Full-automatic bearing production line adopting forging manipulators

A manipulator and fully automatic technology, which is applied in the direction of mechanical equipment, engine components, forging/pressing/hammer devices, etc., can solve the problems of poor safety and low production efficiency, and achieve the effect of high production efficiency and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

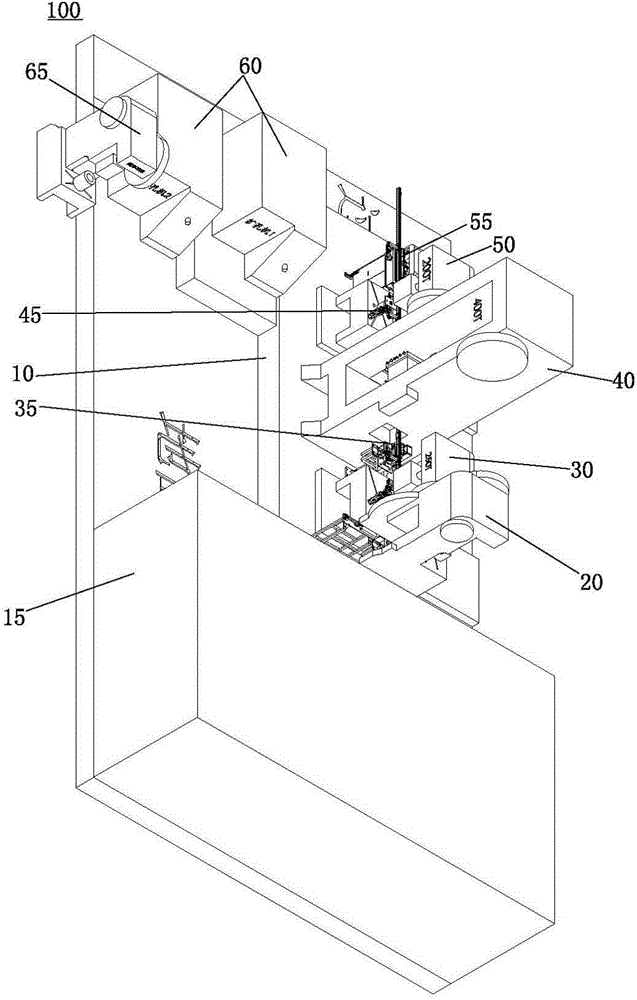

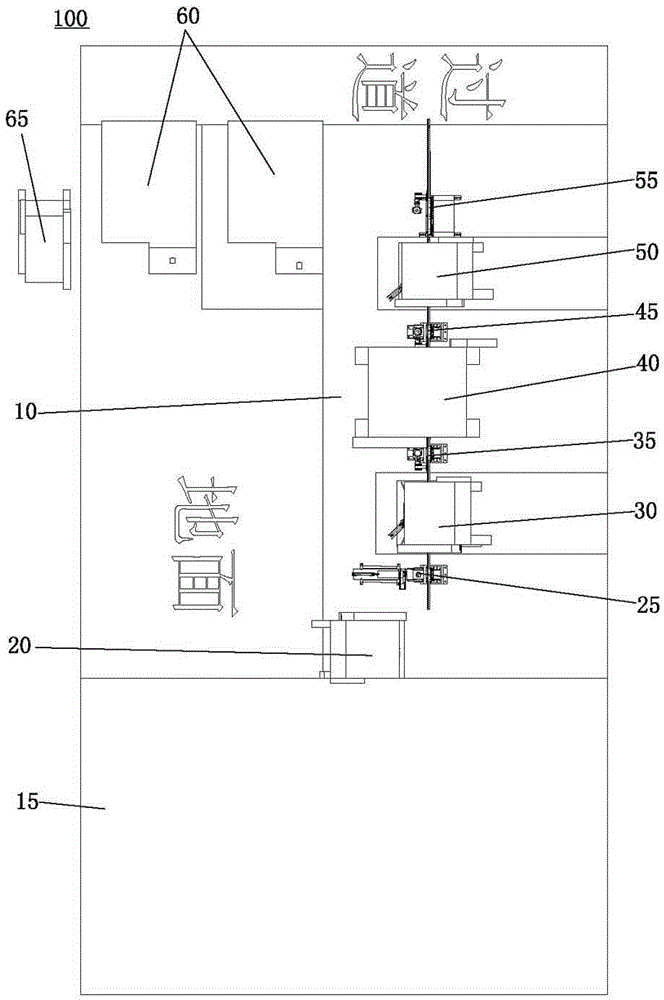

[0011] refer to figure 1 and figure 2 , the fully automatic bearing forging manipulator production line 100 of the present invention includes a control system (not shown), a punch table 10, a blanking punch shelf 15, a blanking punch 20 electrically connected to the control system, a first forging manipulator 25, Upsetting punch 30 , second forging manipulator 35 , forming punch 40 , third forging manipulator 45 , bottom cutting punch 50 , fourth forging manipulator 55 , at least one reaming machine 60 and shaping punch 65 . In this embodiment, the number of the reaming machines 60 is two.

[0012] The blanking punch frame 15 is placed in front of the punch table 10 . The blanking punch 20, the first forging manipulator 25, the flattening punch 30, the second forging manipulator 35, the forming punch 40, the third forging manipulator 45, the bottom cutting punch 50, and the fourth forging manipulator 55 are sequentially installed on the On the punch table 10, the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com