Loading and unloading flexible mechanical gripper for forging

A technology for manipulators and forging, applied in forging/pressing/hammering machinery, manufacturing tools, forging/pressing/hammer devices, etc., can solve problems such as high manufacturing cost, poor adaptability of forged parts, complex mechanical structure, etc. Low cost, high strength and rigidity, simple control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

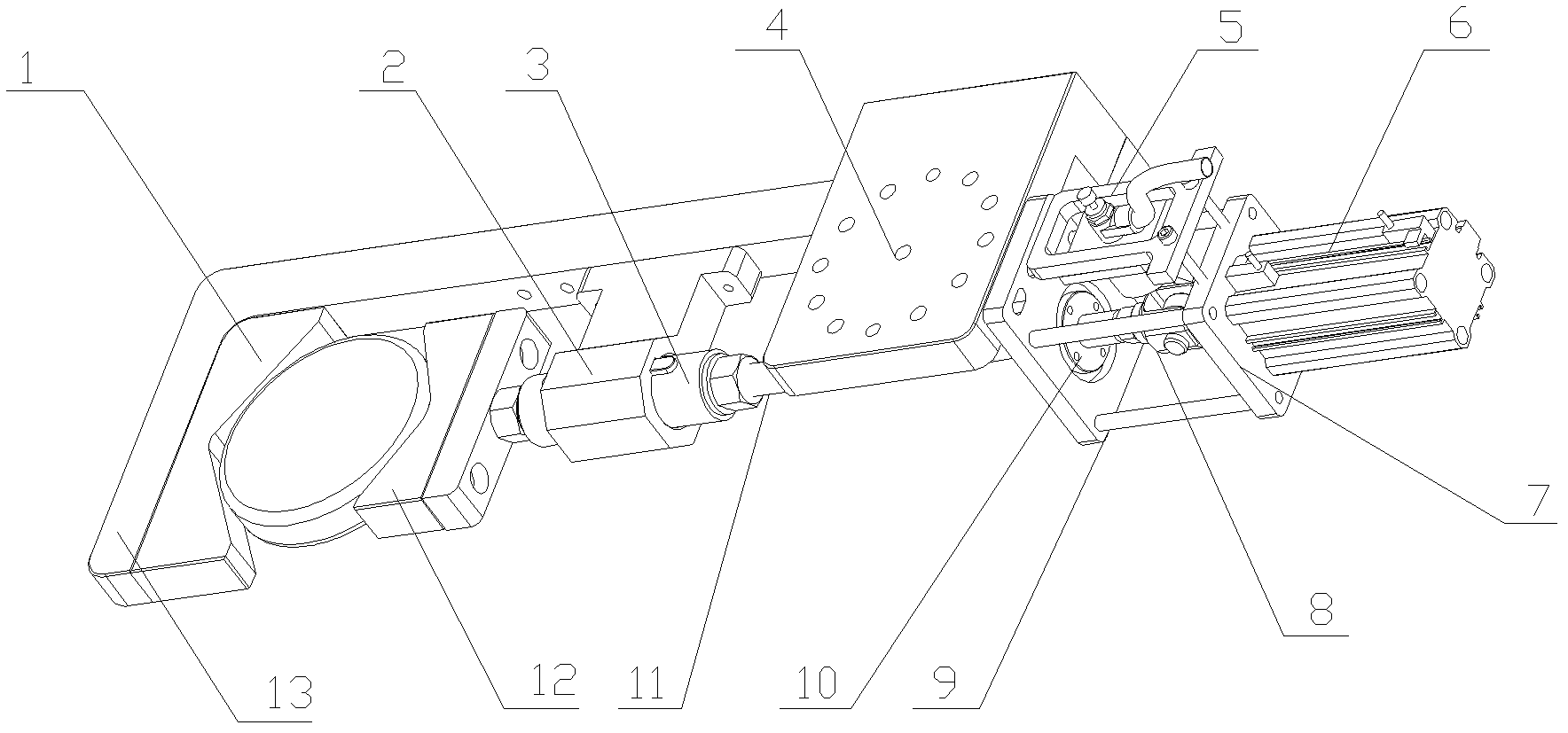

[0011] In order to make the purpose, technical solution and advantages of the present invention clearer, the flexible manipulator grip for loading and unloading for forging of the present invention will be described in detail below with reference to the accompanying drawings.

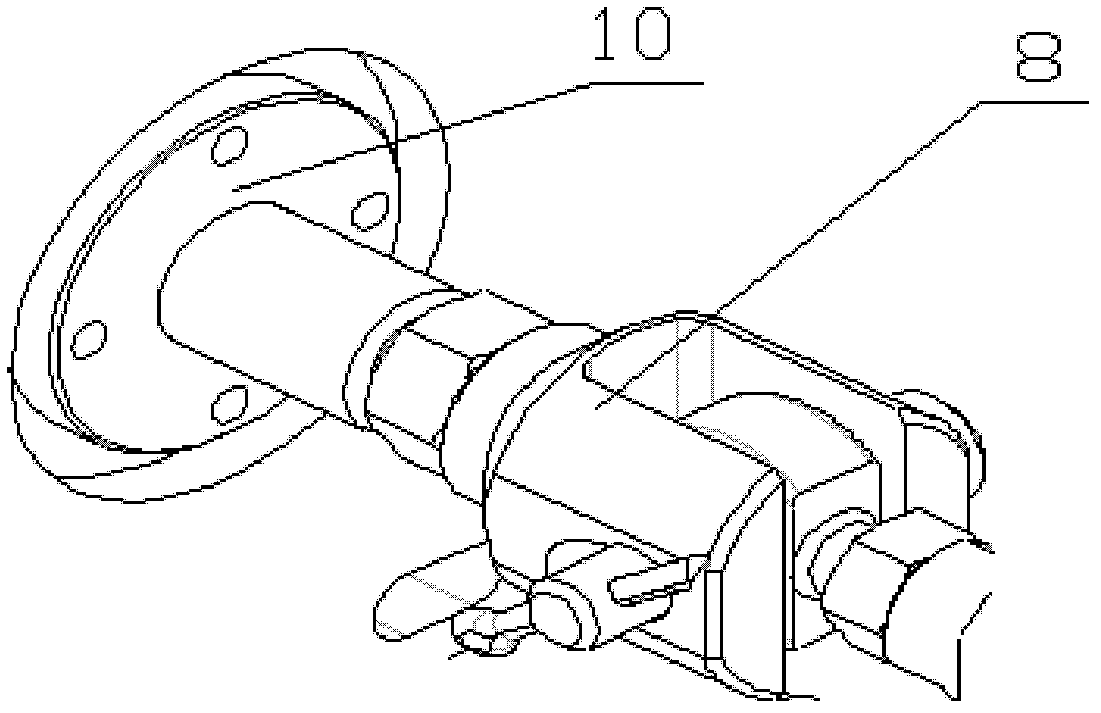

[0012] See figure 1 , figure 2 and image 3 According to the present invention, a flexible manipulator for loading and unloading for forging has a forging manipulator fixing seat 13, and the above-mentioned forging manipulator fixing seat is provided with a hand grasping assembly and a driving assembly. The above-mentioned hand grasping assembly includes a fixed mechanical gripper 1, a mobile mechanical gripper 12 and an optical axis push rod 11 fixed at the end of the forging manipulator fixing seat. claw connection.

[0013] The above-mentioned drive assembly includes a cylinder 6 and a cylinder seat 7. The cylinder 6 is used to drive the optical axis push rod to move, and then push the mobile me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com