Front and back lifting hydraulic system for energy-saving forging manipulator

A forging manipulator and hydraulic system technology, applied in forging/pressing/hammer device, forging/pressing/hammering machinery, mechanical equipment, etc., can solve the problems of synchronous drive and energy waste, and improve speed and energy saving , synchronous control for simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and examples of implementation.

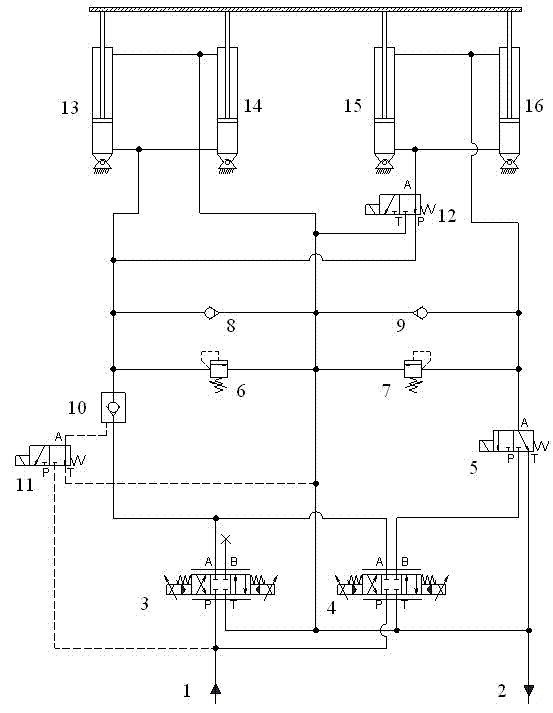

[0013] Such as figure 1 As shown, the P port of the symmetrical proportional directional valve 3 of the present invention is connected with the P port of the asymmetrical proportional directional valve 4, the oil supply port 1, and the P port of the pilot electromagnetic directional valve 11; the A port of the symmetrical proportional directional valve 3 It is connected with port A of asymmetrical proportional directional valve 4 and the inlet of hydraulic control check valve 10, port B of symmetrical proportional directional valve 3 is blocked; port T of symmetrical proportional directional valve 3 is connected with port T of asymmetrical proportional directional valve 4 , Oil source return port 2, T port of pilot solenoid directional valve 11, T port of upper chamber electromagnetic directional valve 5, outlet of lower chamber safety va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com