Jaw clamping hydraulic system of forging manipulator

A forging operation and clamping technology, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, mechanical equipment, etc., can solve the problems of not being able to clamp the forgings, pinching the forgings, and unstable clamping, etc. To achieve stable and reliable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described in detail below in conjunction with accompanying drawing.

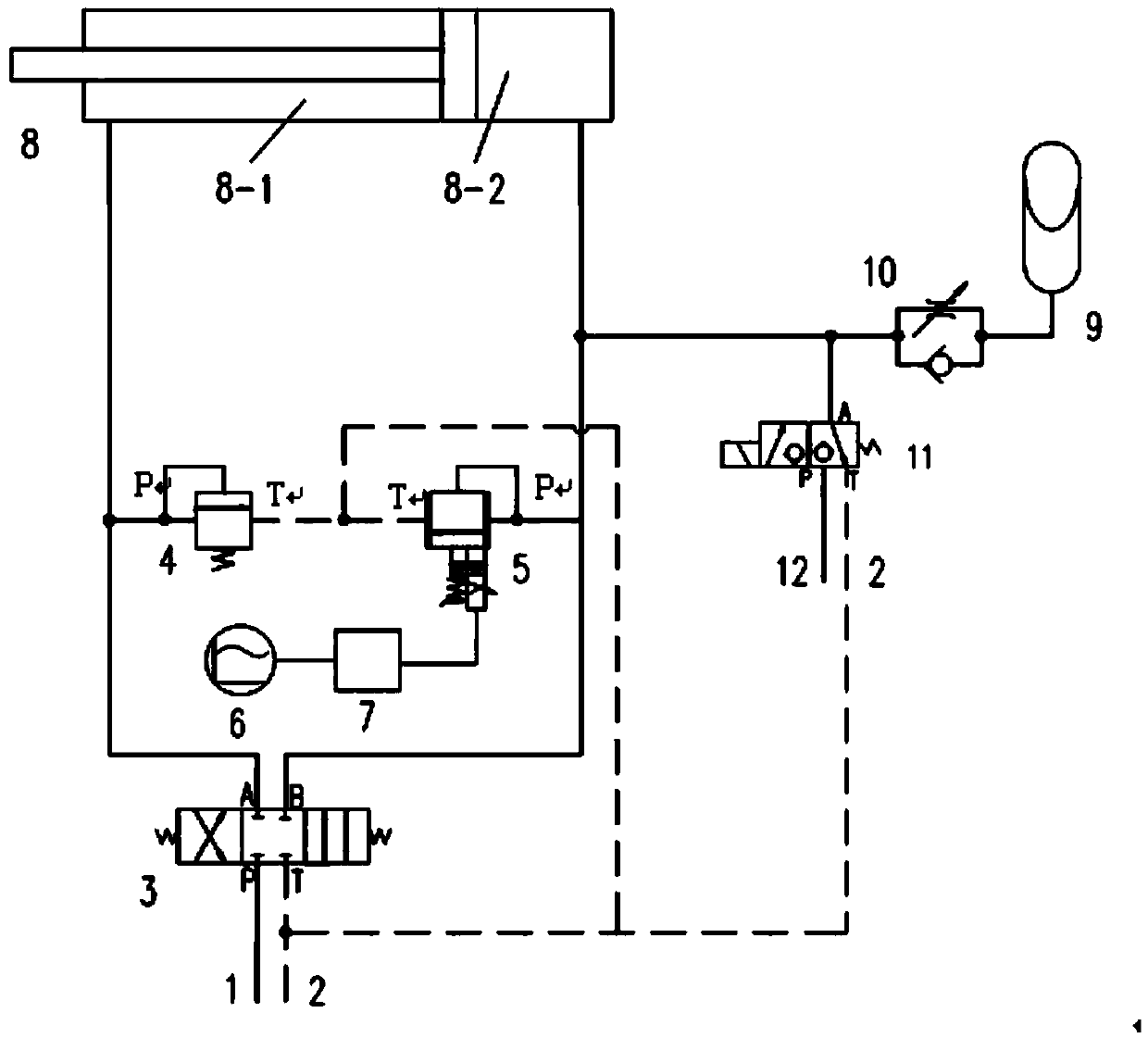

[0011] Referring to the accompanying drawings, a forging manipulator clamping hydraulic system includes a three-position four-way directional valve 3, the P port of the three-position four-way directional valve 3 is connected to the oil supply port 1, and the P port of the three-position four-way directional valve 3 Port T is connected to the oil return port 2, port A of the three-position four-way directional valve 3 is connected to the opening chamber 8-1 of the clamping cylinder, port B of the three-position four-way directional valve 3 is connected to the clamping chamber 8-1 of the clamping cylinder 2 connection; the P port of the relief valve 4 is connected with the opening cavity 8-1 of the clamping cylinder, and the T port of the relief valve 4 is connected with the oil return port 2; the P port of the proportional relief valve 5 is clamped with the clamping cylinder T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com