Clamping control system and radial forging manipulator

A control system and clamping technology, which is applied in manufacturing tools, driving devices of forging presses, forging/pressing/hammering machinery, etc., can solve problems such as inaccurate determination of clamping pressure and inability to adjust clamping pressure, and achieve flexibility The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

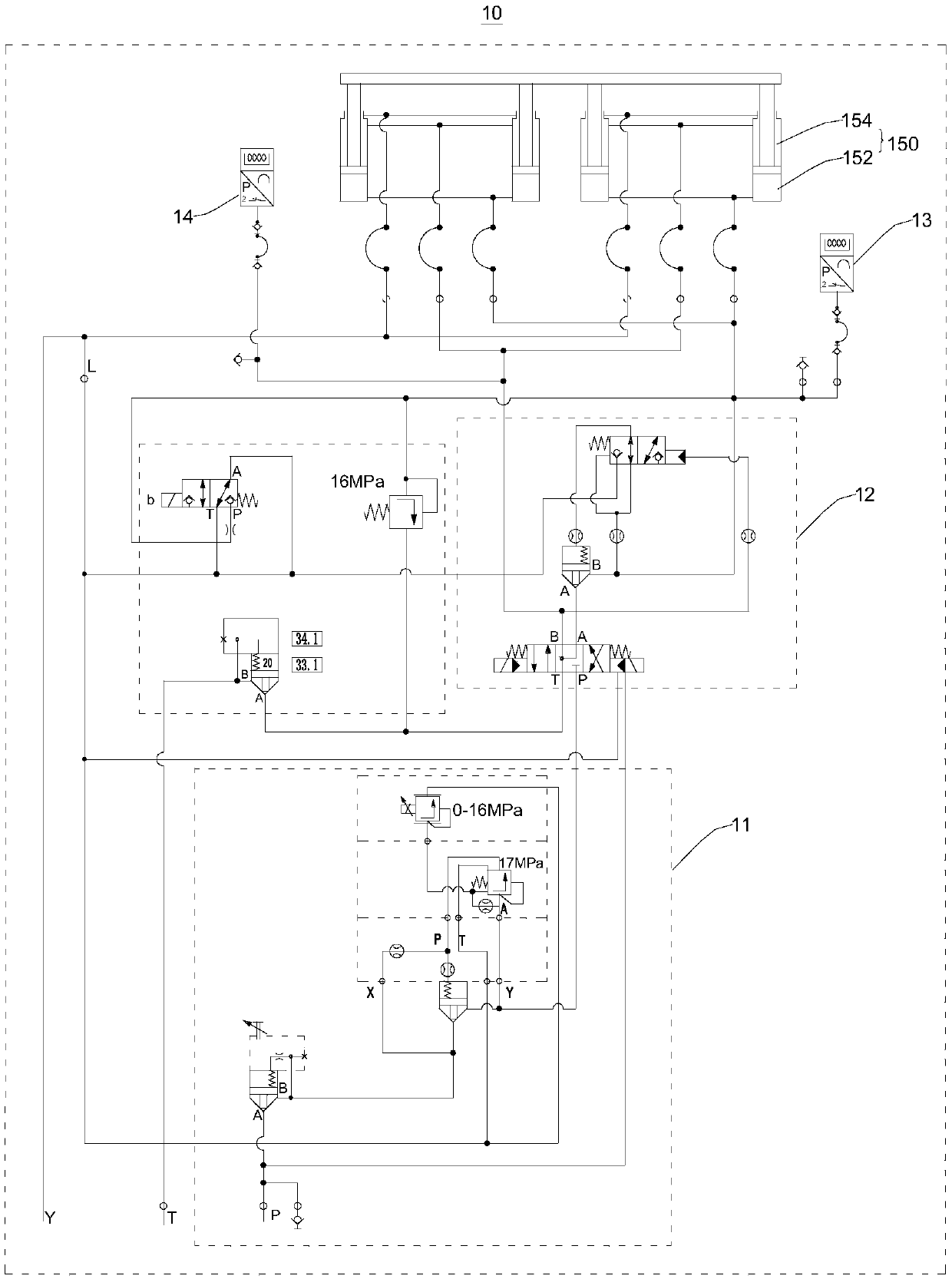

[0032] Radial forging refers to a rotary forging method that specializes in processing solid or hollow long-shaft parts. Forging forming technology is an important technology in metallurgical production, which is widely used in aviation, aerospace, machinery, shipbuilding and other fields, and occupies an extremely important position in the national economy. According to the research of the applicant, the existing radial forging equipment is generally precision forging machines and rotary forging machines. Whether it is precision forging machines or rotary forging machines, it is necessary to manually control and judge the pressure of the clamping mechanism. The problem of inflexible control of the clamping pressure of forgings and low control accuracy. In order to solve the above problems, the first embodiment of the present invention provides a clamping control system 10 .

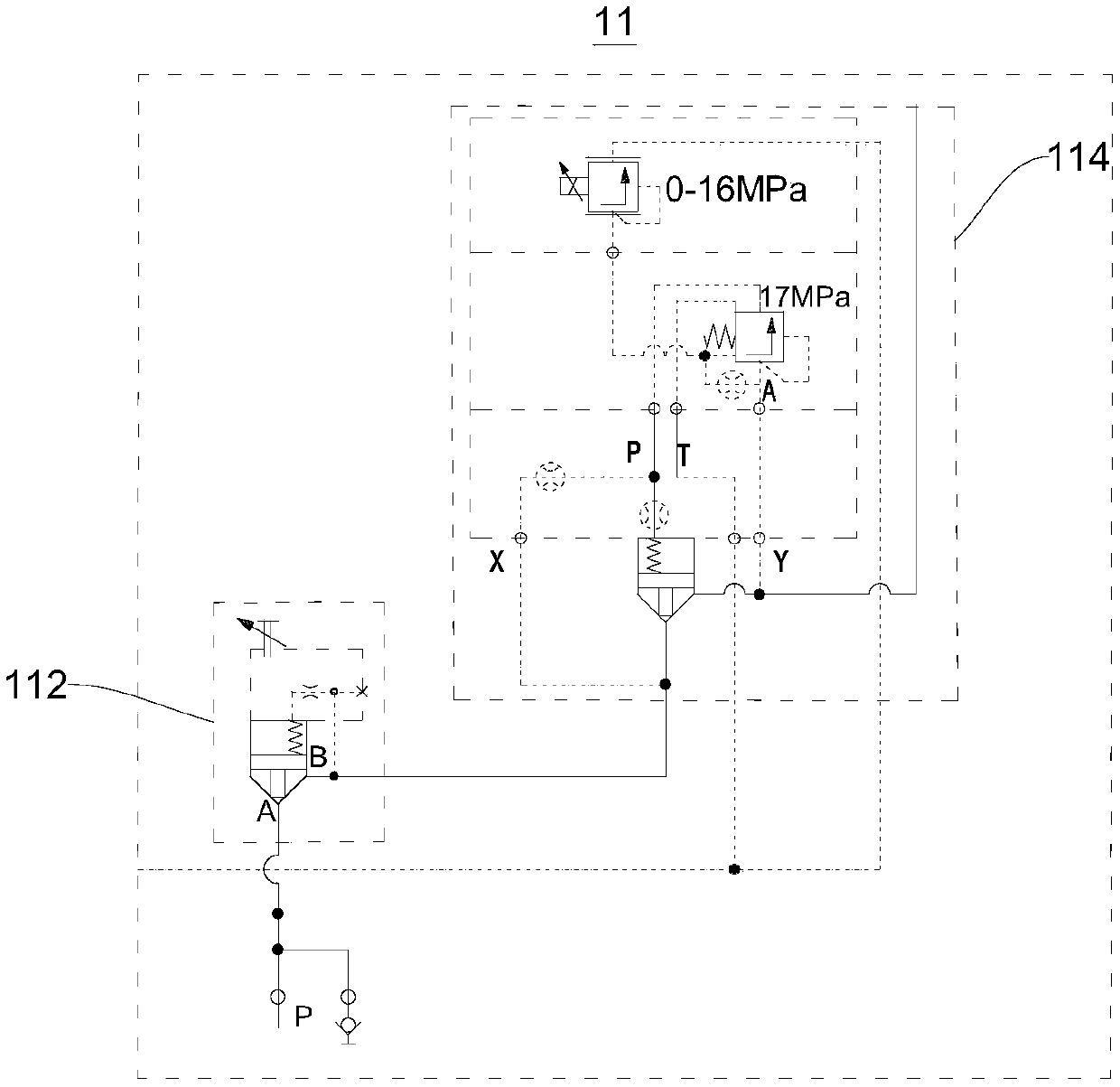

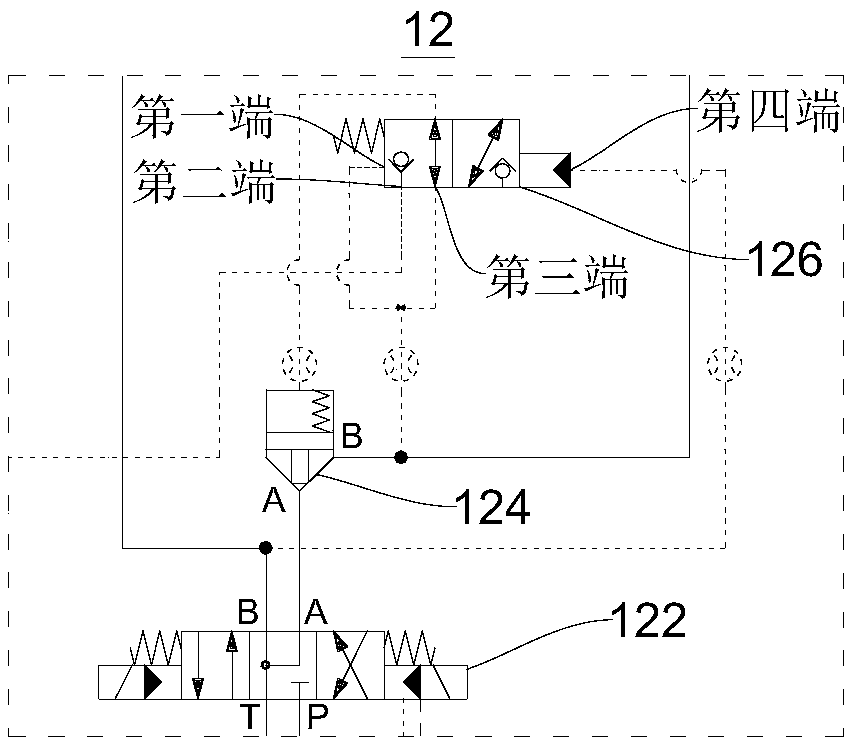

[0033] Please refer to figure 1 , figure 1 It is a schematic structural diagram of a clamping cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com