Circuit board of power amplifier and manufacturing method of circuit board

A technology for power amplifiers and manufacturing methods, which is applied in the direction of circuit substrate materials, printed circuit components, electrical connection printed components, etc., can solve the problems of affecting ground impedance, high scrap rate, and increasing costs, so as to shorten the return path and reduce loss, the effect of good thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The power amplifier circuit board provided by the embodiment of the present invention can be applied to a radio base station or a high-speed transmission line such as an optical module. By adopting the integrated structure of PCB and substrate, using the substrate as the signal return path and at the same time for heat dissipation, while shortening the signal return path, it also takes into account good heat dissipation performance and reduces loss.

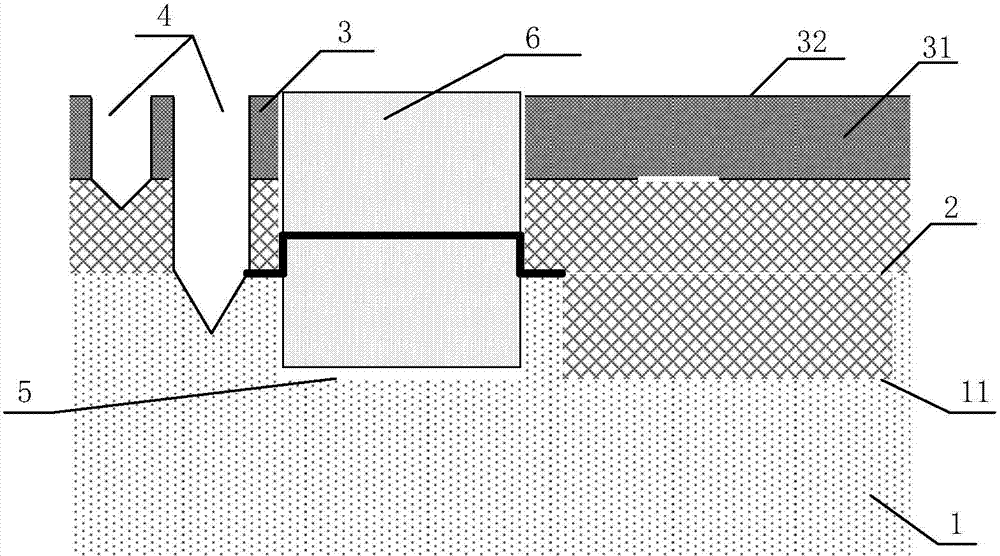

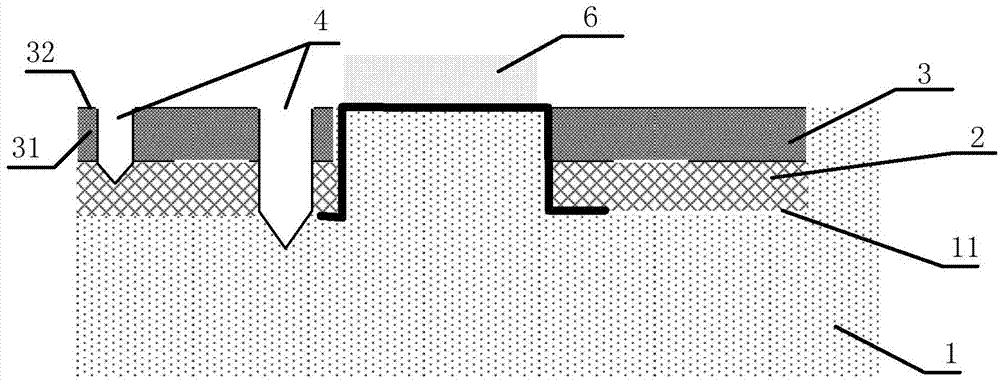

[0043] figure 1 It is a schematic diagram of a power amplifier circuit board provided by Embodiment 1 of the present invention. As shown in the figure, the power amplifier circuit board includes: a substrate 1 , an insulating medium layer 2 , a printed circuit board 3 , a blind hole 4 and a sunken groove 5 .

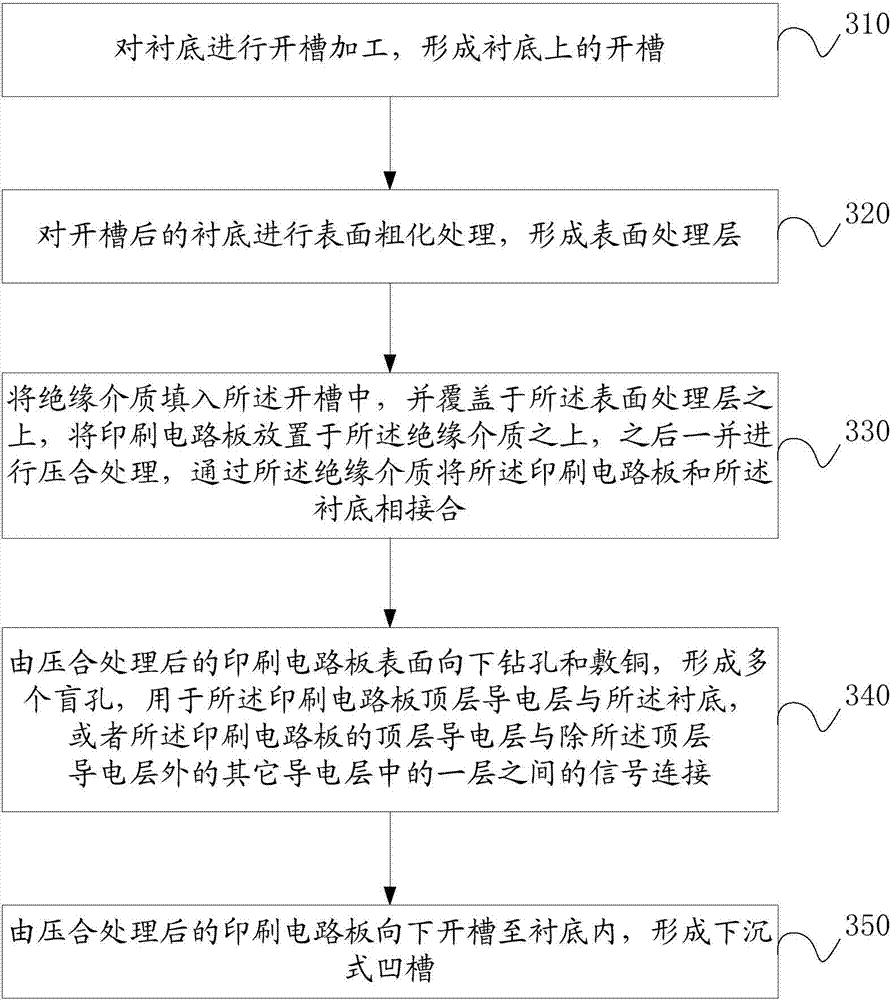

[0044] The substrate 1 has grooves 11, specifically, the grooves 11 with different depths can be formed by etching or machining. A surface treatment layer (not shown in the figure) is formed on the upper surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com