Center fixation type quick clamping mechanical hand used for forging robot

A technology of robots and manipulators, applied in the field of center-fixed fast clamping manipulators, which can solve problems such as error-prone, safety accidents, and long cooling time of gripper jaws, to eliminate errors in program switching, improve replacement efficiency, and reduce replacement times Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

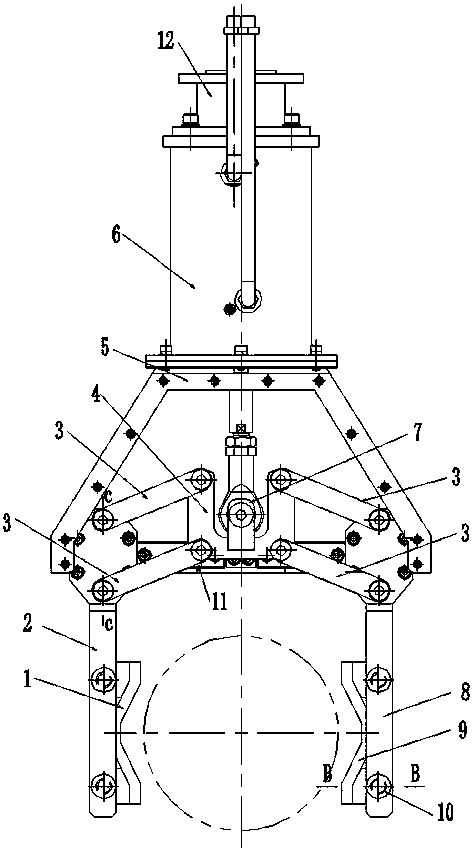

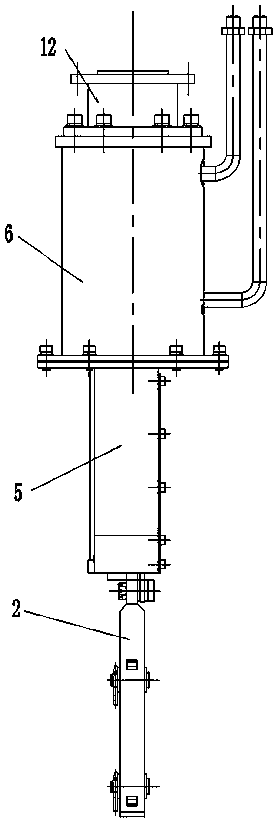

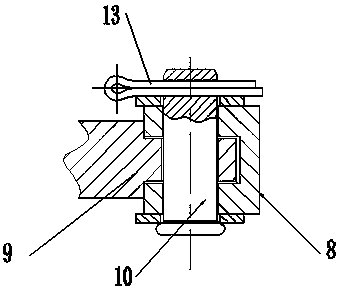

[0011] Such as Figure 1-Figure 4 As shown, the present invention is further described as follows: a center-fixed fast clamping manipulator for forging robots, including a clamp base 5, a heat-resistant cylinder 6 is arranged longitudinally at the rear of the clamp base, and the rear end of the heat-resistant cylinder 6 is fixed with a connection Flange A (connected to the forging robot through connecting flange A); there is an empty slot on the fixture base 5, and the two sides of the empty slot of the piston rod of the heat-resistant cylinder form two connecting parts symmetrically. The front end is horizontally arranged and connected with a high temperature resistant guide rail 11; on the high temperature resistant guide rail 11, there are two sliders 1101 symmetrically supported on the left and right (the slider 1101 belongs to the part of the high temperature resistant guide rail 11), the left jaw fixing seat 2 and the left slider 1101 Fixedly connected, the right jaw fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com