Sand filling method compaction detection system and detection method

A detection system and detection method technology, applied in the direction of measuring devices, specific gravity measurement, instruments, etc., can solve the problems of long time spent on manual digging, high compactness of roadbed soil layer, sedimentation, etc., and achieve the effect of improving excavation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0057] A method for detecting the degree of compaction by sand filling method, comprising the following steps:

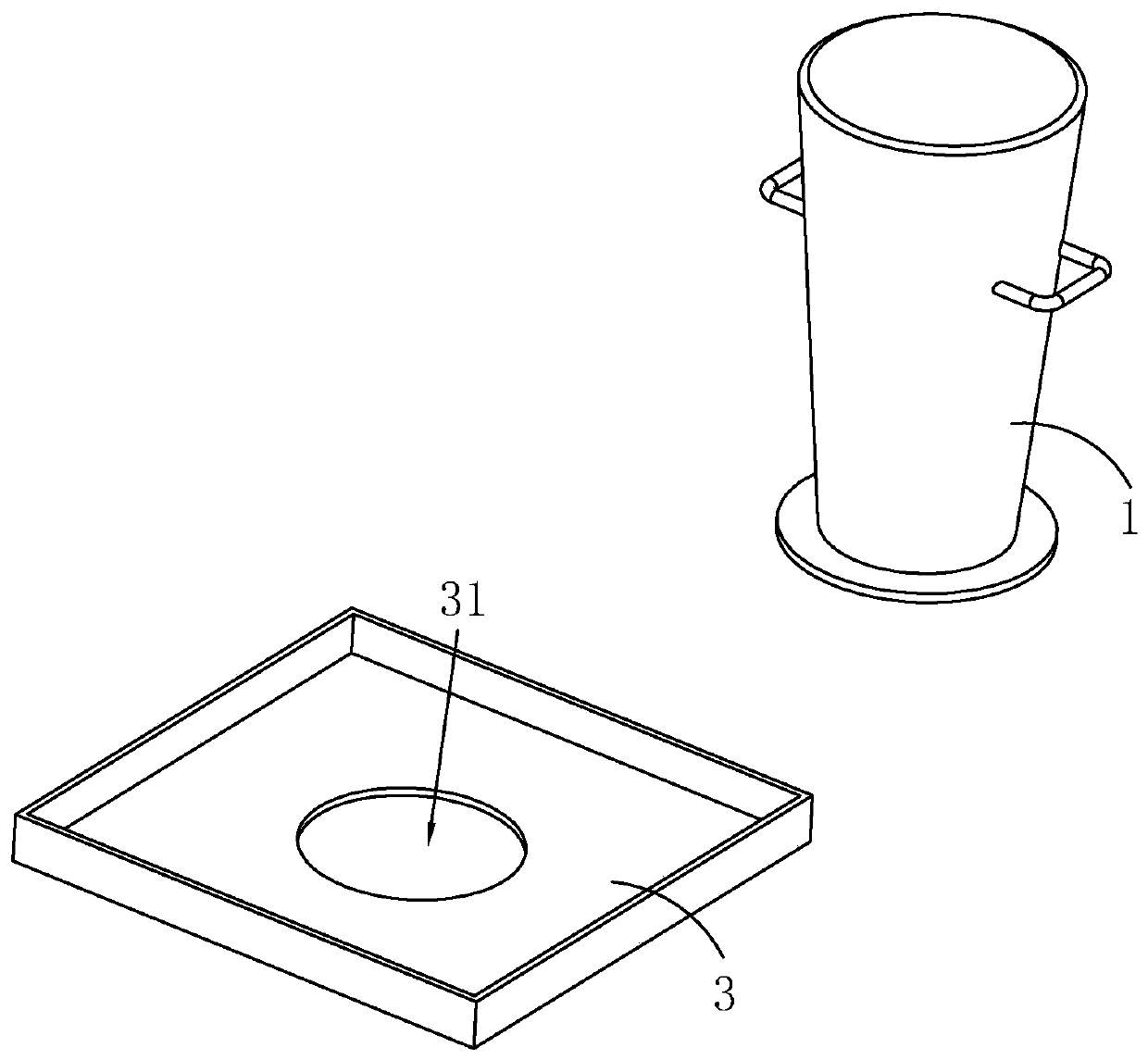

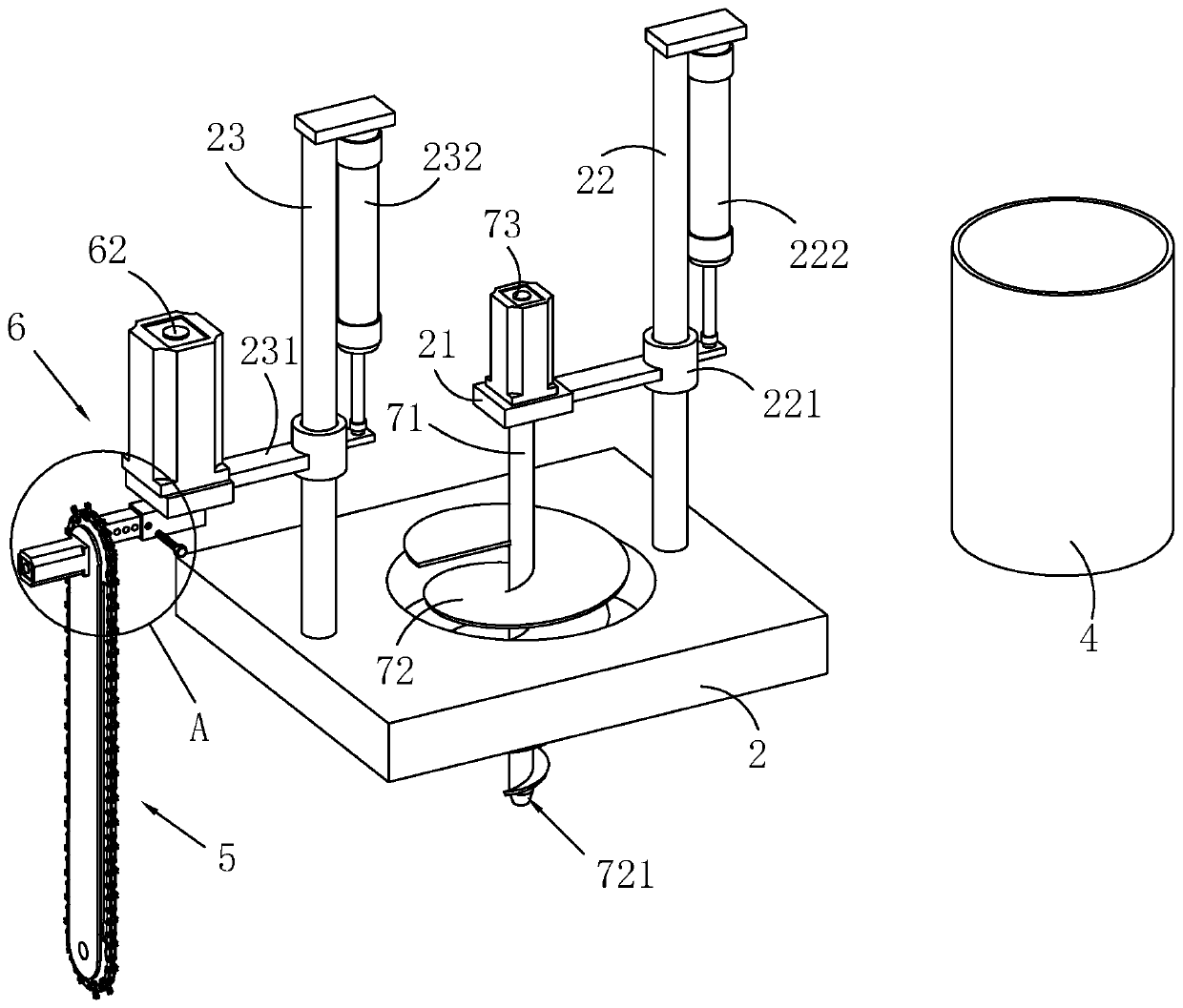

[0058] S1, select the sampling site, and mark it with a line, and place the soil collection box 3 at the mark;

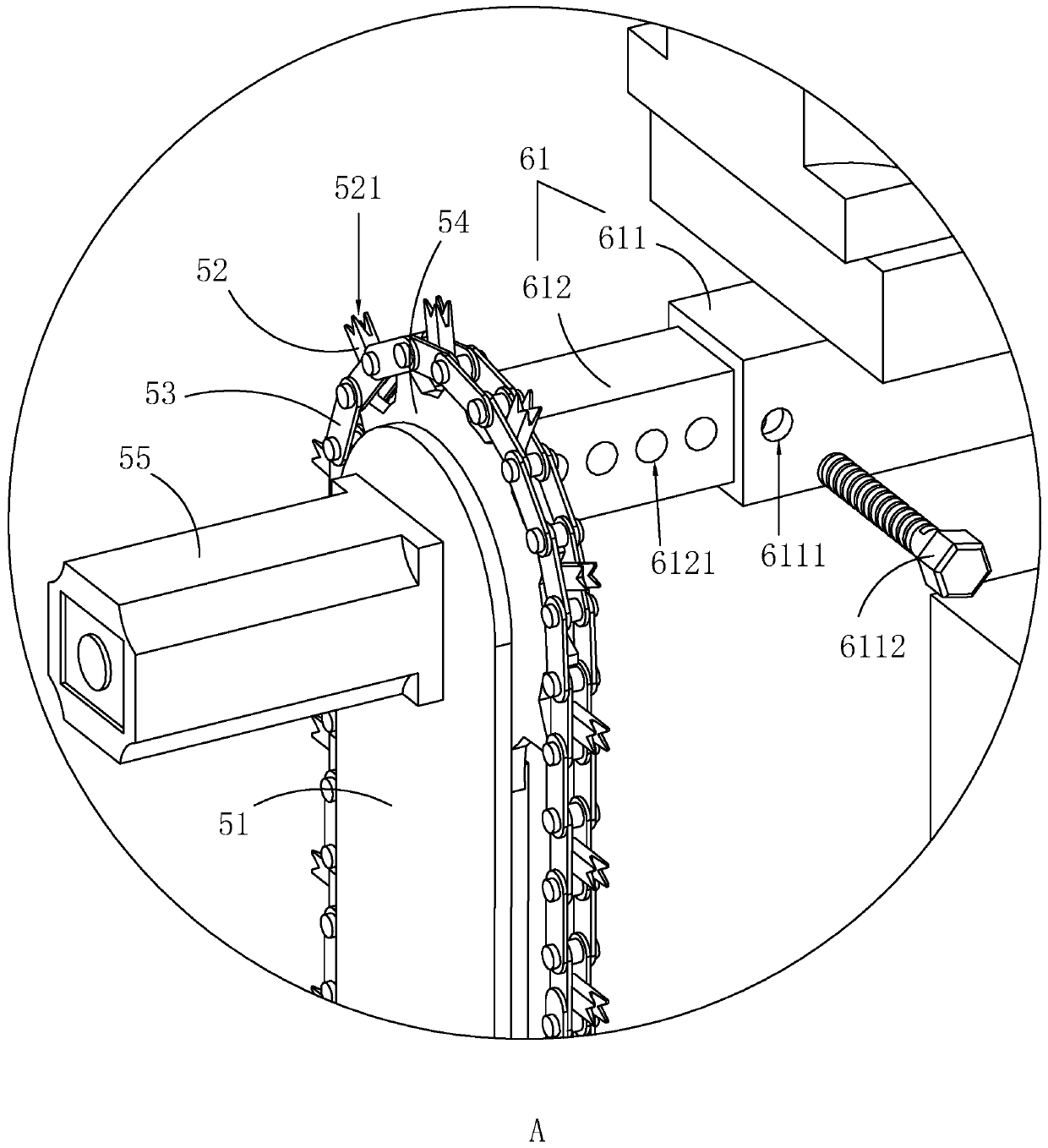

[0059] S2, drive the cutting assembly 5 to move around the round hole 31 of the soil collection box 3 through the driving assembly 6, so that the cutting assembly 5 cuts a cylindrical cutting seam on the foundation, and the depth of the cutting seam reaches the bottom of each compacted layer;

[0060] S3. Insert the casing 4 into the cutting seam. When the insertion is difficult, tap the top wall of the casing 4 with a hammer until the insertion depth of the casing 4 is equal to the depth of the cutting seam;

[0061] S4, excavating a hole and taking soil, digging out the soil in the casing 4 into the soil collecting box 3 through the excavating component to form a cylindrical foundation hole;

[0062] S5. Take out the casing 4, clean the soil at the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com