Fully automatic fastener forging manipulator production line

A manipulator and fully automatic technology, applied in the direction of forging/pressing/hammering machinery, forging/pressing/hammer device, manufacturing tools, etc., can solve the problems of low production efficiency and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

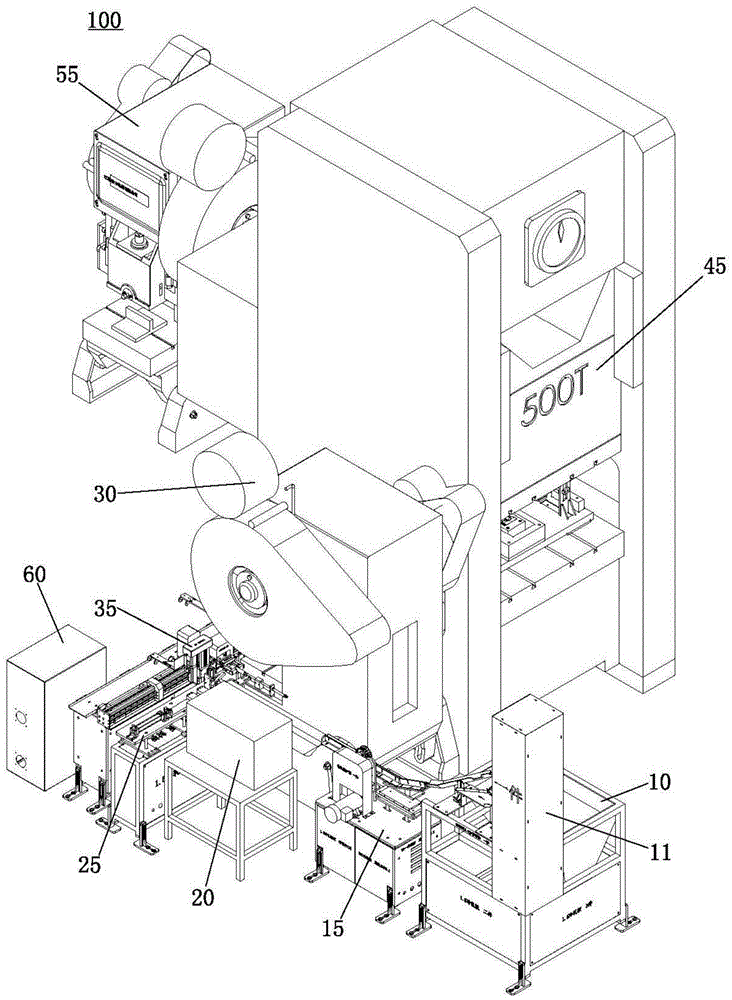

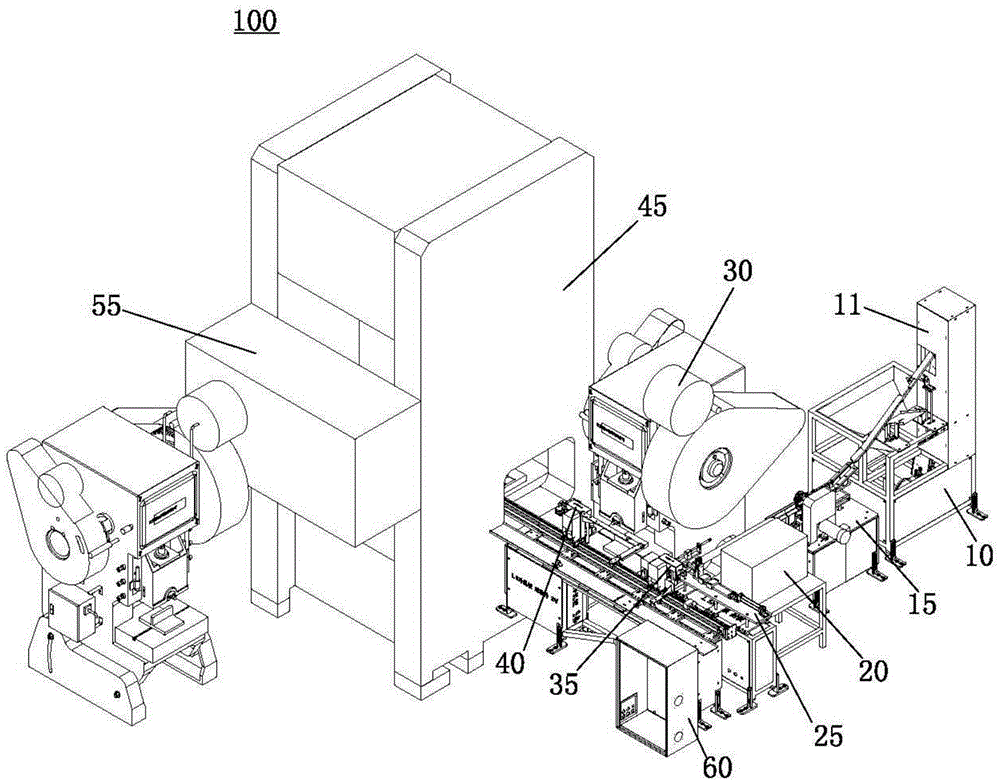

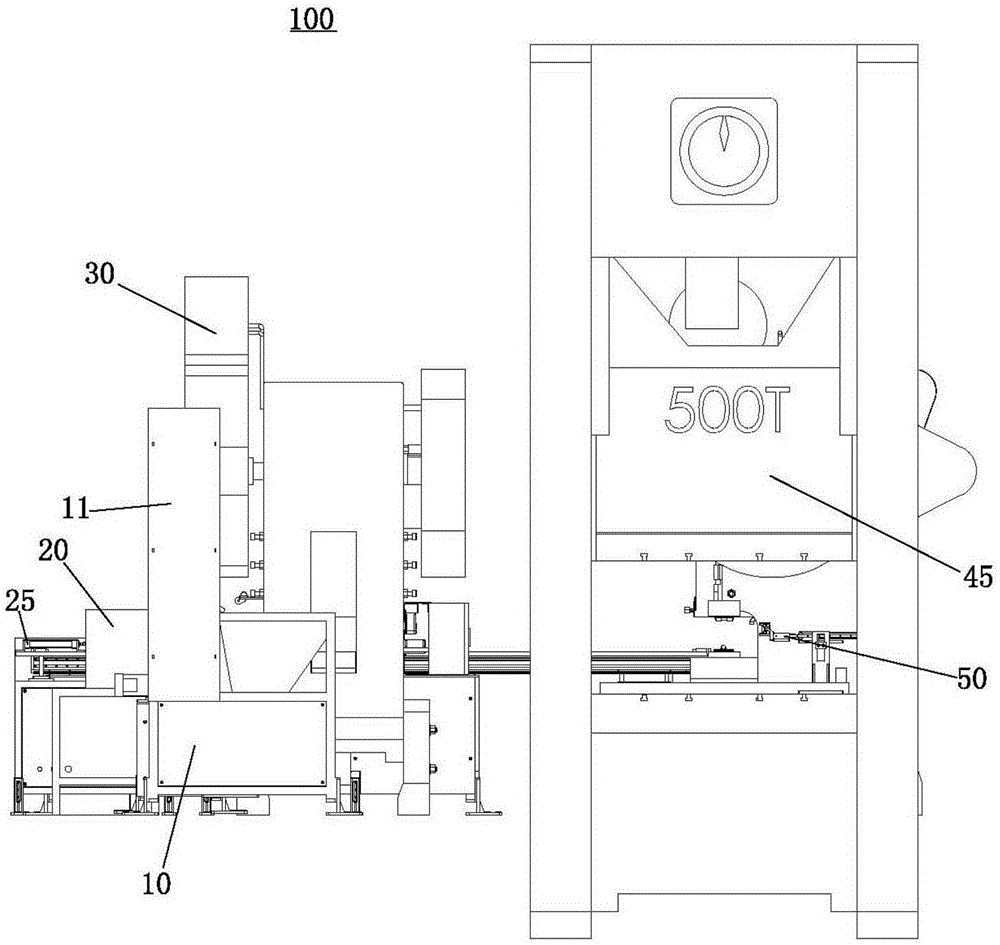

[0013] refer to Figure 1 to Figure 3 , the automatic fastener forging manipulator production line 100 of the present invention comprises a control system (not shown), a material storage box 10, an automatic hoist 11 electrically connected to the control system, a roller feeder 15, and a high-frequency heating furnace 20 , feeder 25, flattening punch 30, first manipulator 35, second manipulator 40, forging press 45, graphite spray manipulator 50, trimming punch 55 and power distribution cabinet 60. The automatic elevator 10 is used to lift and adjust the direction of the material in the storage box 10, and send it to the roller feeder 15, and the roller feeder 15 is used to send the material to the high frequency The heating furnace 20, the high-frequency heating furnace 20 heats the material to a set temperature, the feeder 25 is used to send the heated material to the positioning position and position it for the first manipulator 35 to grip, the The first manipulator 35 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com