Multifunctional hydraulic track forging manipulator

A forging manipulator and multi-functional technology, applied in forging/pressing/hammering machinery, manufacturing tools, forging/pressing/hammer devices, etc., can solve problems such as workers are prone to danger, pliers rods cannot be retracted, and working conditions are poor , to achieve the effect of shortening the auxiliary time, expanding the working range and reducing the loss of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

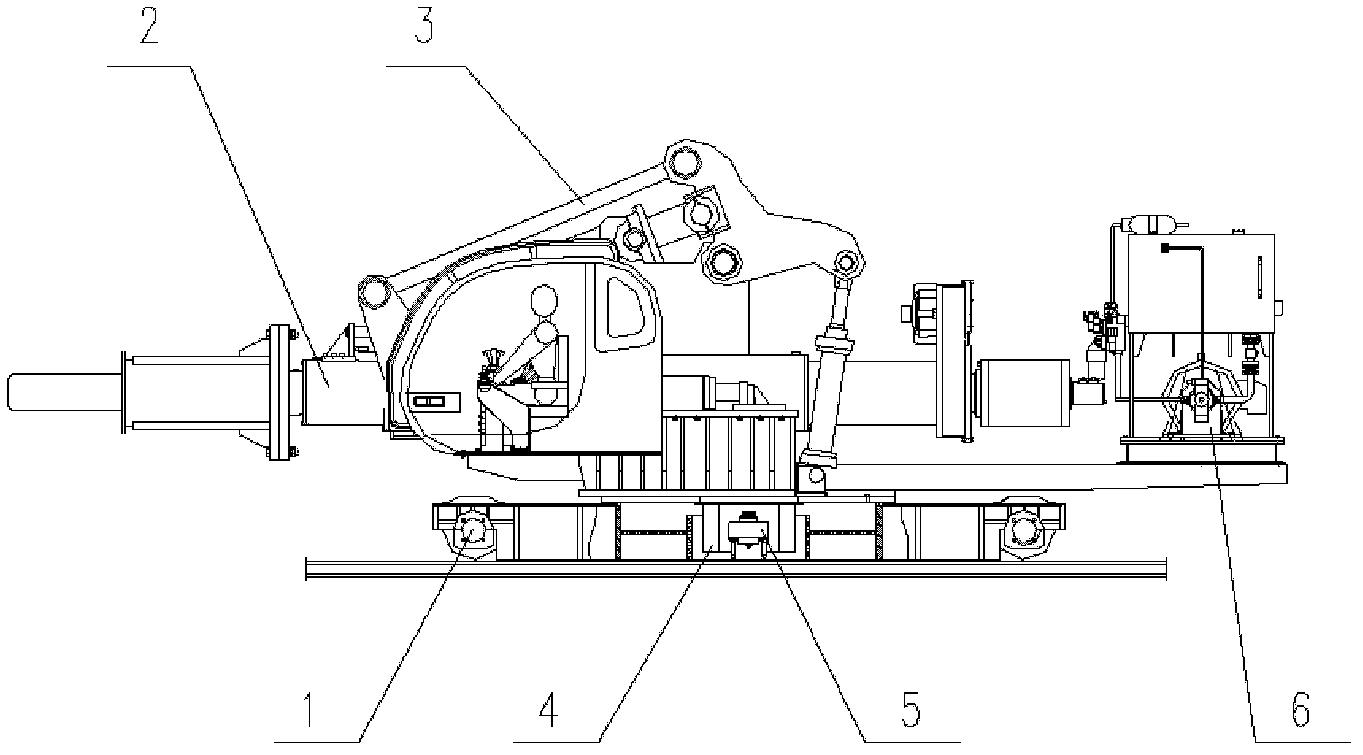

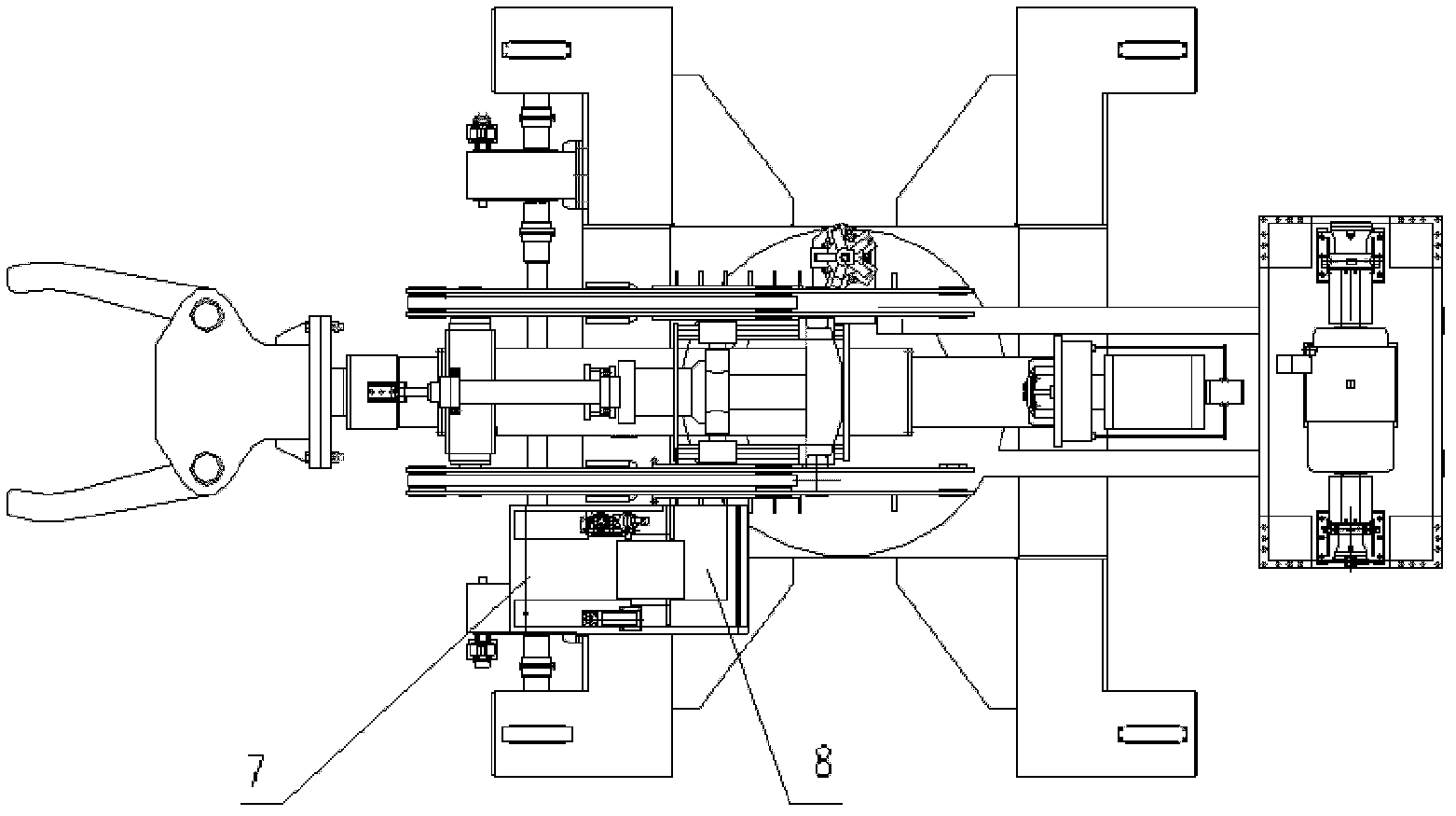

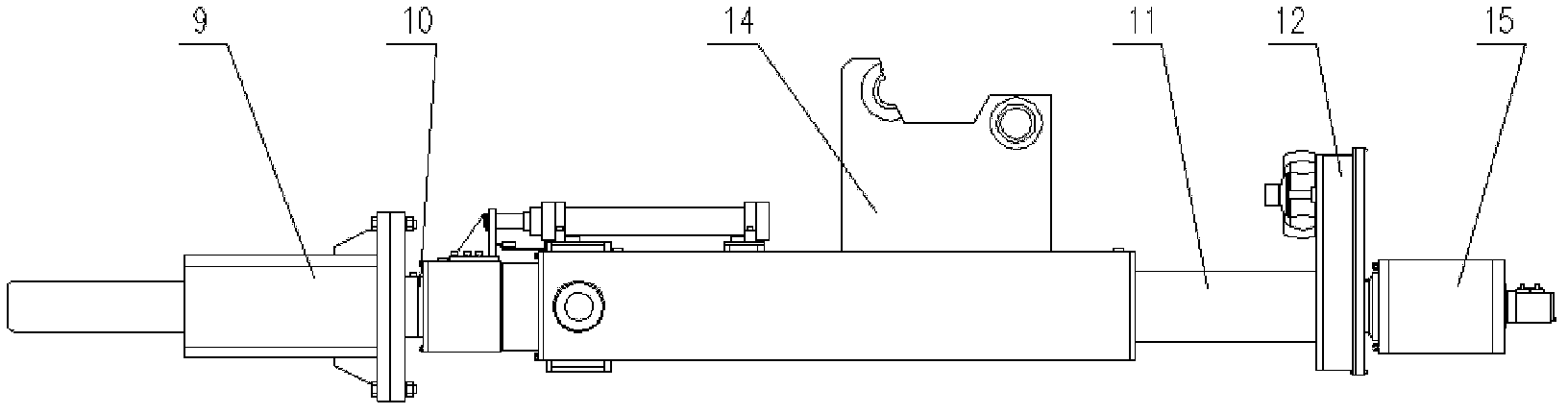

[0023] refer to figure 1 and figure 2 , a hydraulic multifunctional rail forging manipulator, comprising a car body running device 1, the car body running device 1 is connected with the inner ring of the slewing bearing 31 through bolts, the outer ring of the slewing ring 31 is connected with the four-bar linkage mechanism 3, and the four The connecting rod mechanism 3 is located at the upper center of the vehicle body running device 1, the four-bar linkage mechanism 3 and the clamp frame device 2 are connected by pins to form an integral part, and the vehicle body running device 1 supports the entire four-bar linkage mechanism 3 and the clamp frame Device 2, the rotary oil joint 4 is connected to the bottom plate of the vehicle body running device 1 through bolts and hydraulic hoses, the conductive slip ring 5 is installed on the vehicle body running device 1 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com