Vacuum anti-siphon backflow preventing valve

An anti-siphon and vacuum technology, applied in valve details, control valves, valve devices, etc., can solve problems such as inability to prevent backflow, low sensitivity, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

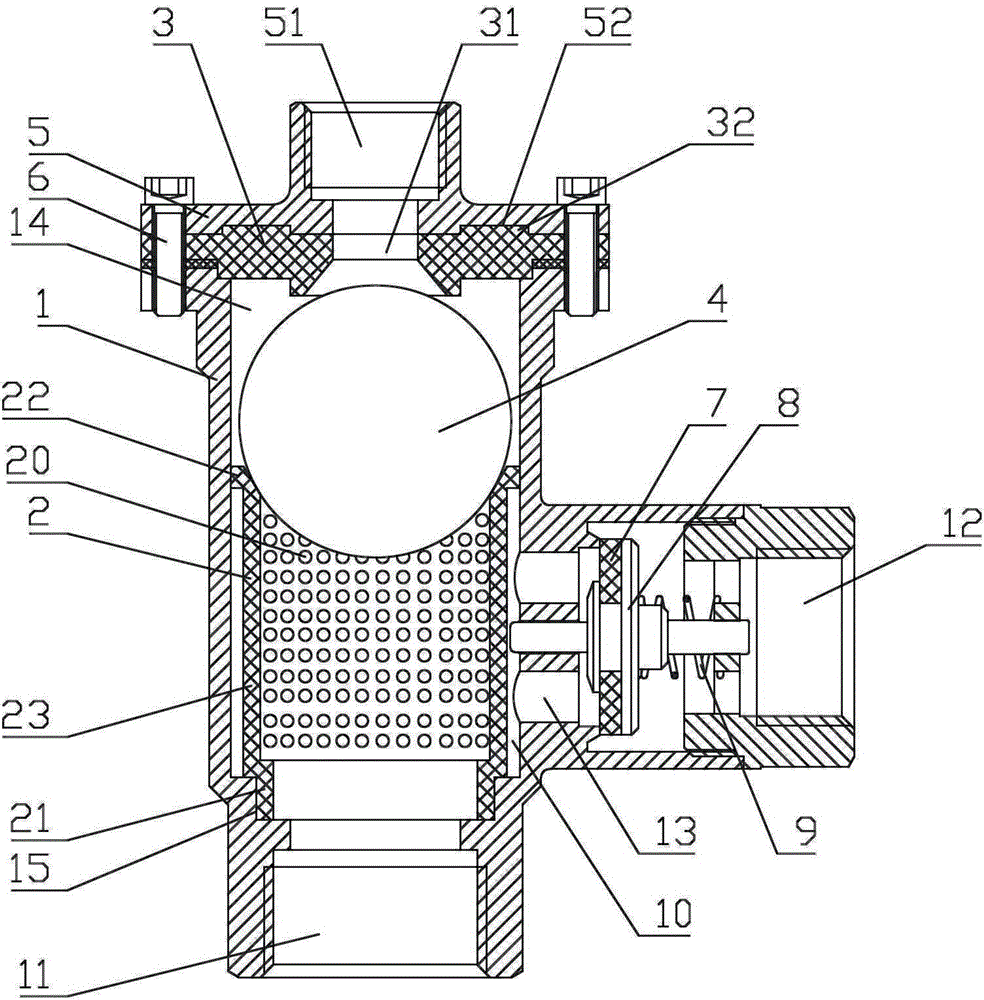

[0020] Such as figure 1 Shown is an embodiment of the present invention, a vacuum anti-siphon backflow prevention valve, including a valve body 1, a water inlet 11 and a water outlet 12 are arranged on the valve body, a valve chamber 10 connected to the water inlet is arranged in the valve body, and the valve chamber There is a valve port 13 in communication with the water outlet, and the valve disc assembly is provided in the water outlet to allow the medium to flow from the valve cavity to the water outlet in one direction, and an air outlet 14 is provided on the top of the valve body to communicate the valve cavity with the outside world. The valve cavity is provided with a supporting filter 2 covering the valve port, and the air outlet is provided with a seal to seal the air outlet when the medium flows from the water inlet to the water outlet in a forward direction or when the medium flows from the valve cavity to the water inlet in the reverse direction. A buoyancy seal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com