Completely-decoupled type forging manipulator lifting mechanism

A forging manipulator, complete decoupling technology, applied in the direction of forging/pressing/hammering machinery, manufacturing tools, forging/pressing/hammer devices, etc., to achieve the effect of complete decoupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

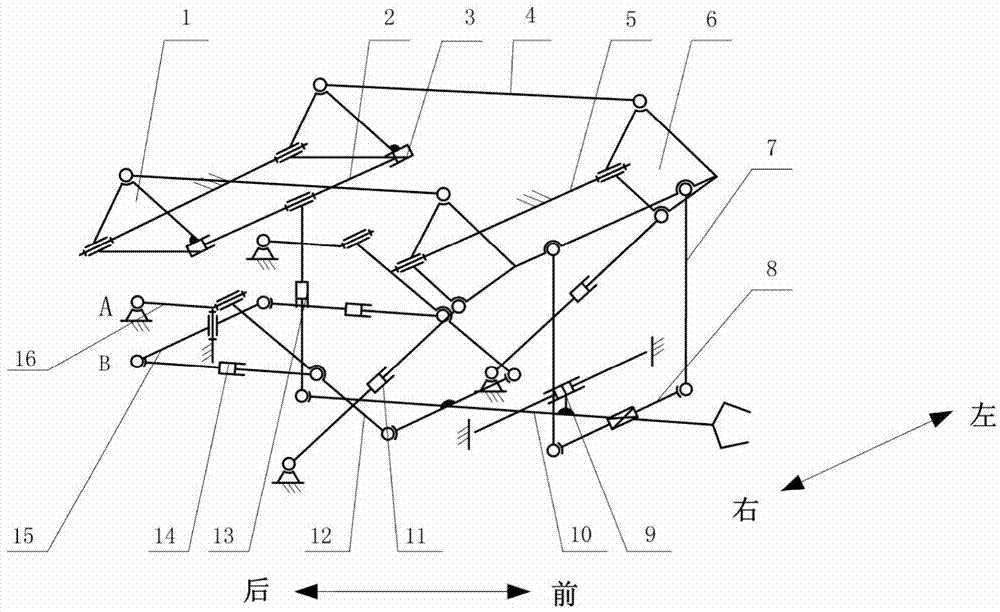

[0011] exist figure 1 In the schematic diagram of the hoisting mechanism of a completely decoupled forging manipulator shown, the front end of the tong rod 10 is connected to the front sliding rod 8 through a moving pair, and the two ends of the front sliding rod are respectively connected to the lower ends of a pair of front suspension rods 7 through ball joints. , the upper end of the front suspension rod is connected to the beam of a pair of front lifting arms 6 through a ball joint, the upper part of the front lifting arm is connected to the front end of the synchronization rod 4 through a ball joint, and the rear end of the synchronization rod is connected to the upper part of the rear lifting arm 1 through a ball joint , the above-mentioned front and rear lifting arms are respectively connected with the frame 5 by rotating hinges arranged in the left and right horizontal directions of the axis; The arranged rotary hinge is connected to the rear slide bar 2; the moving en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com