectively prevented.

Owner:CHINA MCC17 GRP

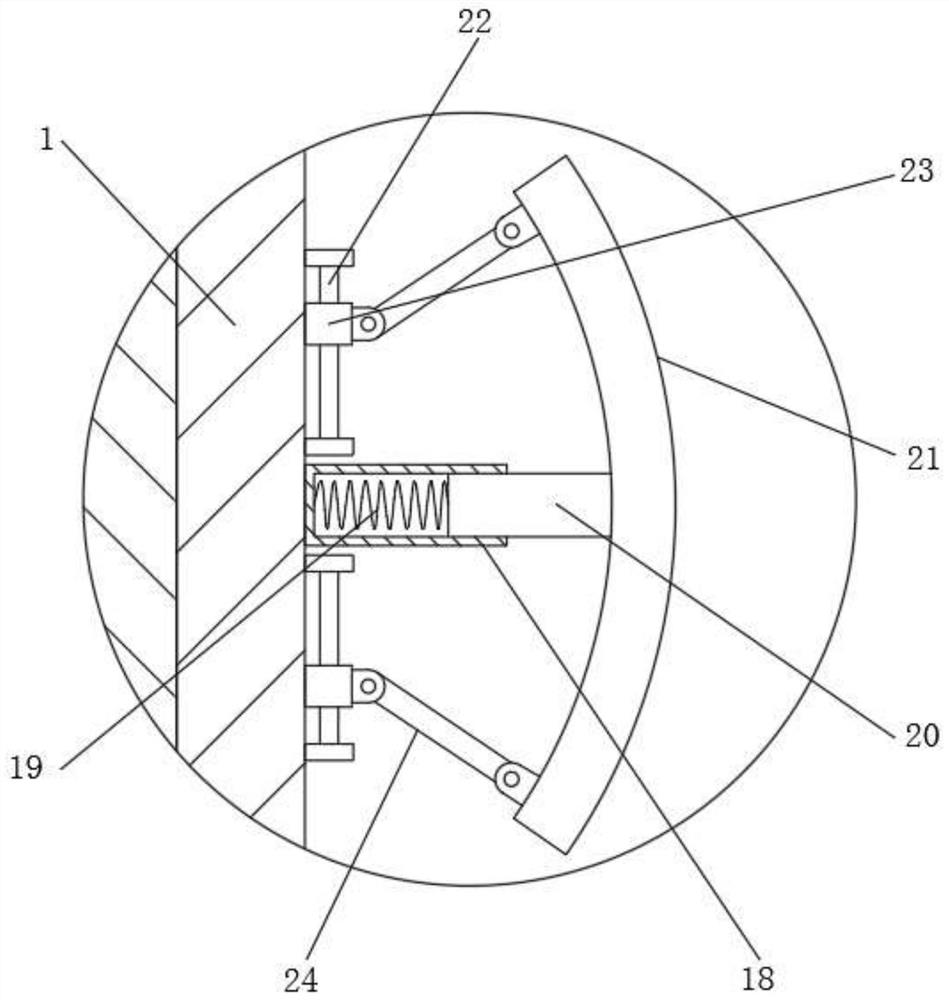

Auxiliary assembler for vehicle damping rubber

PendingCN113124079ALow frequency and small vibration avoidanceReduce excessive impact damageSpring motorHigh internal friction springsStructural engineeringMechanical engineering

The invention discloses an auxiliary assembler for vehicle damping rubber. The auxiliary assembler for the vehicle damping rubber comprises a dust-proof cover and an upper connecting body, wherein multiple lower connecting holes are formed in the lower end of the dust-proof cover in a penetrating mode; two protection tables are symmetrically fixed to the side wall of the dust-proof cover; alarm mechanisms are arranged in the two protection tables; two window grooves are formed in the side wall of the dust-proof cover in a penetrating mode; filter screens are fixed to the inner walls of the two window grooves correspondingly; two pieces of mounting rubber are fixed to the inner wall of the dust-proof cover; and main buffer rubber is fixed to the side walls of the two pieces of mounting rubber jointly. The auxiliary assembler for the vehicle damping rubber provided by the invention has the advantages that by arranging a buffer spring, the upper connecting body can move up and down in the operation vibration process, so that a pressing plate and upper pressing rubber are driven to move downwards, and deformation of the buffer spring is mainly caused in the initial stage of movement; and then low-frequency small-amplitude vibration can be effectively avoided by utilizing the spring characteristics of the buffer spring, so that low-frequency stability which cannot be obtained by conventional rubber cushioning is obtained.

Owner:TONGCHENG SUPER RUBBER

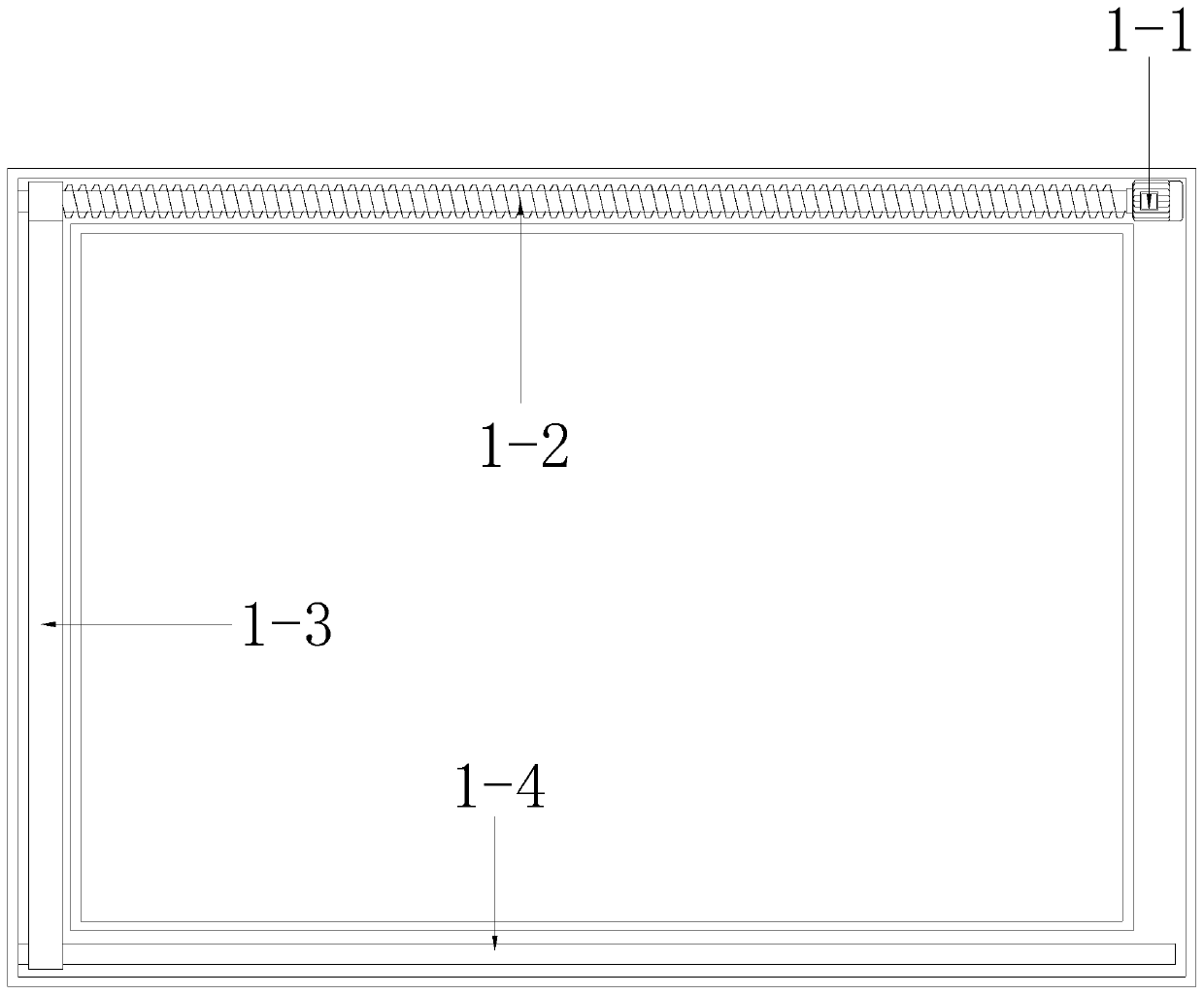

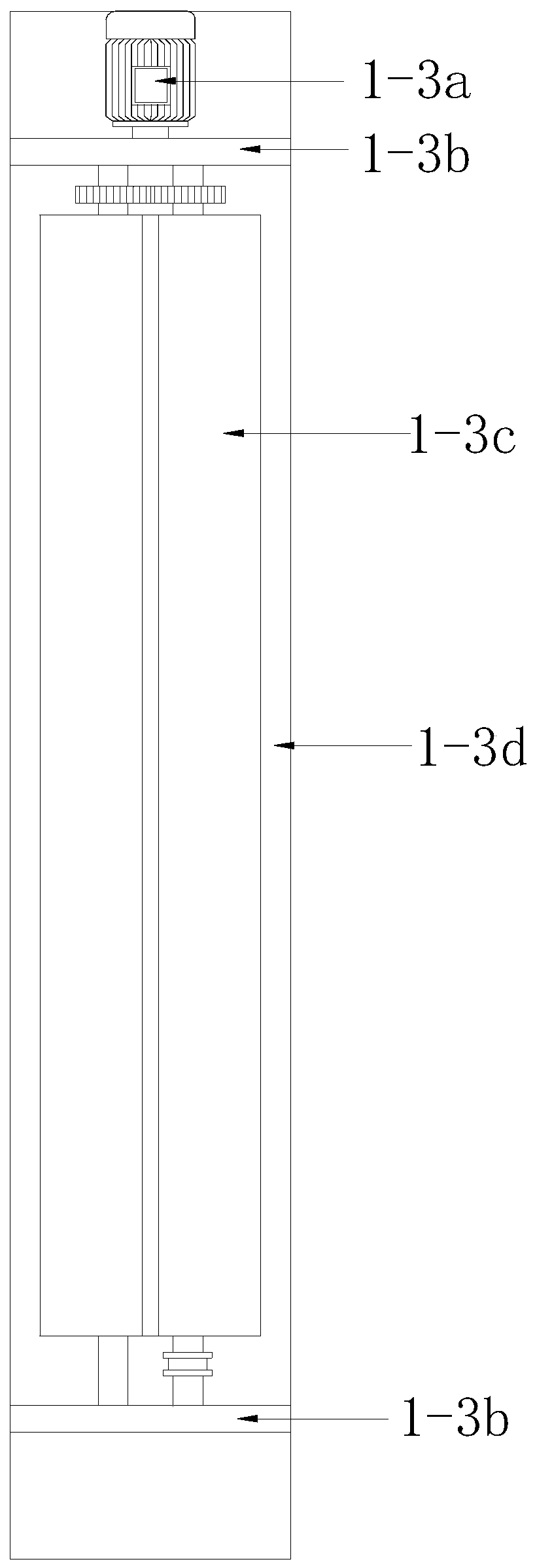

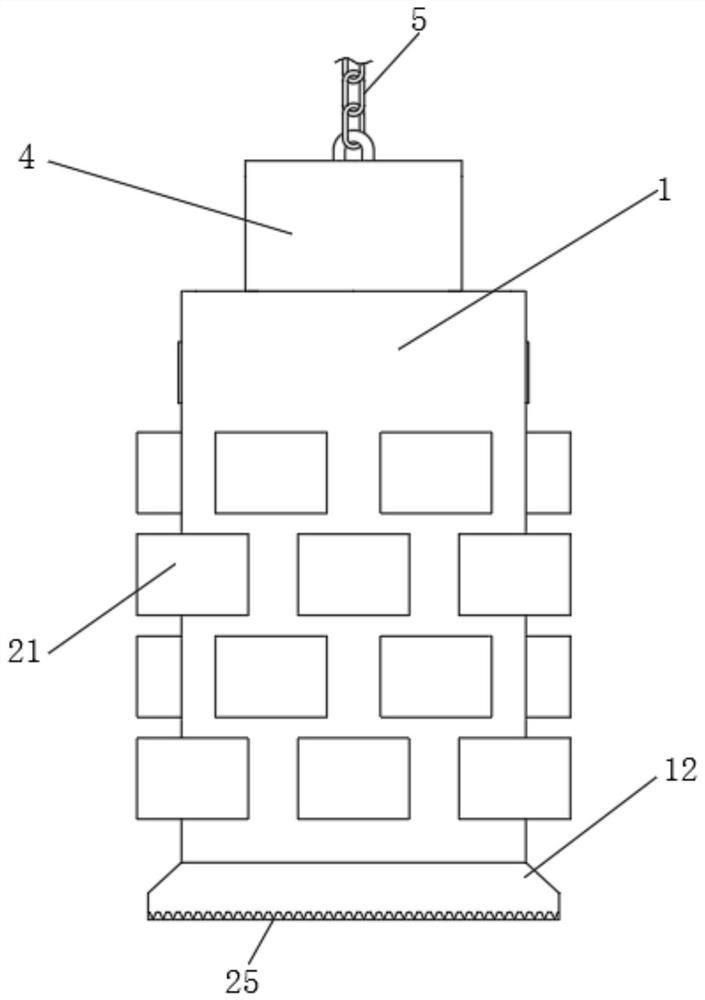

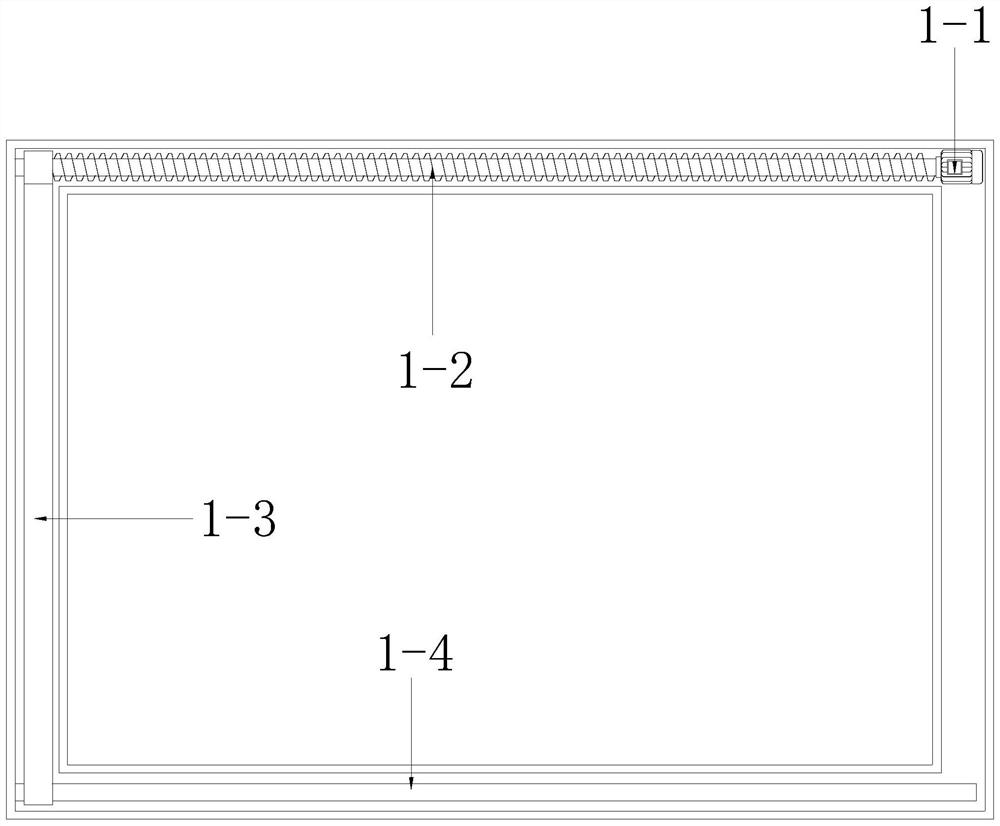

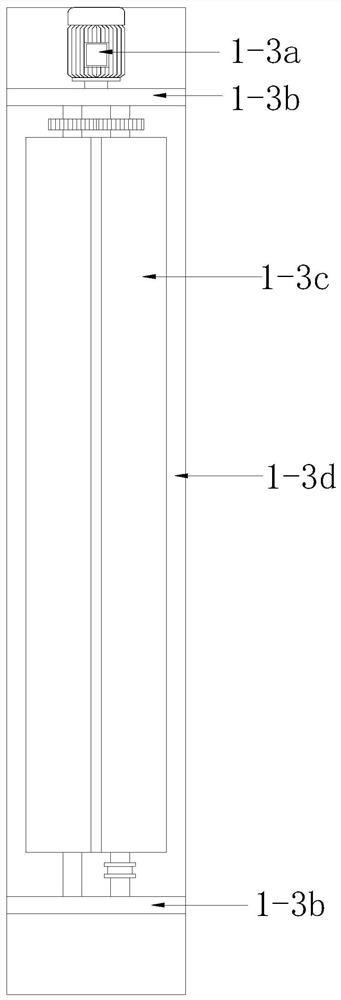

Efficient and self-cleaning outdoor LED display screen

ActiveCN110264896AEasy to cleanPrevent invaginationCleaning using toolsHeating element shapesLED displayCentrifugal force

The invention discloses an efficient and self-cleaning outdoor LED display screen. The efficient and self-cleaning outdoor LED display screen structurally includes a screen automatic cleaning device, a display screen body and a display screen box body, the display screen body is mounted on the display screen box body, and the screen automatic cleaning device is arranged outside the display screen body and mechanically connected with the display screen box body. The efficient and self-cleaning outdoor LED display screen has the beneficial effects that the efficient and self-cleaning outdoor LED display screen has the self-cleaning function, a cleaning cloth is used for translation to wipe and clean the screen, centrifugal force generated by autogiration of the cleaning cloth is used for getting rid of dirt on the screen, a built-in spring of a double-layer soft cloth makes the double-layer soft cloth stiffer to avoid the double-layer soft cloth to encounter bigger dirt and sink in, cleaning of the screen is more advantageous, during cleaning, heat is transferred to the double-layer soft cloth by an electric heating bar and the spring, so that solvent is heated indirectly to improve enzymatic activity to increase the cleaning degree, the double-layer soft cloth is heated and kept dry after cleaning, the cleaning effect is good, and the LED display screen is effectively prevented from appearing unclear, mosaic and other phenomena in the process of action.

Owner:湖南禾辉信息技术有限公司

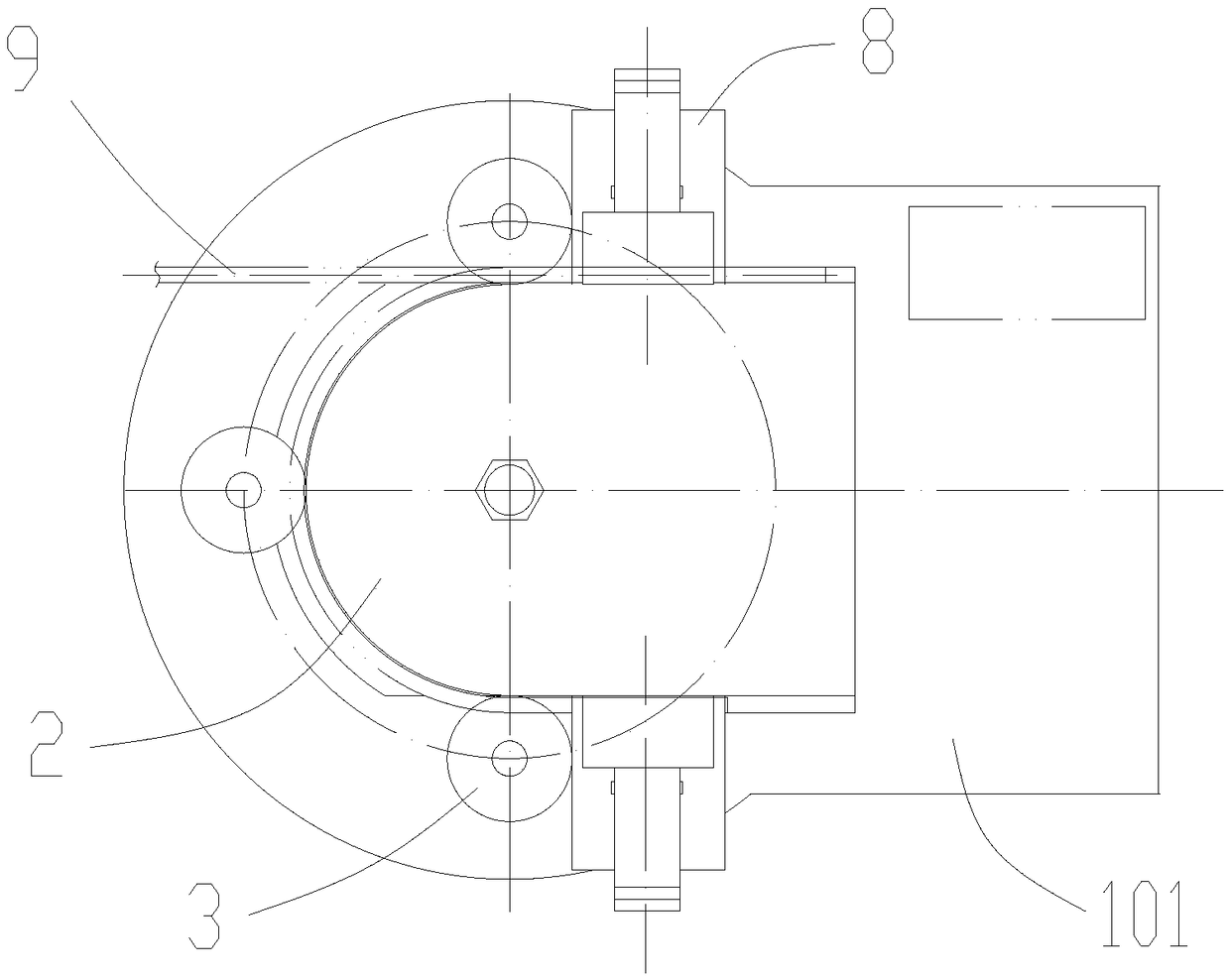

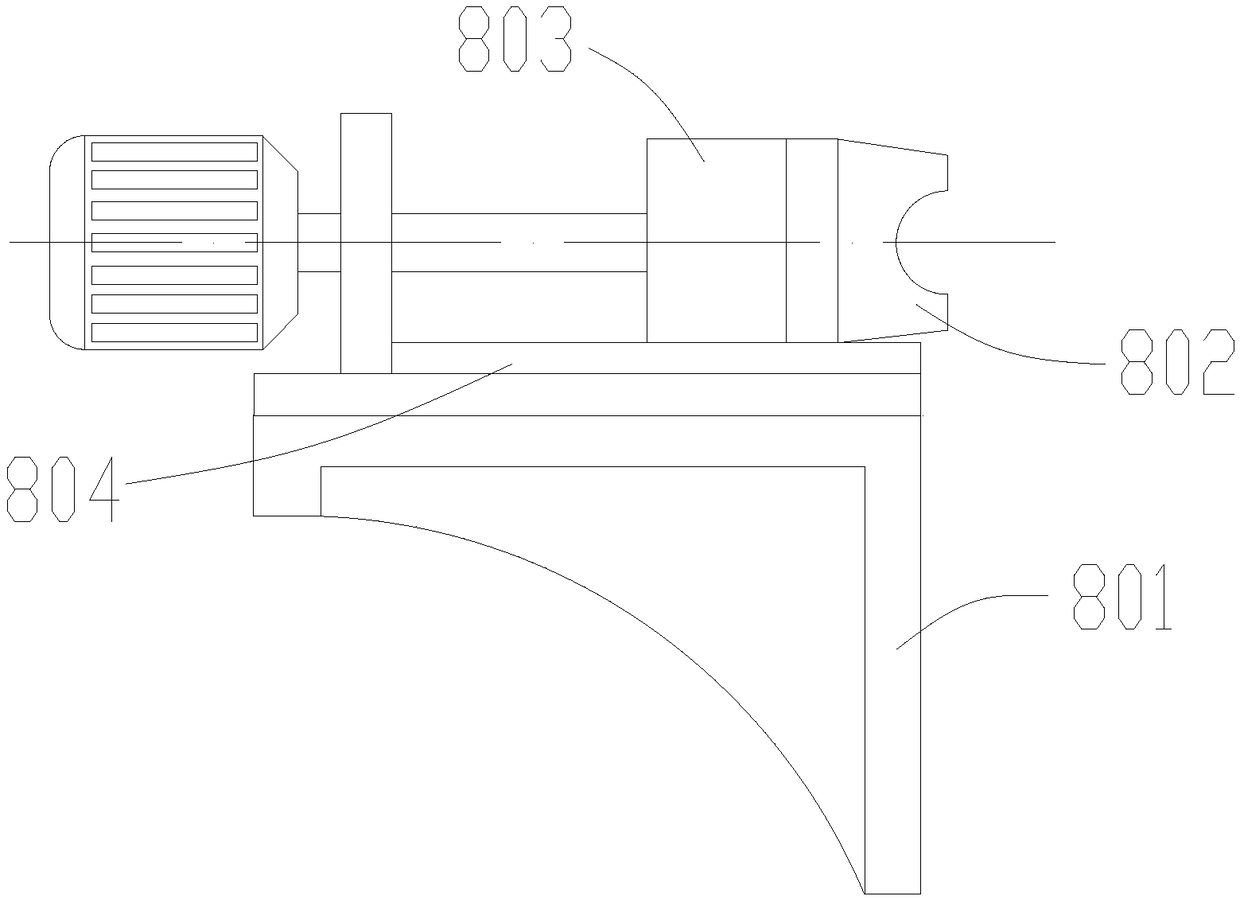

Aluminum alloy U-shaped pipe forming mechanism

The invention discloses an aluminum alloy U-shaped pipe forming mechanism. The aluminum alloy U-shaped pipe forming mechanism comprises a rack and is characterized in that a fixed mold is arranged onthe rack and comprises a semicircular mold plate and a rectangular mold plate which is in tangent connection with the semicircular mold plate to form a whole body; concave arc-shaped mold grooves areformed in two sides of the rectangular mold plate which is tangent to the semicircular mold plate along the circular arc periphery of the semicircular mold plate; a planet mold matched with the fixedmold is arranged along the circular arc periphery of the semicircular mold plate; the motion trail of the planet mold is the circular motion taking the center of the semicircular mold plate of the fixed mold as the center of the circle; and a pipe fixed mold is arranged on the rack and is matched with the rectangular mold plate of the fixed mold; and a mold cavity equivalent to the outer diameterof a bent pipe is formed outside a bent pipe body, so that basic requirements such as the roundness of a bended-arc segment are ensured, the whole forming process is stable and continuous, and the cracking of the pipe body caused by uneven stress is avoided.

Owner:湖州织里宝丰铝业有限公司

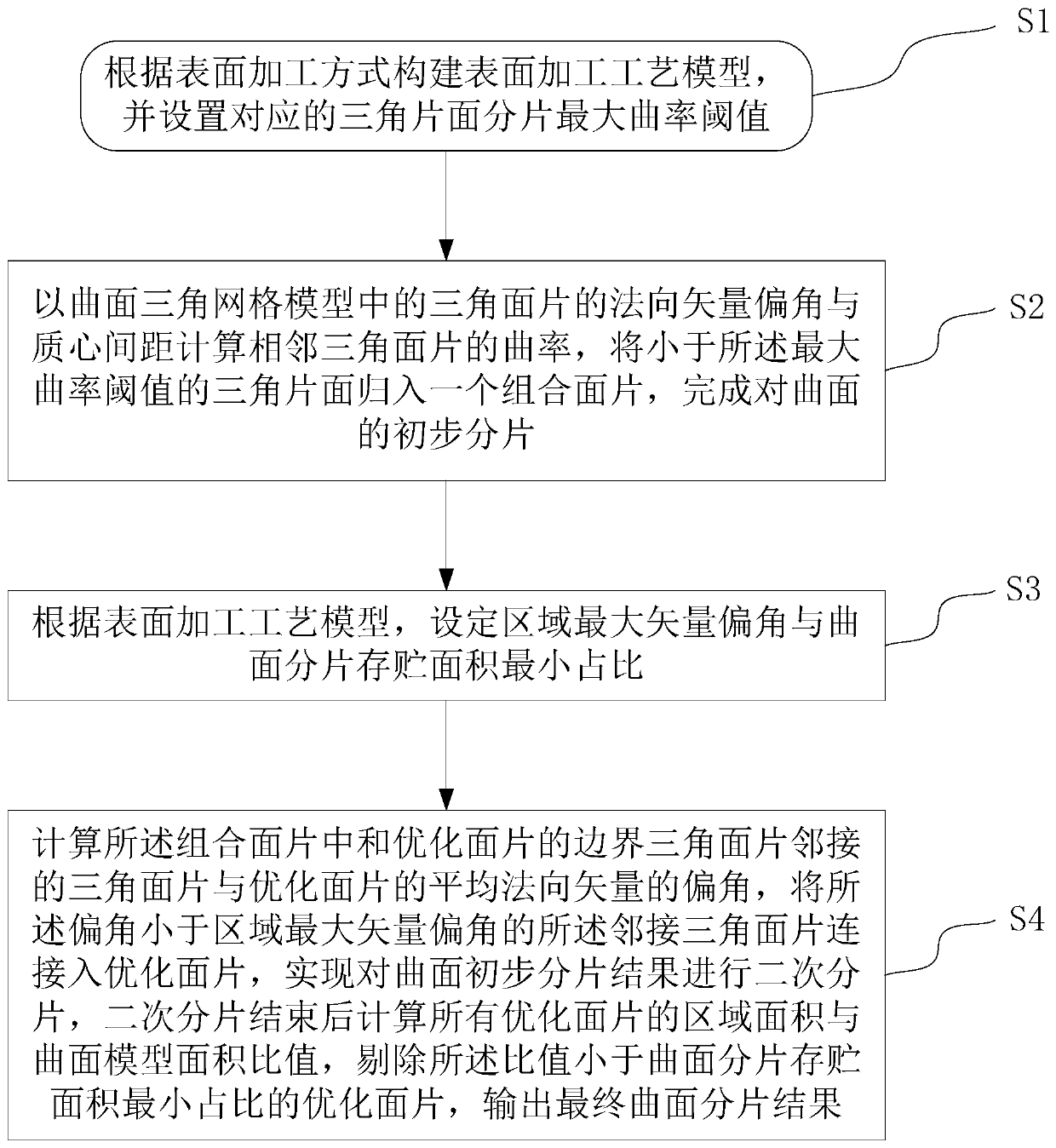

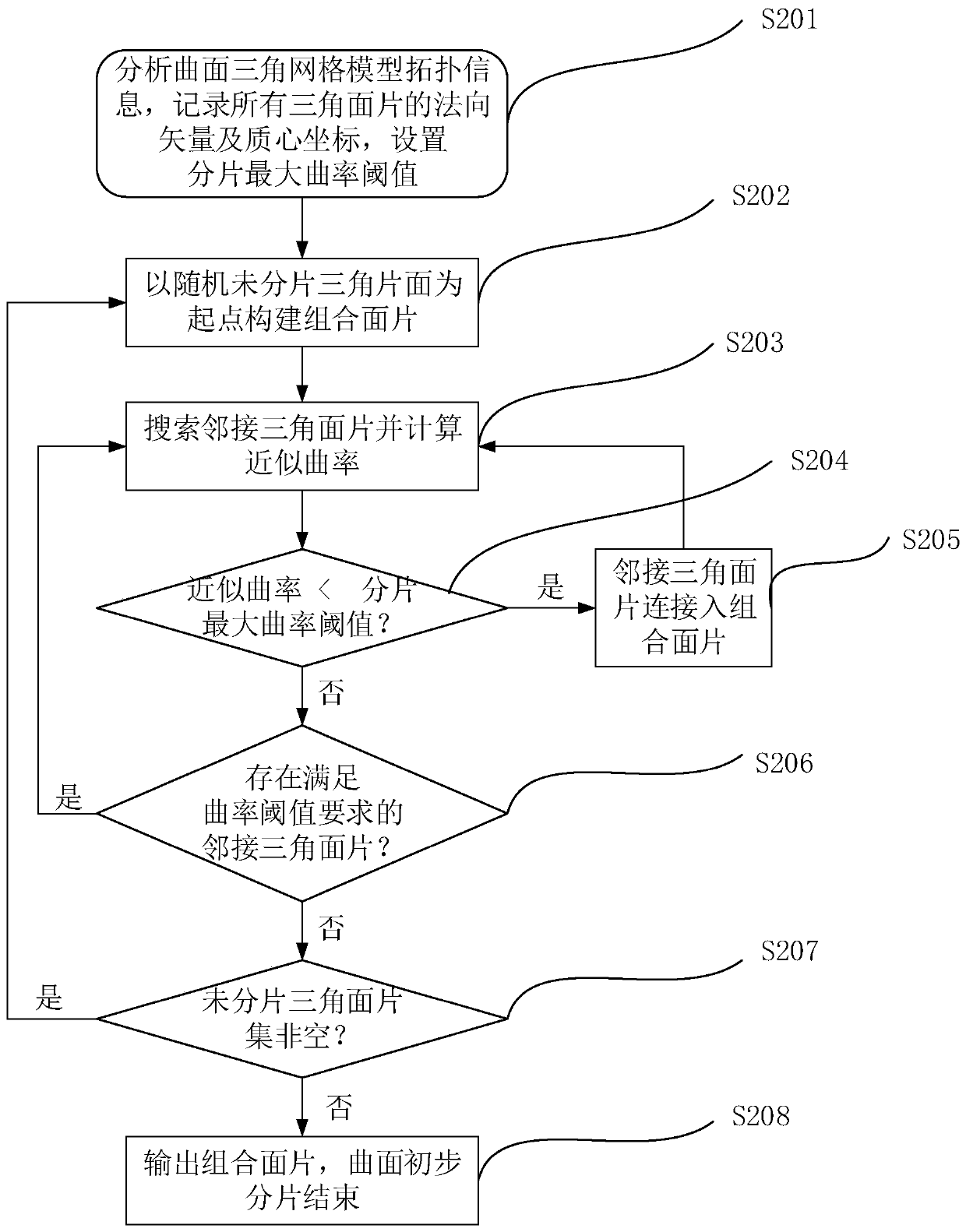

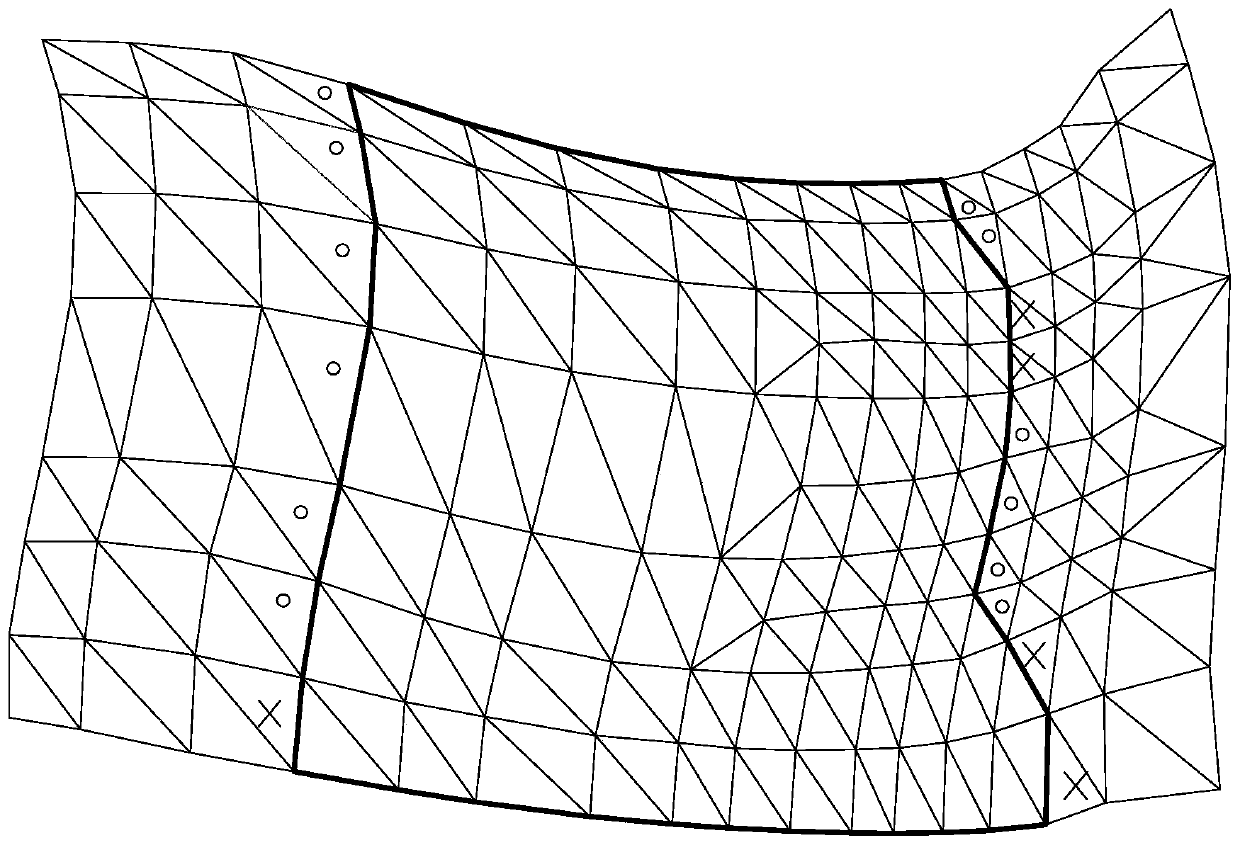

Autonomous segmentation method of large-scale complex curved surface robot automatic surface machining

ActiveCN110488752APrevent invaginationGuarantee the uniformity of processing thicknessProgramme controlComputer controlComputer scienceMachining

The invention discloses an autonomous segmentation method of large-scale complex curved surface robot automatic surface machining. The method is characterized in that firstly, a surface processing technology model is constructed according to a surface processing mode, and the corresponding maximum curvature threshold of triangle patch segmentation is set; based on the approximate curvature of adjacent triangular patches, the triangular patches are initially segmented; secondly, the ratio of a maximum vector deflection angle of a region and a minimum curved surface segmentation storage area isset, and secondary segmentation preparation is performed; based on an average normal vector of the optimized patches, deflection angles of other adjacent triangular patches to the average normal vector are calculated, the adjacent triangular patches smaller than the maximum vector deflection angle of the region are connected with the optimized patches to achieve secondary segmentation, the optimized patches whose ratio of the region area to a curved surface model area does not meet requirements are eliminated, and the final curved surface segmentation result is outputted. The method is advantaged in that robustness is good, hand-operated adjusting demands are substantially reduced, and result consistency and processing feasibility are good.

Owner:武汉数字化设计与制造创新中心有限公司

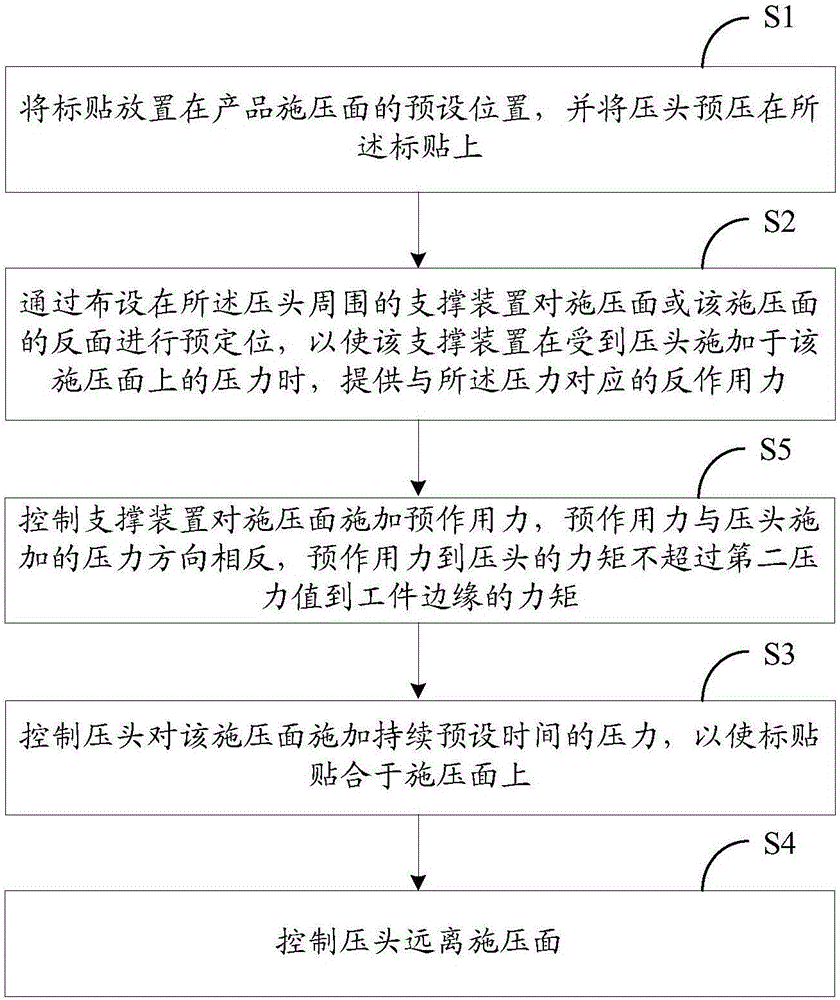

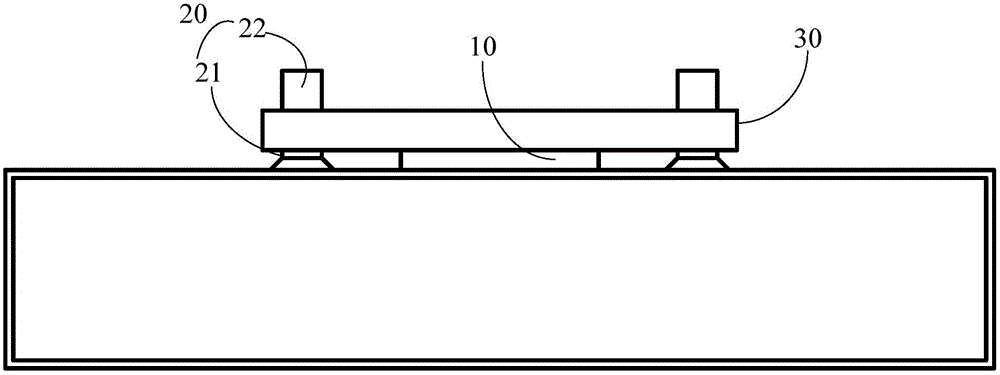

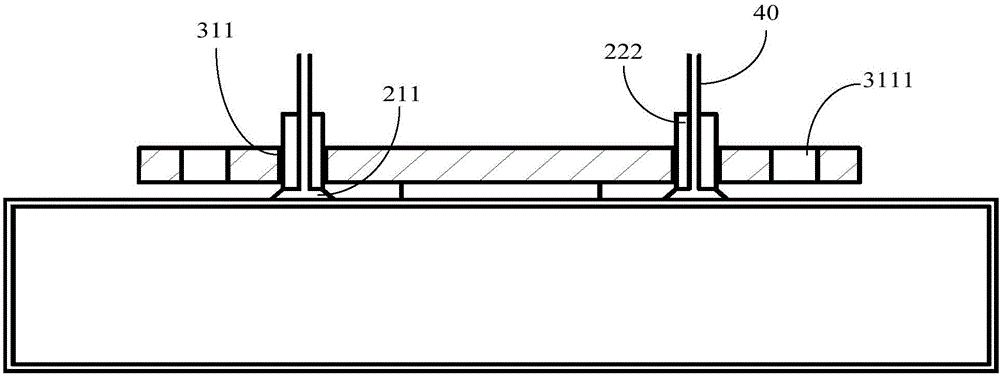

Label pressing and attaching process and label pressing and attaching tool

ActiveCN106219007APrevent invaginationReduce distortionLabelling machinesMechanical engineeringThin walled

The invention discloses a label pressing and attaching process and a label pressing and attaching tool. The label pressing and attaching process comprises the following steps that a label is placed in the preset position of the pressure application surface of a product, and a pressing head is pre-pressed on the label; prepositioning is conducted on the pressure application surface or the reverse side of the pressure application surface through supporting devices arranged on the periphery of the pressing head, so that the supporting devices provide reactive force corresponding to the pressure when subjected to the pressure applied to the pressure application surface by the pressing head; the pressing head is controlled to apply continuous pressure to the pressure application surface for a preset time, so that the label is attached to the pressure application surface; and the pressing head is controlled to be away from the pressure application surface. The reactive force corresponding to the pressure applied by the pressing head is applied to the pressure application surface of the product, so that the pressure application surface of the product is prevented from being inwards sunk, and deformation of the pressure application surfaces of thin-wall type products in the label pressing and attaching process is reduced.

Owner:TCL KING ELECTRICAL APPLIANCES HUIZHOU

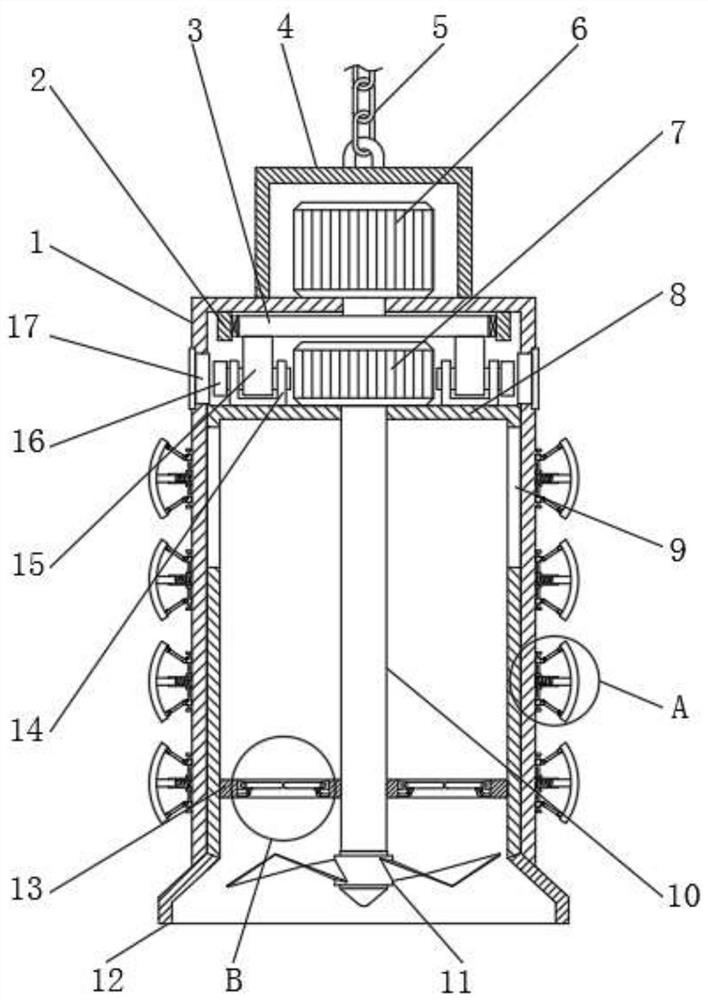

Geological mineral exploration device

InactiveCN114293984APrevent leakageIncrease drill depthEarth drilling toolsConstructionsClassical mechanicsEngineering

The invention relates to the technical field of geological exploration, in particular to a geological mineral exploration device which comprises a fixing cover, a rotating cylinder is arranged in the fixing cover, discharge ports are formed in the outer wall of the periphery of the rotating cylinder, a tunneling cylinder is arranged at the end of the rotating cylinder, and tunneling teeth distributed annularly are arranged at the end of the tunneling cylinder. The end of the fixing cover is attached to the outer wall of the tunneling barrel, a protection cover is arranged on the outer wall of the fixing cover, a traction piece is arranged on the protection cover, a first driving piece is arranged in the protection cover, a rotating disc is arranged at the driving end of the first driving piece, and the wall scraping device further comprises a partition plate, a lifting mechanism, a connecting assembly and a wall scraping mechanism. The device is small in overall size and convenient to carry, tunneling operation can be repeatedly carried out, the drilling depth of a tunneling channel is effectively increased, when the device is repeatedly tripped into the tunneling channel, the wall scraping mechanism can conduct wall scraping operation again, the purpose of secondary reinforcement is achieved, and the using effect is better.

Owner:刘文波

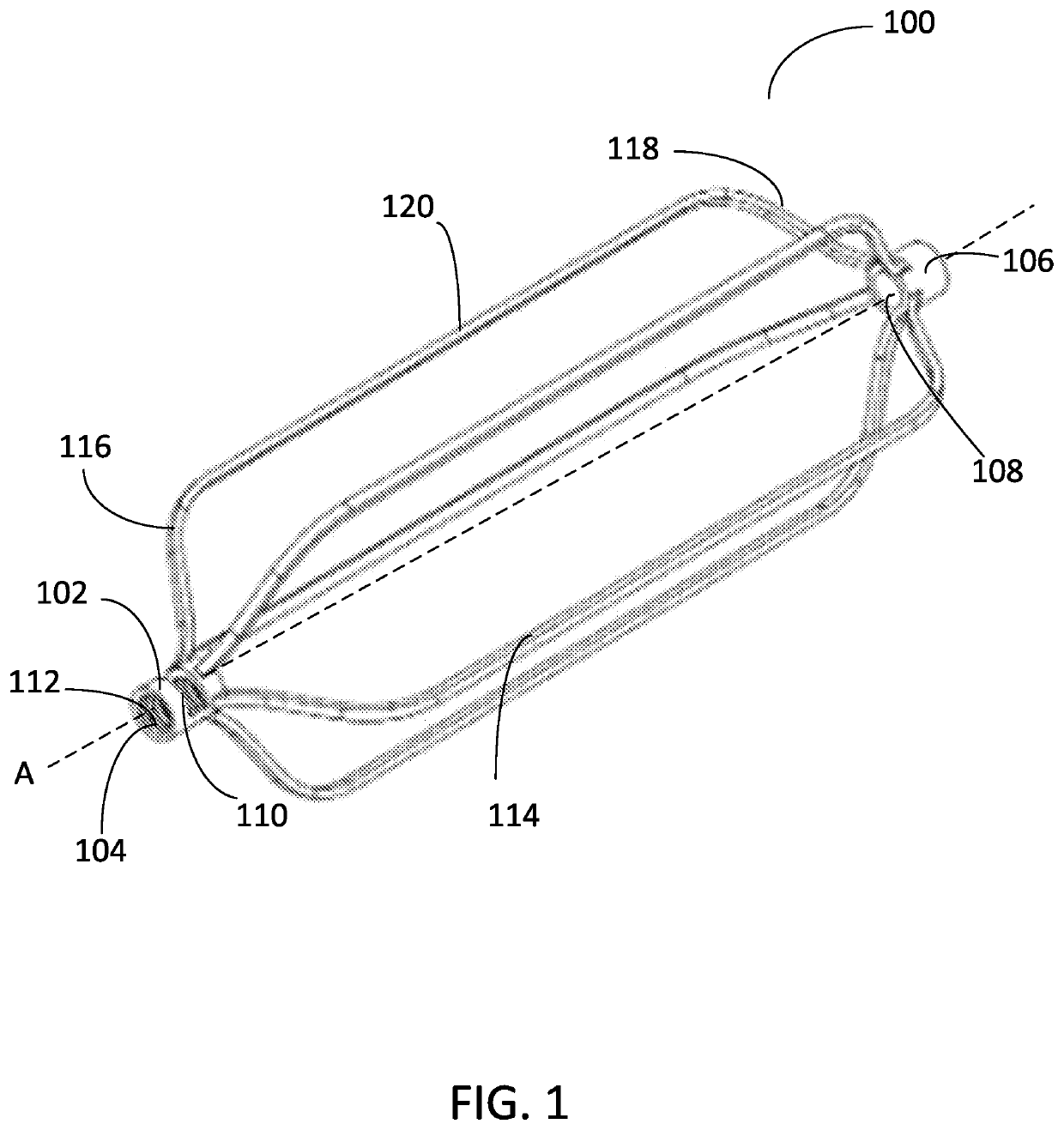

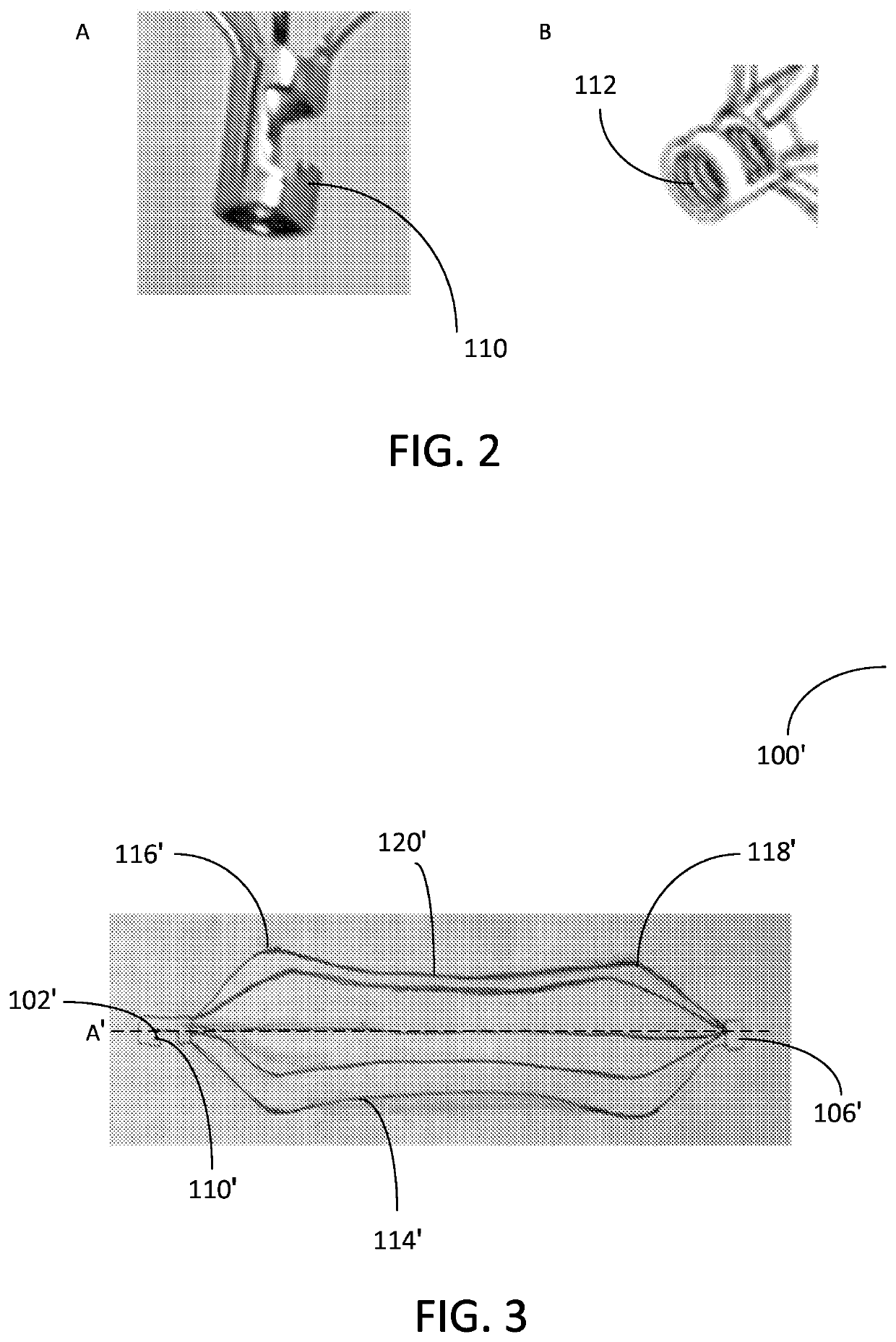

Patent ductus arteriosus stent

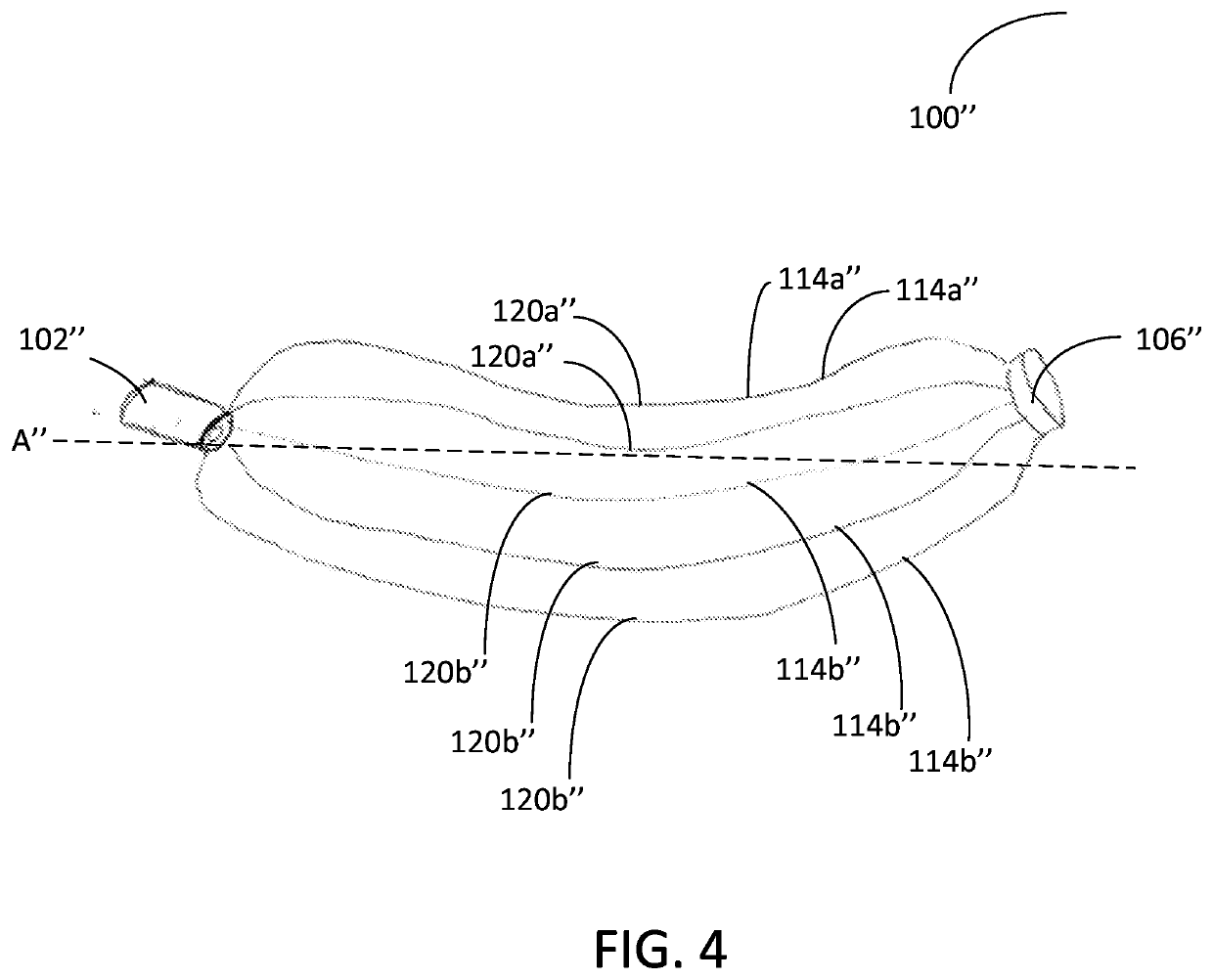

PendingUS20220175561A1Prevent invaginationSufficient blood flowStentsProsthesisHuman patientCatheter

A retrievable stent configured to be positioned across the ductus arteriosus in a pediatric human patient to keep the ductus arteriosus open and ensure adequate blood flow is described. The retrievable stent can include a plurality of 4 to 8 struts that extend from a proximal end connector to a distal end tip, each having a curved proximal strut end, a curved distal strut end and an elongated strut body portion that extends from the curved proximal strut end to the curved distal strut end. When the stent is positioned in the ductus arteriosus, the curved proximal strut ends and the curved distal strut ends engage the ductus arteriosus to provide the radial force necessary to keep the ductus arteriosus open while the elongated strut body portions minimally engage the ductus arteriosus to prevent invagination into the vascular wall and thus allow for subsequent retrieval.

Owner:VANDERBILT UNIV

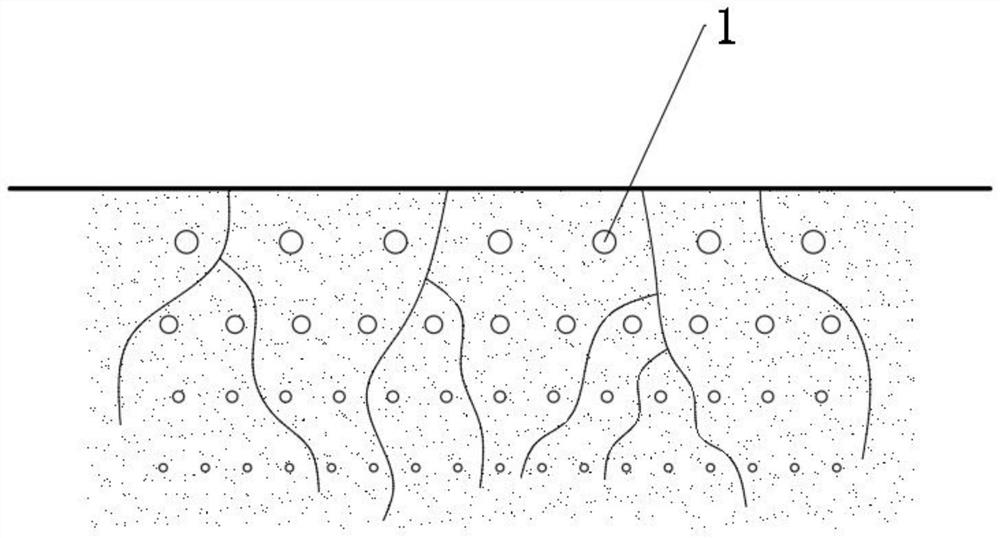

Air impact type treatment method for desertified soil

InactiveCN112958616AEffective sand fixation and water retentionTackling the causes of desertificationContaminated soil reclamationSoil scienceSoil treatment

The invention discloses an air impact type treatment method for desertified soil, and belongs to the technical field of soil treatment. According to the method, the characteristics of desertified soil are utilized, embedded balls permeate into the soil on the basis of the mode that the embedded balls are wrapped with a remediation liquid, the embedded balls of different sizes are vertically distributed in the soil in a mode that bigger balls are placed at the top and smaller bags are placed at the bottom under the effect of external vibration, the remediation liquid doped with tartaric acid is used to dissolve isolation materials on the surfaces of the embedded balls, so that the air impact action of the embedded balls is triggered, viscous media are diffused and released to all areas of the soil, the desertified soil is bonded, effective sand-fixing and water-retaining effects on the desertified soil can be achieved based on the hydrophilic characteristic of the soil, and meanwhile, the remediation effect of the remediation liquid is employed, so that the reason of soil desertification is fundamentally solved, and the desertified soil can be efficiently treated within a short time.

Owner:李慧

An efficient self-cleaning outdoor led display

ActiveCN110264896BEasy to cleanPrevent invaginationCleaning using toolsHeating element shapesLED displayEngineering

The invention discloses a high-efficiency self-cleaning outdoor LED display screen. The structure includes an automatic screen cleaning device, a display screen body, and a display screen box. Compared with the prior art, the screen automatic cleaning device connected mechanically with the display box has the beneficial effect of: having a self-cleaning function, using the cleaning cloth to wipe and clean the screen, and using the centrifugal force generated by the cleaning cloth to clean the screen. Get rid of the dirt on the screen, and the built-in spring of the double-layer soft cloth makes it stiffer, preventing the double-layer soft cloth from sinking when encountering large dirt, which is more conducive to cleaning the screen. When cleaning, use electric heating rods and spring heat It is passed on the double-layer soft cloth, which indirectly makes the solvent heated to increase the enzyme activity to improve the cleaning degree. After cleaning, the double-layer soft cloth is heated to keep it dry. The cleaning effect is good, and it can effectively prevent the LED display from being unclear, mosaic, etc. Phenomenon.

Owner:湖南禾辉信息技术有限公司

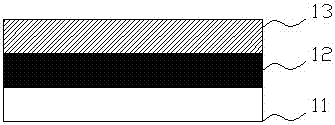

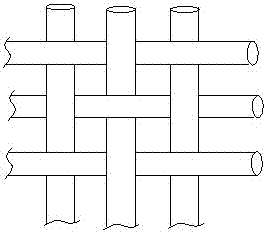

Conductive fabric and manufacturing method thereof

ActiveCN107216826AHigh hardnessPrevent heat warpingFilm/foil adhesivesPolyureas/polyurethane adhesivesFiberAdhesion force

The invention provides a conductive fabric which comprises a conductive fiber fabric coated with a metal coating layer and a conductive adhesive layer. The conductive fabric further comprises a hard adhesive layer arranged between the conductive fiber fabric and the conductive adhesive layer, wherein the hard adhesive layer is prepared from viscous resin, a conductive agent and a curing agent. Compared with a conductive fabric only comprising a conductive fiber fabric and a conductive adhesive, the hardness of the conductive fabric is increased by adding the hard adhesive layer, and the edge of the conductive fabric is prevented from warping and rolling when being heated. In addition, the viscous resin can be filled into gaps of the fiber fabric before being cured, the conductive adhesive layer is prevented from recessing concavely, a fabric sizing rate is reduced, and the viscosity of an adhesive face is improved; meanwhile, the conductive agent in the hard adhesive layer has an effect of electrically connecting the conductive adhesive layer and the metal coating layer; as the conductive fiber fabric is covered by the hard adhesive layer, adhesion force of the conductive fiber fabric is strong, and a resistance value is relatively stable. Therefore, the viscosity of the conductive fabric disclosed by the invention is improved, and the conductive property is not affected.

Owner:HISENSE VISUAL TECH CO LTD

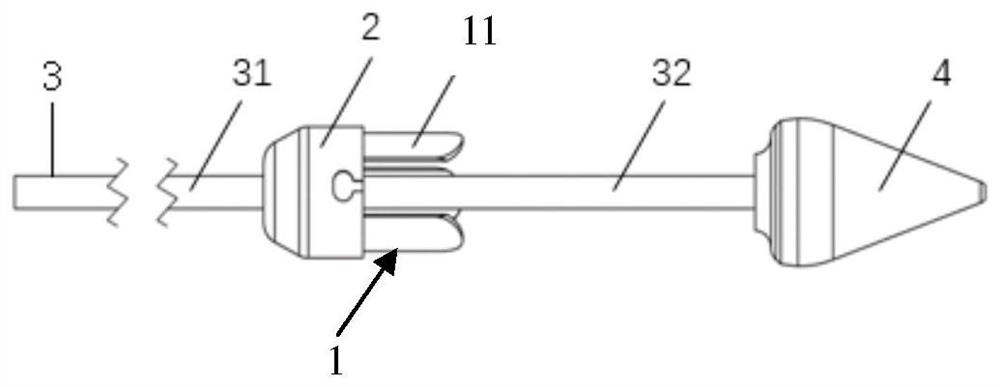

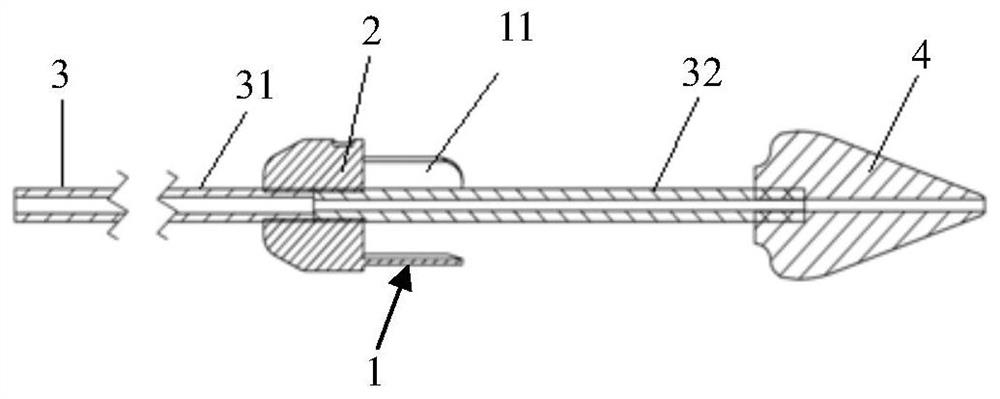

Implant conveying device and inner tube assembly and catheter thereof

The invention discloses an implant conveying device and an inner tube assembly and a catheter thereof, the inner tube assembly comprises an implant protection part, an inner tube and a fixing head connected with the inner tube, and the implant protection part is connected with the inner tube or / and the fixing head. The implant protection part is used for being in contact with an implant so as to support the implant; and a protection body is in a circular ring sheet shape or an arc sheet shape. According to the implant conveying device provided by the invention, the implant protection part is arranged, so that a non-anchoring rod with relatively weak circumferential supporting force of a valve stent can be supported, and inclination and damage of the valve stent in a loading process and distortion and inward sinking of the valve stent in a releasing process are avoided.

Owner:SHANGHAI MICROPORT CARDIOFLOW MEDTECH CO LTD

Formwork supporting method for shear wall of high-rise building

InactiveCN105464363AAvoid bulgingPrevent invaginationForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksEngineeringHigh rise

The invention discloses a formwork supporting method for a shear wall of a high-rise building. The method is characterized by including a construction joint position outer mould treatment process, a shear wall section control process and an elevator shaft formwork supporting process. Special nuts are embedded in concrete at the roots of construction joints to form reliable anchor points by wire drawing so as to prevent outward expansion of root outer moulds. By special inner side supports for shear wall formworks, the formworks are prevented from recessing inwards, and precision section size of the shear wall is guaranteed. By combination of L-shaped formworks and linear formworks of an elevator shaft and adoption of a lightweight turnover operating platform, the problem of difficulty in mass control of corners of the elevator shaft is solved, and construction efficiency is improved.

Owner:CHINA HUAYE GROUP +1

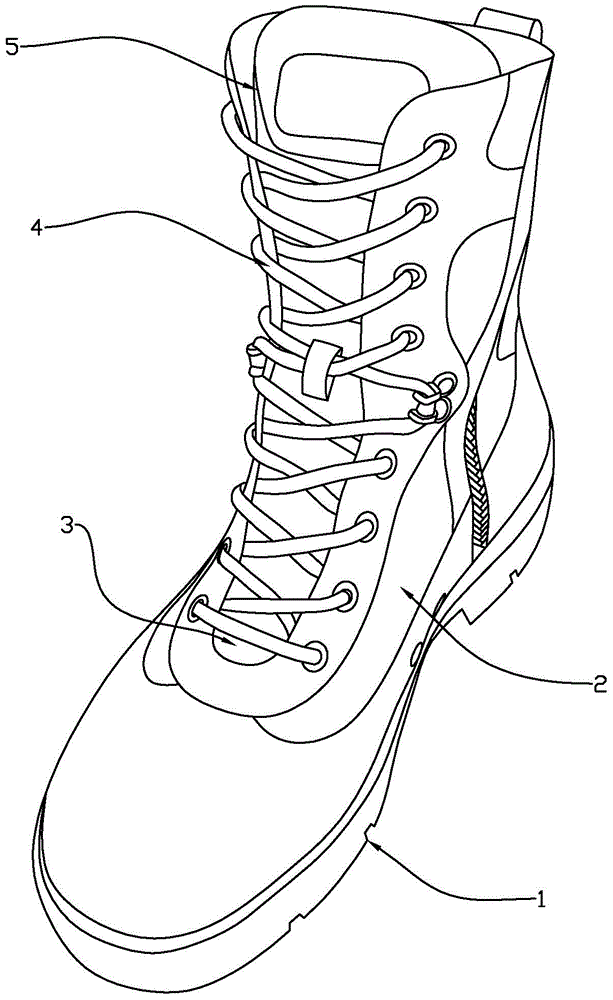

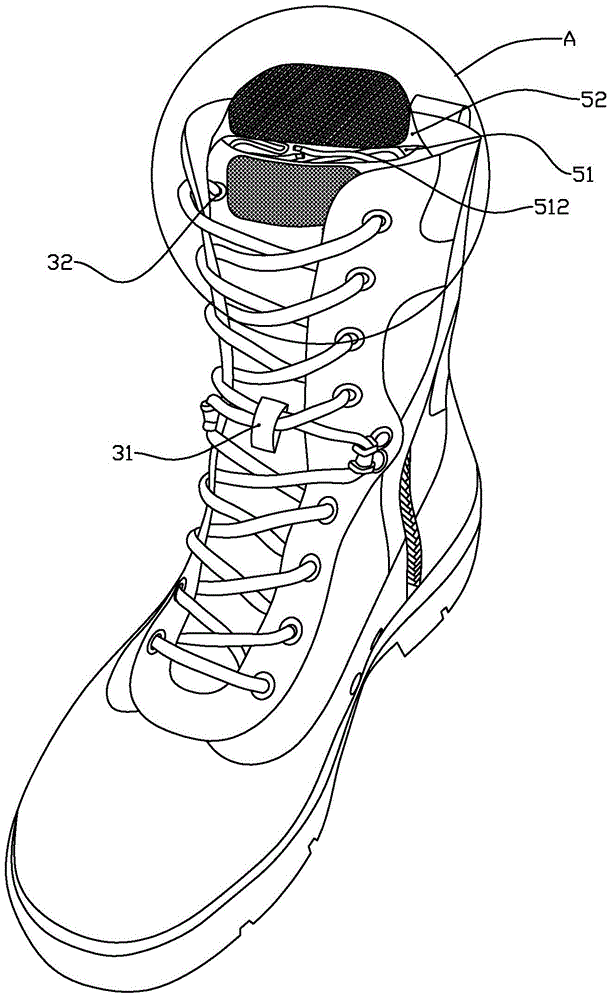

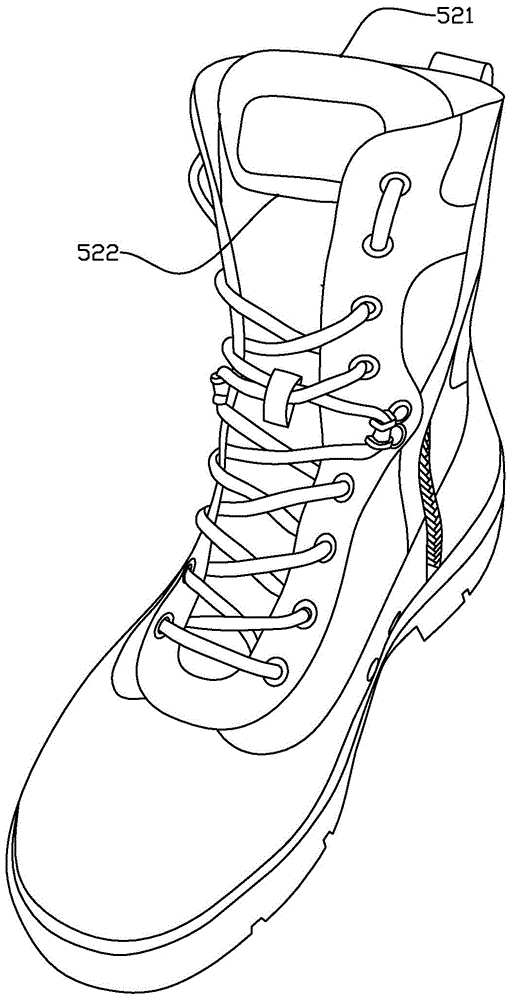

Shoelace concealment structure, shoe tongue with shoelace concealment structure and shoe with shoelace concealment structure

InactiveCN104939435APrevent invaginationSimple structureShoe lace fasteningsUpperSurface layerShoe laces

The invention discloses a shoelace concealment structure. The shoelace concealment structure comprises a storage pocket. The storage pocket is arranged on a shoe tongue and provided with a sealing structure, the sealing structure comprises a sealing layer, the sealing layer is detachably and fixedly connected with a pocket surface layer of the storage pocket and comprises a connecting end and a free end, the connecting end is sewn on the shoe tongue, the sealing layer is arranged at the open end of the storage pocket in a covering mode, the free end extends downwards from the open end to cover the pocket surface layer, and the pocket surface layer and the free end are connected through a hook and loop fastener or a zipper structure. The shoelace concealment structure is simple, novel in design, simple and elegant in appearance and suitable for a low-upper or high-upper lace-up shoe; the two free ends of a shoelace of the shoe penetrate through shoe holes in the upper or positioning holes in the shoe tongue in sequence and then are located in the storage pocket, then the opening of the storage pocket is closed through the sealing structure so that the free ends of the shoelace or a shoelace knot will not fall out of the storage pocket, and the phenomenon of treading or stumbling caused when the shoelace knot is loose or hooks debris is avoided.

Owner:郑颖博

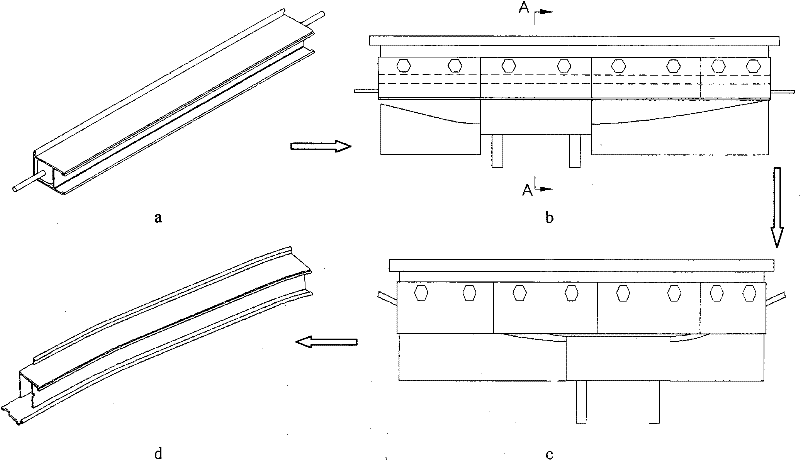

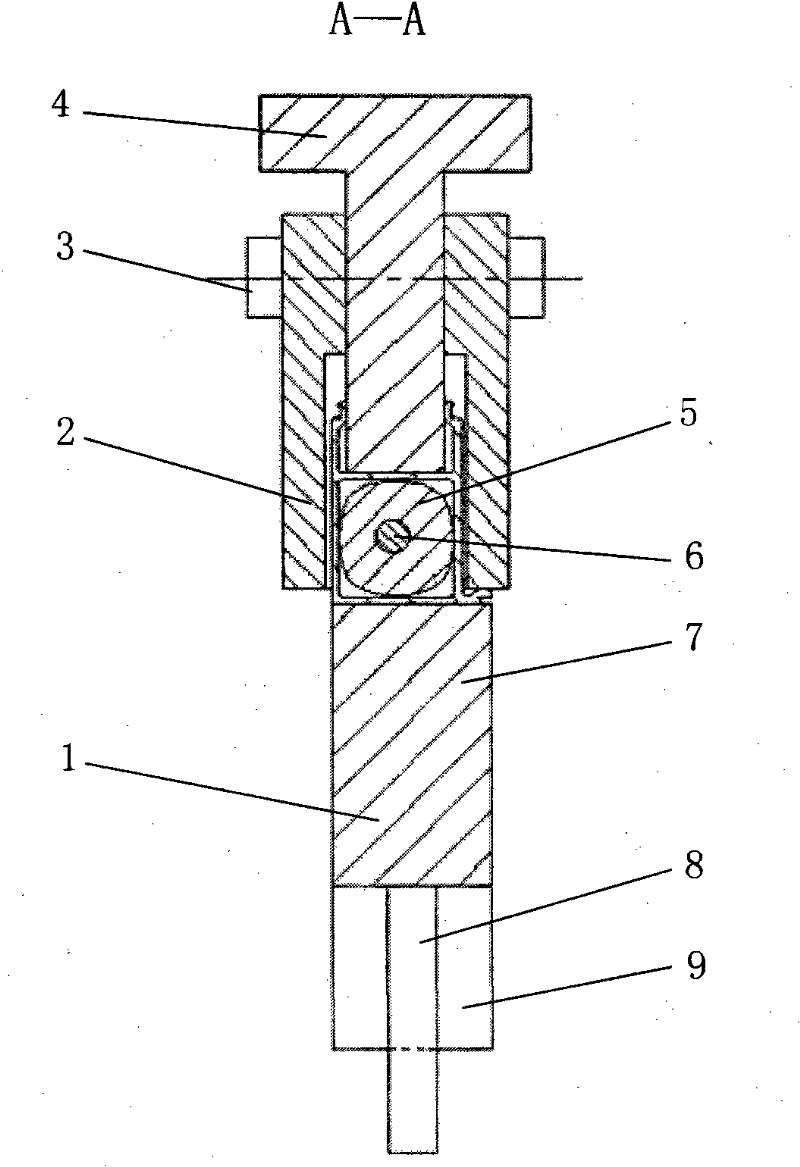

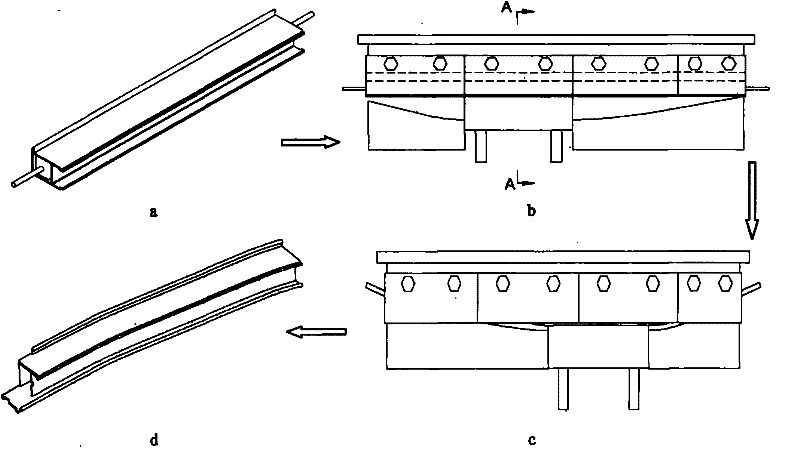

Method for forming aluminum alloy end wall column member for new-generation high-speed motor train unit

The invention relates to a method for forming an aluminum alloy end wall column member for a new-generation high speed motor train unit, belonging to the technical field of bending and forming. In the invention, a die profiling method is adopted and mainly comprises the following steps of: a, filling a cavity; b, positioning a section bar; c, profiling; and d, post-treating. The method specifically comprises the following steps: firstly, filling a continuous chaplet in the lower cavity of the section bar; then starting a hydraulic machine, raising a line segment of a lower die under the action of an ejector rod, horizontally placing the section bar on the line segment of the lower and dropping an upper die slowly so that the section bar is sandwiched between the upper die and the lower die; and then profiling: bending and deforming the section bar so that the section bar gradually fits on the section surface of the lower die, stopping the hydraulic machine, and maintaining a compaction state for a while so that the shape is stable; and finally, taking the section bar out, cutting off allowances at the two ends of the section bar, machining other geometrical characteristics, correcting parts, and clearing the surface so as to obtain the complete end wall column member. By the method, the problems existing in the forming process of the end wall column member of the motor train unit body, such as large section distortion, longitudinal profile size errors and the like, are solved, and the forming precision is improved.

Owner:JILIN UNIV

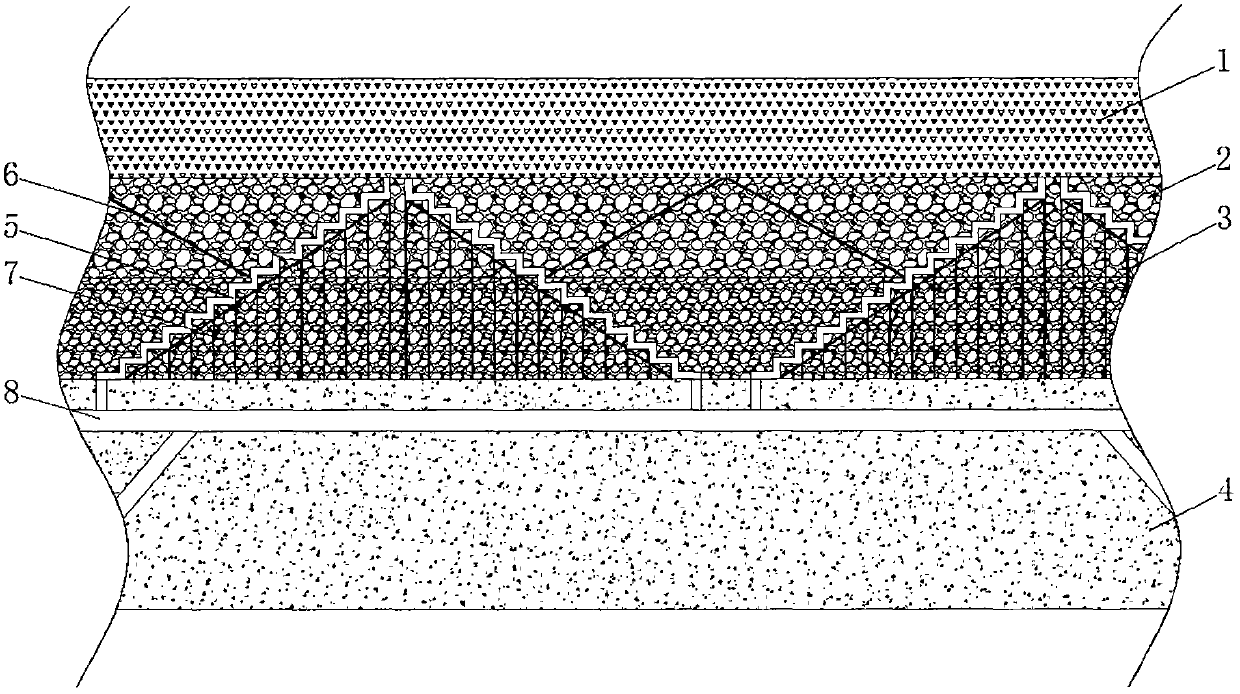

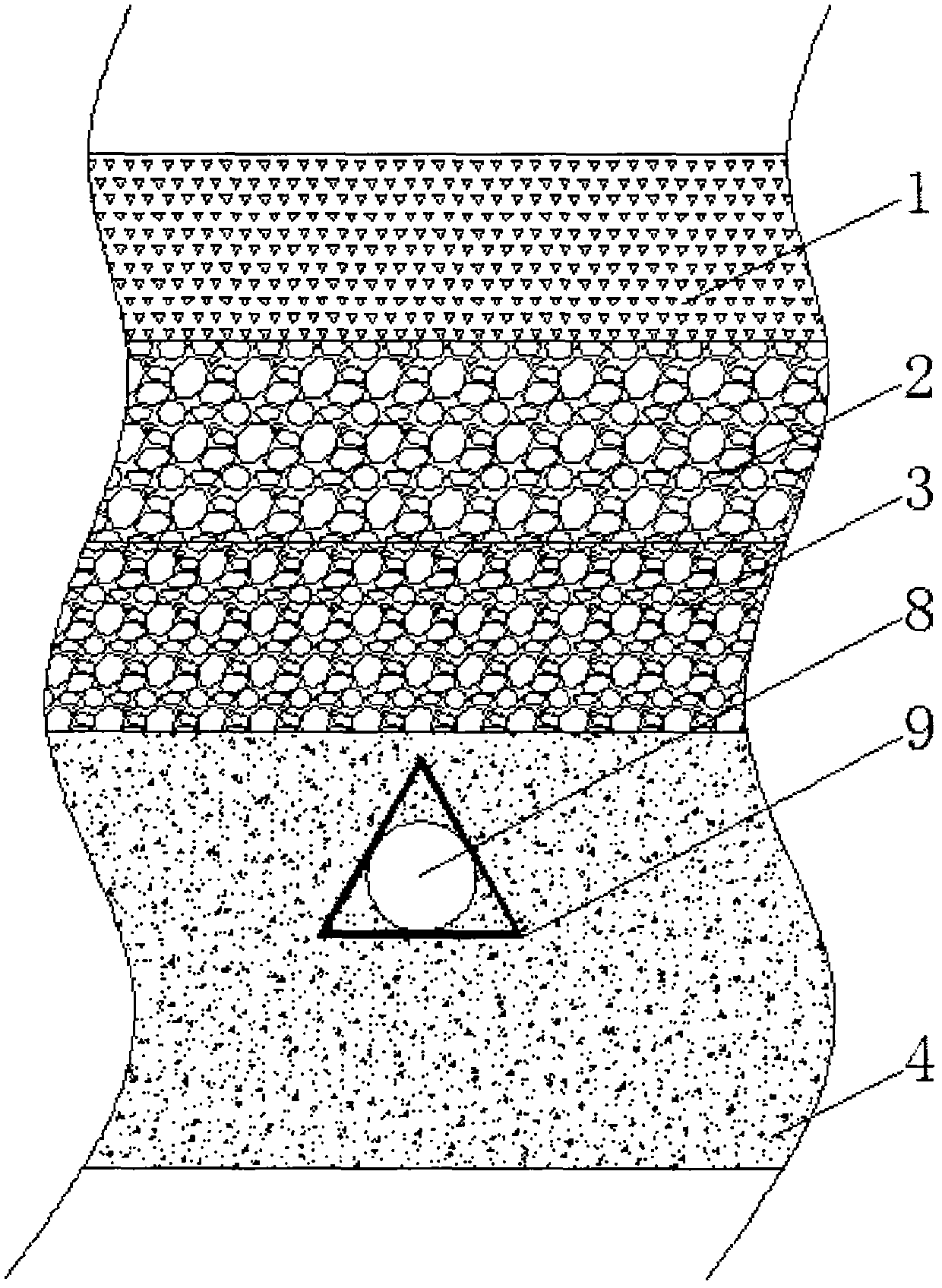

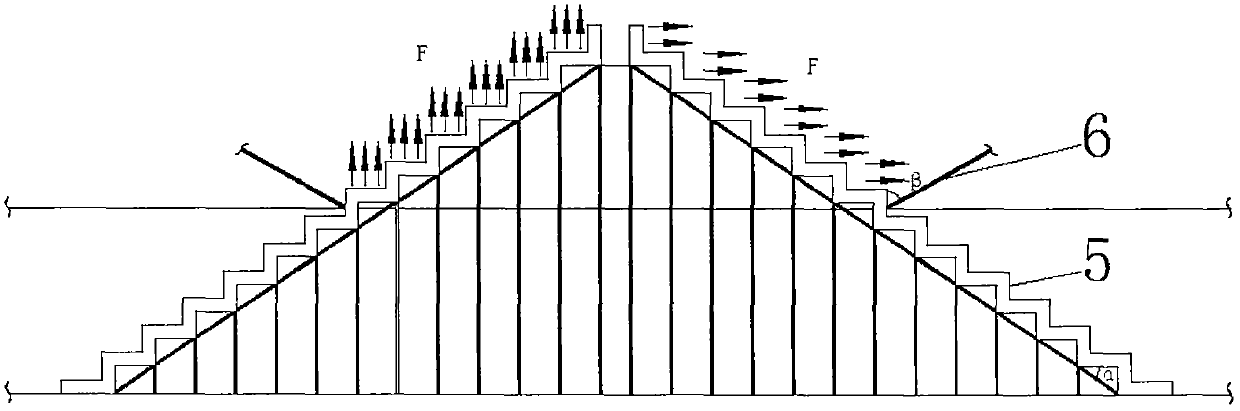

A permeable asphalt concrete structure and its construction method

The invention relates to the technical field of road engineering and discloses a pervious asphalt concrete structure. The pervious asphalt concrete structure comprises a pervious asphalt concrete layer and a pervious cement concrete layer; an airflow dispersion layer is laid between the pervious asphalt concrete layer and the pervious cement concrete layer; an airflow air drying layer is laid at the bottom of the pervious cement concrete layer; a plurality of groups of step type air dispersion pipelines are arranged in the airflow dispersion layer in the transverse direction in the form of a straight line; the step type air dispersion pipelines extend into the pervious cement concrete layer to be in contact with the airflow air drying layer; air guide plates are in contact with both left and right edges of each group of step type air dispersion pipelines in the airflow dispersion layer; and the two adjacent groups of air guide plates form a triangle together with the pervious cement concrete layer. According to the pervious asphalt concrete structure, the problem that roads are slippery and icy because water on pavements cannot be effectively removed in rainy seasons and continuouscloudy and rainy weathers in the prior art is solved; the pavements can be rapidly air-dried to avoid slipping of pedestrians and vehicles so that traffic accidents are avoided.

Owner:HUANGHUAI UNIV +1

Flat heat pipe with nested porous liquid-absorbing core and manufacturing method thereof

InactiveCN104534906BRaise the capillary limitShorten return pathIndirect heat exchangersVapor liquidCapillary pressure

The invention provides a panel heat pipe with an embedded porous wick and a manufacturing method thereof. The panel heat pipe comprises an upper metal cover plate, a lower metal cover plate, and a closed cavity is formed between the upper metal cover plate and the lower metal cover plate in a welded and sealed mode. The cavity is filled with liquid working media. The inner surface of the cavity is divided into an evaporation face and a condensation face. The condensation face and the evaporation face are paved with a thin-layer porous wick structure formed by sintering metal powder particles. Sintering porous columns with inner grooves which are distributed in an array mode are machined on the evaporation face. Porous protrusions matched with the inner grooves are machined in the condensation face. The sintering porous columns and the porous protrusions are in close fit to form an embedded porous structure column. A working medium backflow channel is formed in the embedded porous structure column. According to the panel heat pipe, the capillary pressure is improved, the working medium backflow speed is remarkably increased, vapor-liquid two-phase separation is achieved, and the heat transfer performance is greatly improved; meanwhile, the embedded wick plays a supporting column role, and panel heat pipe inward sinking or crack deformation or other problems are effectively avoided.

Owner:XIAMEN UNIV

A kind of preparation method of silicon dioxide coated microcapsule of essential oil

ActiveCN103263877BGranular strongSmall particlesMicroballoon preparationMicrocapsule preparationColloidOil phase

The invention discloses a preparation method of an essential oil-contained silicon dioxide microcapsule, which comprises the following steps: evenly mixing essential oil, a silicon dioxide precursor and co-emulsifier to obtain an oil phase mixed solution; adding acid into a silicon dioxide water dispersion solution until the pH value is regulated to 4.5-5.7, mixing with the oil phase mixed solution, and performing ultrasonic dispersion to obtain a fine emulsion; and performing closed reaction on the fine emulsion at 10-60 DEG C for 1-6 hours to obtain a colloid emulsion of the essential oil-contained silicon dioxide microcapsule. According to the invention, the liquid essential oil is contained in a hard shell of silicon dioxide; the preparation process is quick, convenient, clean and pollution-free; the essential oil-contained silicon dioxide microcapsule is small in particle size, high in structural strength and favorable in water-phase dispersibility; and the release performance adjustable range of the essential oil contained in the microcapsule is large. The preparation method disclosed by the invention is suitable for industrial large-scale production.

Owner:义乌市中力工贸有限公司

Sealed waterproof jacking mechanism of movable bearing seat

ActiveCN112677005APlay a waterproof rolePrevent intrusionGrinding wheel securing apparatusGrinding machinesEngineeringStructural engineering

The invention discloses a sealed waterproof jacking mechanism of a movable bearing seat. The sealed waterproof jacking mechanism comprises a working roller seat, a sliding rail seat. a sliding block, a protection cover, a locking block and a power source. The movable bearing seat is arranged at one end of the working roller seat. The sliding rail seat is arranged below the working roller seat, and a sliding groove is formed below the sliding rail seat. The sliding block is arranged below the sliding rail seat and connected with the sliding groove in a sliding manner, and the movable bearing seat is installed on the sliding block. The protection cover is arranged around the sliding rail seat and comprises a front baffle, a rear baffle, a left baffle, a right baffle and a lower baffle, and a hollow cavity is defined among the front baffle, the rear baffle, the left baffle, the right baffle, the lower baffle and the sliding rail seat. The locking block is inserted between the sliding block and the sliding rail seat, and the sliding block and the sliding rail seat are locked by pushing the locking block through slope extrusion fit. The power source is provided with a push rod, and the push rod is located in the cavity of the protection cover. The push rod acts on the locking block and the sliding block so as to drive the locking block and the sliding block to move forwards along the sliding rail seat together and to be kept at the preset position. The protection cover not only plays a waterproof role on the push rod, but also plays a waterproof role on the slide rail seat.

Owner:ZHEJIANG MOPPER ENVIRONMENTAL TECH CO LTD

Combination cap, double-valve upright infusion bag and preparation method thereof

ActiveCN104287965BLarge retraction forcePrevent slidingPharmaceutical containersMedical packagingColloidSyringe needle

The invention provides a combination cap, a double-valve upright infusion bag and a preparation method thereof. The combined cover includes an outer cover (1), an inner cover (2) and a gasket (3) arranged between the inner cover (2) and the outer cover (1). The gasket (3) is an integrated design, including part Two overlapping circular parts, the two circular parts are combined to form a butterfly shape, the top of the outer cover (1) is provided with an opening boss (4), and the inner side of the opening boss (4) is provided with a gasket (3) Matching slots. According to the combination cap of the present invention, the gasket can provide greater retraction force, so that the colloid of the gasket can hold the needle tightly without leakage, and the design is reasonable, safe and reliable. The double-valve stand-up bag infusion package is controlled by dual valves in the dosing and infusion channels, which can reduce disinfection and pollution, and there is no need for air intake during infusion, and it automatically shrinks, which can avoid secondary pollution and make dosing more convenient.

Owner:SHIJIAZHUANG NO 4 PHARMA +1

Self-adhesive long-acting slow-release essential oil microcapsule and preparation method and application thereof

ActiveCN102746450BEasy to attach evenly and firmlyImprove structural strengthFibre treatmentMicroballoon preparationFiberIce water

The invention discloses a self-adhesive long-acting slow-release essential oil microcapsule and a preparation method and an application thereof. The method comprises the following steps of: uniformly mixing essential oil, a reaction monomer, an auxiliary emulsifying agent, oil-soluble initiator and a newly-added oil-soluble crosslinking agent to obtain an essential oil / monomer mixed solution; adding an aqueous solution of an emulsifying agent; pre-emulsifying in a shearing and stirring state for 10-20 minutes; performing ultrasonic dispersion in an ice-water bath to obtain a fine emulsified liquid; and performing a polymerization reaction on the fine emulsified liquid in a nitrogen atmosphere in a shearing and stirring state at the temperature of 65-70 DEG C for 3-6 hours, and cooling after finishing reaction to obtain self-adhesive long-acting slow-release essential oil microcapsule rubber latex. The preparation method has the advantages of ready availability of raw materials, simple process, high good controllability over the morphological structure of the microcapsule, no relevance to organic solvents and suitability for industrial production; and the prepared microcapsule has high structural strength, a good slow release effect, and high self-adhesive properties on substrates such as fibers and the like. The invention further discloses a self-adhesive long-acting slow-release essential oil microcapsule and an application thereof.

Owner:HANGZHOU WENSLI SILK DIGITAL PRINTING CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com