Method for planning linkage track of automatic forging manipulator and pressing machine

A technology of trajectory planning and manipulating machines, applied in the field of forging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

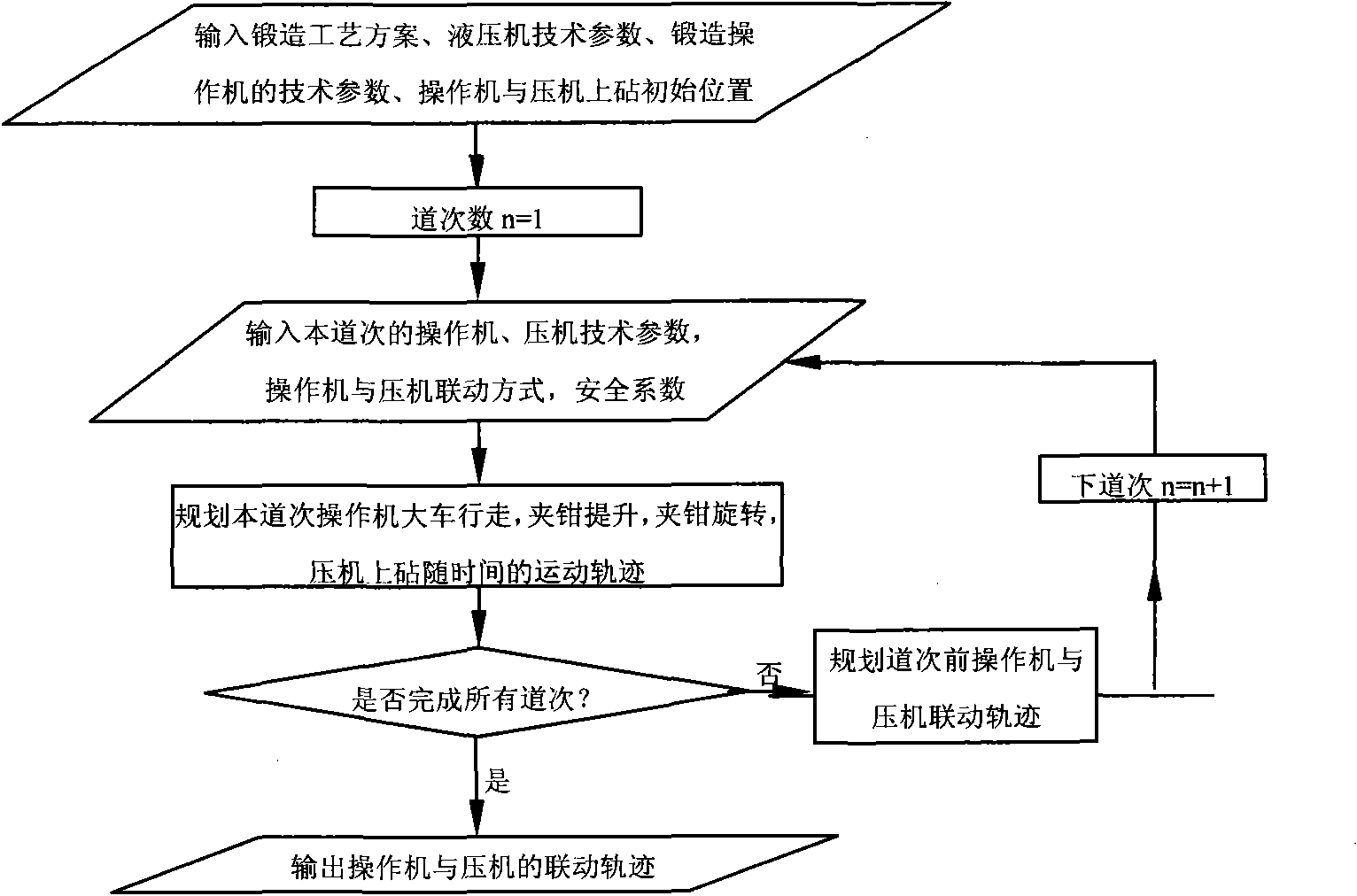

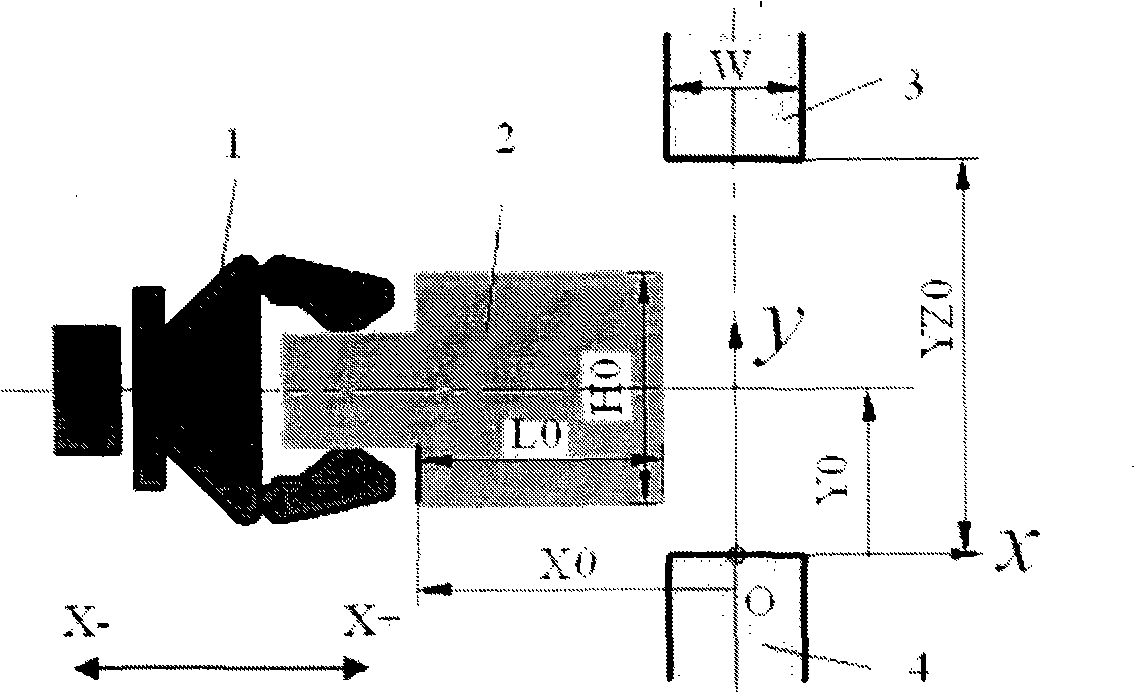

[0082] An embodiment of the method for planning the linkage track between the manipulator and the press for drawing a long rectangular section forging with a flat anvil according to the present invention, the method includes three major steps:

[0083] Step 1: the step of designing and calculating the process scheme of flat anvil uplifting;

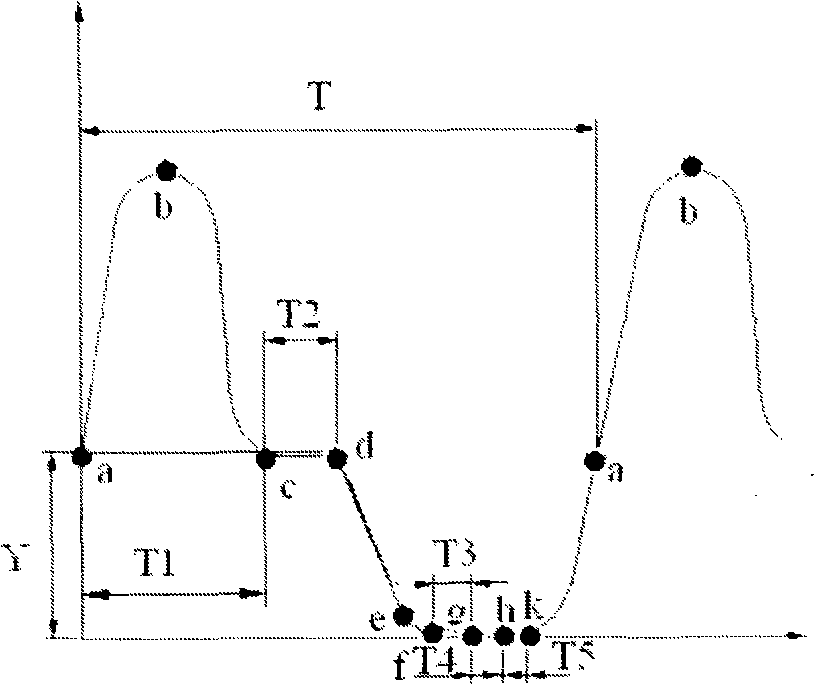

[0084] Step 2: The step of planning the linkage trajectory of the manipulator and the press for executing the process plan;

[0085] Step 3: The step of evaluating the rationality of the linkage trajectory.

[0086] The steps of step 1 designing and calculating the flat anvil uplifting process scheme include the following sub-steps:

[0087] (1) Steps for establishing a window for the user to input blank size, process parameters, number of passes, elongation direction of each pass, turning angle before...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com