Autonomous segmentation method of large-scale complex curved surface robot automatic surface machining

A complex surface and surface processing technology, applied in the direction of instruments, simulators, computer control, etc., to avoid indentation or closed-angle features, reduce the need for manual adjustment, and ensure the uniformity of processing thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

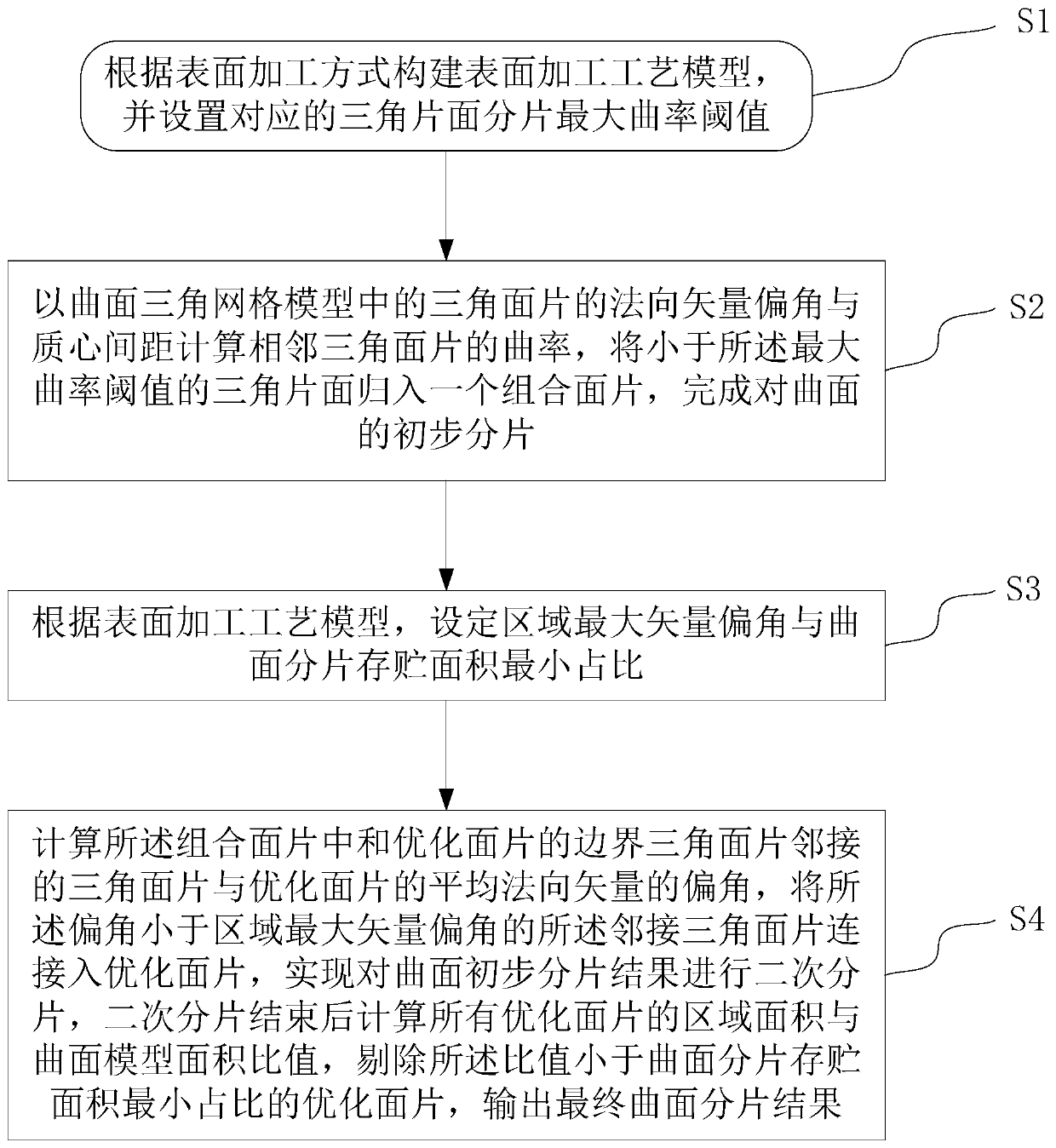

[0046] like figure 1 As shown, the present invention provides a method for autonomously slicing curved surfaces in a large-scale complex curved surface robot automated surface processing process, comprising the following steps:

[0047] S1. Construct a surface processing technology model according to the surface processing method, and set the corresponding maximum curvature threshold of the triangular one-sided slice.

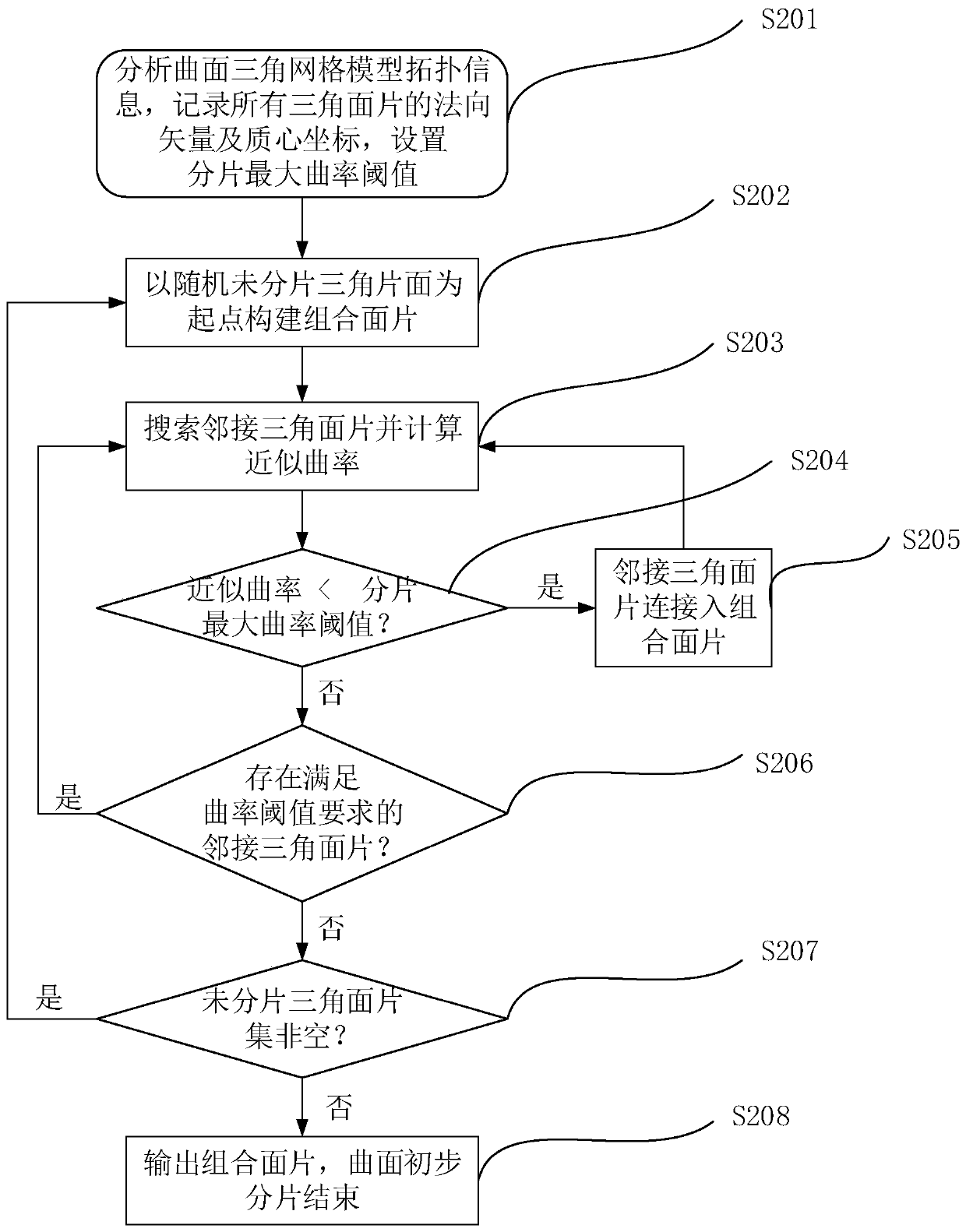

[0048]S2. Calculate the curvatures of adjacent triangular patches based on the normal vector declination of the triangular patches in the surface triangular mesh model and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com