A permeable asphalt concrete structure and its construction method

A technology of permeable concrete and concrete structure, which is applied to the coagulation pavement, roads, buildings and other directions of on-site paving, can solve the problems of not being able to effectively remove road moisture, icing, road slippery, etc. Penetration effect, the effect of increasing the air-drying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

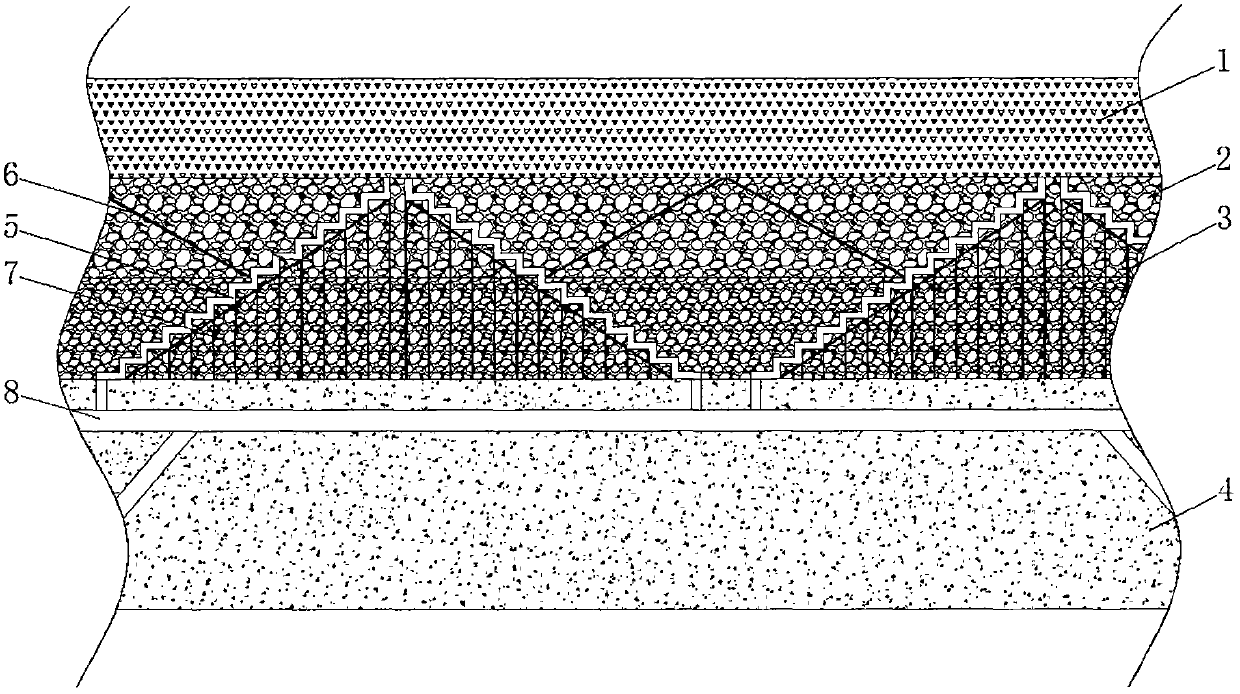

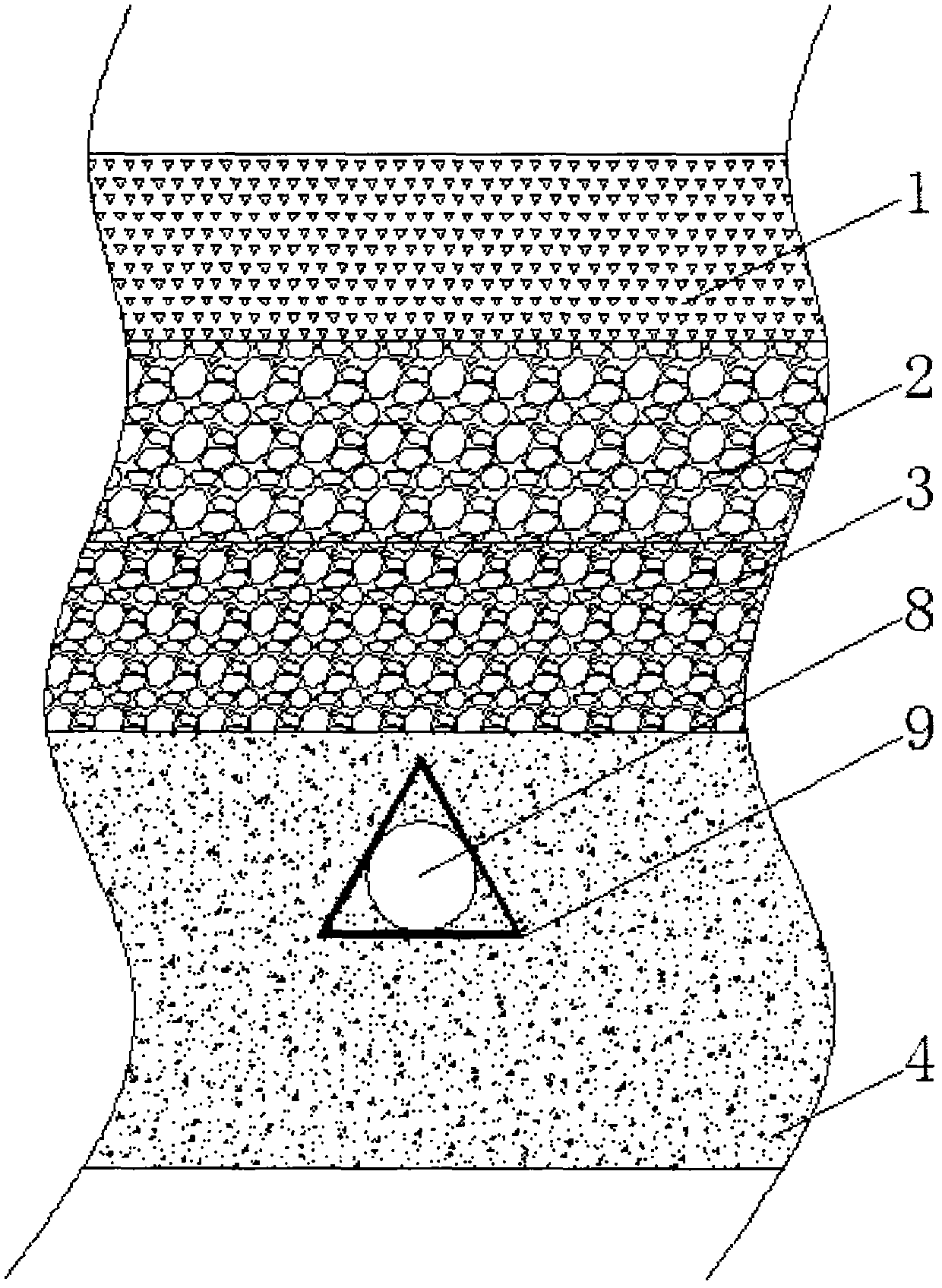

[0034] Such as Figure 1-2 Shown, a kind of permeable asphalt concrete structure, comprises asphalt permeable concrete layer 1 and cement permeable concrete layer 3, is laid with a layer of airflow divergence layer 2 between asphalt permeable concrete layer 1 and cement permeable concrete layer 3, cement permeable concrete layer 3 A layer of air-drying air-drying layer 4 is laid on the bottom, and several groups of stepped air-diffusing ducts 5 are arranged horizontally and linearly in the air-diffusing layer 2, and the stepped air-diffusing ducts 5 extend into the cement permeable concrete layer 3 and are in contact with the air-drying air-drying layer 4 , the left and right sides of each set of stepped air-diffusing ducts 5 in the air-flow diverging layer 2 are in contact with the air guide plates 6, and the adjacent two sets of air guide plates 6 form a triangle with the cement permeable concrete layer 3, and each set The right angles at the bottom of the stepped air-disper...

Embodiment 2

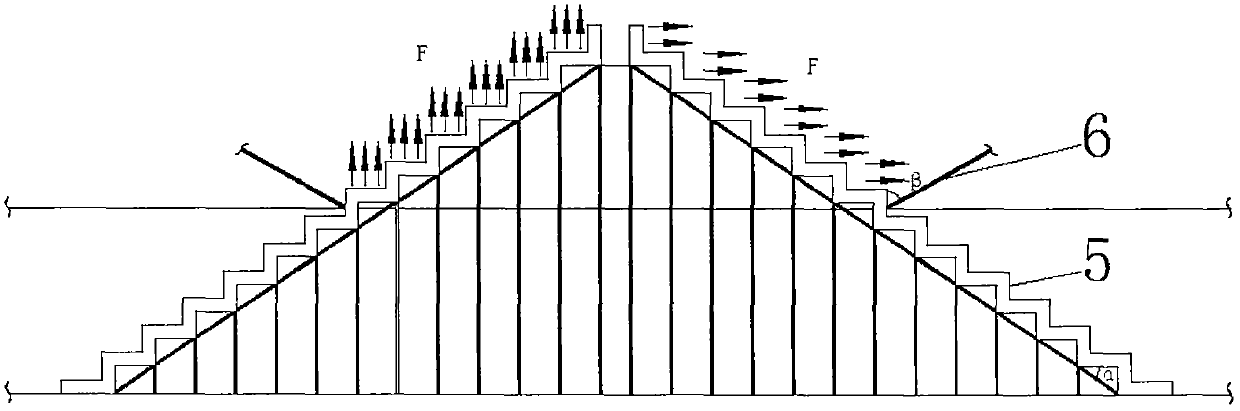

[0036] On the basis of Example 1, such as image 3 As shown, the air guide direction of the air guide plate 6 is based on the plane of the cross section, and the air guide area is based on the area of the air guide plate 6 . Preferably: the included angle between the air guide plate 6 and the direct contact side of the stepped air diffuser duct 5 is 60°-80° based on the plane of the cross section.

Embodiment 3

[0038] On the basis of Examples 1 and 2, such as image 3 As shown, the individual channel surfaces of the stepped air diffusion ducts 5 in the air distribution layer 2 are all provided with wide openings, and the air flow direction formed by the wide openings is consistent with the air guide direction of the air guide plate 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com