Patents

Literature

212results about "Floats for valve actuation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Domestic hot water service inlet shut off valve triggered by fluid level in overflow tray

InactiveUS6336469B1Avoid inductionFluid heatersOperating means/releasing devices for valvesValve actuatorEngineering

A mechanism for opening or closing a shut-off valve, the mechanism having a valve actuator for moving the valve from a first position to a second position, an urging means, a trigger which, when activated, triggers operation of the valve actuator, the trigger including a retainer which ordinarily holds the shut-off valve in the first position against the force applied by urging means, and a sensor reactive to an external stimulus which releases the trigger upon receiving appropriate external stimulus.

Owner:NIXON ADRIAN JOHN +1

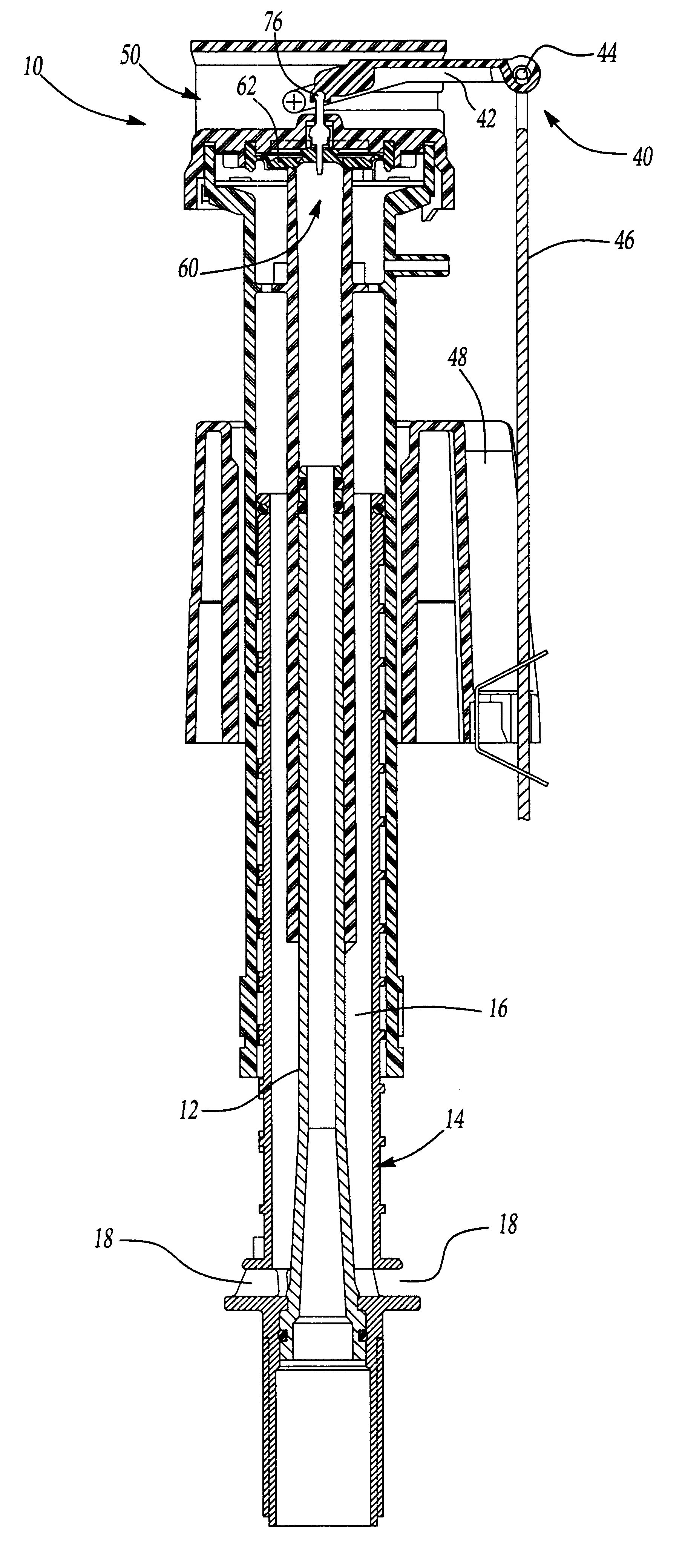

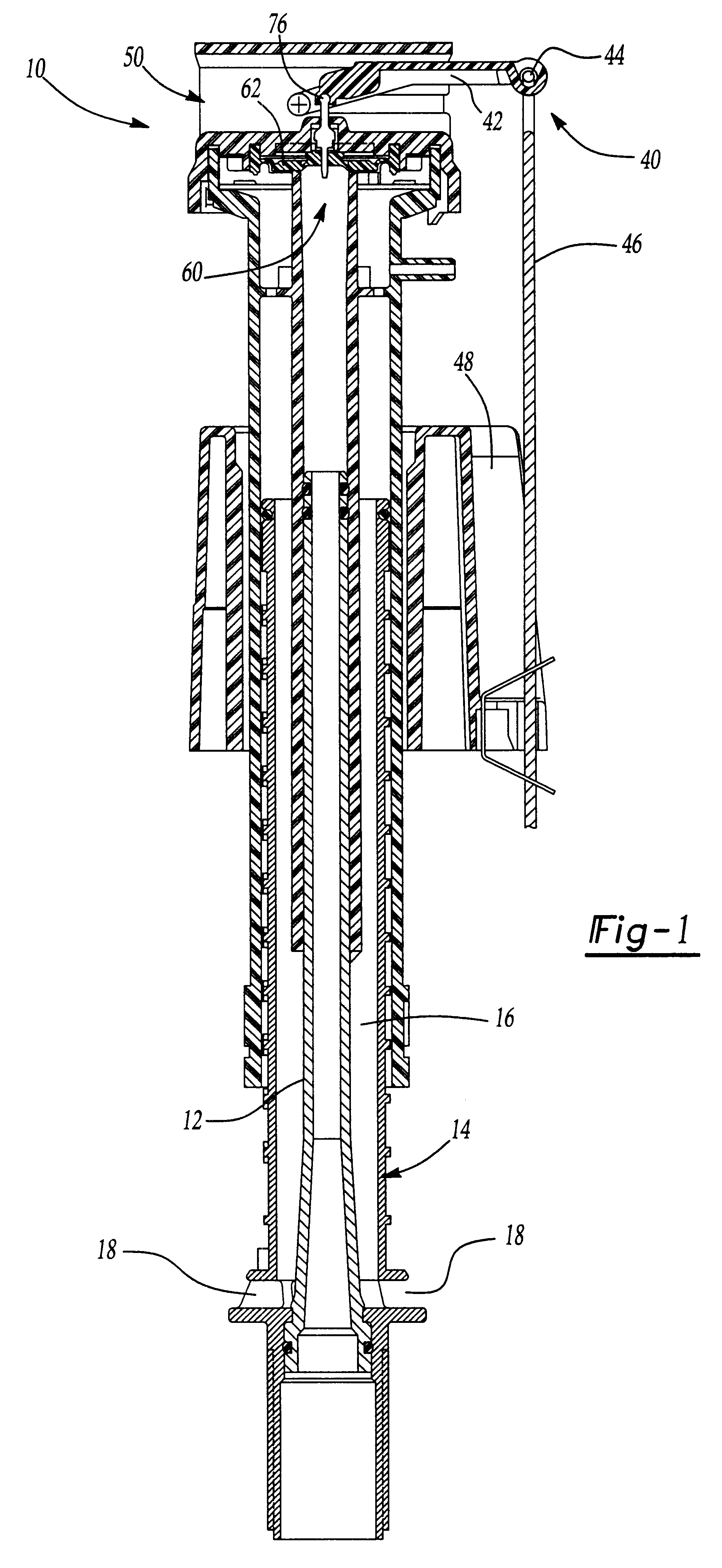

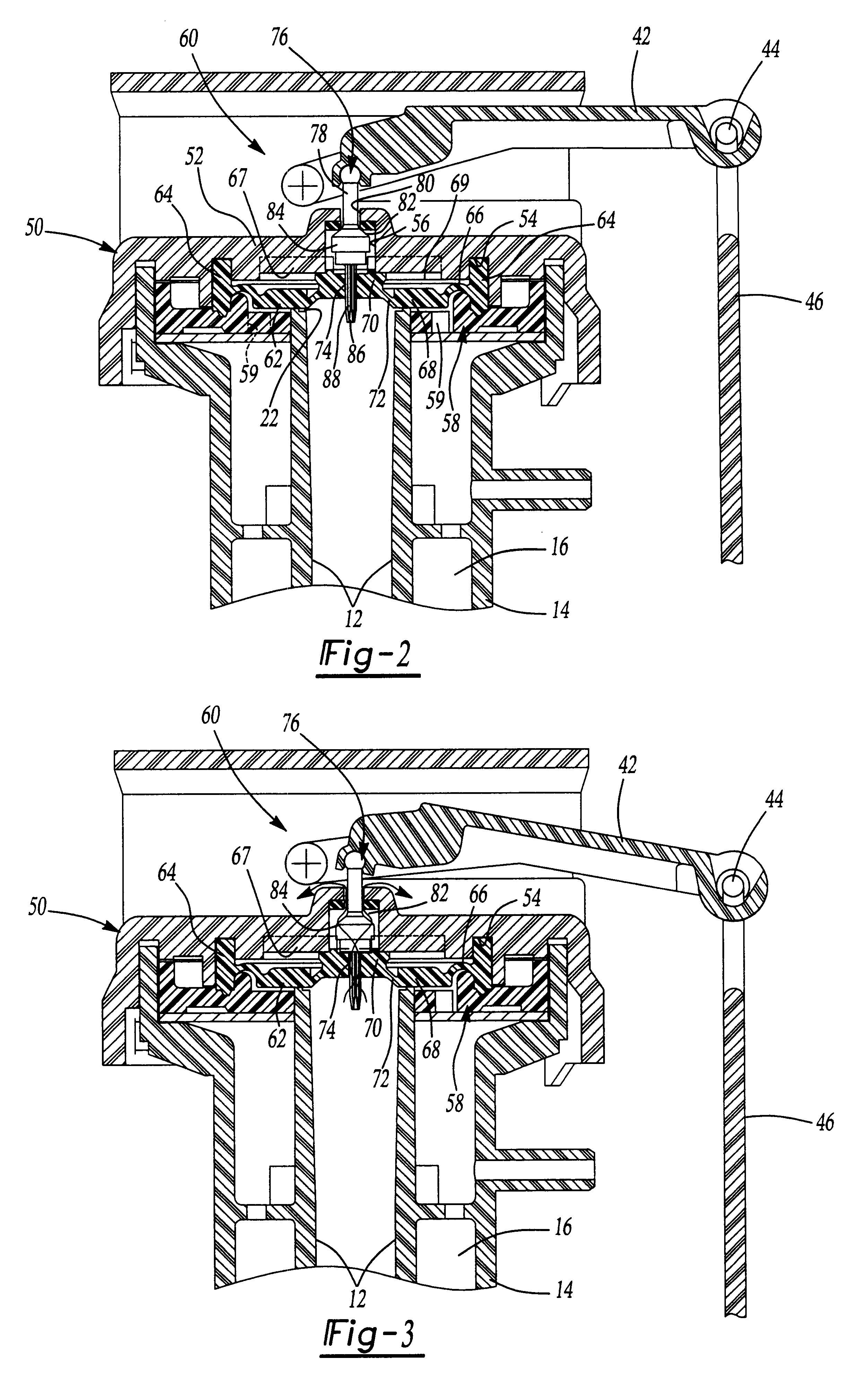

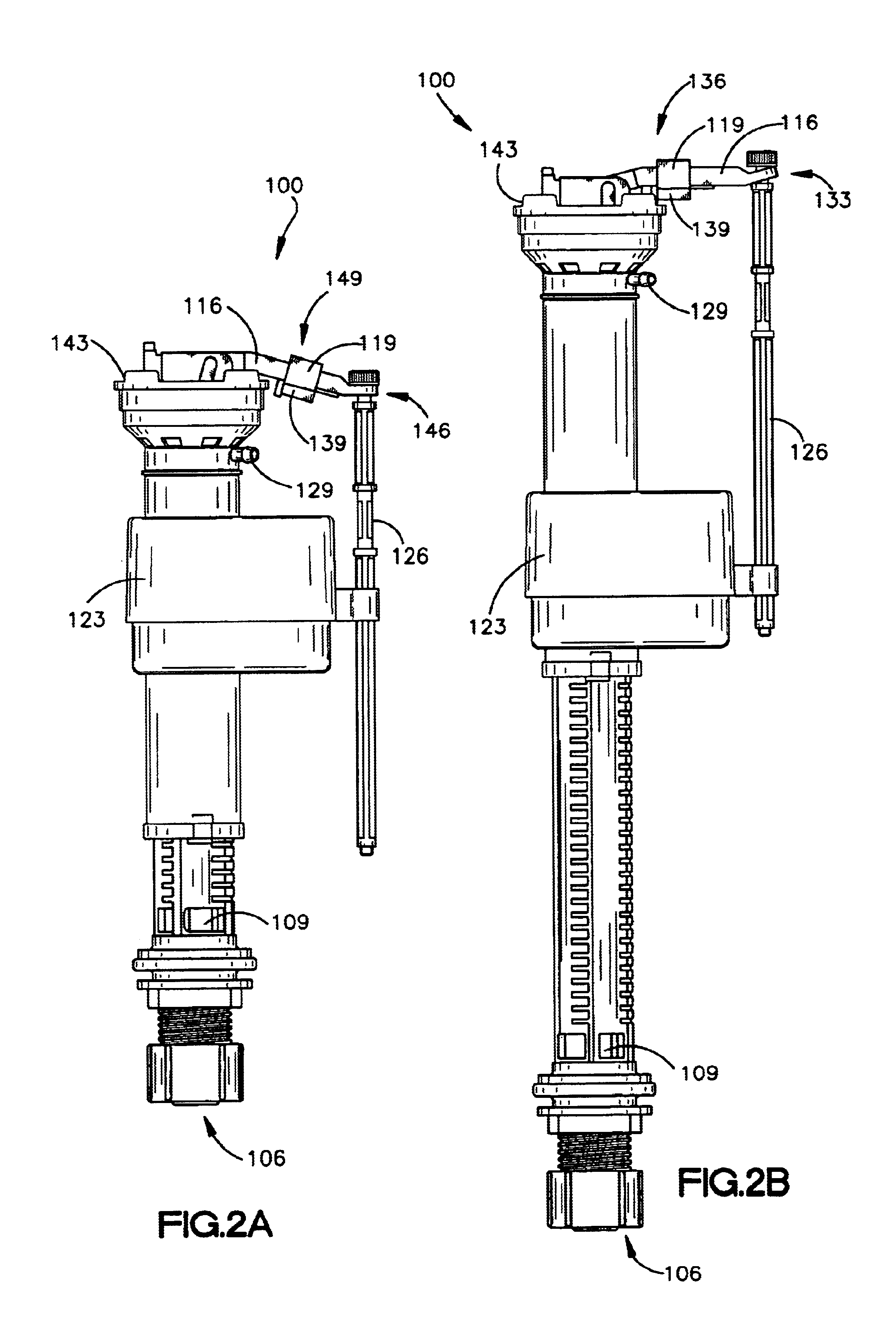

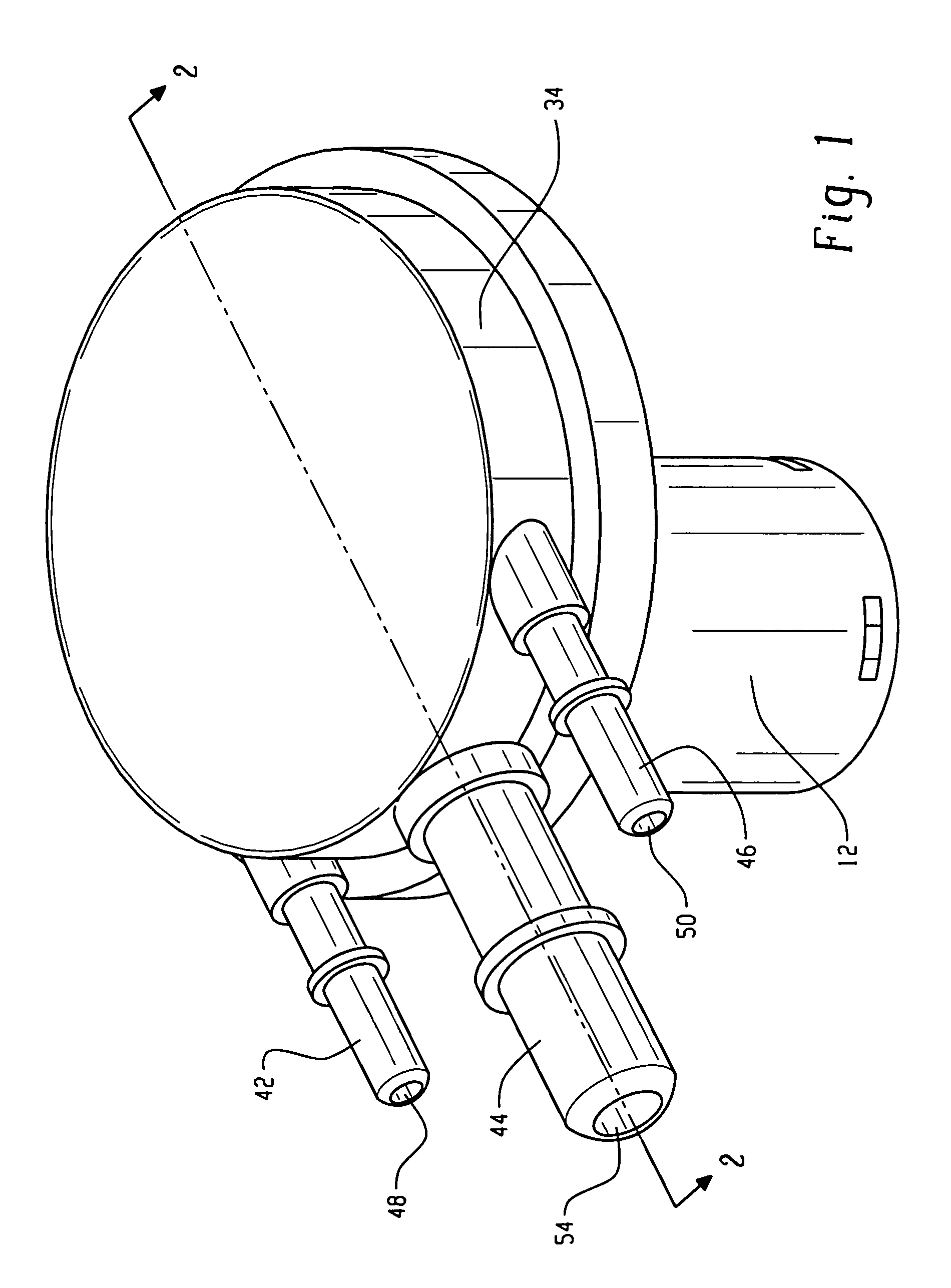

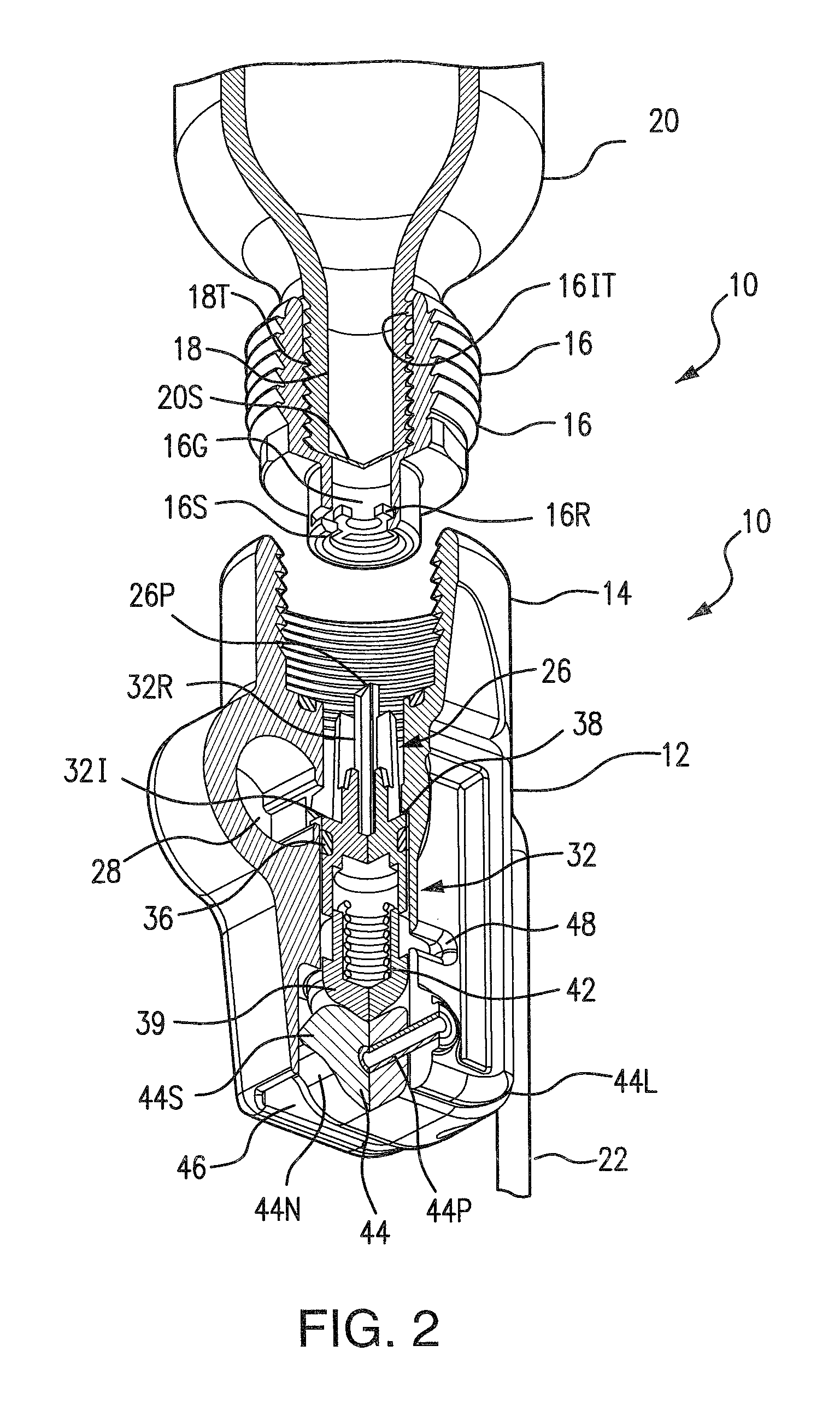

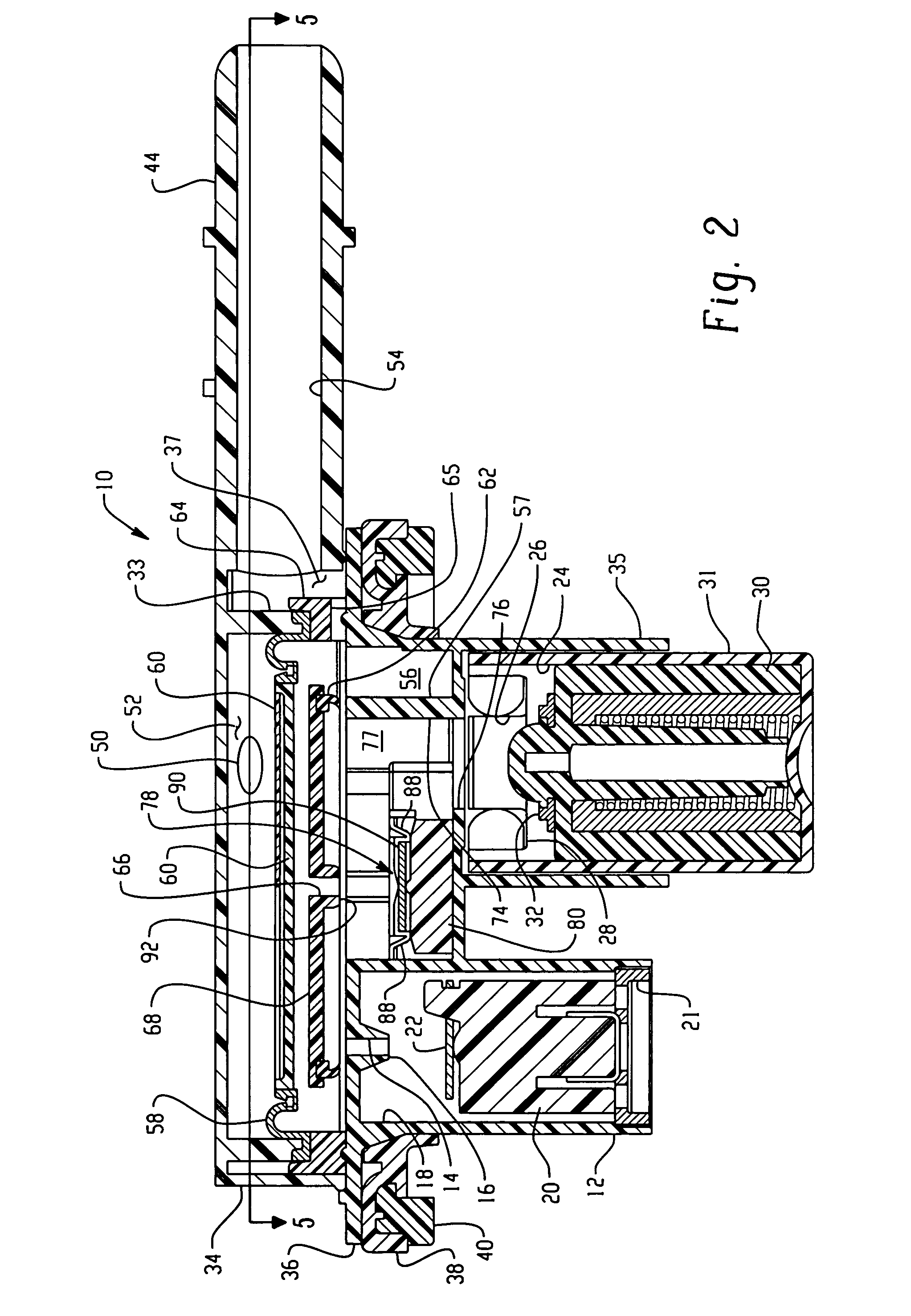

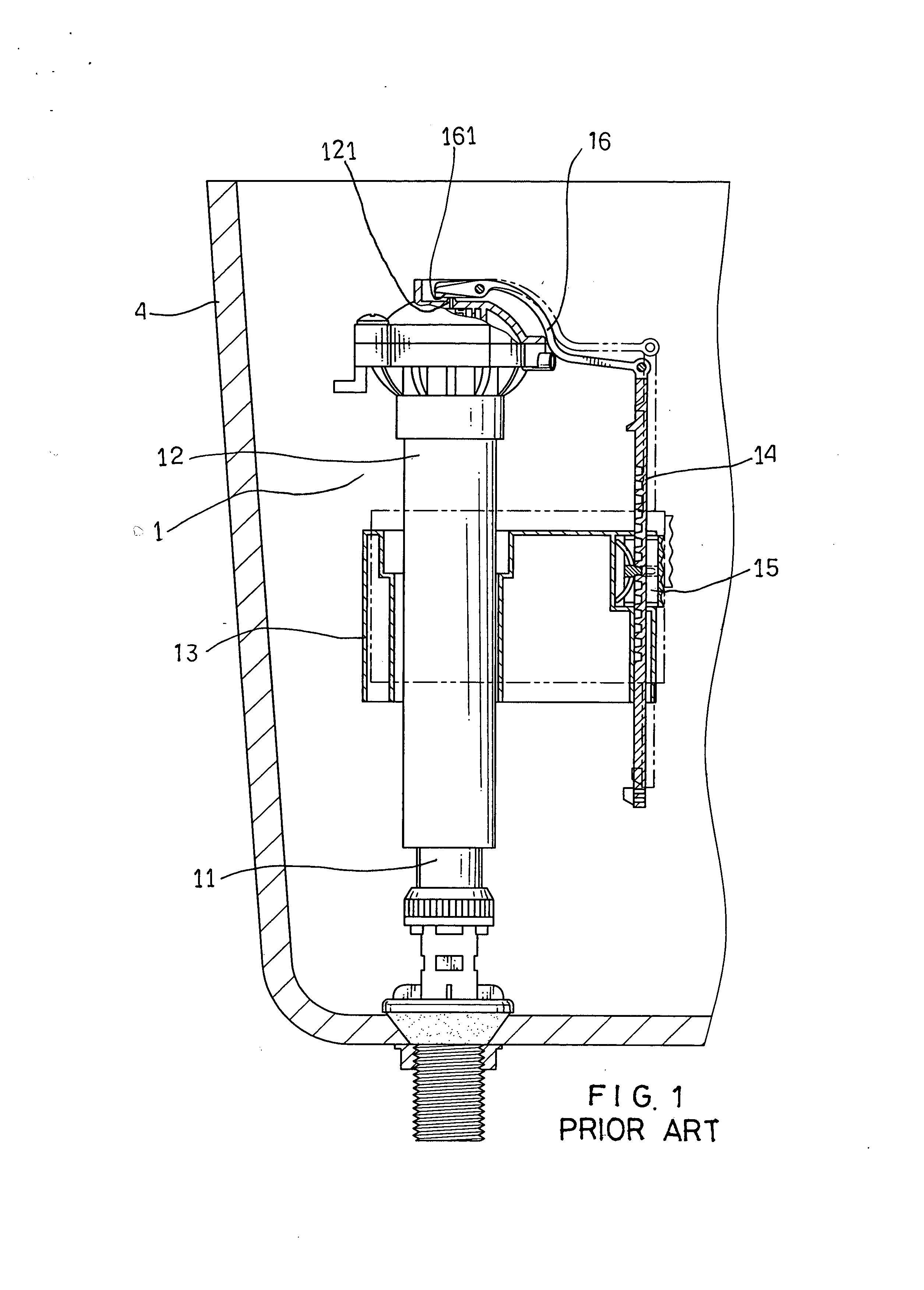

Toilet tank fill valve with float

InactiveUS6450195B1Easy to operateOvercome disadvantagesOperating means/releasing devices for valvesFlushing devicesEngineeringCistern

A fill valve assembly for a toilet tank including a vertical standpipe, a pilot valve assembly located at the top end of the standpipe, and a vertically movable float which is connected to the pilot valve assembly. The pilot valve assembly opens the valve assembly when the float moves vertically downward and closes the valve assembly when the float moves vertically upward.

Owner:BRASSCRAFT MFG CO

Toilet fill valve with valve lock

ActiveUS6837264B1Operating means/releasing devices for valvesThin material handlingEngineeringToilet

Various toilet valves and methods are described that provide for locking of the toilet filled in a closed state. In one embodiment, a toilet fill valve is provided having an actuating arm. The toilet fill valve is closed when the actuating arm is disposed in a first position and is open when the actuating arm is disposed in a second position. A valve lock is attached to the actuating arm. The valve lock includes an unlock position and a lock position. The valve lock fixes the actuating arm in the first position when the valve lock is in the lock position.

Owner:DANCO

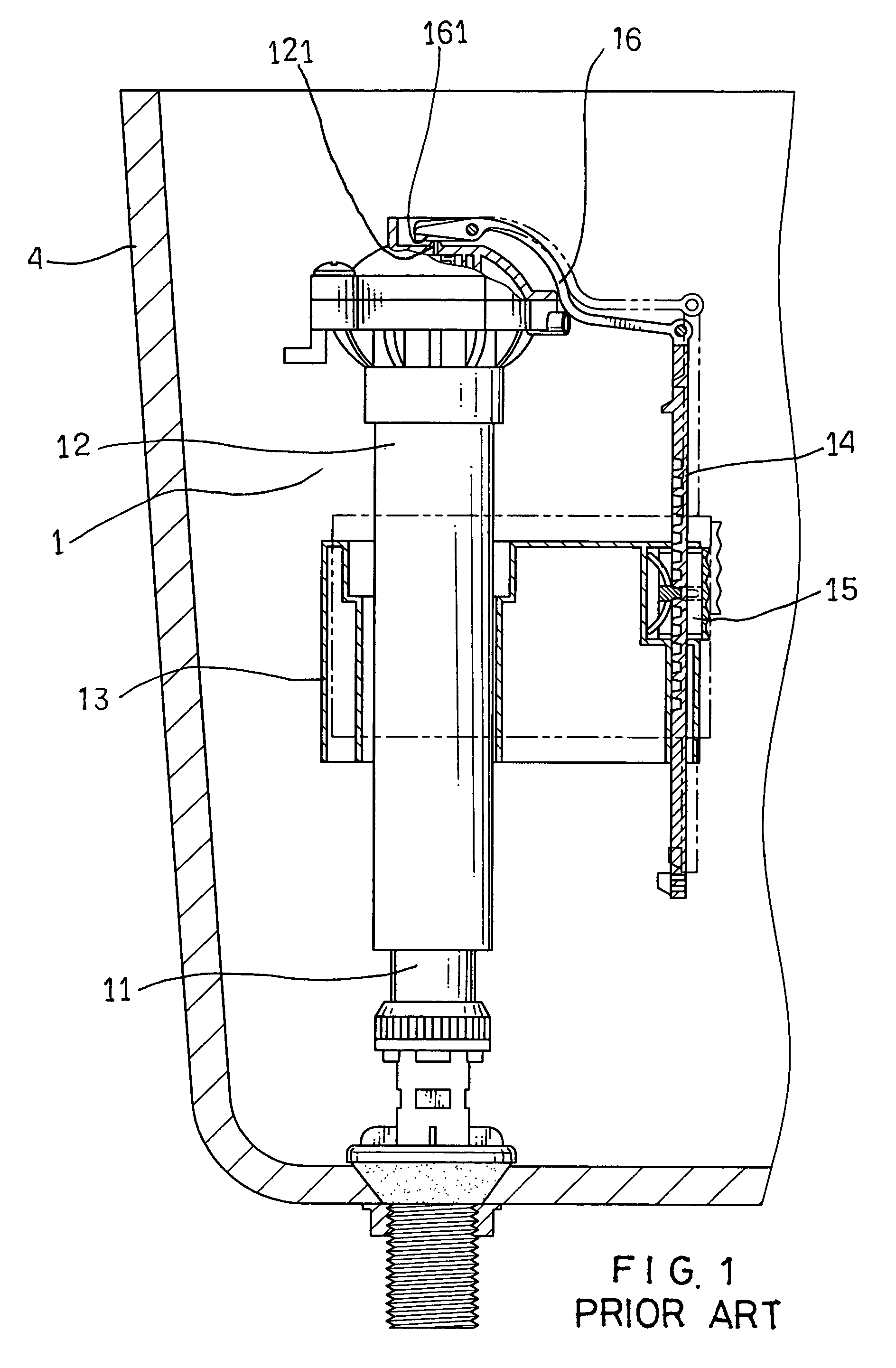

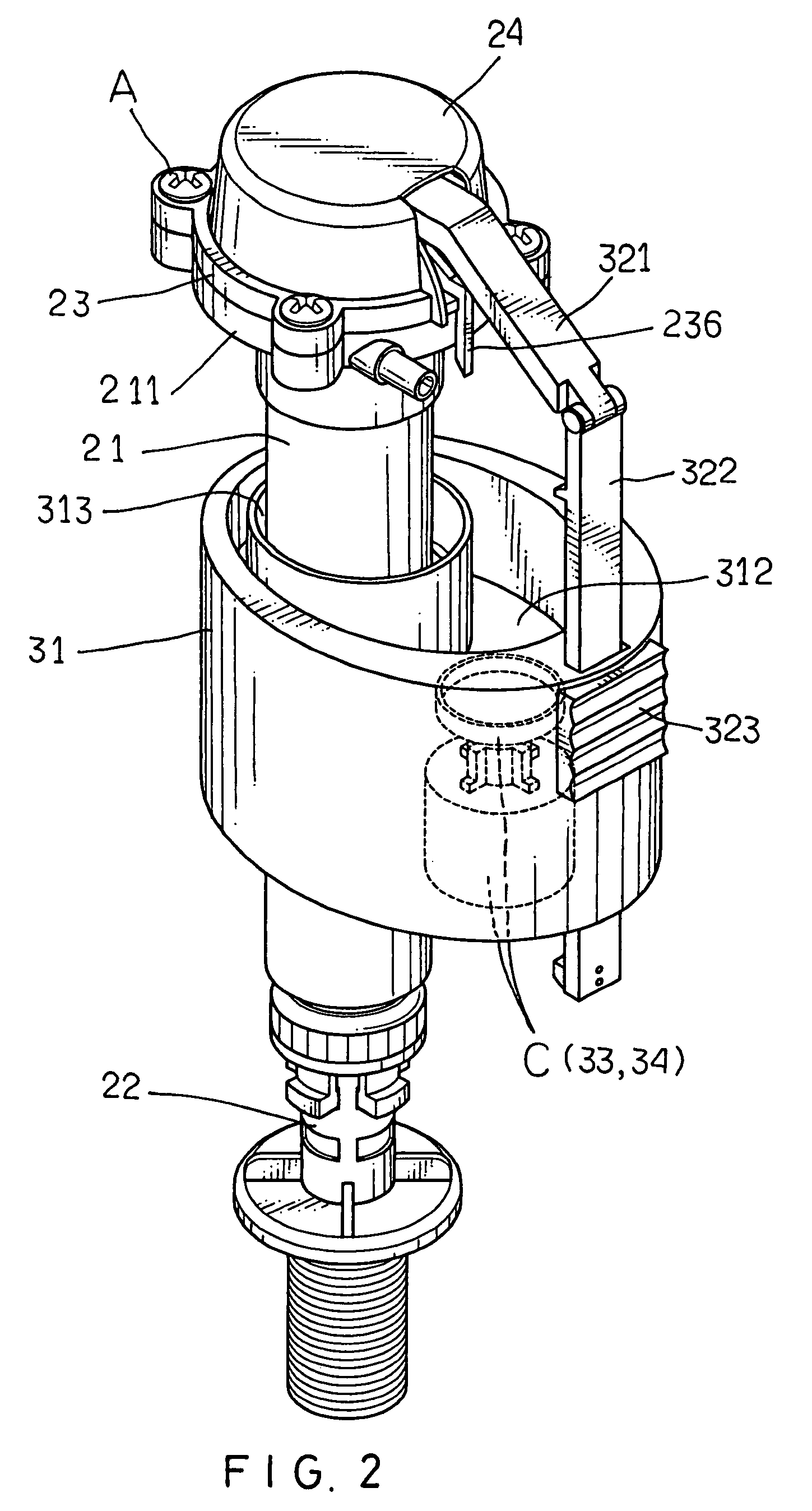

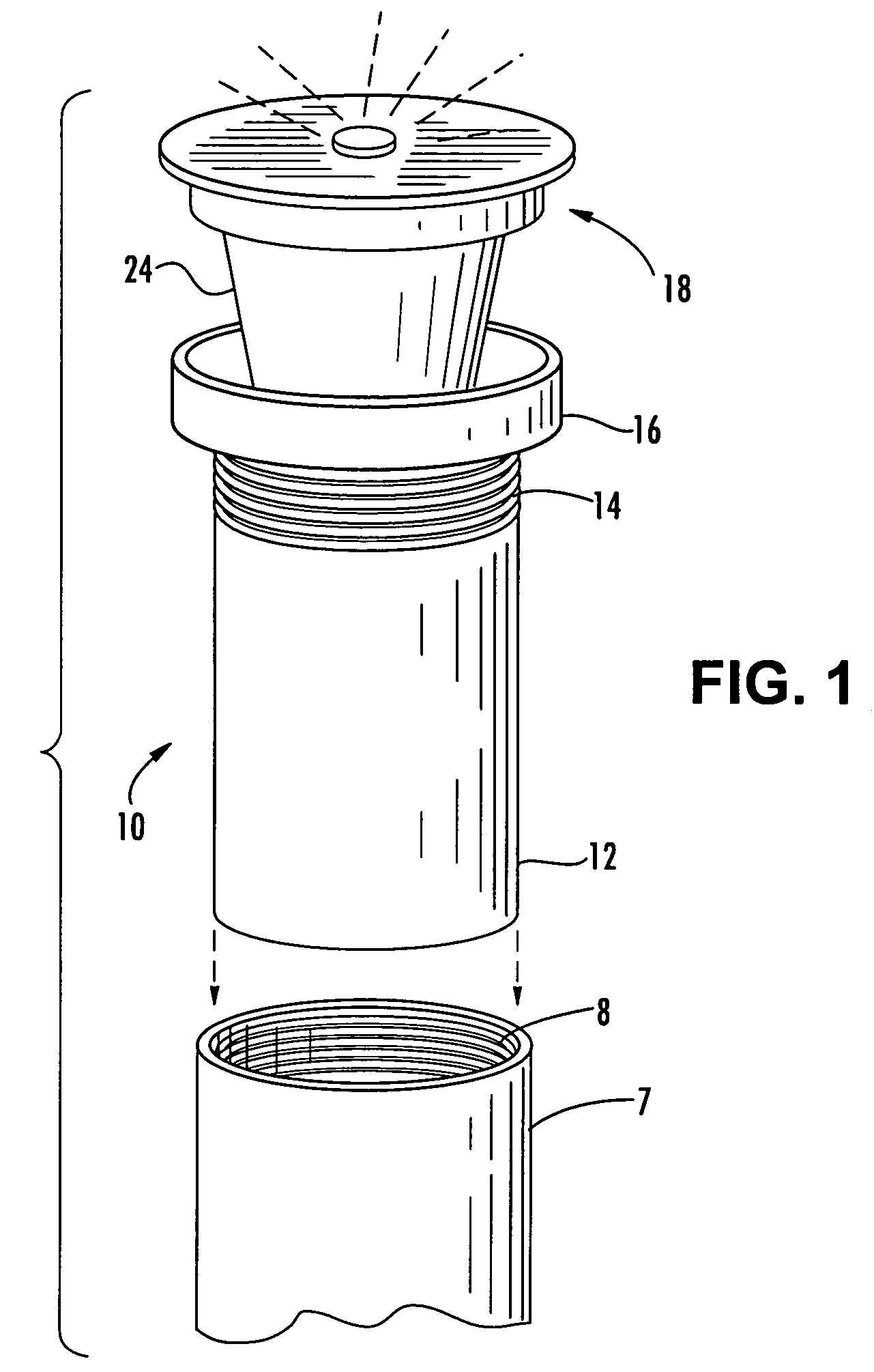

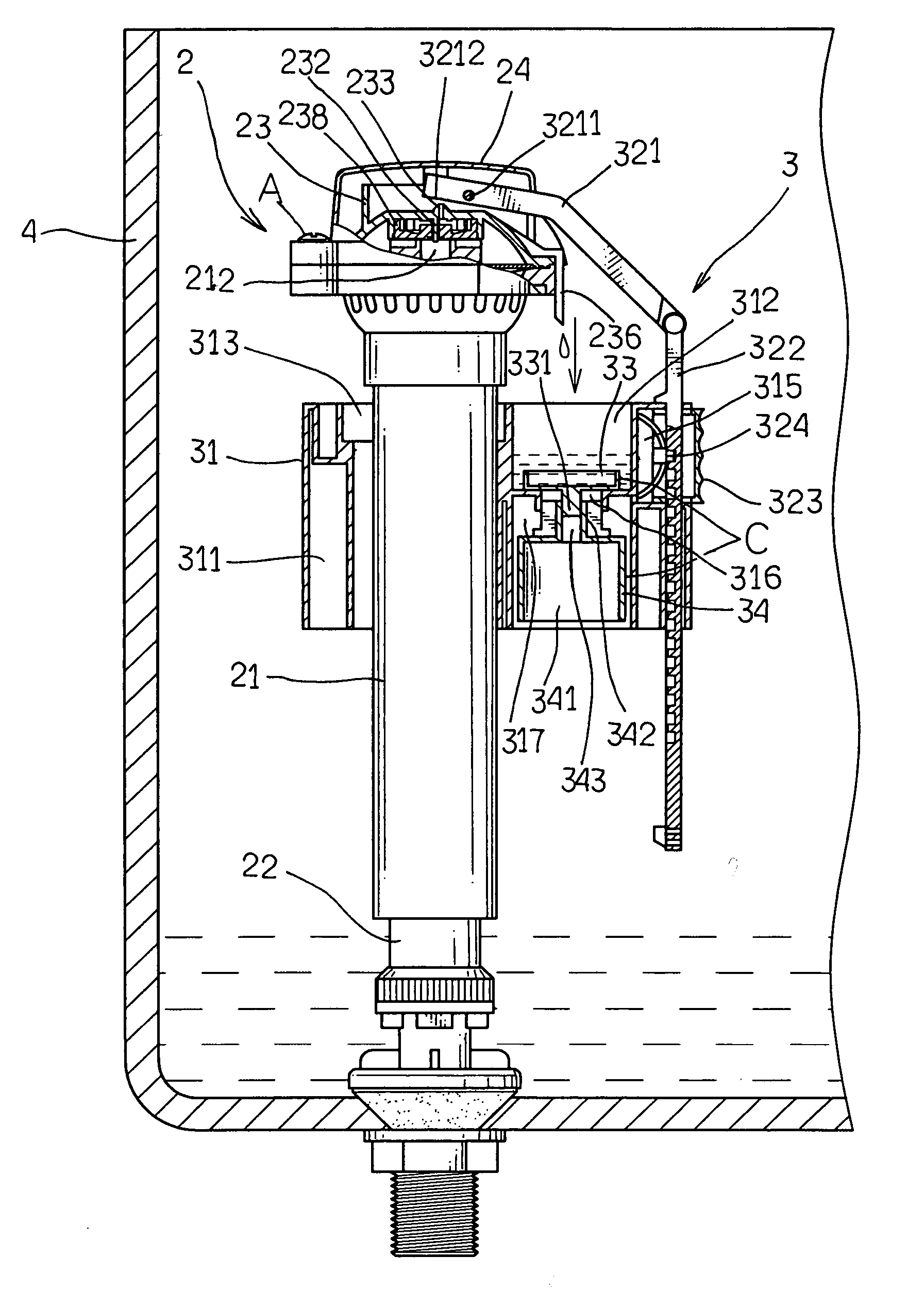

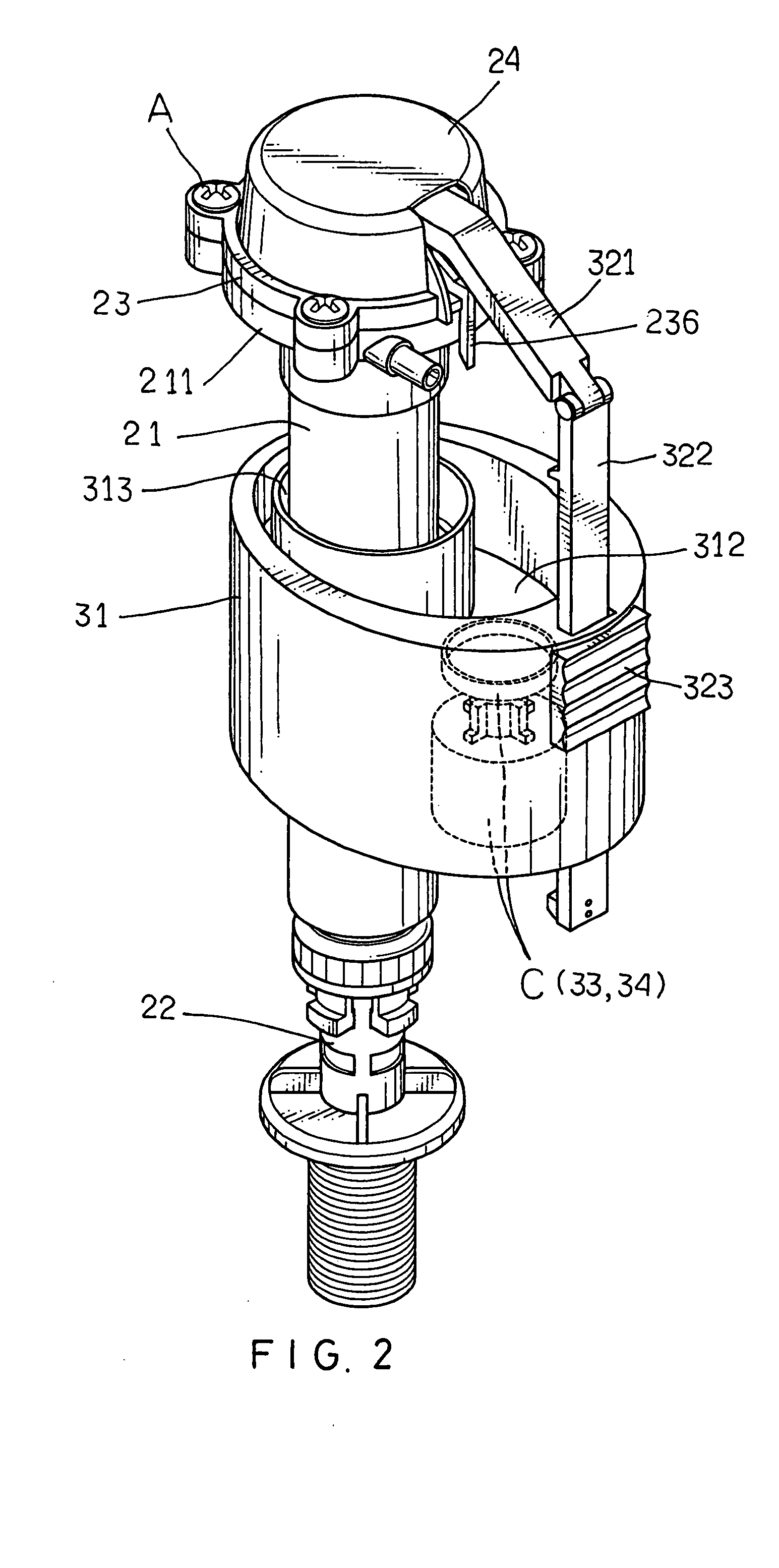

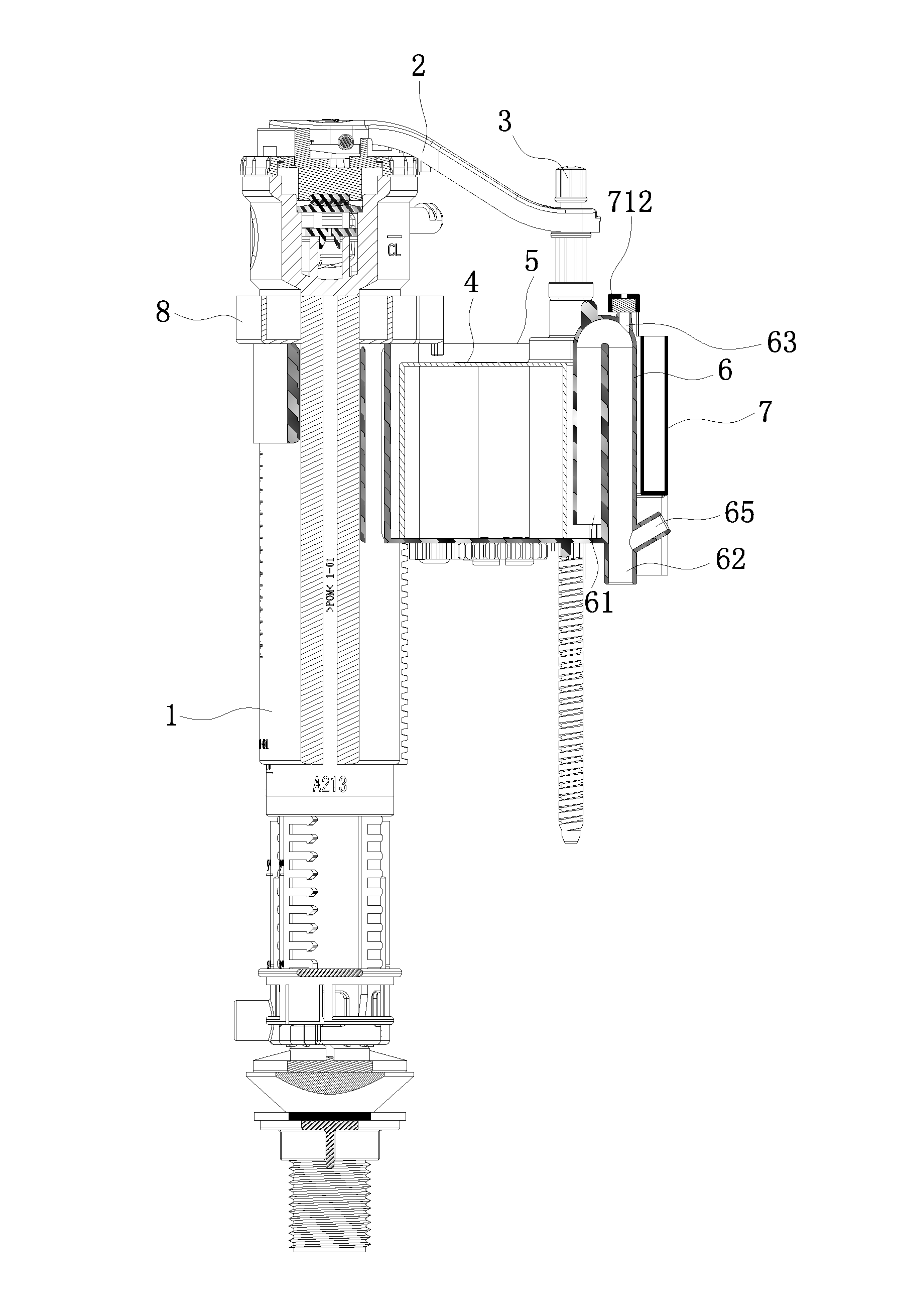

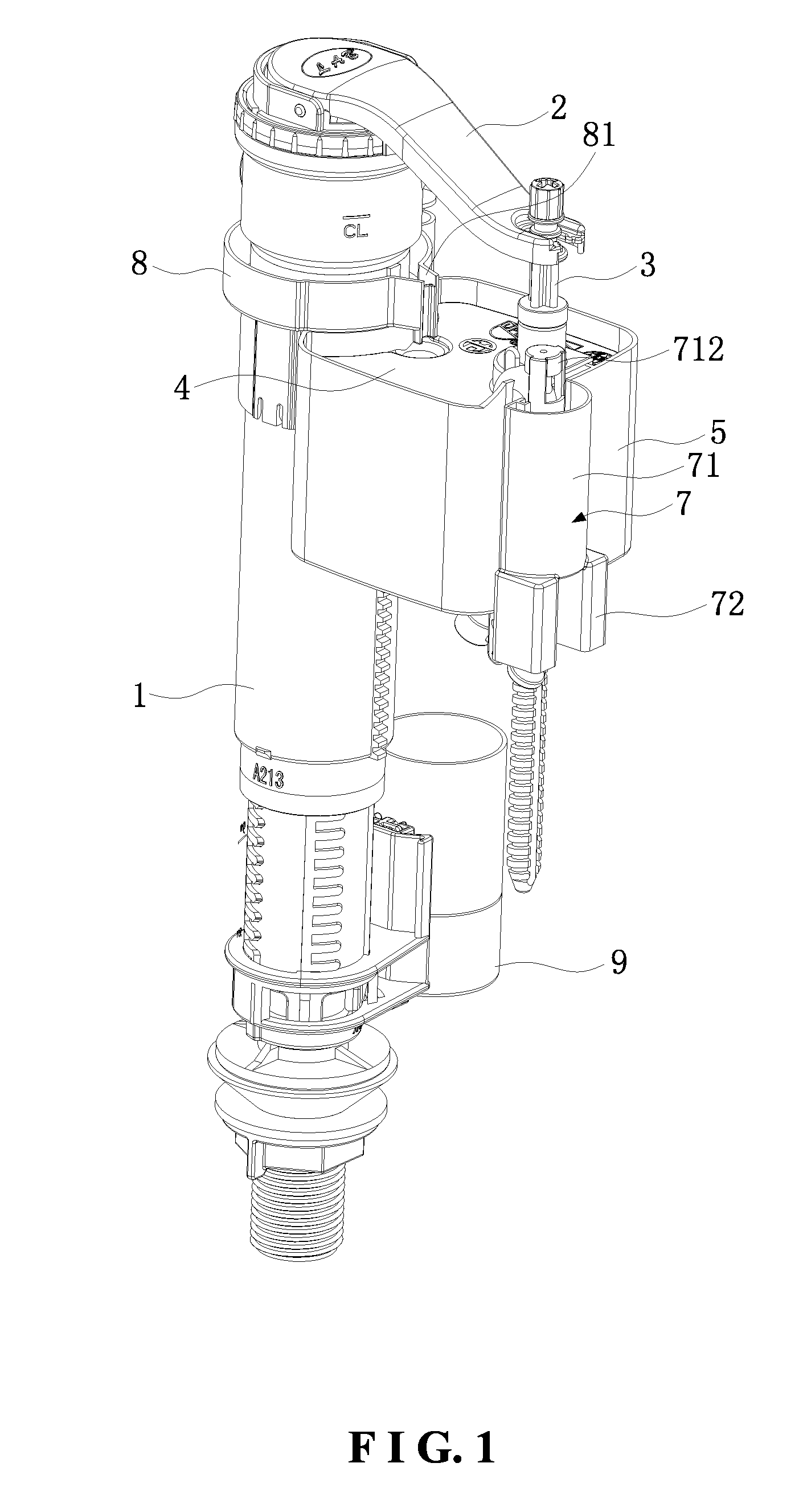

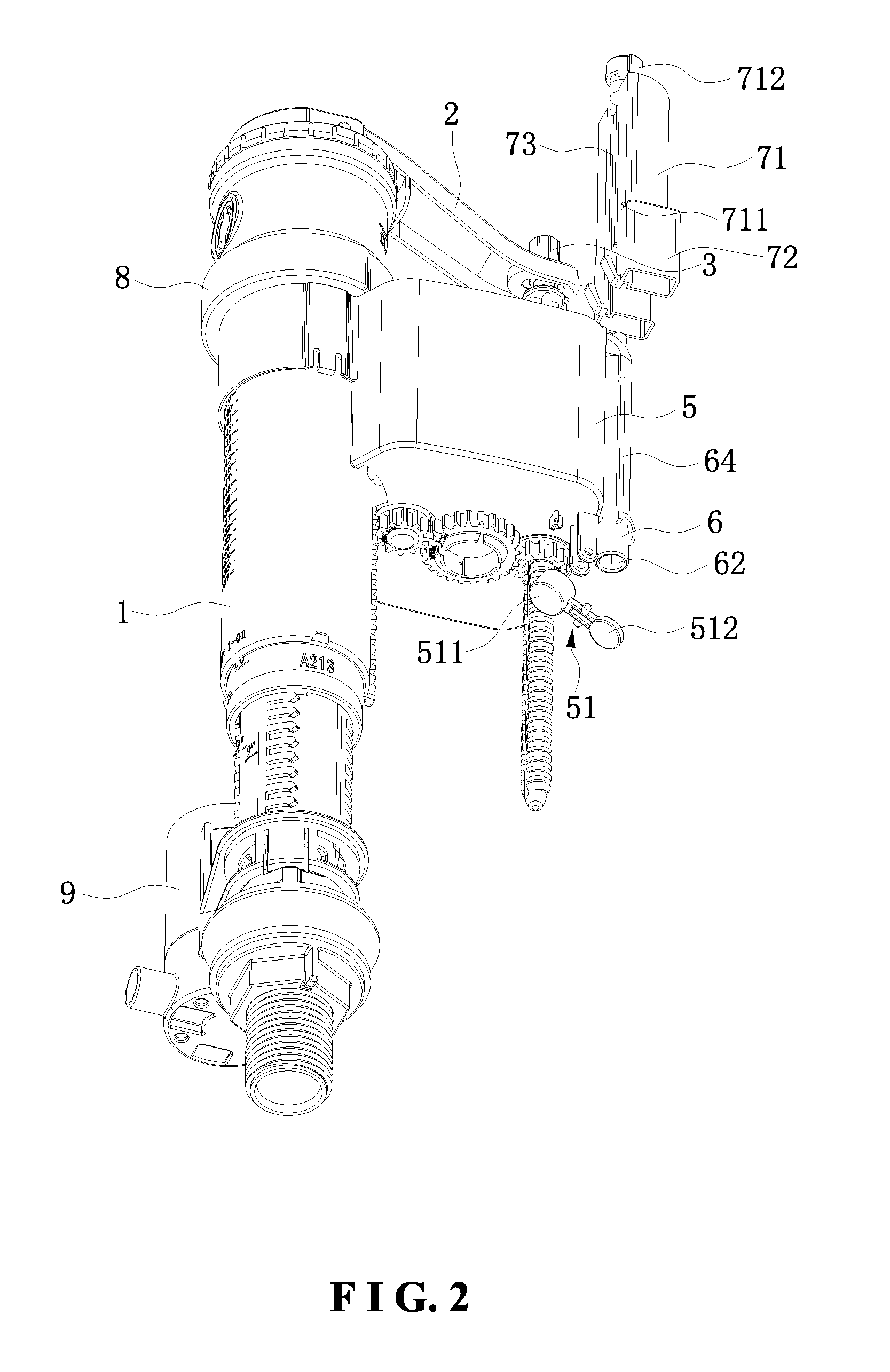

Water filler for water tank

InactiveUS6913035B2Operating means/releasing devices for valvesFlushing devicesWater sourceEngineering

A water filler includes a water filling device, and a regulating device. The water filling device includes an inner filling tube, an outer filling tube, and an upper cover. The regulating device includes a floating barrel, a sliding barrel, a water support disk, and an adjusting unit. Thus, the floating barrel is lifted instantaneously and rapidly to stop the water filling action exactly and actually, thereby saving the water source. Thus, the water filler has a quick water stop function.

Owner:HUANG SO MEL

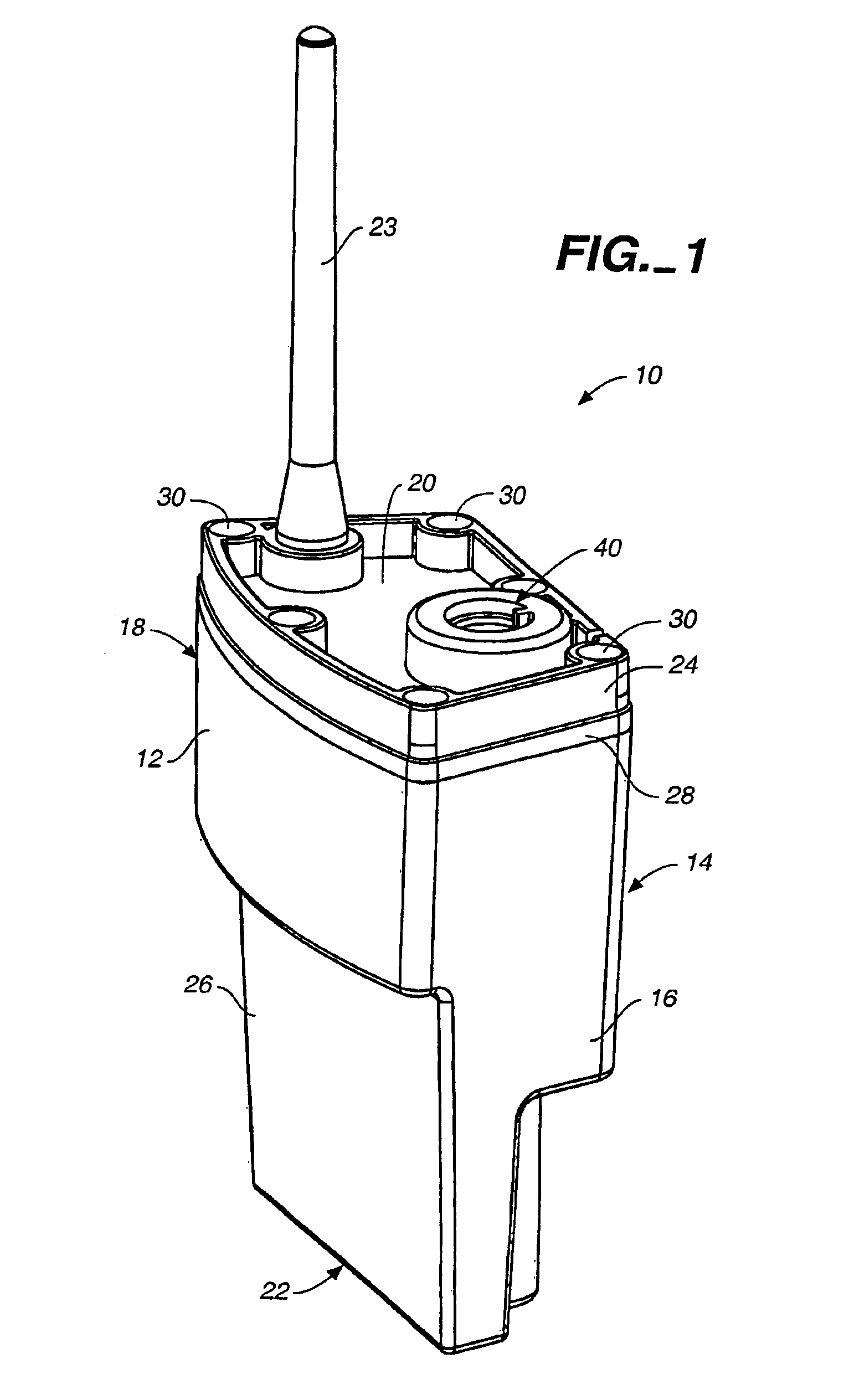

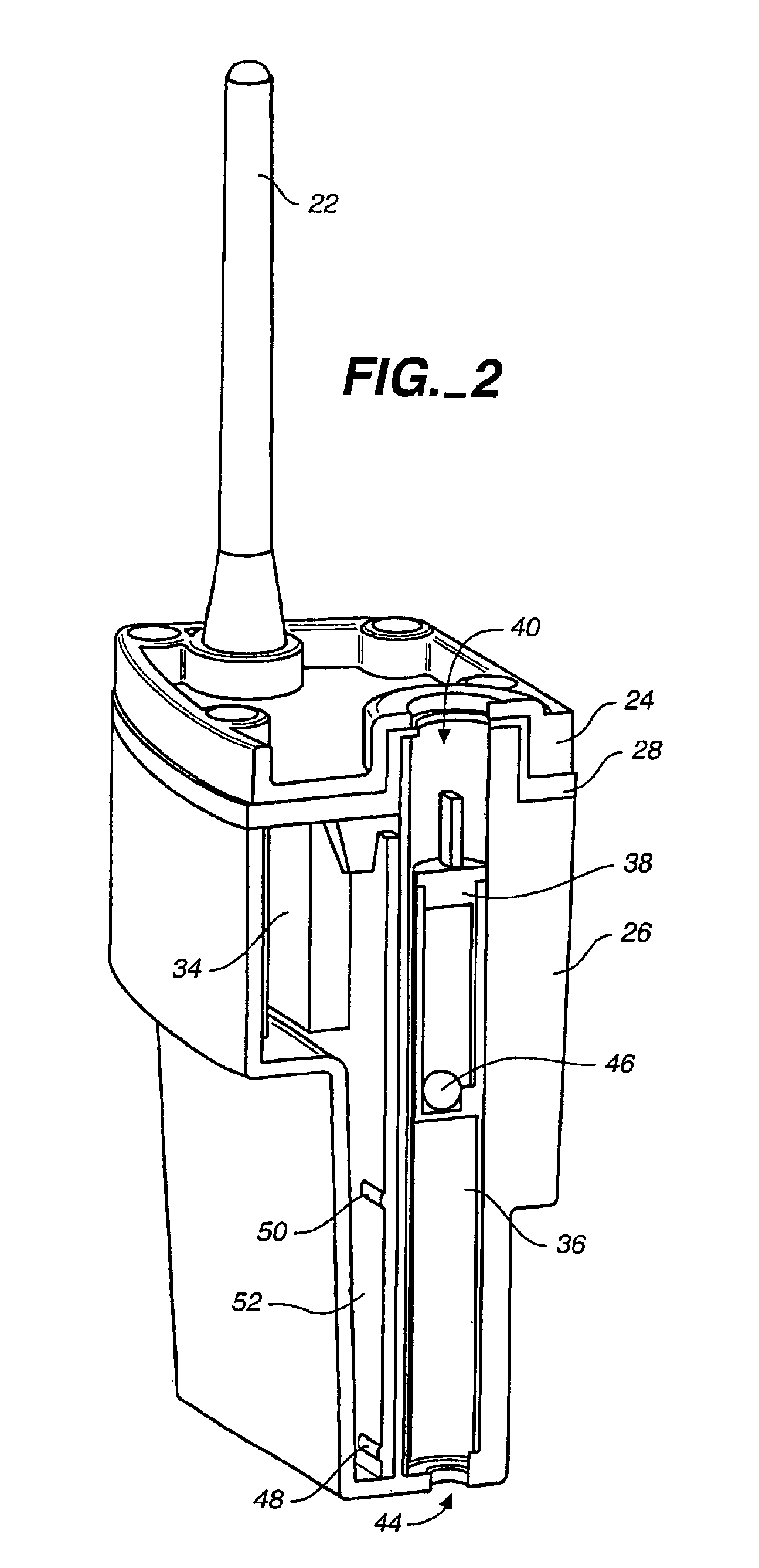

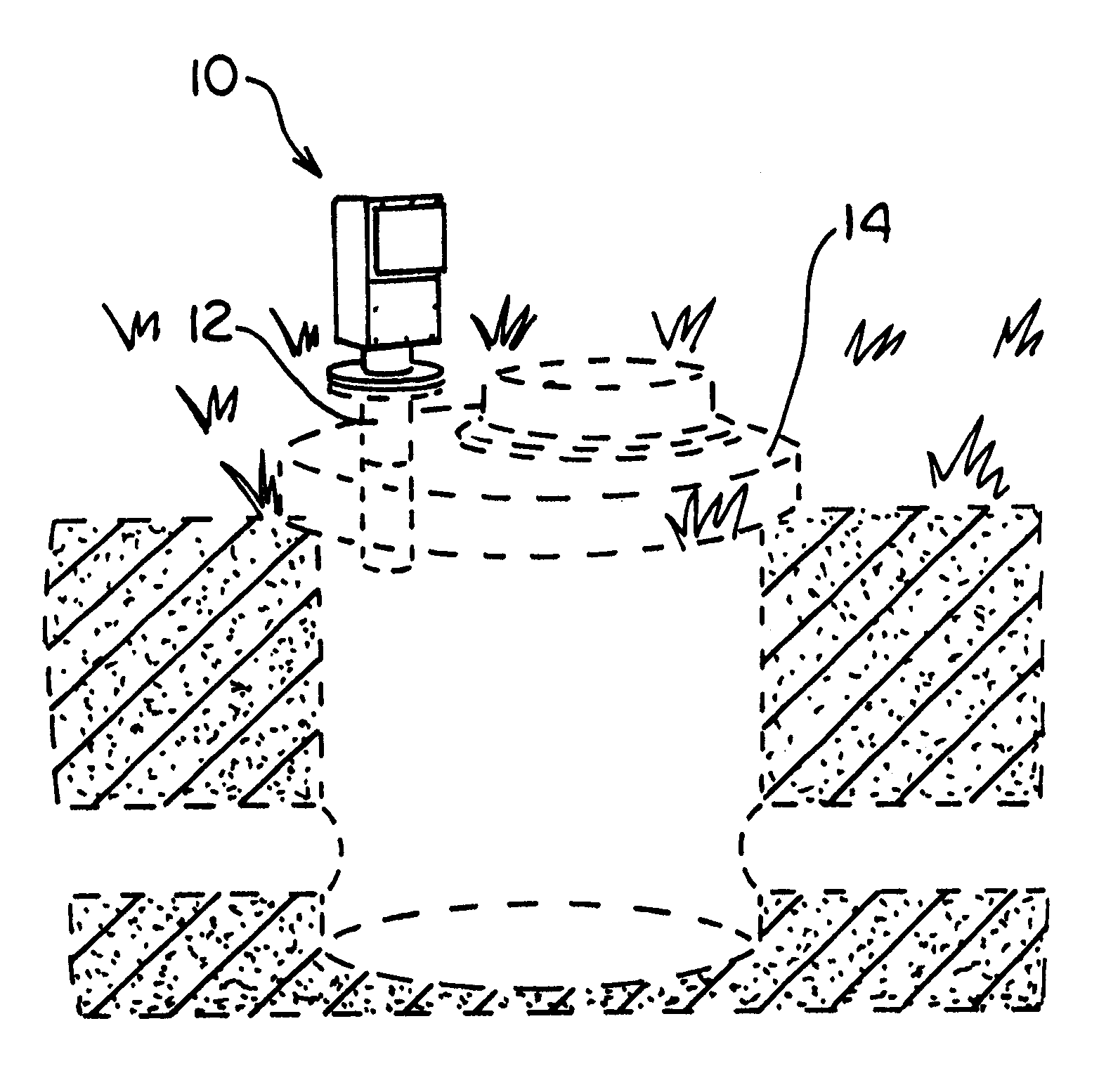

Liquid level controller

InactiveUS6910498B2Easy to installOperating means/releasing devices for valvesLevel controlControl systemEngineering

A liquid level control system for detecting and responding to changes in the level of liquid in a container. The system includes a transmitter in radio communication with a receiver, which is in turn connected to a valve assembly. The transmitter unit is programmable to respond to changes in the level of liquid in a container and to emit a radio signal receivable by the receiver unit, which controls the release of liquid to the liquid container via the valve assembly. The signal may be suppressed by a timing circuit in the transmitter circuitry unless and until a liquid level change is sufficiently sustained. The receiver is also programmable to keep the liquid control valve open a predetermined amount of time or to close the valve upon receipt of a high liquid level signal.

Owner:CAZDEN MICHAEL L

Dual-action vent check valve

A dual-action vent check valve is disclosed. The valve includes a first check valve which is responsive to elevated fluids inside the valve. A second check valve is responsive to elevated fluids external to the valve. The first check valve prevents overflow from a vented structure, such as a sewer out-fall line, from passing through and out of the valve, thereby preventing spills. The second check valve operates to prevent floodwater from passing into an underground structure, such as a sewer, through the vent. One embodiment of the invention includes a basket for enclosing a deodorizing material inside the valve for deodorizing gases which pass through the valve.

Owner:ROBERT H WAGER CO INC

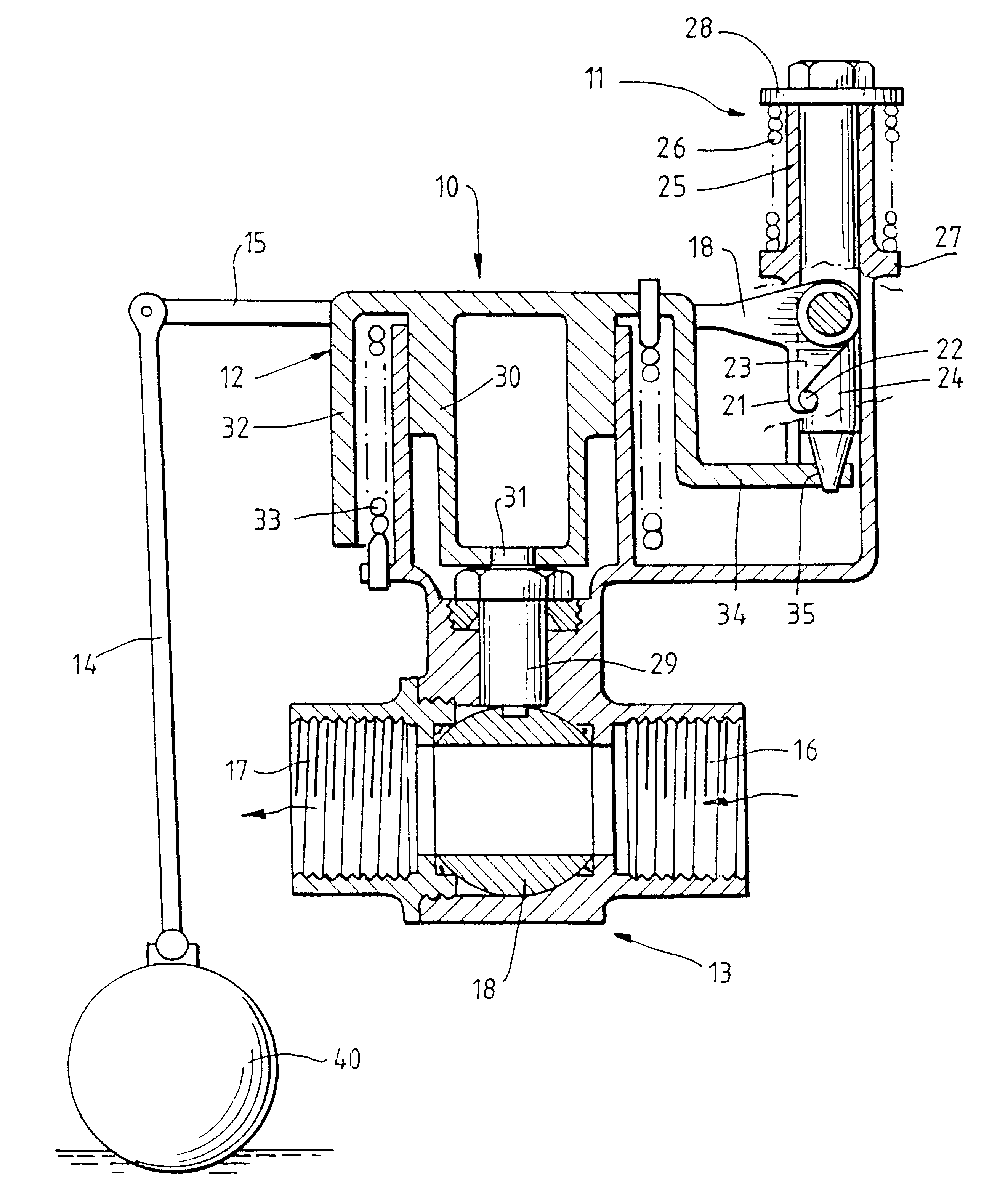

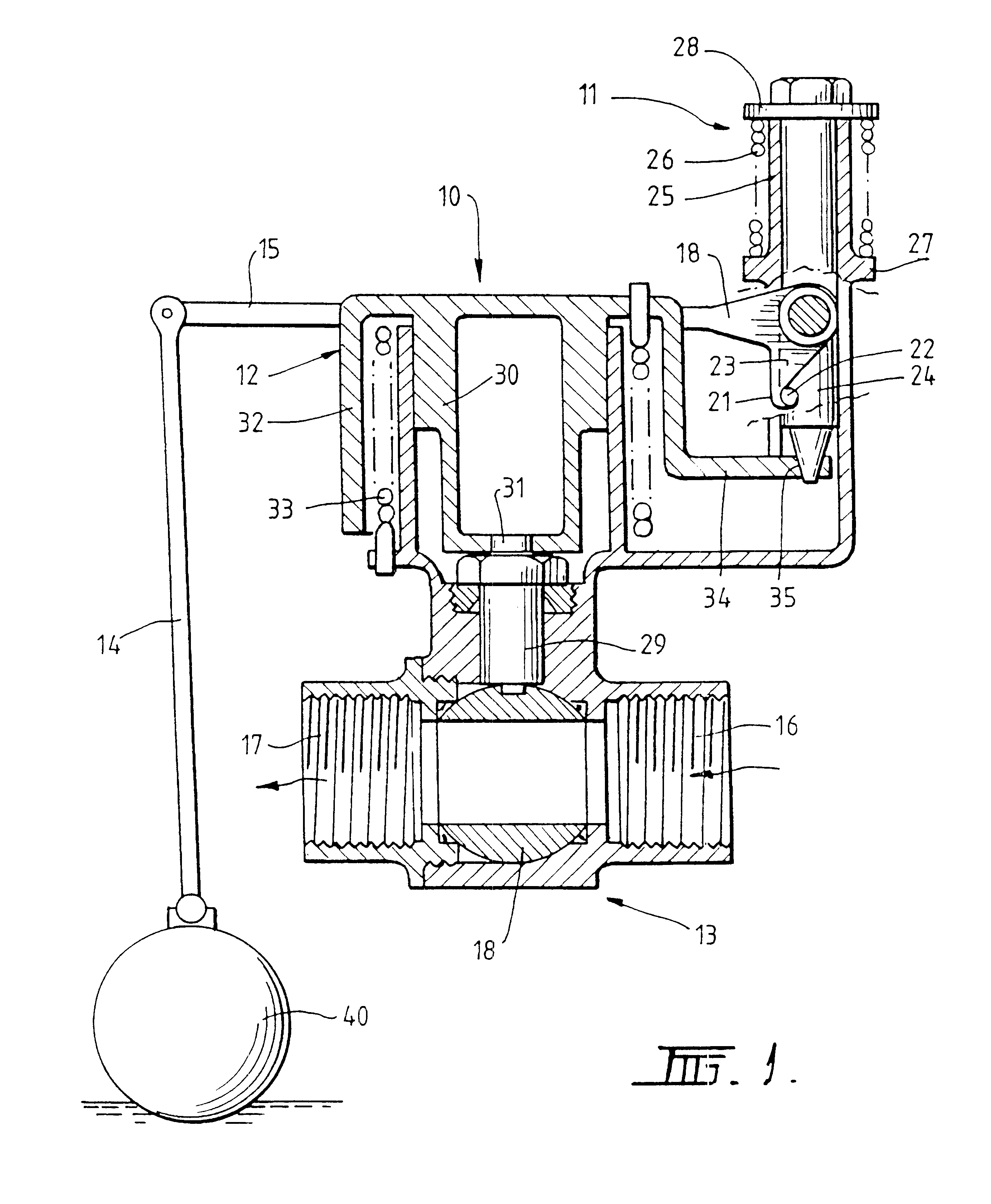

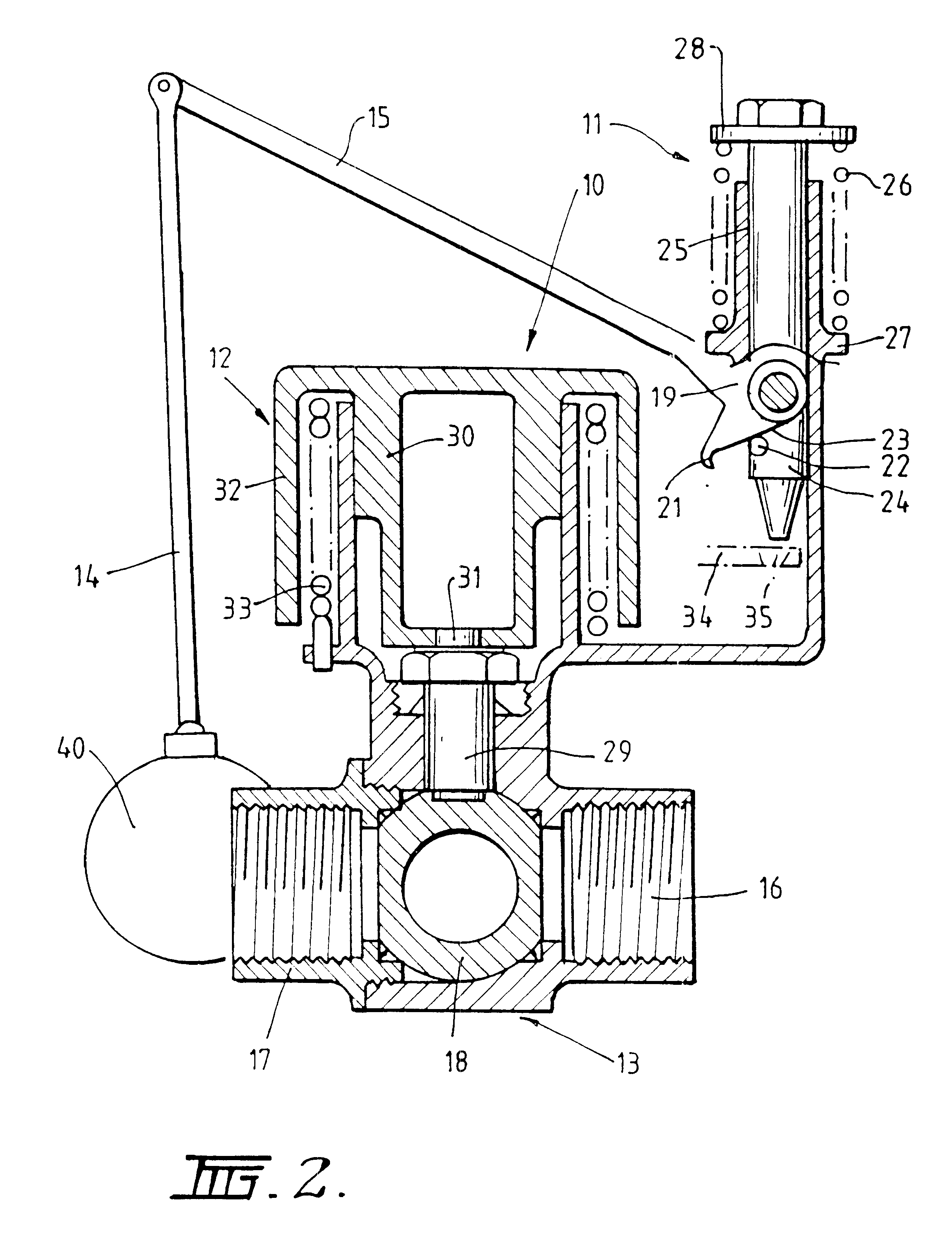

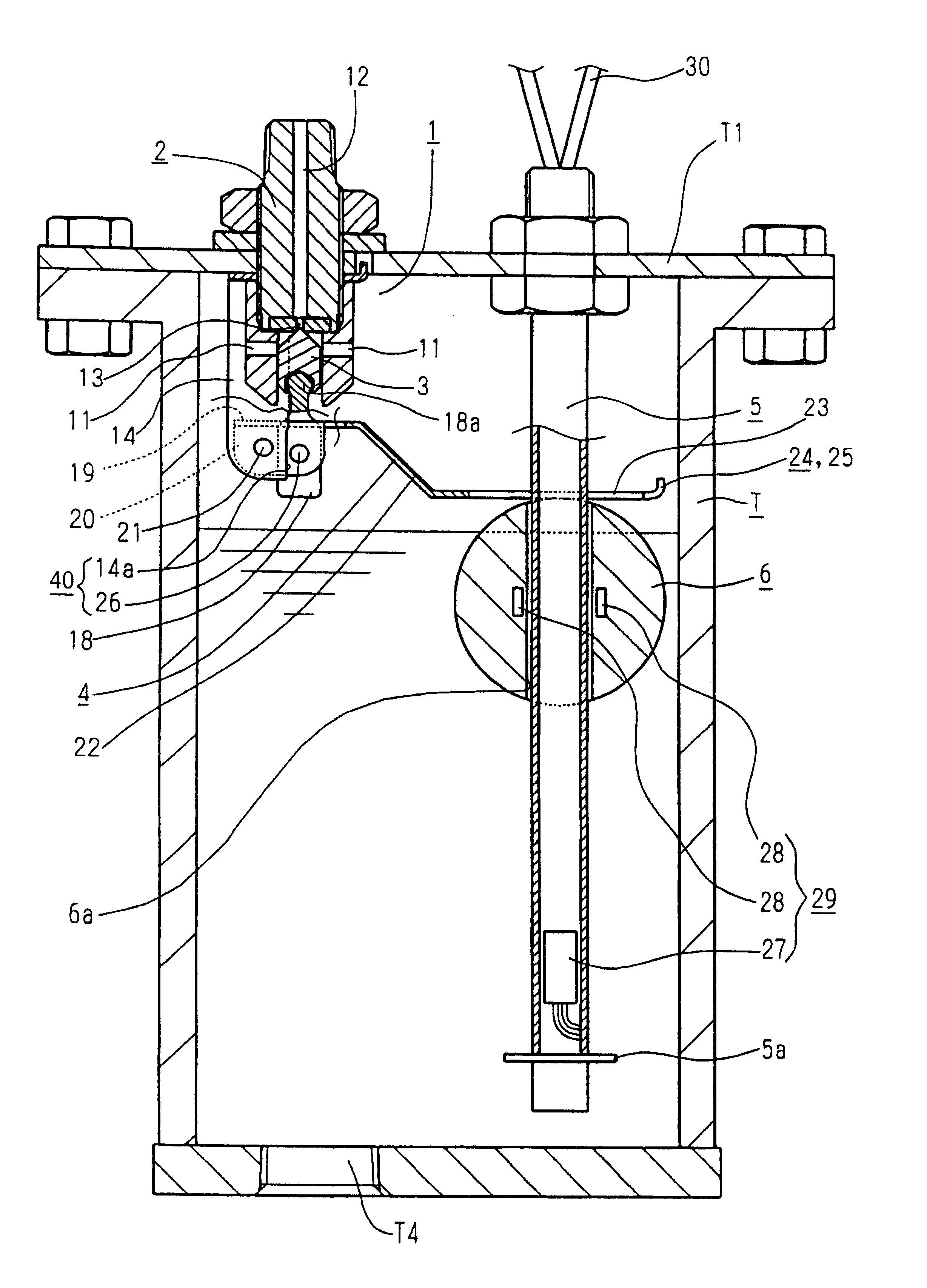

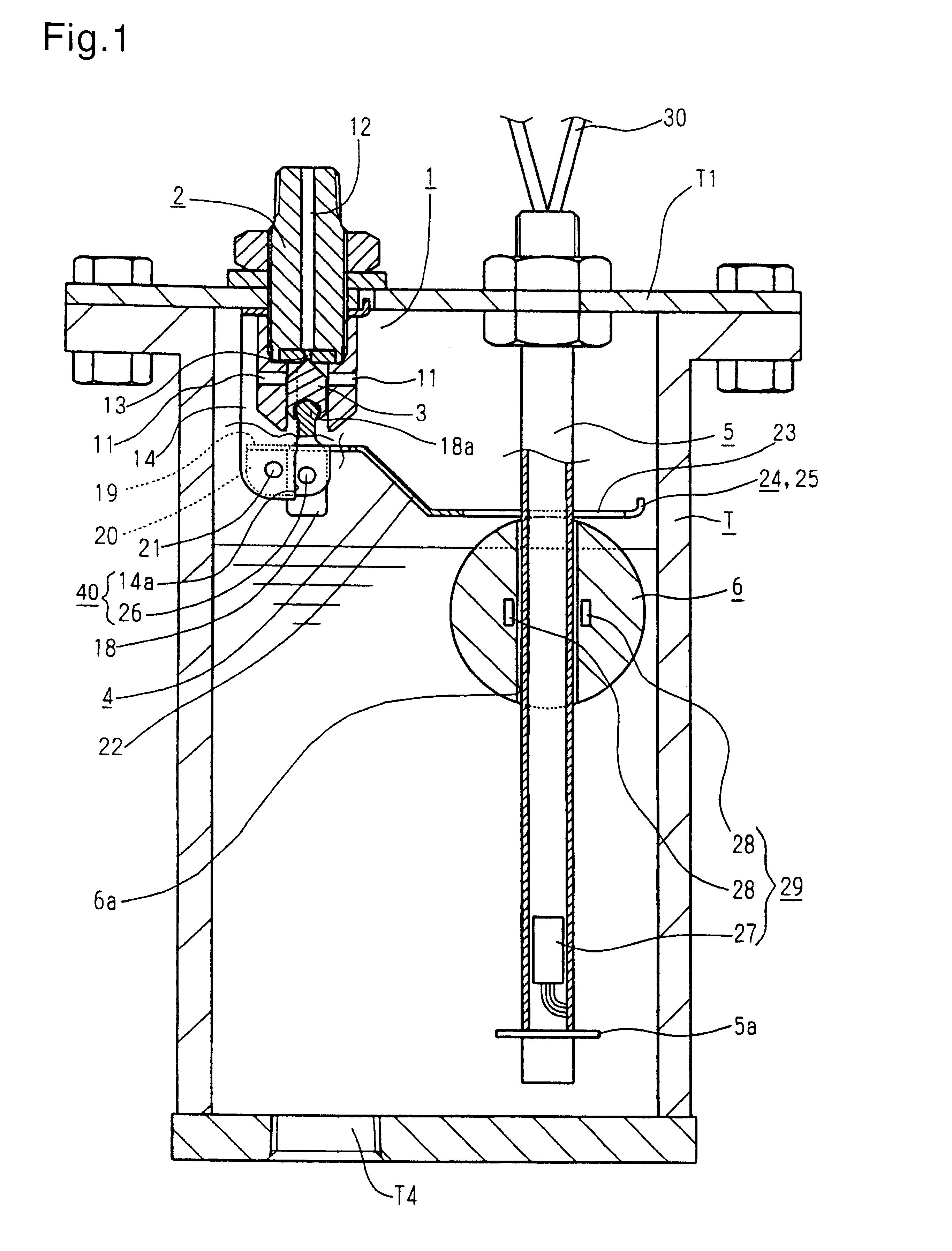

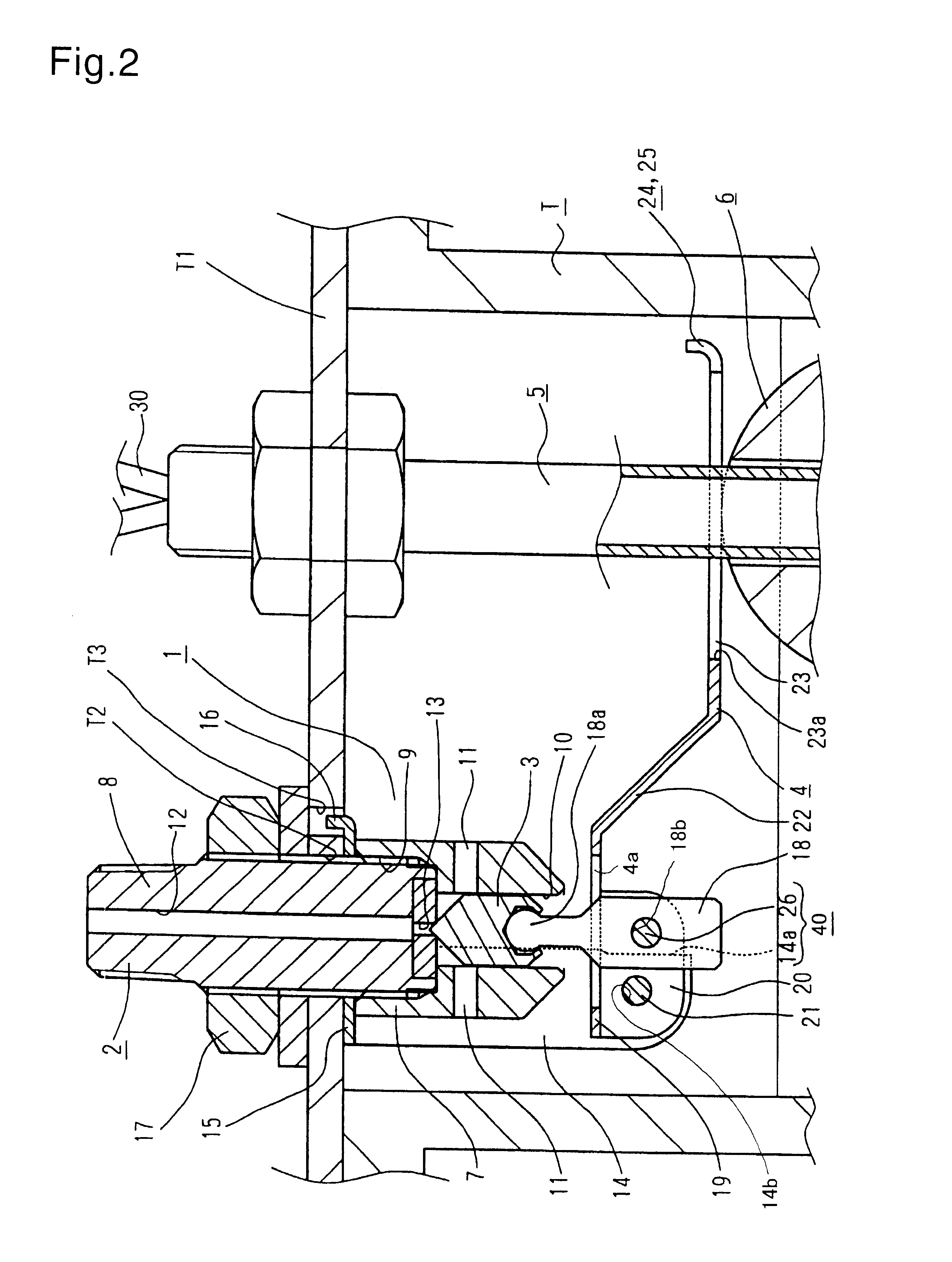

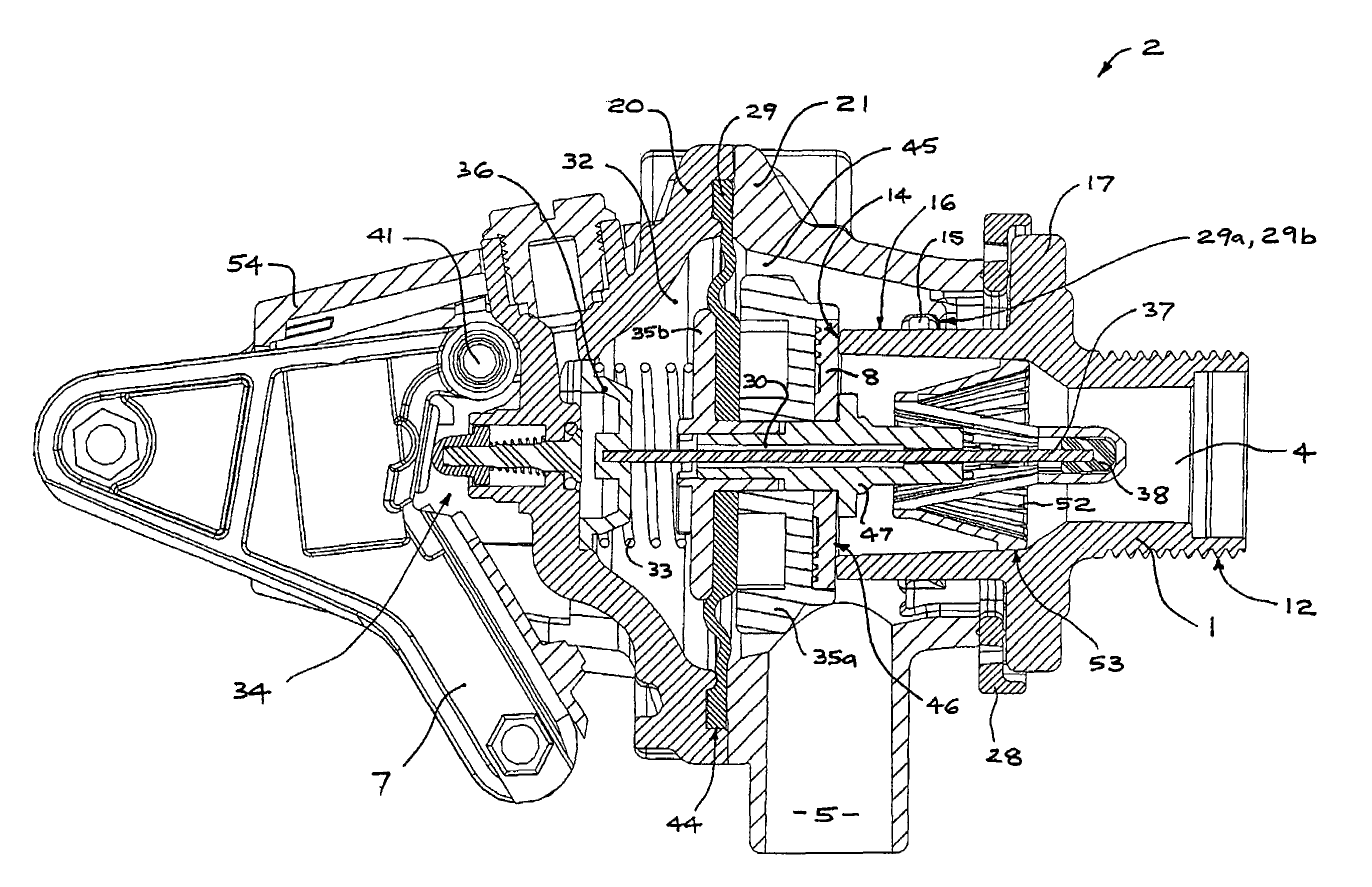

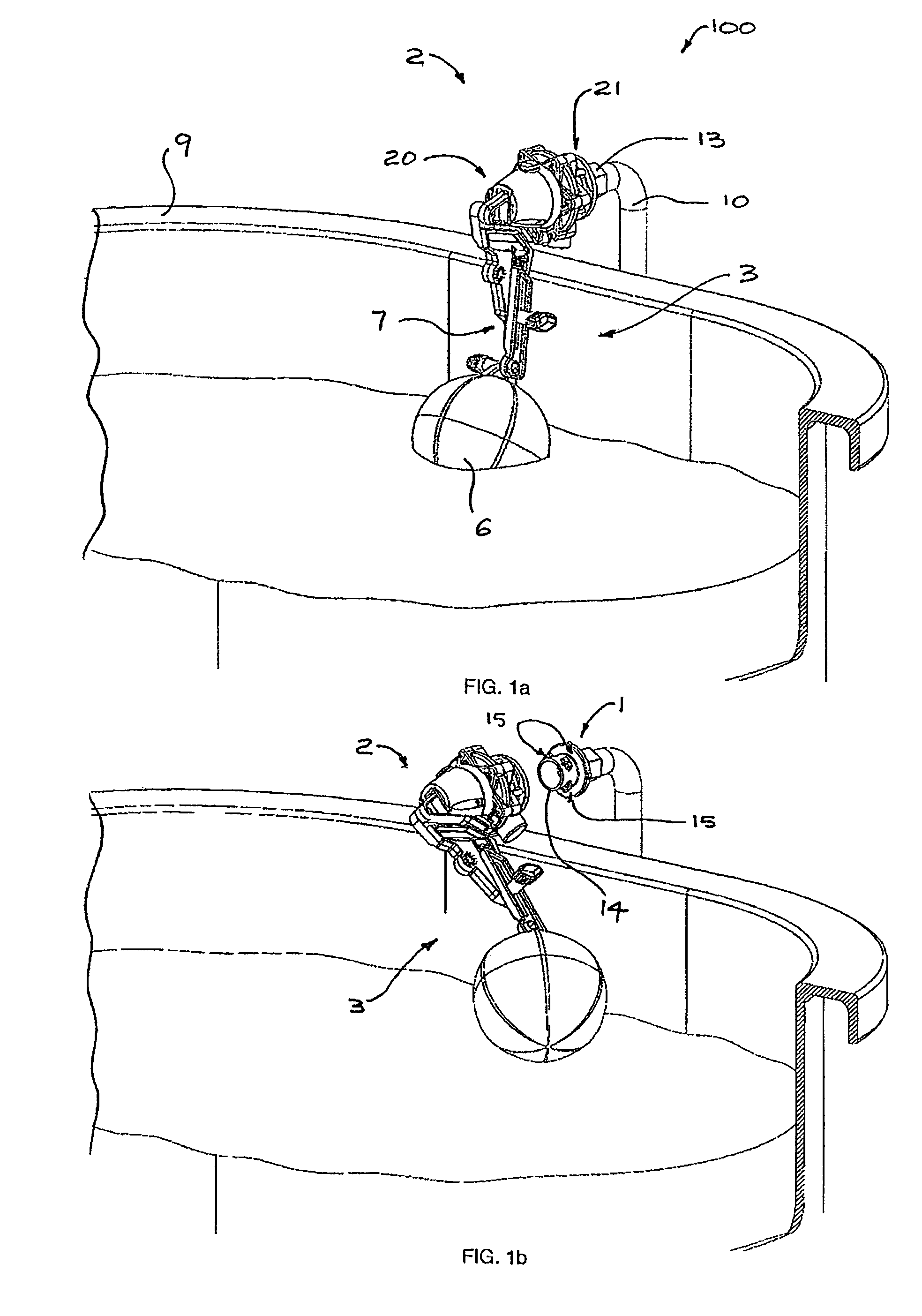

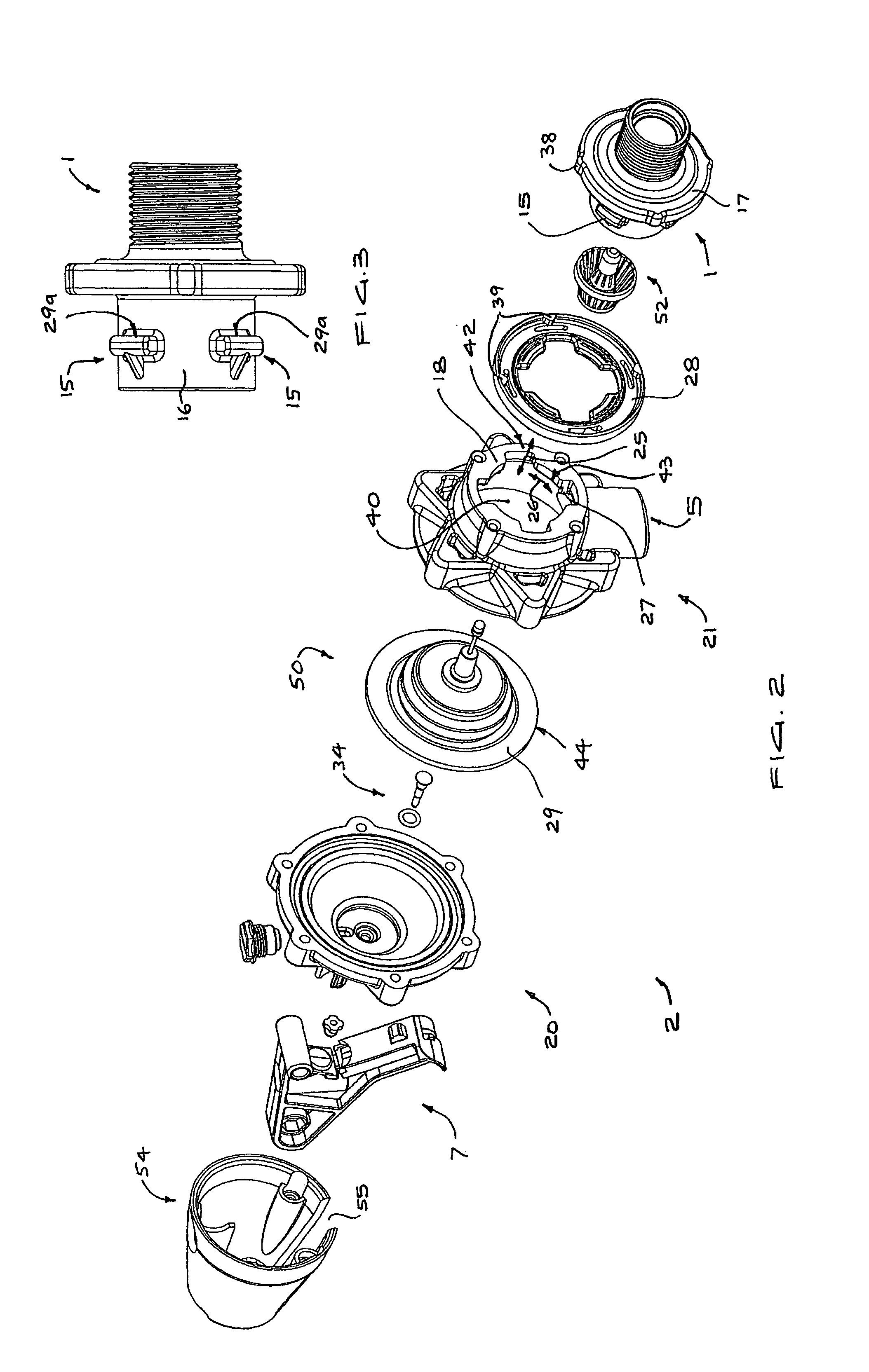

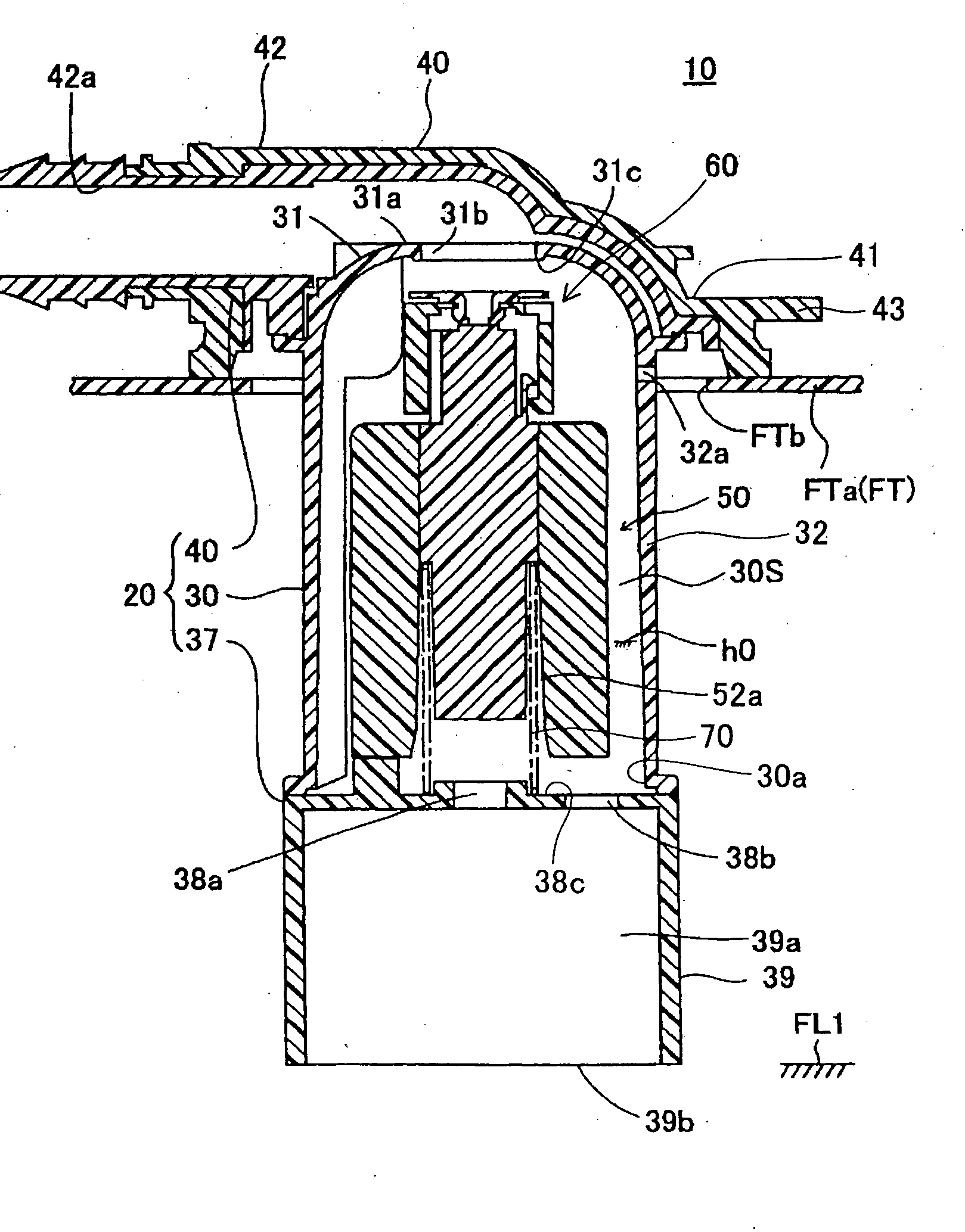

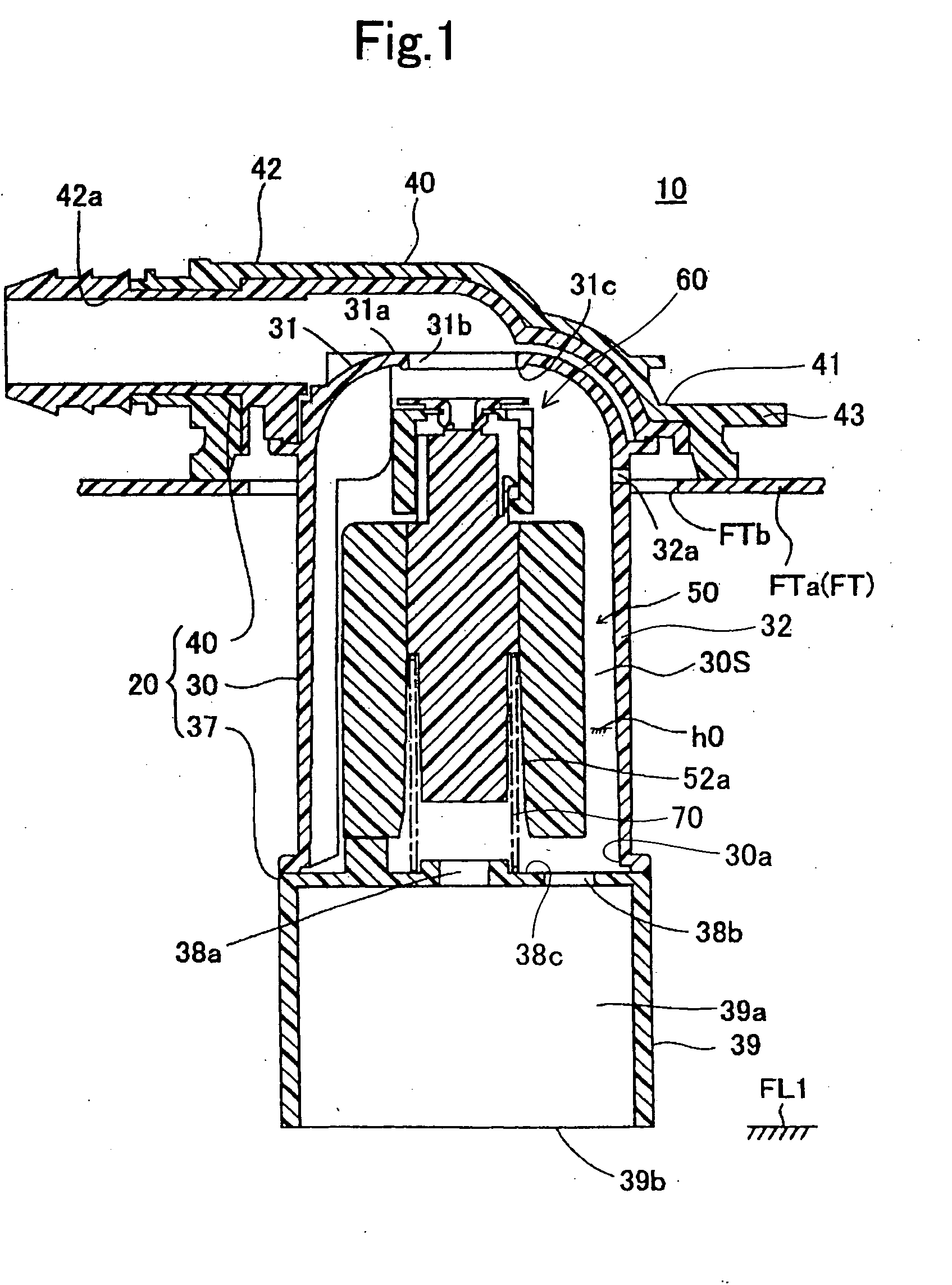

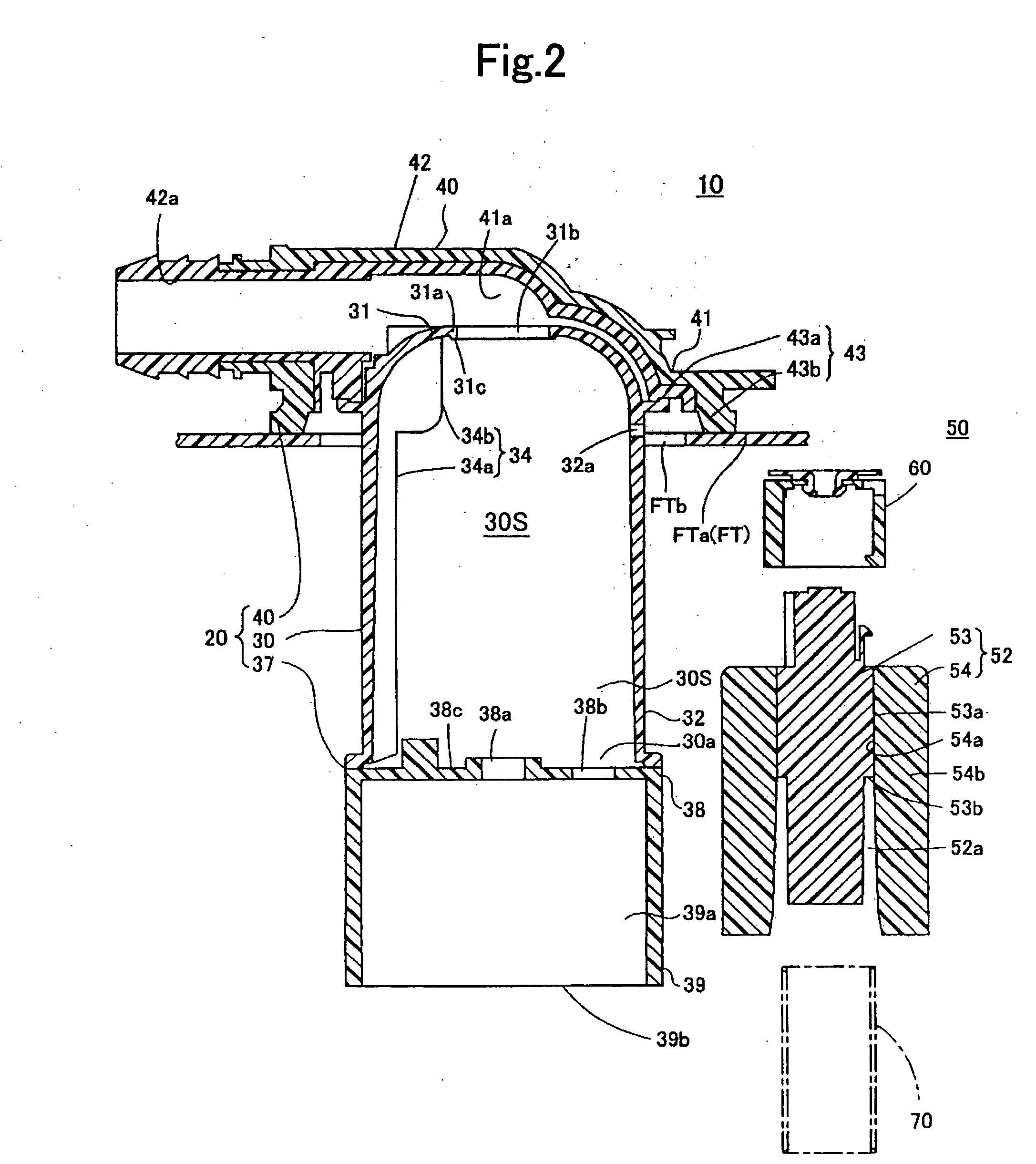

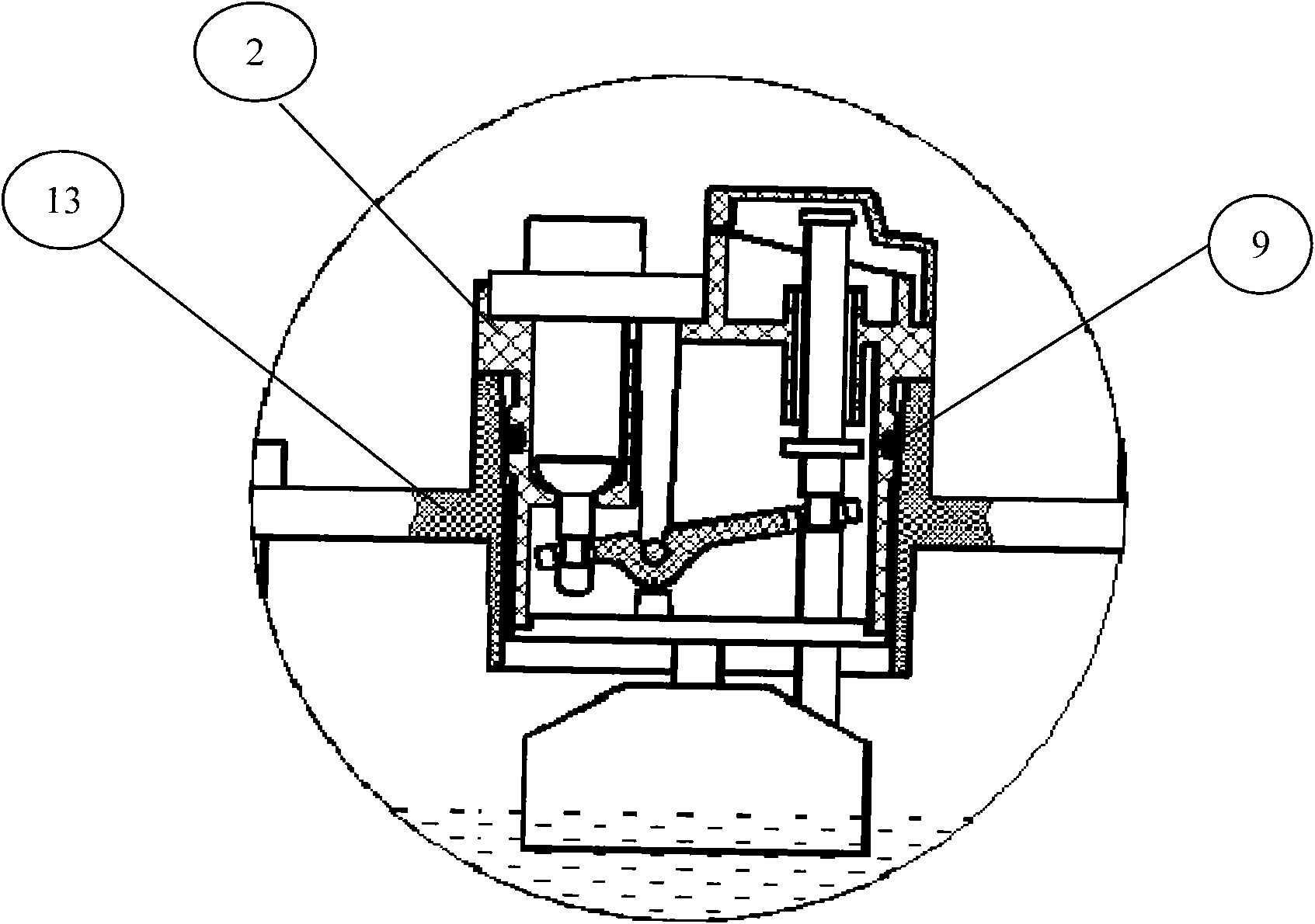

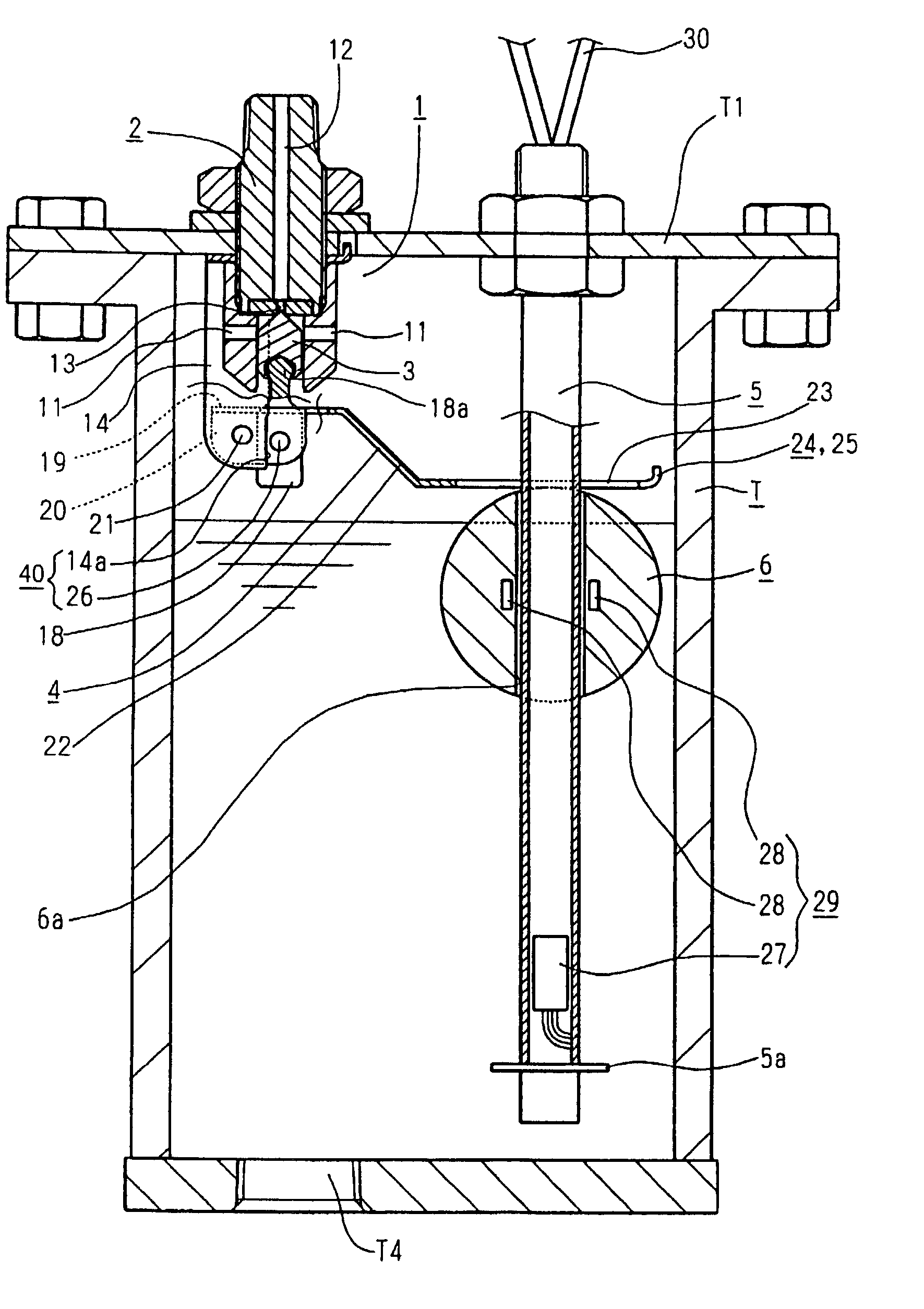

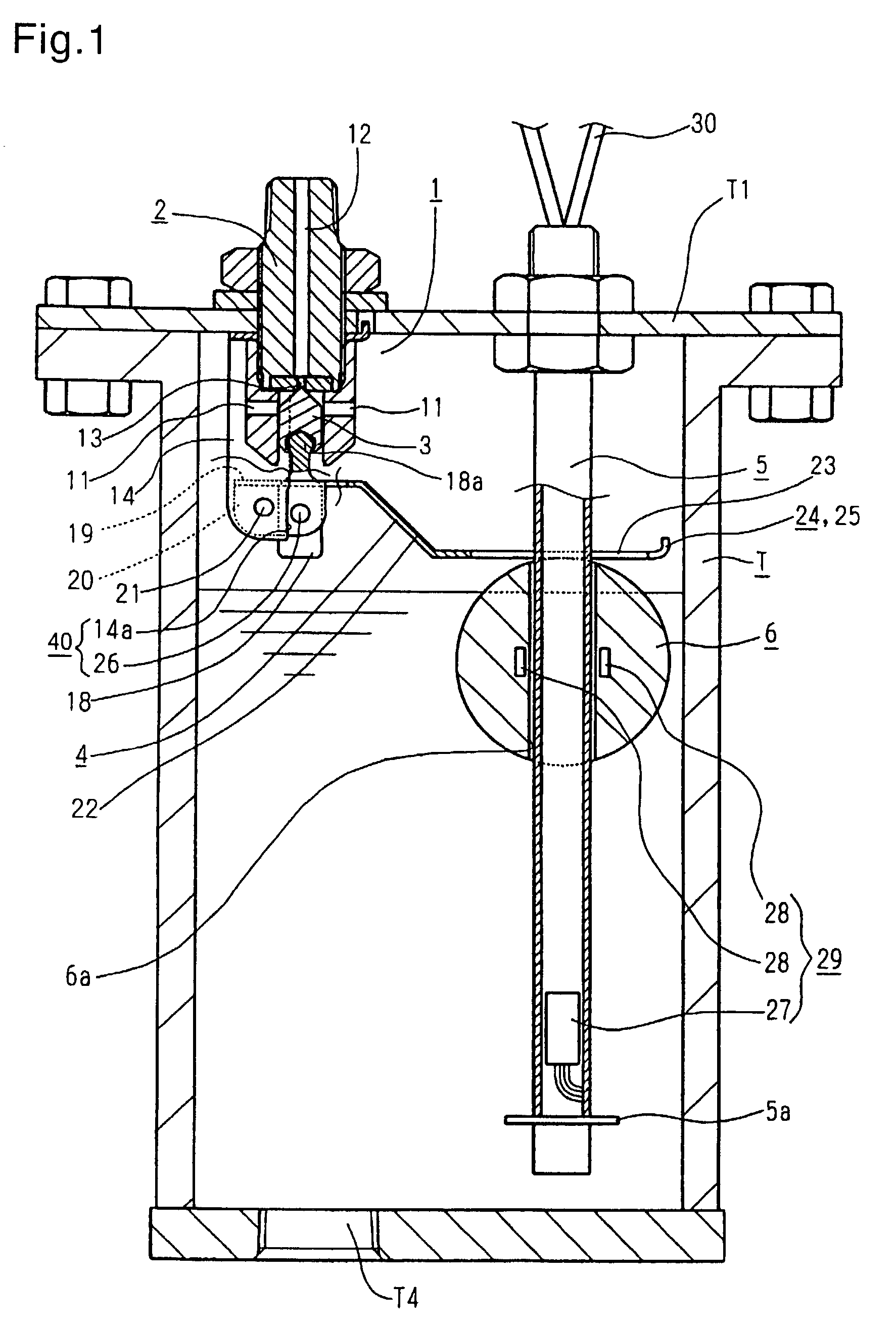

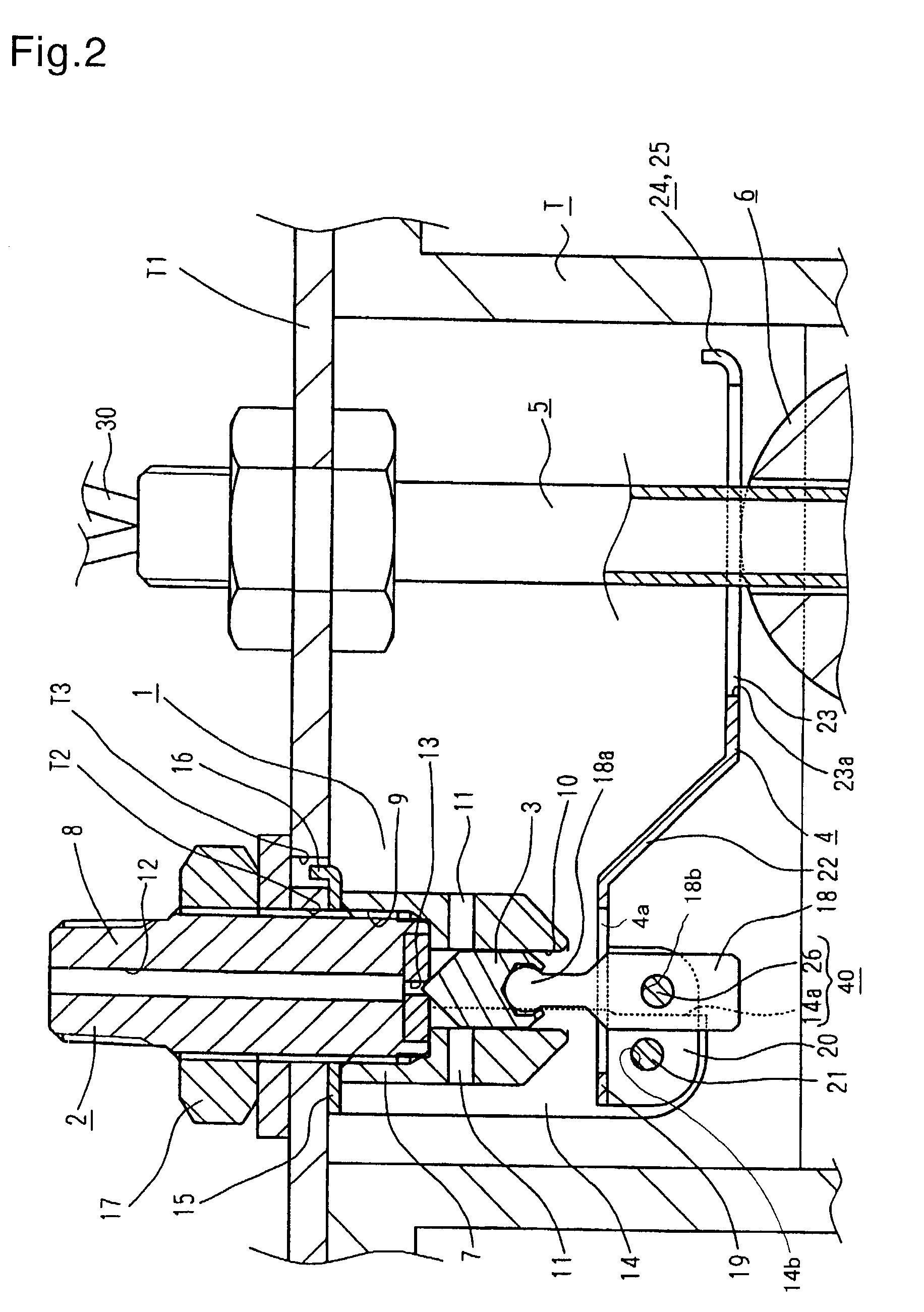

Ball tap with a water level switch

A compact ball tap with 1 a water level switch which comprises a guide standpipe 5 vertically arranged in a tank T, a float 6 slidably installed on the guide standpipe 5, a valve 3, a lever 4 controlling an open-close action of the valve 3 connected with the float 6, and a water level switch 29 transmitting predetermined control signals when the float 6 shifts to a predetermined water level, wherein one float 6 is shared by the ball tap 1 and the water level switch 29.

Owner:YOSHITAKE INC

Sewer relief valve with integral disinfectant means

A sewer relief valve assembly comprises a cylindrical sleeve dimensioned for insertion into a clean out which has an interior surface formed as a conduit and exterior threads adapted for mated engagement with the interior threads of the clean out. A valve means is disposed in the cylindrical sleeve which is displaceable from a closed position to an open position by pressurized fluid in the clean out. At least one perforated compartment is disposed inside the cylindrical sleeve which contains a water-soluble disinfectant composition. The valve means is displaceable by fluid pressure to the open position permitting discharge of the effluent through the clean out and the simultaneous release of the water-soluble disinfectant composition from the perforated compartment into the effluent. A water-soluble dye composition can also be included in the perforated compartment so that sewage overflow from the clean out is readily visible.

Owner:HART JR JAMES R

Buoyancy flushing apparatus and method thereof

InactiveUS6886588B2Increase pressureGood flexibilityEqualizing valvesSafety valvesWastewaterPreviously treated

A buoyancy flushing apparatus is disclosed which comprises a reservoir for accumulating liquid, having an inlet for receiving liquid and an outlet chamber recessed in a bottom wall of the reservoir. The outlet chamber includes an outlet for draining liquid out of the reservoir. The apparatus further comprises an outlet valve movable between a down position where liquid accumulates in the reservoir and a raised position where liquid accumulated in the reservoir is flushed out via the outlet. The outlet valve comprises a ballast unit sized and shaped to fit loosely in the outlet chamber when said valve is in the down position; and a float unit topping the ballast unit to move the valve in the raised position by buoyancy when a sufficient amount of liquid is accumulated in the reservoir, thereby providing a passageway for liquid between the bottom wall of the reservoir and the valve leading to the outlet in the outlet chamber to flush liquid out of the reservoir. Guiding means are provided for guiding the outlet valve between the down position and the raised position. The apparatus can be used for applications such as water treatment and irrigation. It could advantageously be used for directing and spreading waste water previously treated in a septic tank to different sanitary treating fields.

Owner:PREMIER TECH EAU & ENVIRONNEMENT LTEE

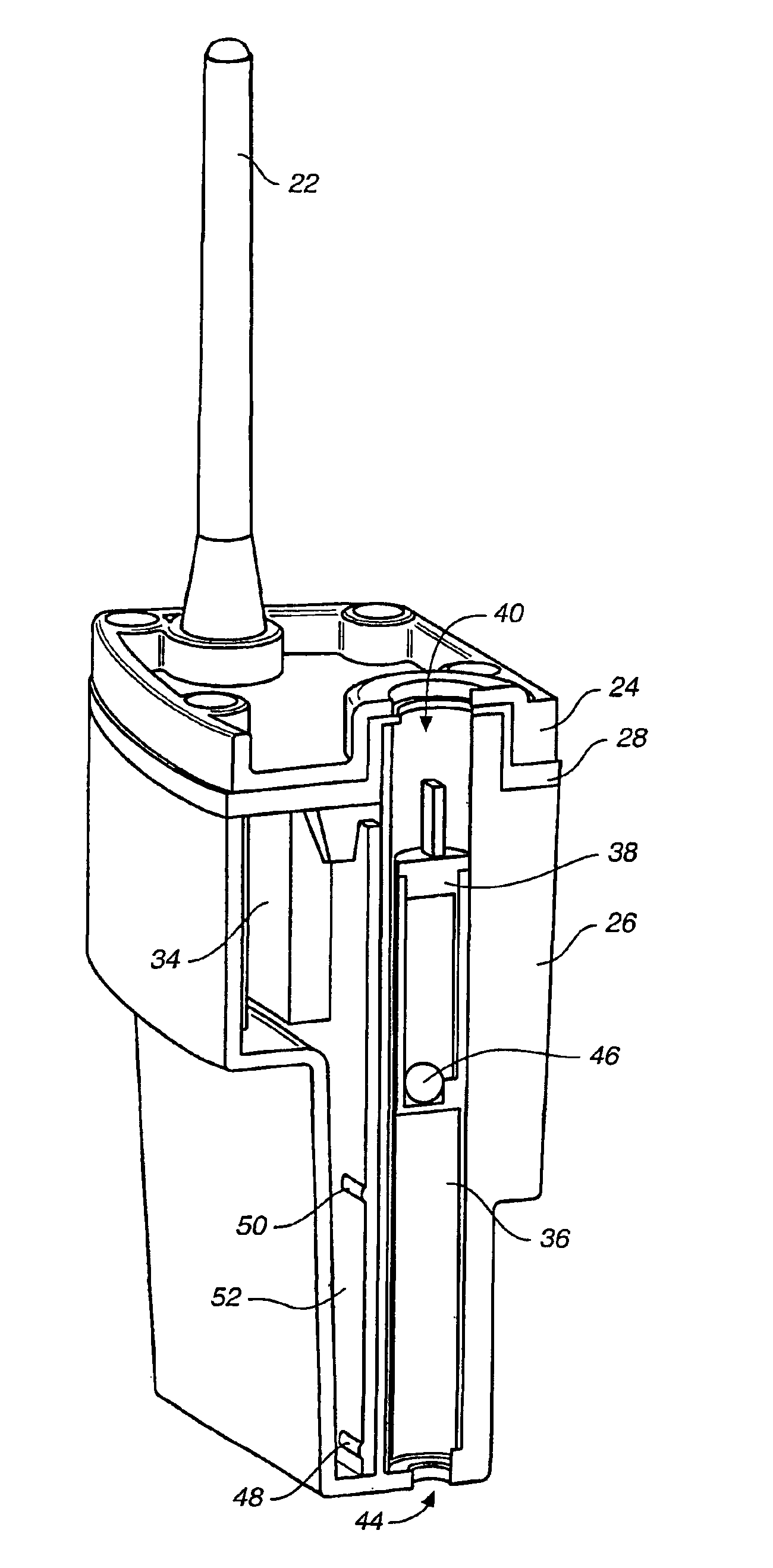

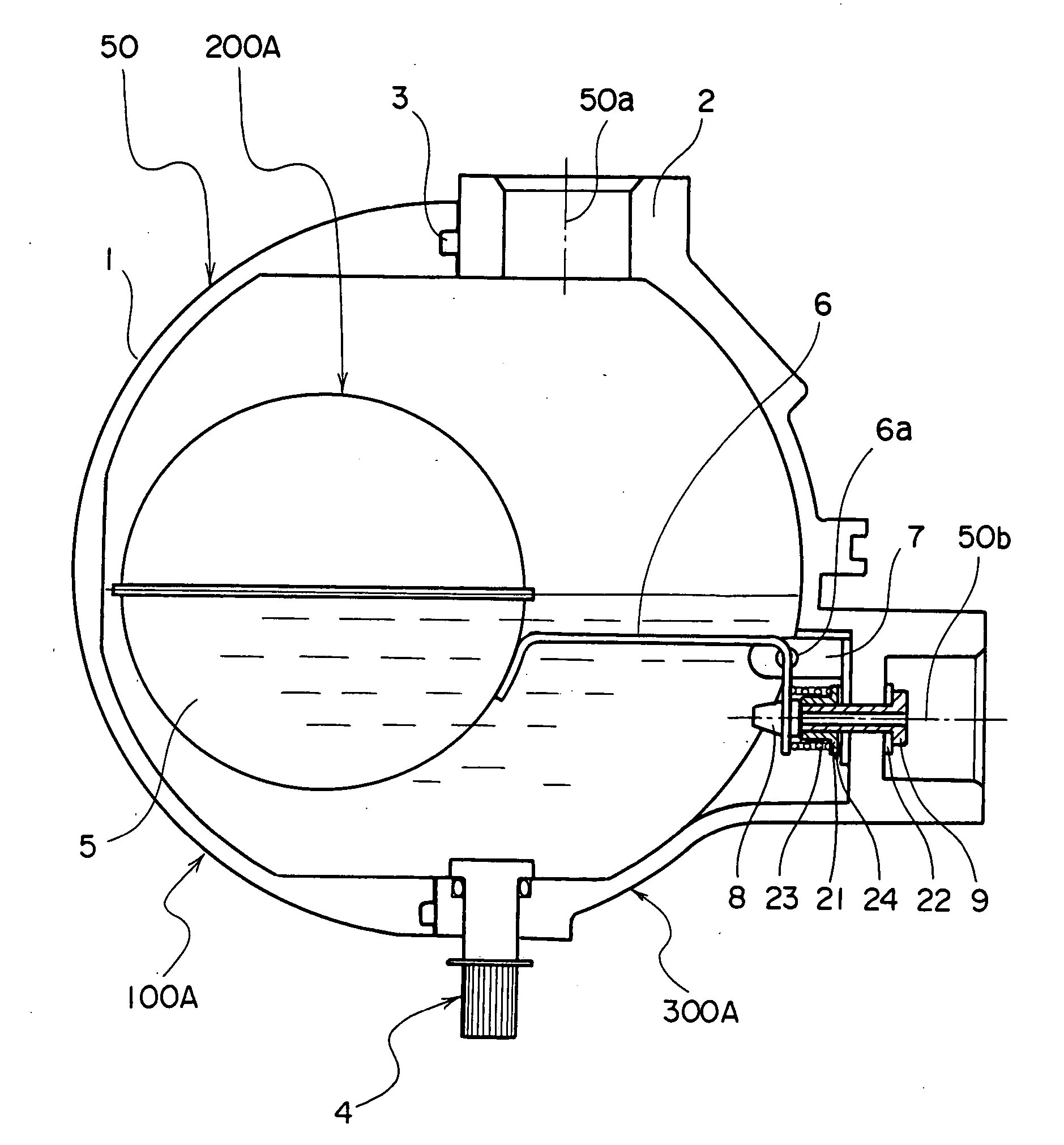

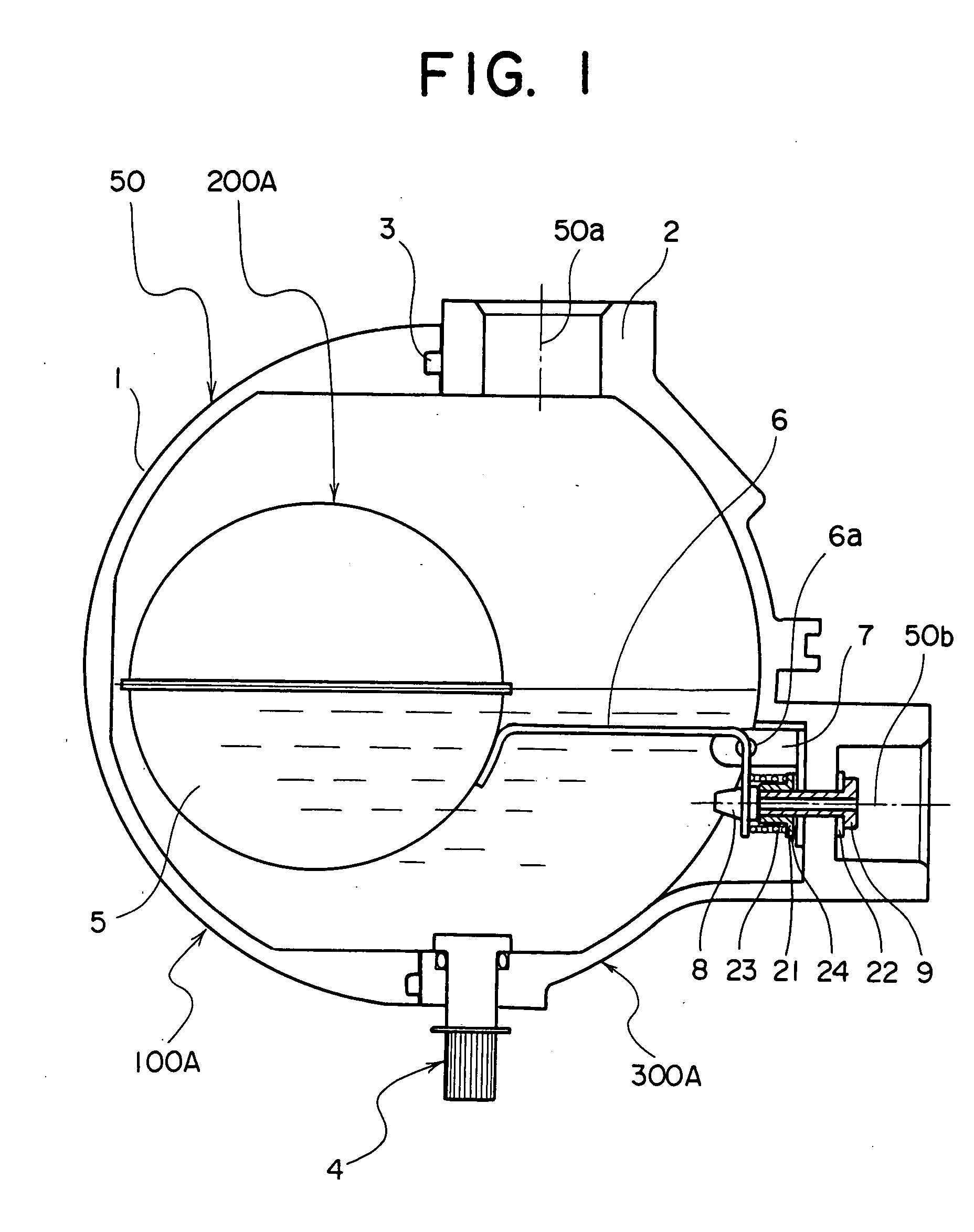

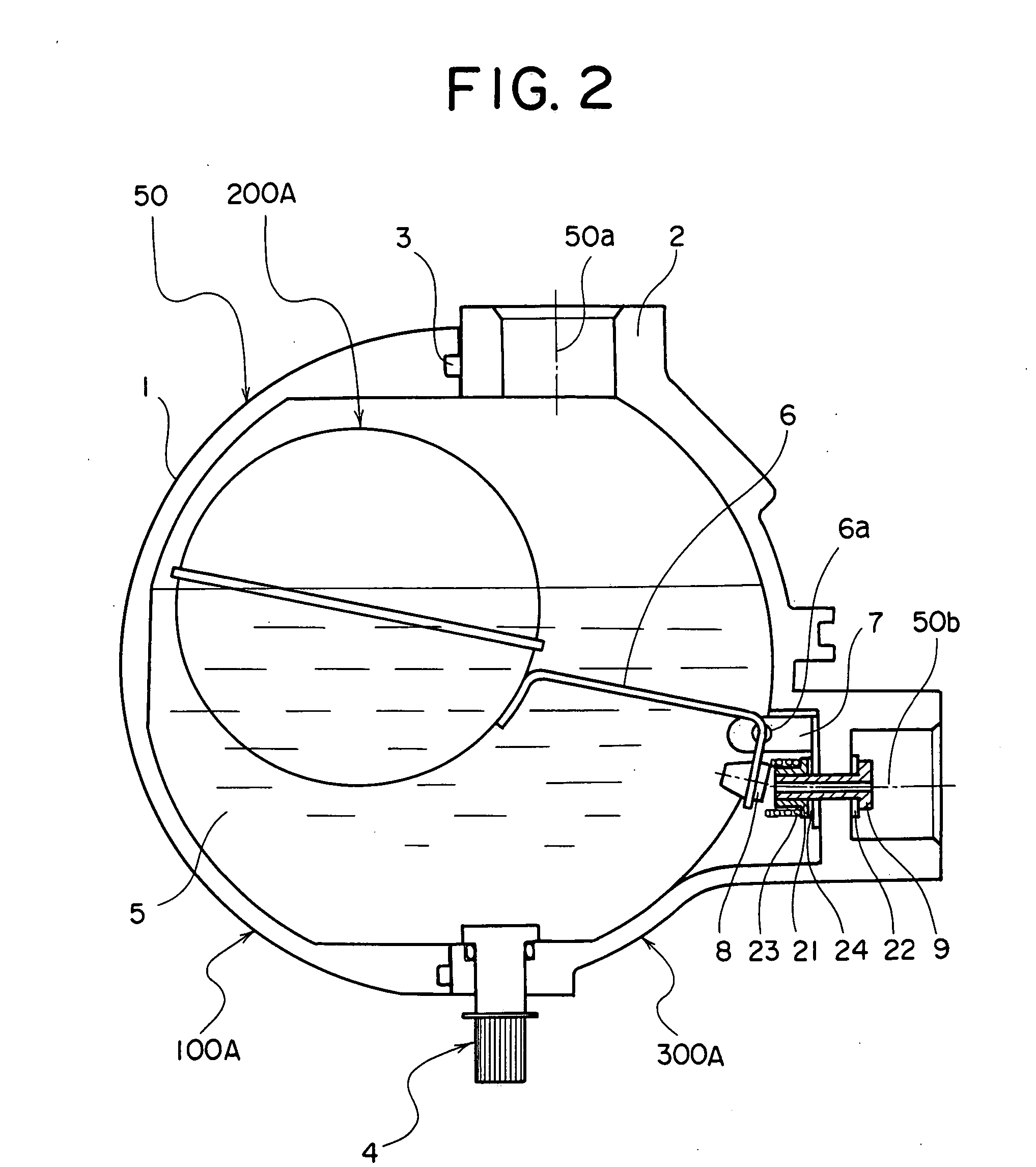

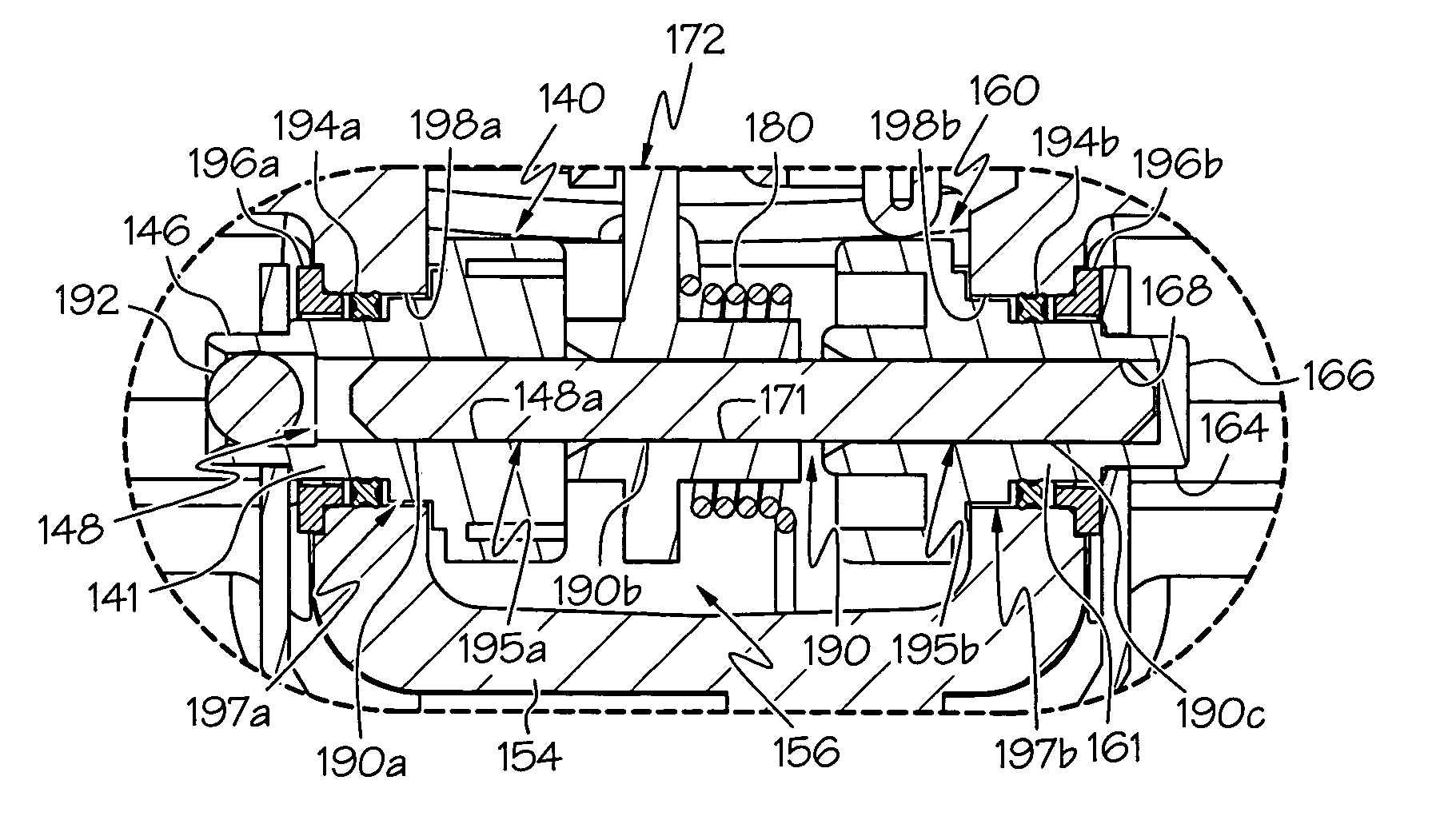

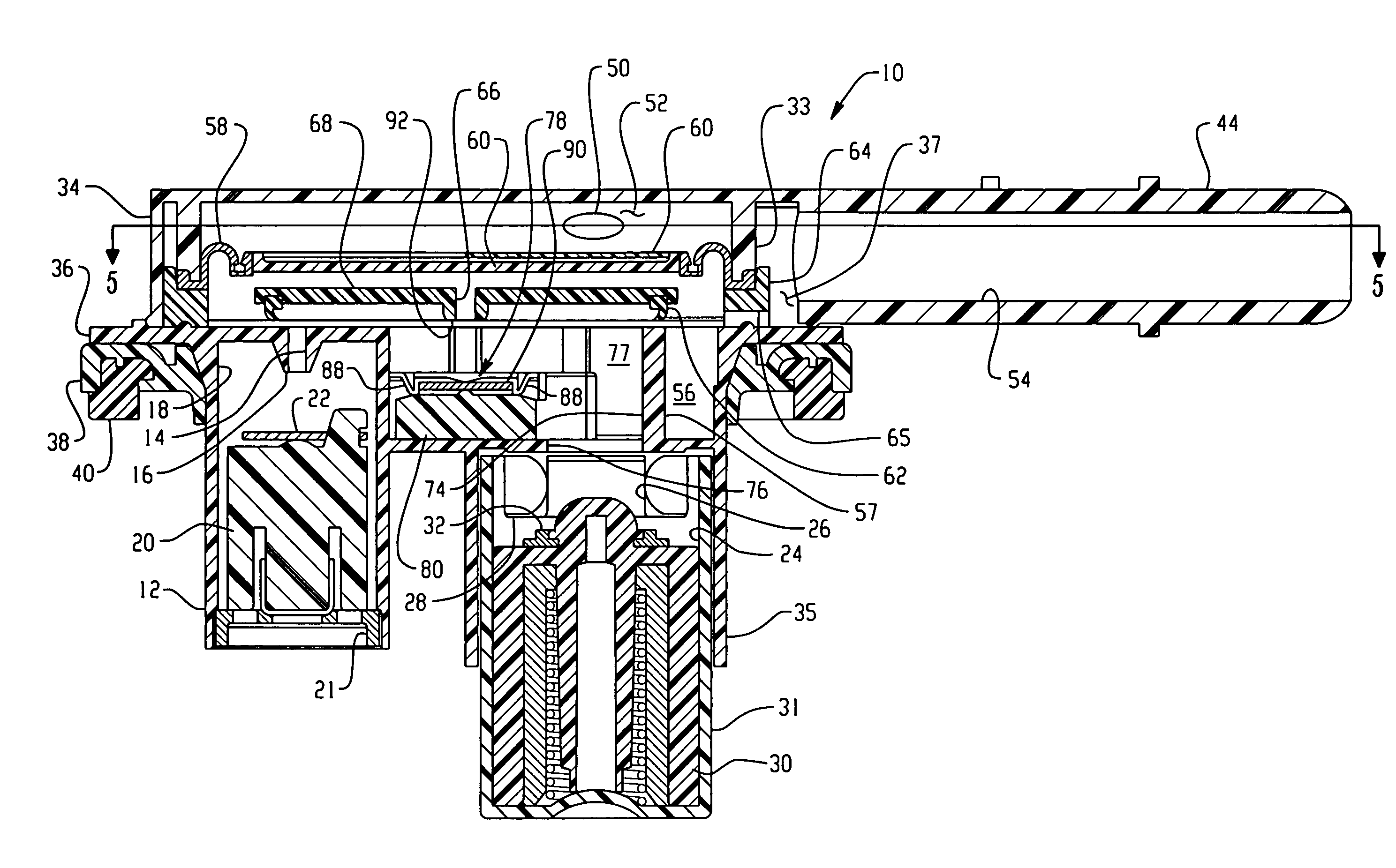

Fuel vapor vent valve float assembly and method of making same

ActiveUS7163023B2Easy to assemblePrevent escapeOperating means/releasing devices for valvesPipe elementsExhaust valveValve float

A float assembly for a multifunction fuel vapor vent valve with a float having a recess formed in the upper surface of the float with a slot formed in the side of the float and communicating with the recess. A raised surface portion is formed in the bottom of the recess and downwardly extending projections are formed in the slot at the recess. A flexible wafer like valve disk is inserted in the slot and deformed or curled to pass under the projections and over the raised surface and into the recess. When fully received in the recess the disk returns to its flat configuration; and, the downward projections prevent removal without distortion. Radially inwardly projections about the recess retain the disk for limited lost motion in the direction of float movement.

Owner:EATON INTELLIGENT POWER LTD

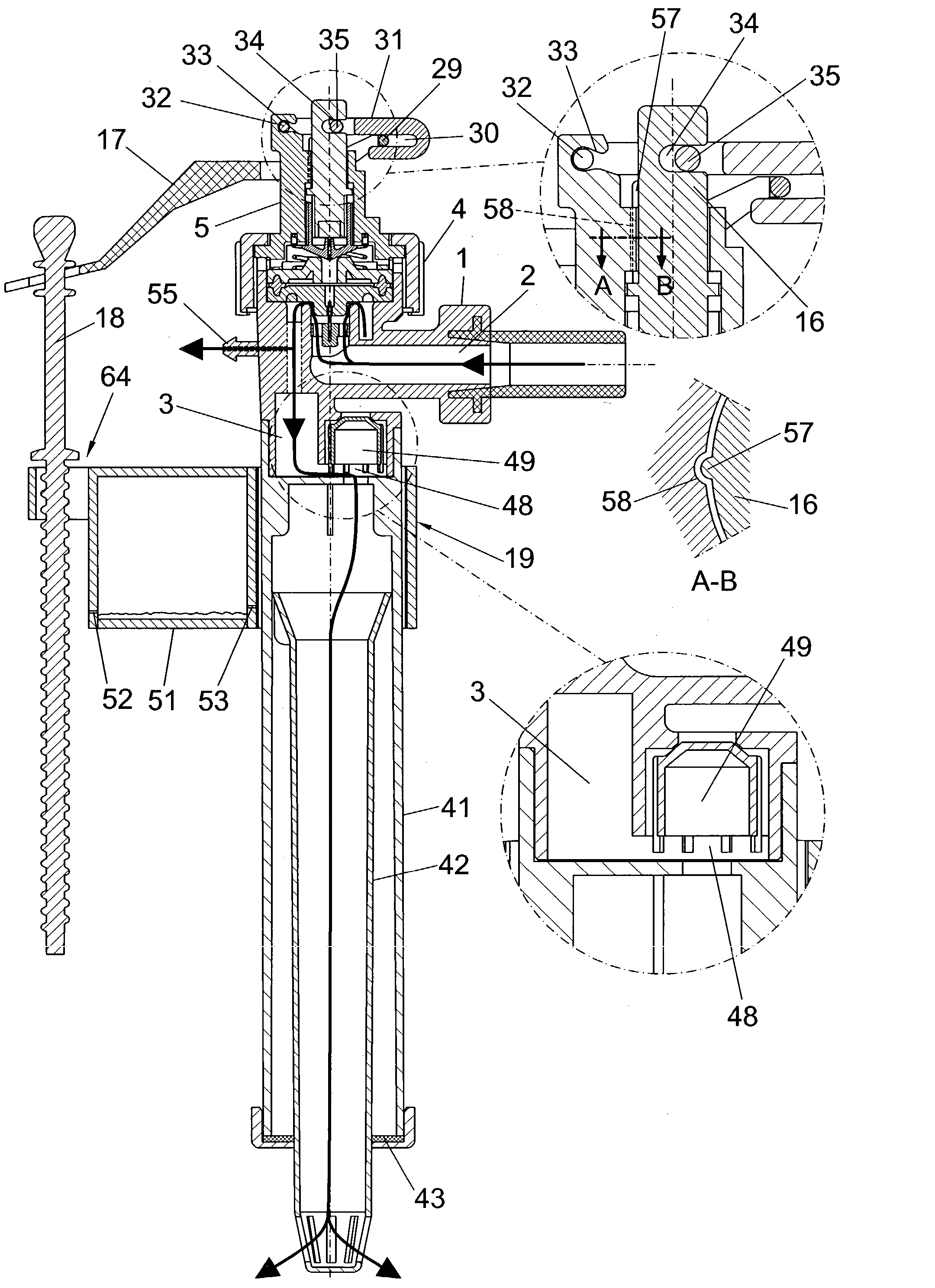

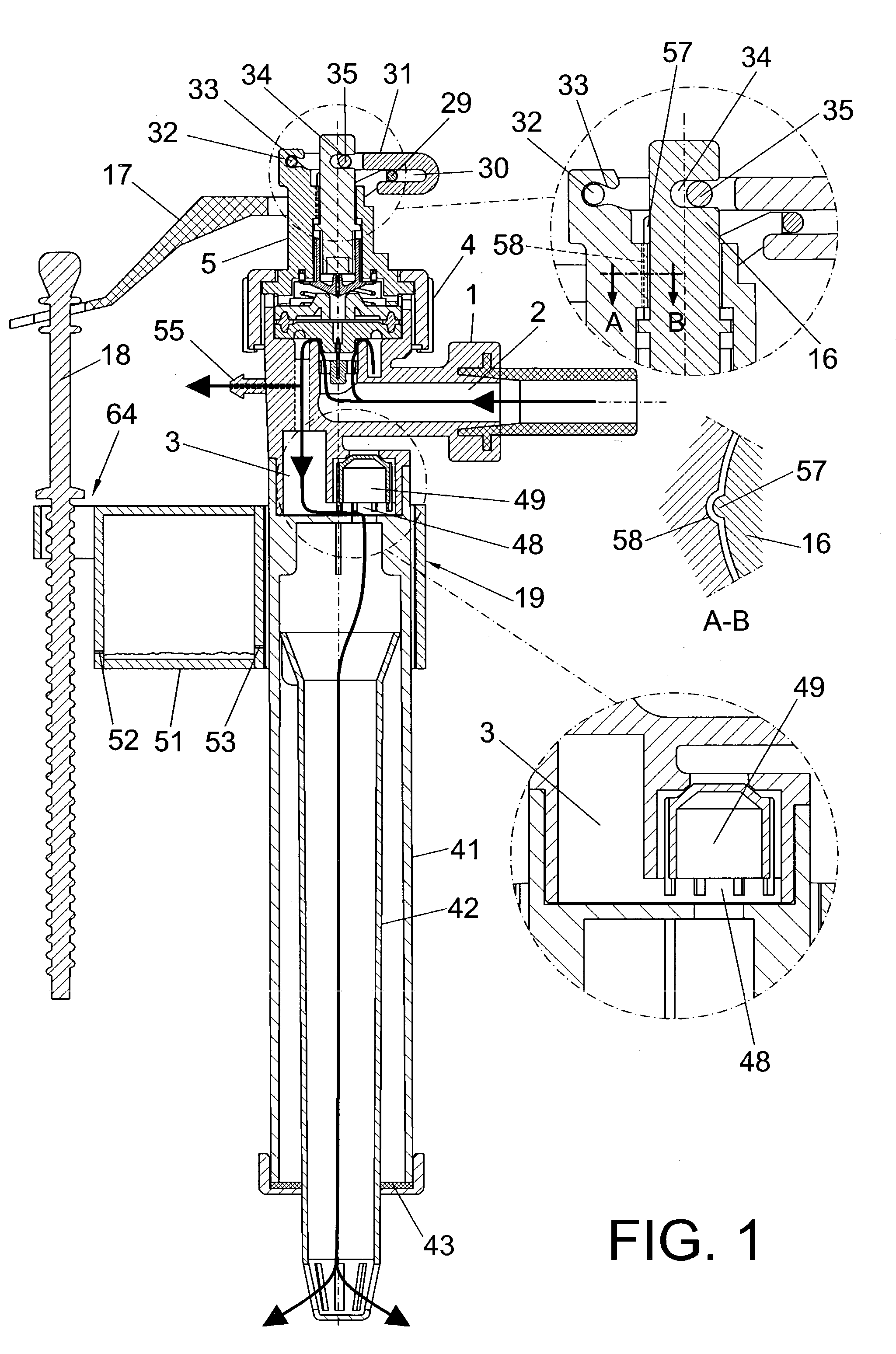

Faucet for filling tanks

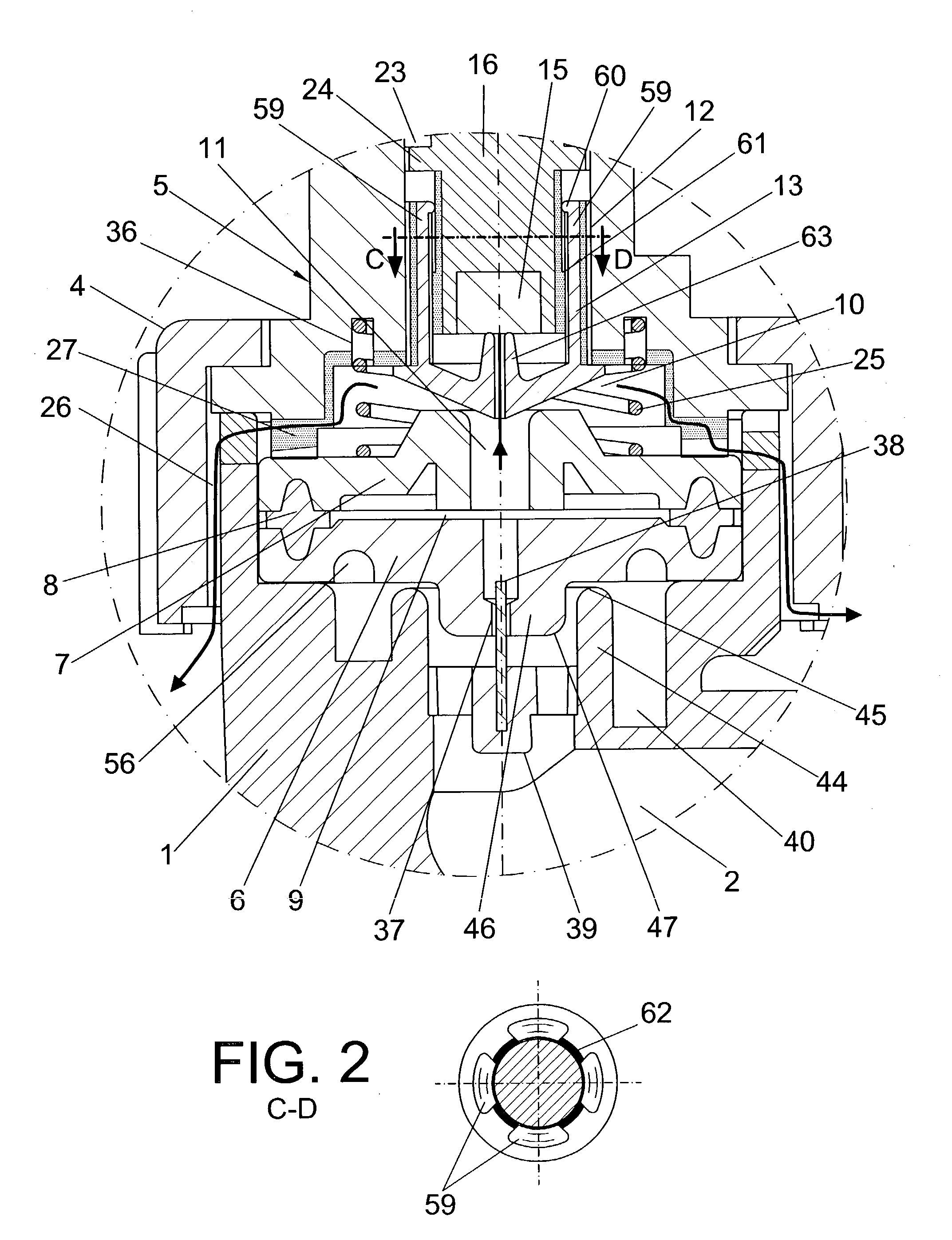

InactiveUS20030079780A1Efficient workReduce noiseOperating means/releasing devices for valvesFlushing devicesEngineeringMechanical engineering

The invention relates to a faucet for filling tanks known as silent and / or fast-closing faucets. The faucet comprises a basic structure and functionalities such as those disclosed in Patent 9400095. The device assembly controlling opening and closing of the faucet has important improvements in comparison with other conventional faucets and in comparison with the above-mentioned patent. The faucet also includes a lever system connecting the float and the piston acting upon the opening and closing device. In additional, improvement deals with the telescopic structure of the fluid outlet tubes to the tank in order to regulate the height thereof depending on the depth of the tank so that the fluid is always discharged into the water with the aim of preventing noises.

Owner:PABLO FOMINAYA AGULLO

Fuel Vent Valve And Improvement Thereof

InactiveUS20090071543A1Save spaceLow costOperating means/releasing devices for valvesAeration devicesMechanical engineering

Owner:RAVAL - AGRI COOP SOCIETIES

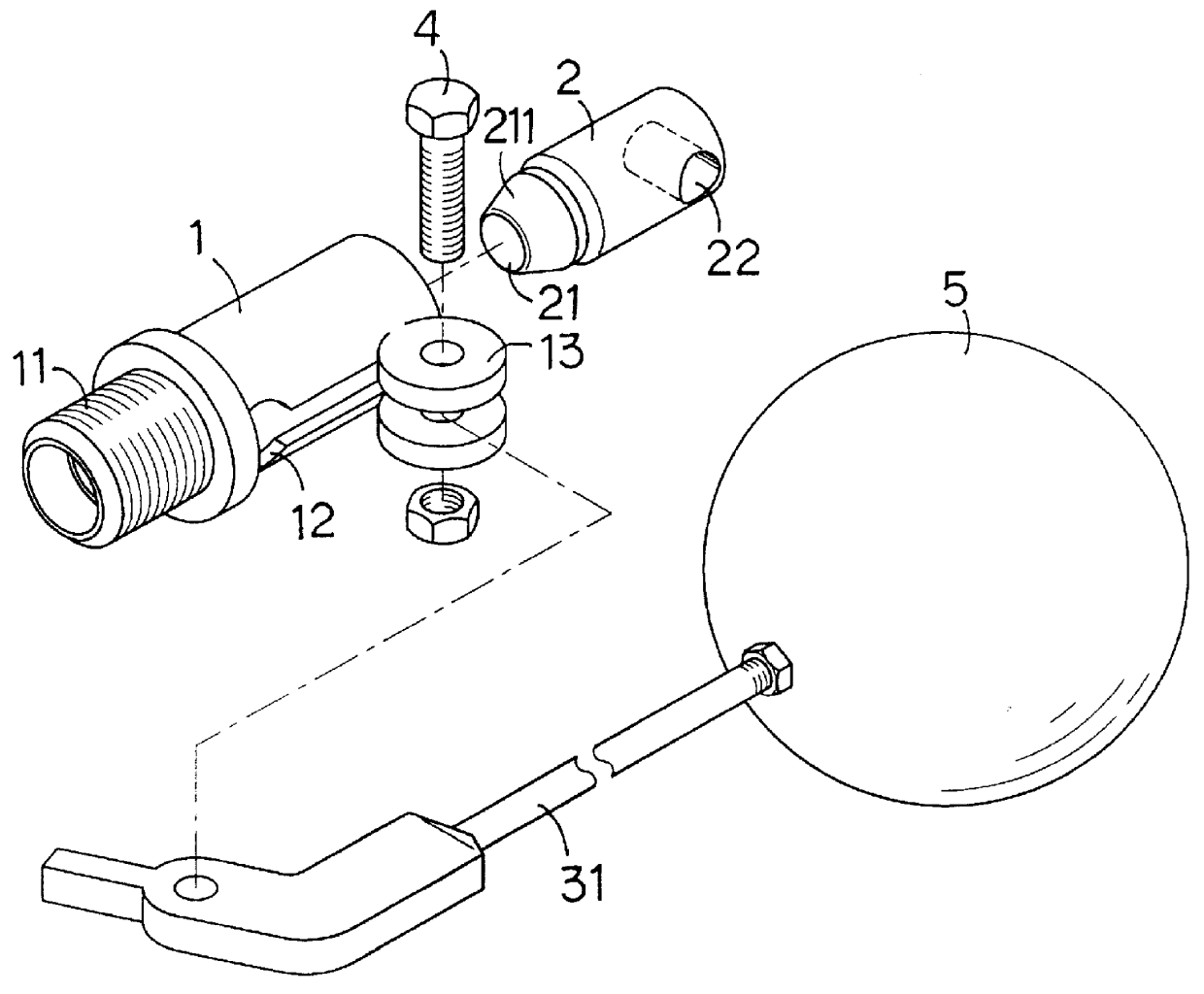

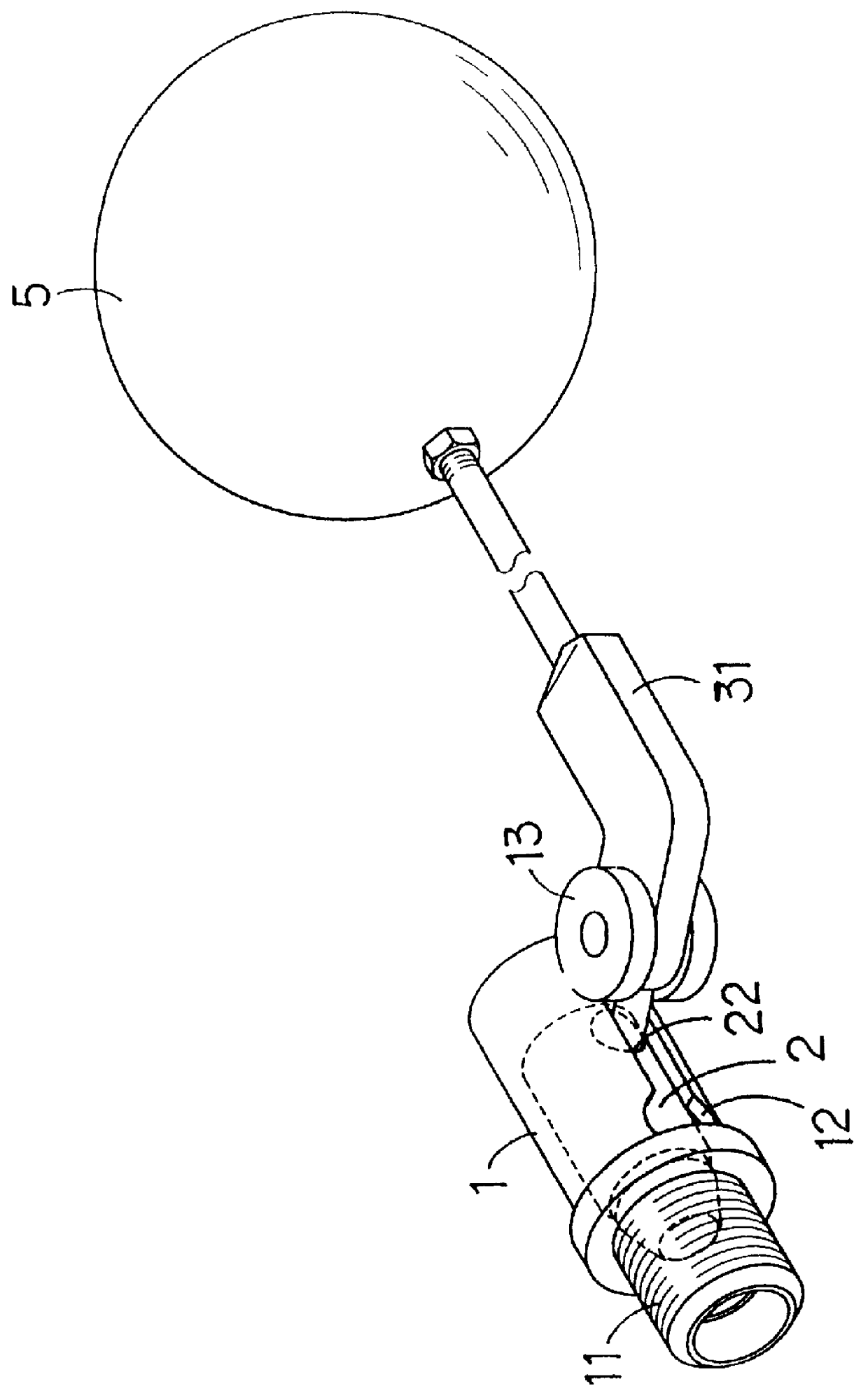

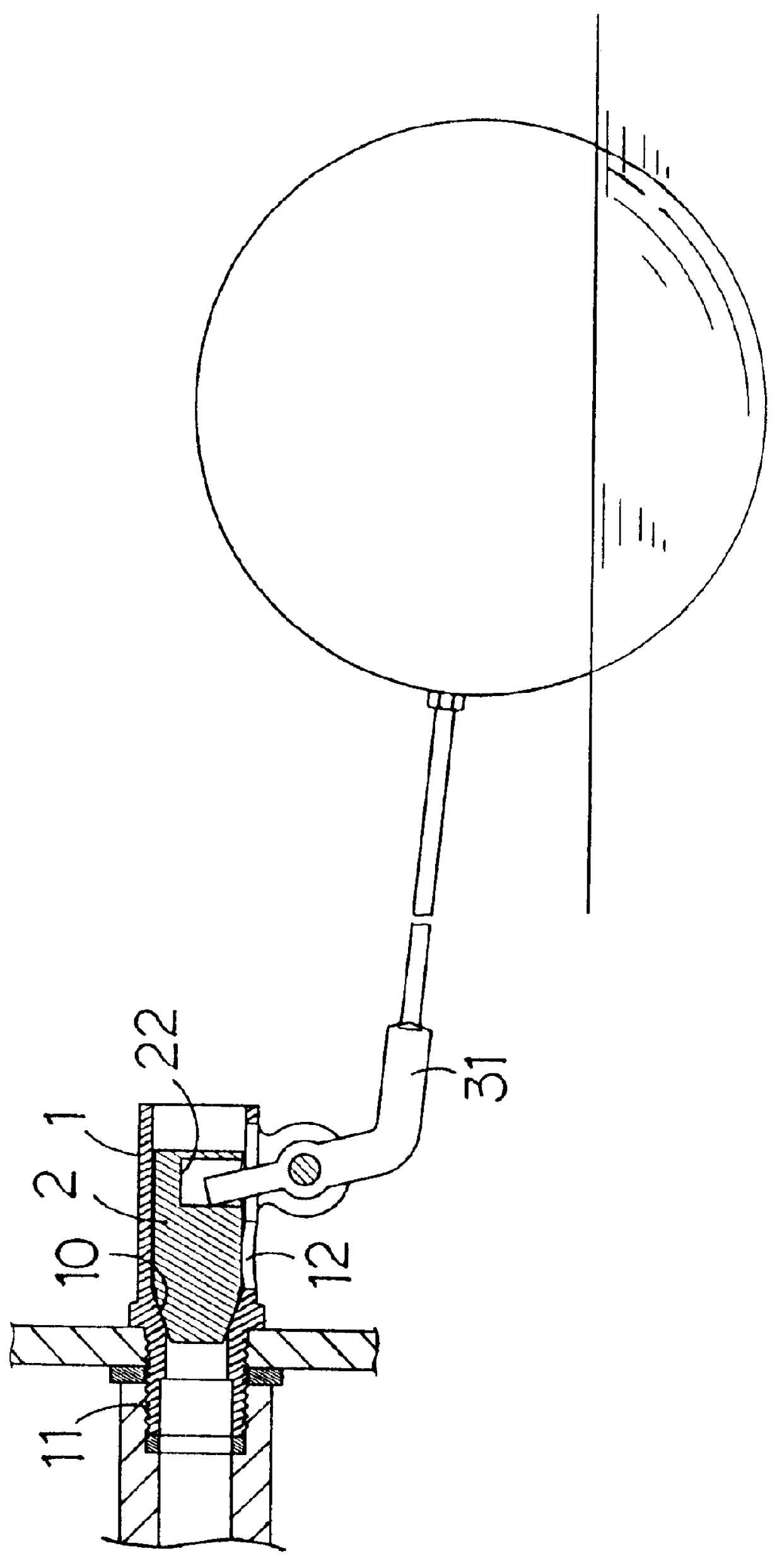

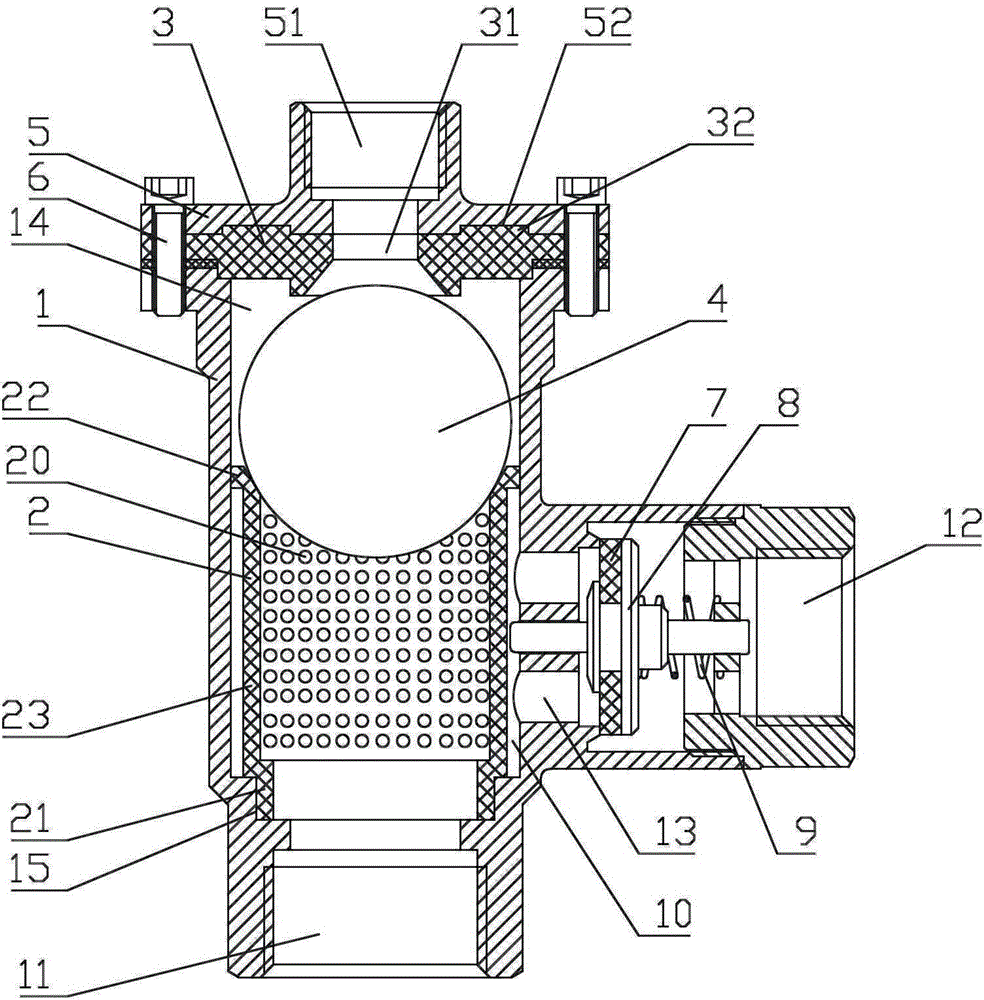

Structure of a floating-ball valve

InactiveUS6142175ASimple structureOperating means/releasing devices for valvesThin material handlingEngineeringWater block

An improved structure of a floating-ball valve for industrial fluid comprising a valve seat, a valve insert, a cap, a crankshaft, a float and a floating arm, wherein a valve chamber is formed at the internal of the valve seat, and together with a water inlet are pipe hole of various diameter, the lower section of the valve chamber is provided with a water outlet and an elongated slot, at the bottom of the valve seat, a pair of corresponding protruded members are provided, and each is pivotally mounted with a rocking arm, one end of the crankshaft is connected to the floating arm, the valve insert is mounted within the valve chamber characterized in that a vertical water-blocking wall is formed in between the valve chamber and the water inlet, and the valve insert consists of a metallic valve stem and a plastic valve plug, the valve plug has a front protruded rim and a rear conic face, the external wall of the protruded rim is sealable with the wall of the water inlet to form a first water-blocking structure, and the conic face is sealable with the wall hole of the water-blocking wall to form a second water-blocking structure, the crankshaft is substantially L-shaped and pivots in between the two protruded members, the top end of the crankshaft is a rocking member being inserted into a cylindrical slot, and the other end is connected to the end of the floating arm, and an opening at the end of the valve seat is provided with a plurality of external threads for mounting with a threaded cap to seal the opening.

Owner:KU CHIN KUANG

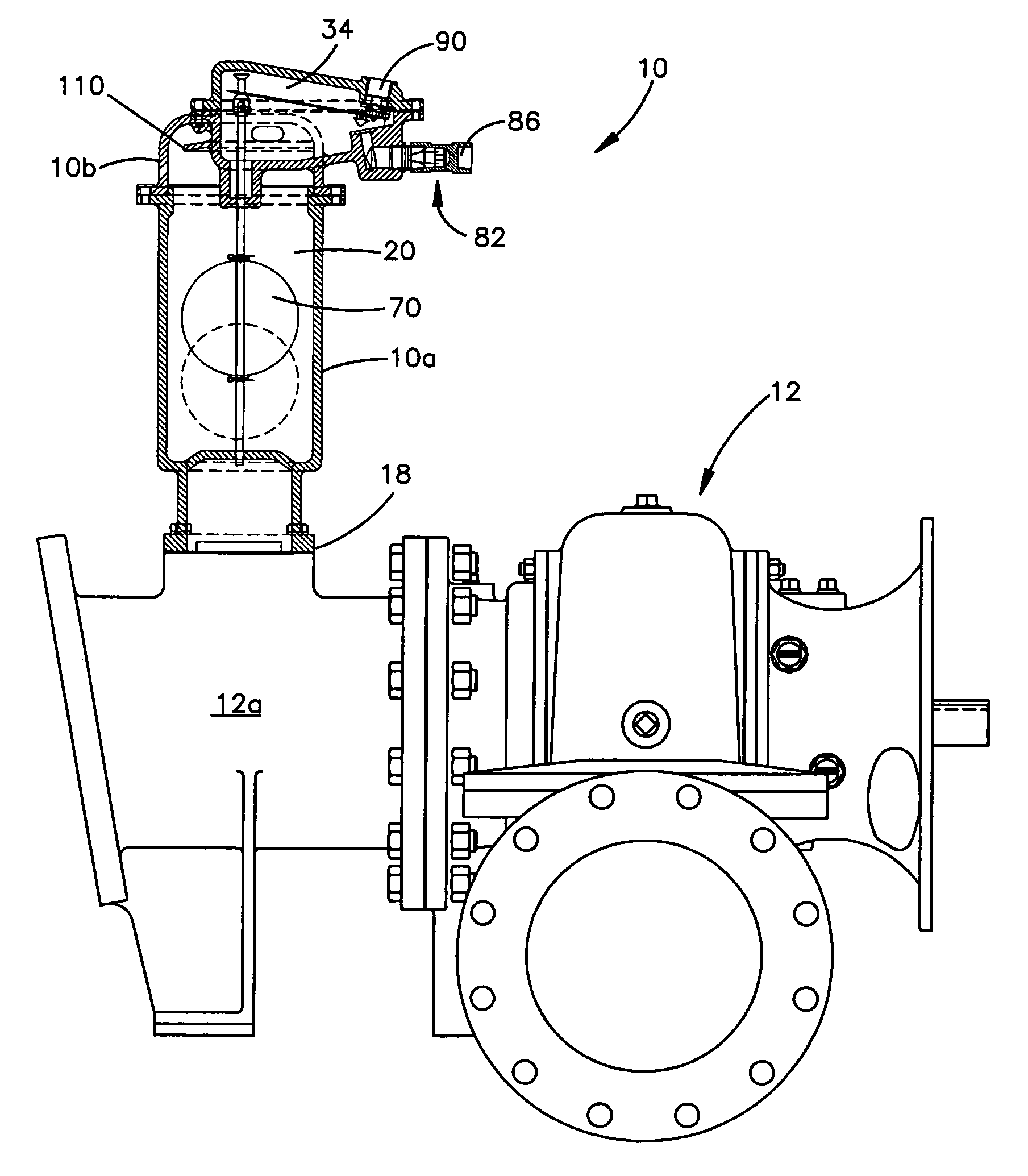

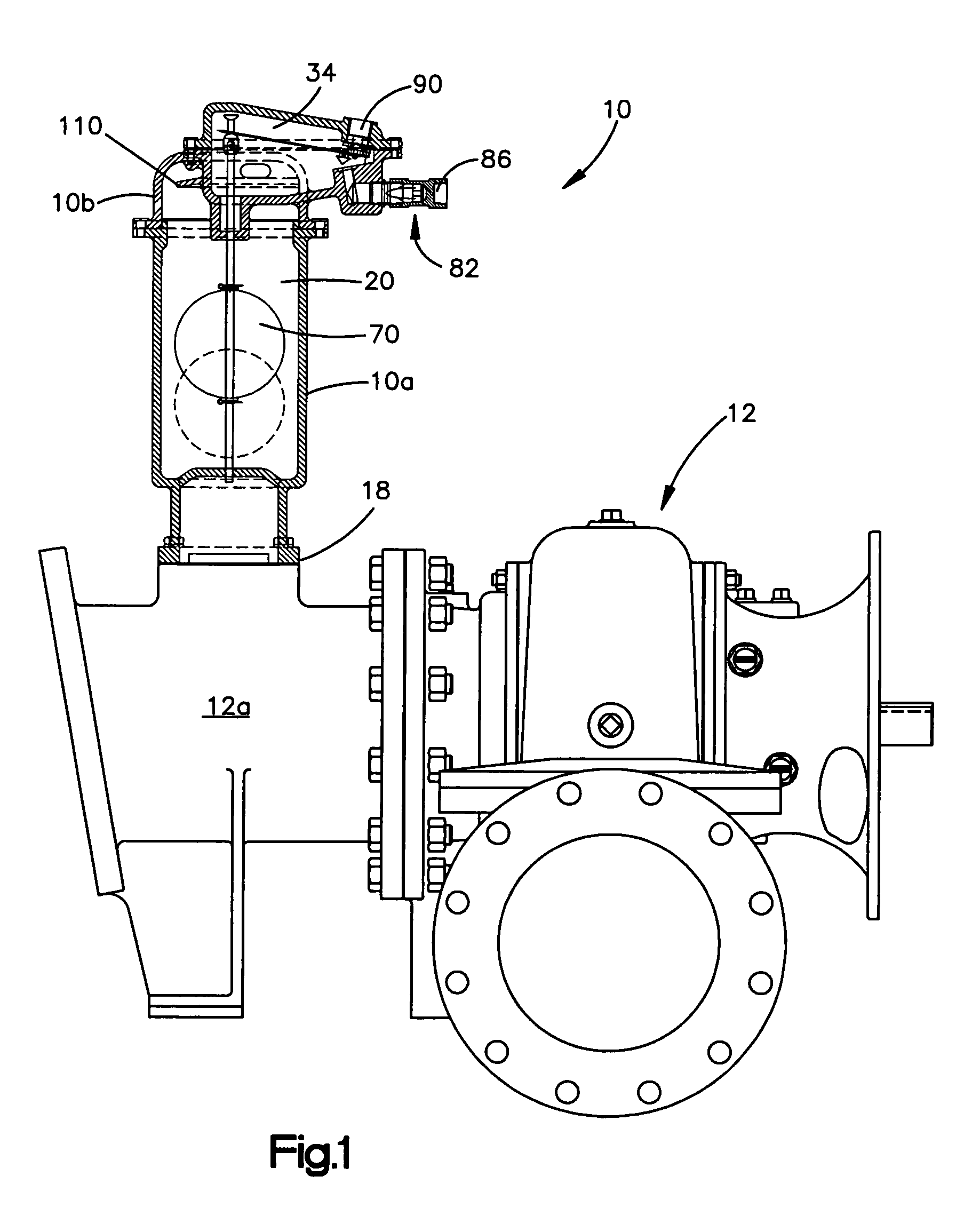

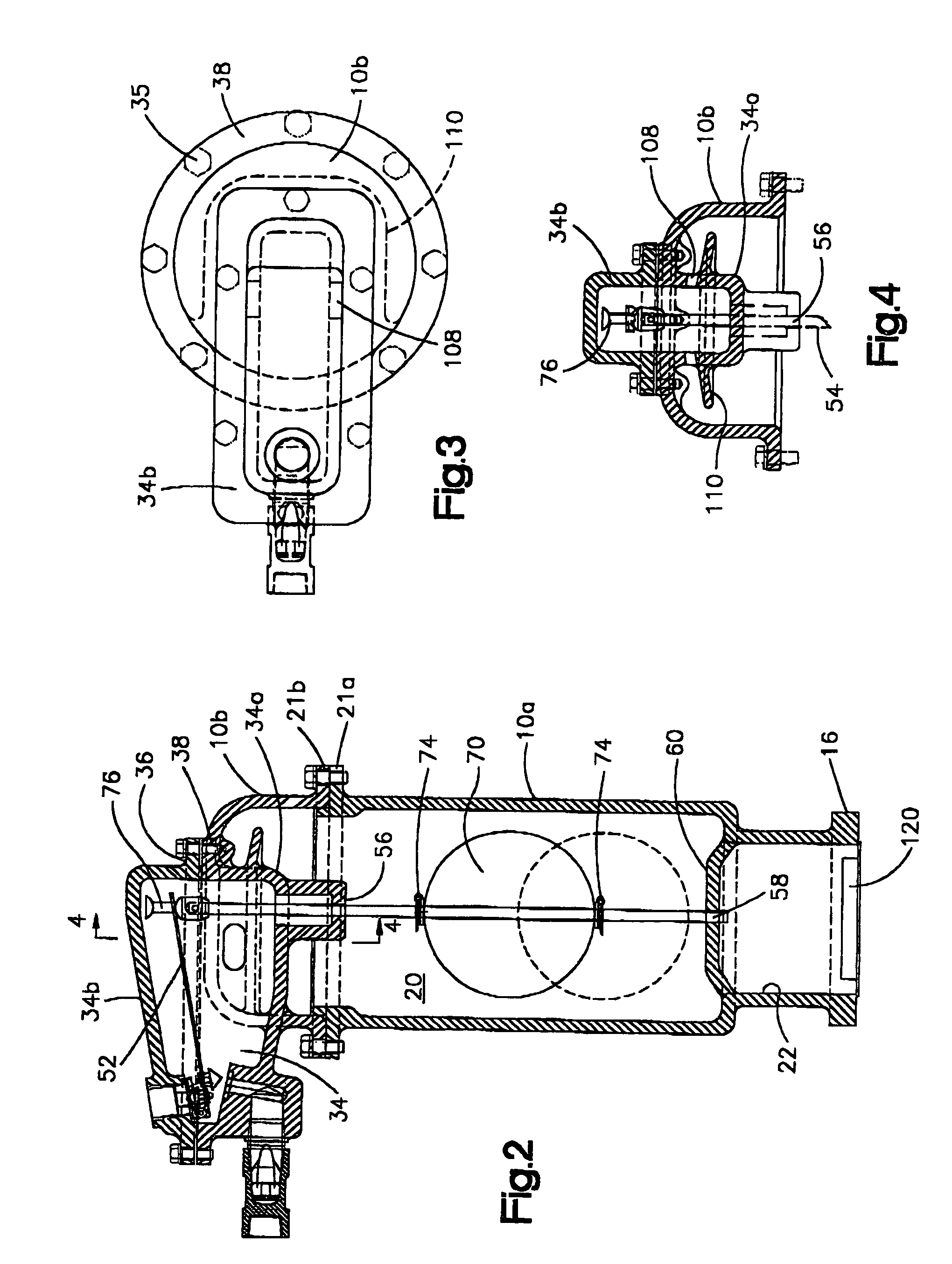

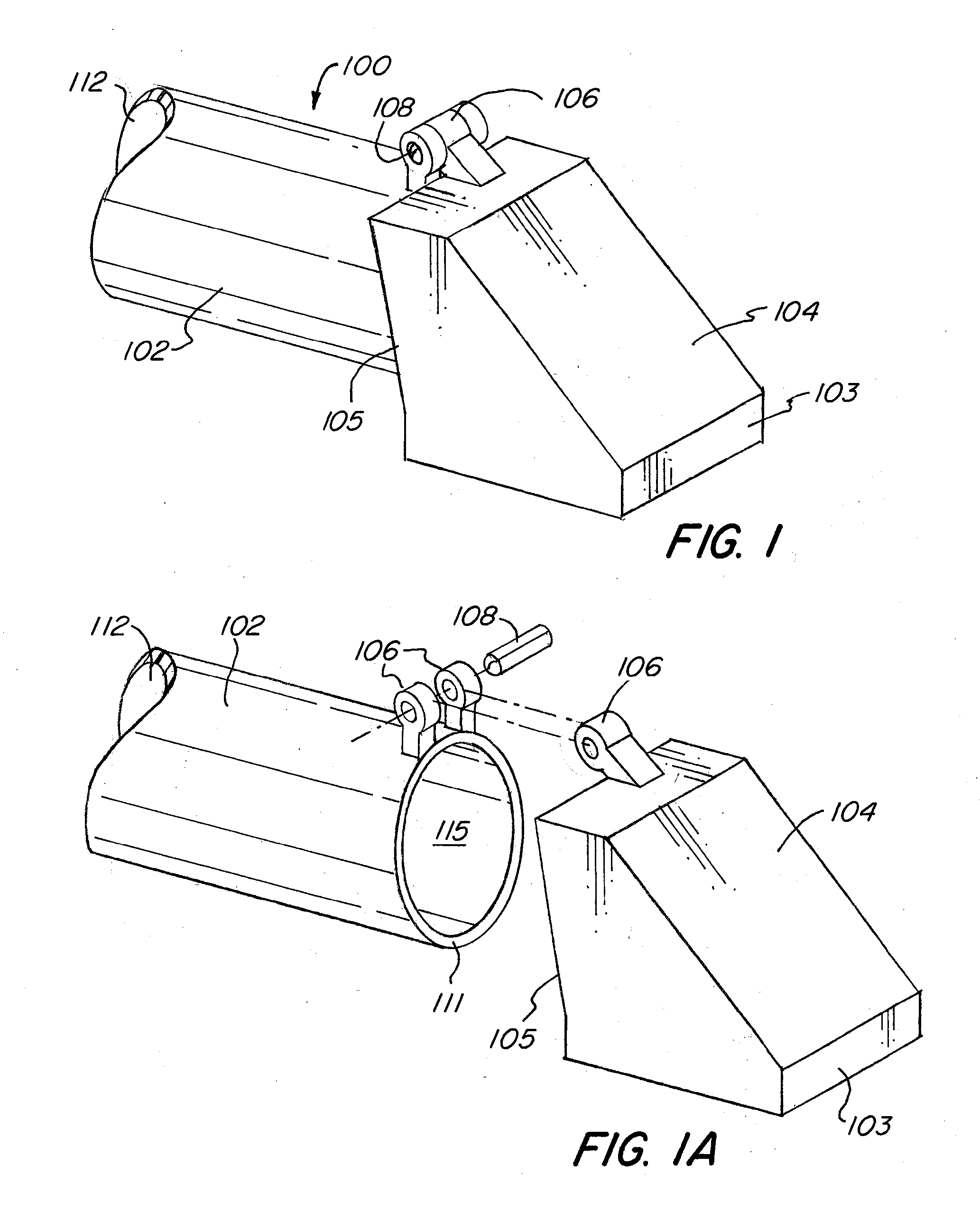

Priming apparatus for a centrifugal pump

InactiveUS7334600B2Reduce surging and turbulenceReduce morbidityLighting and heating apparatusPressure pumpsVacuum assistedAtmospheric air

A vacuum assisted priming system for a fluid pump including a housing defining a hopper that communicates with a pump inlet. The housing mounts a first port that communicates with the source of vacuum and a second port that communicates with atmosphere. A check valve allows atmospheric air to flow into the housing under certain operating conditions but inhibits reverse flow. A valve member pivotally mounted within a valve chamber carries first and second sealing elements that are engageable with first and second seats. The lever arm is operatively connected to a float via a lost motion connection. When the fluid level in the hopper rises to a predetermined level, an actuating rod moves the lever arm to a first sealing position. When the fluid level falls to a predetermined level, the actuating rod moves the lever arm to a second sealing position. A baffle located at an inlet to the hopper reduces surging and turbulence in the hopper and defines a circuitous path through which the fluid must flow in order to enter the hopper.

Owner:GORMAN RUPP COMPANY THE

Manual inflator with cylinder connector and status indicator

A manual inflator having a status indicator that indicates whether a fully-charged, unspent gas cylinder has been installed on the inflator. The status indicator comprises a “single point” indicator having an indicator window that displays the color “green” when the automatic inflator is fully operational or the color “red” when the inflator is at least partially inoperable automatically due to the removal of the gas cylinder or due to the firing of the inflator resulting in a spent gas cylinder.

Owner:HALKEY ROBERTS CORP

Vacuum anti-siphon backflow preventing valve

InactiveCN103062453AProtection deformationProtection from being brokenCheck valvesStationary filtering element filtersSiphonUrban water supply

The invention discloses a vacuum anti-siphon backflow preventing valve and relates to a fluid medium pipeline control part. The valve comprises a valve body, a water inlet and a water outlet are arranged on the valve body, a valve cavity communicated with the water inlet is arranged on the valve body, a valve opening is arranged between the valve cavity and the water outlet to communicate the valve cavity with the water outlet, and a valve clack component enabling media to flow unidirectionally from the valve cavity to the water outlet is arranged in the water outlet. An air outlet for communicating the valve cavity with the outside is arranged at the top of the valve body. A support filter screen covering the valve opening is arranged in the cavity. A buoyancy seal component is arranged at the air outlet for sealing the air outlet when media flow forward from the water inlet to the water outlet or opening the air outlet when media flow reversely from the valve cavity to the water inlet. By means of the vacuum anti-siphon backflow preventing valve, the structure is simplified, backflow is prevented effectively, air in the valve cavity can be discharged rapidly when media get back to forward flow, and functions of impurity filtering and purifying are provided. The valve is mainly applied to pipeline systems in need of anti-pollution check, such as urban water supply systems.

Owner:ZHEJIANG DUNAN INTELLIGENT CONTROL TECH CO LTD

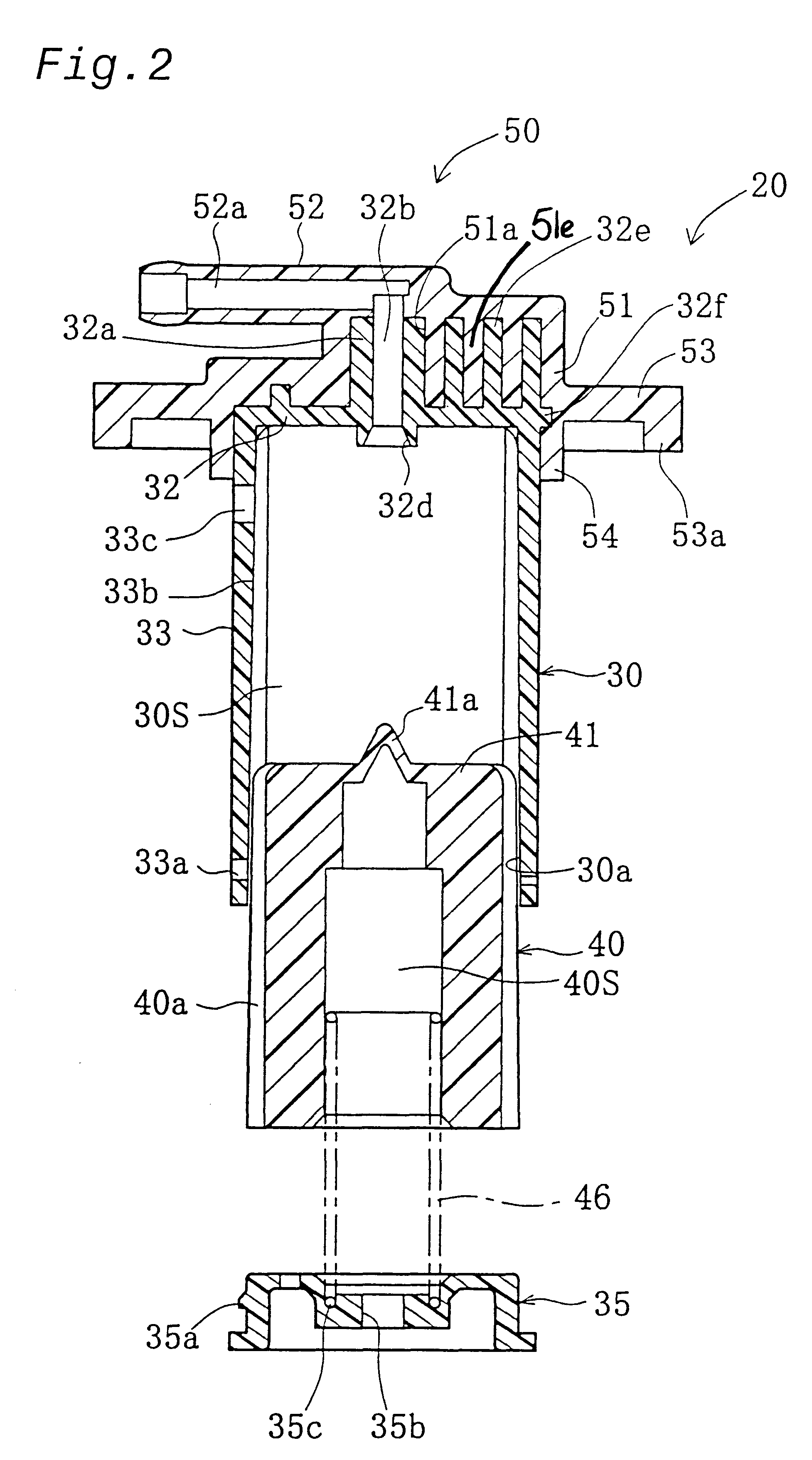

Fuel cutoff valve and production method thereof

InactiveUS6382231B2Easy to installPrevent outflowOperating means/releasing devices for valvesLarge containersEngineeringBung

Owner:TOYODA GOSEI CO LTD

Buoyancy type drain trap

InactiveUS20060272705A1Reduce weightIncrease discharge flowOperating means/releasing devices for valvesSteam trapsWater dischargeEngineering

Provided are a drain water discharging method and a buoyancy type drain trap in which a float is accommodated in a case and drain water allowed to flow into the case can be discharged by buoyancy acting on the float. In a case where an inner diameter of the valve is increased in order to increase a discharge flow rate at a valve connected to an outlet port formed in the case, the movement of a valve seat for opening the valve is facilitated through addition of some force to increase the buoyancy or through a reduction in a weight of the float itself.

Owner:FUKUHARA KK

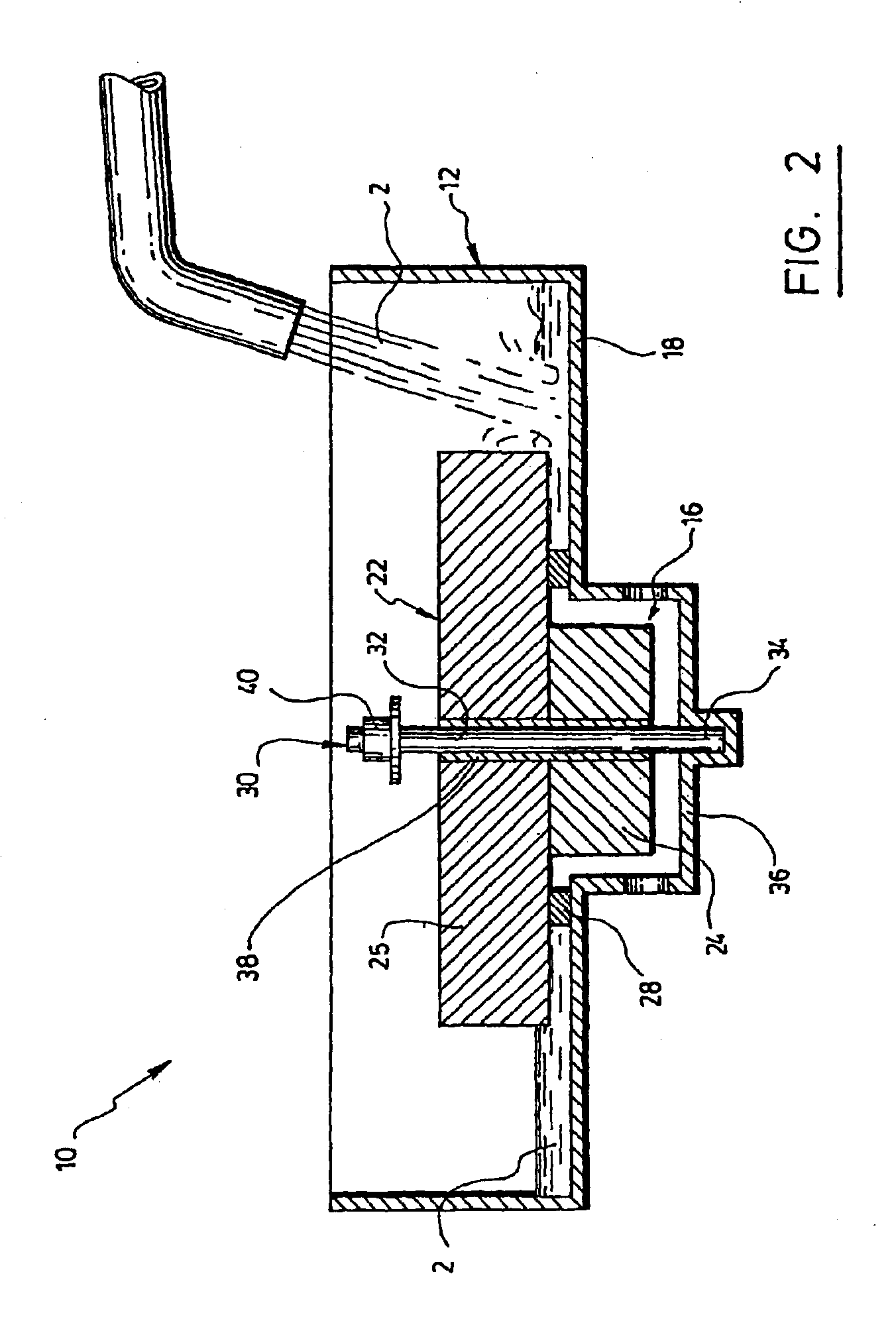

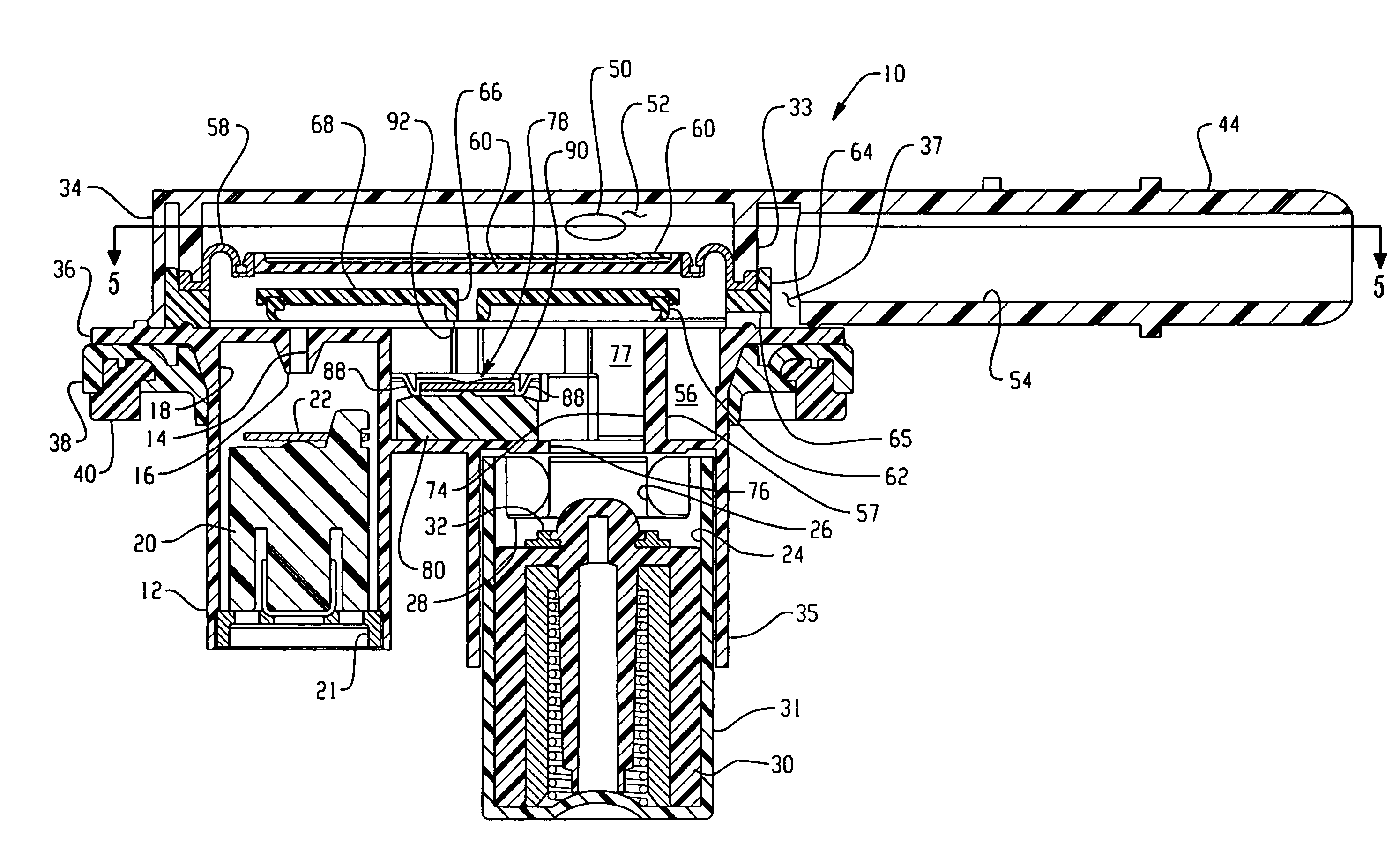

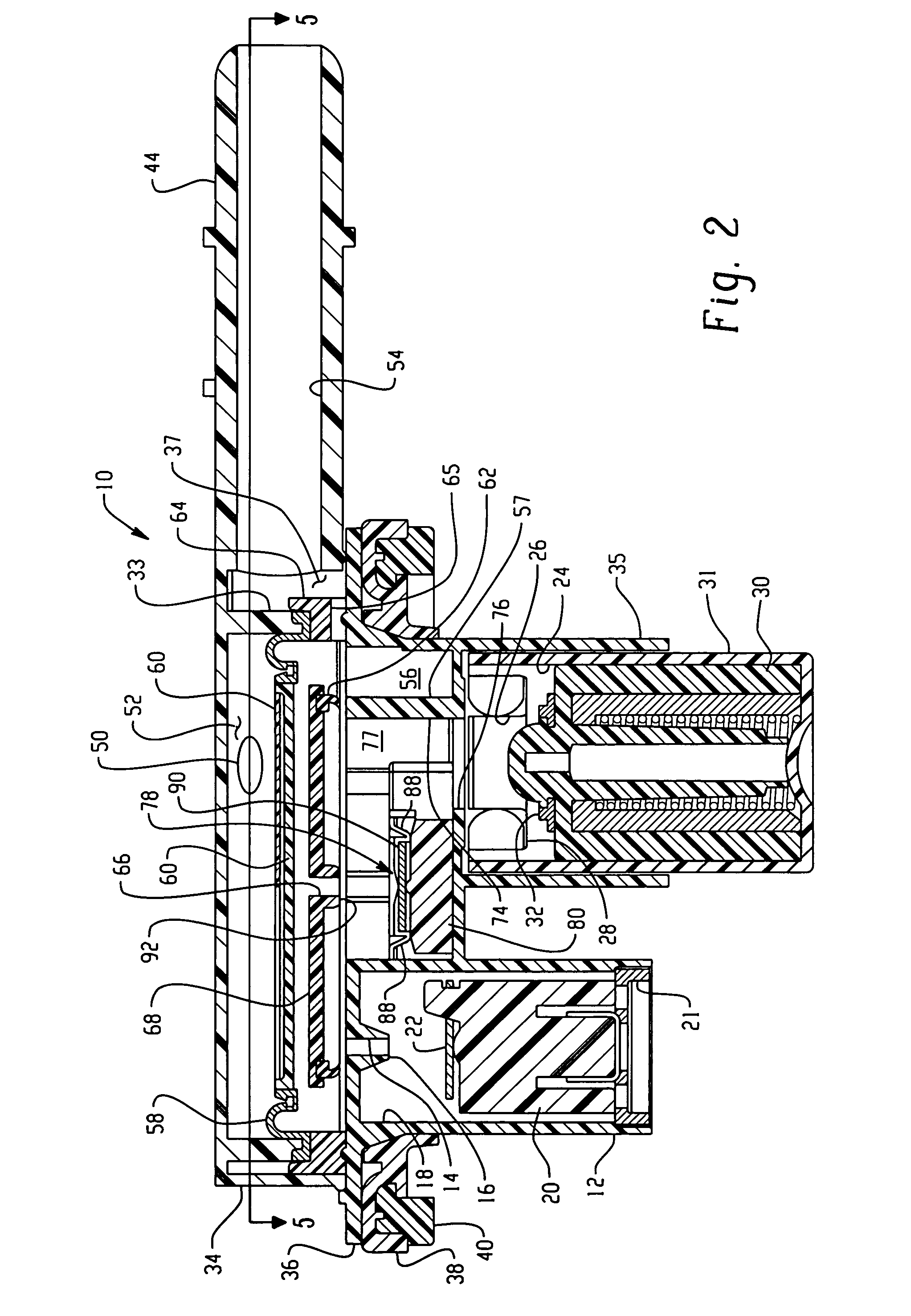

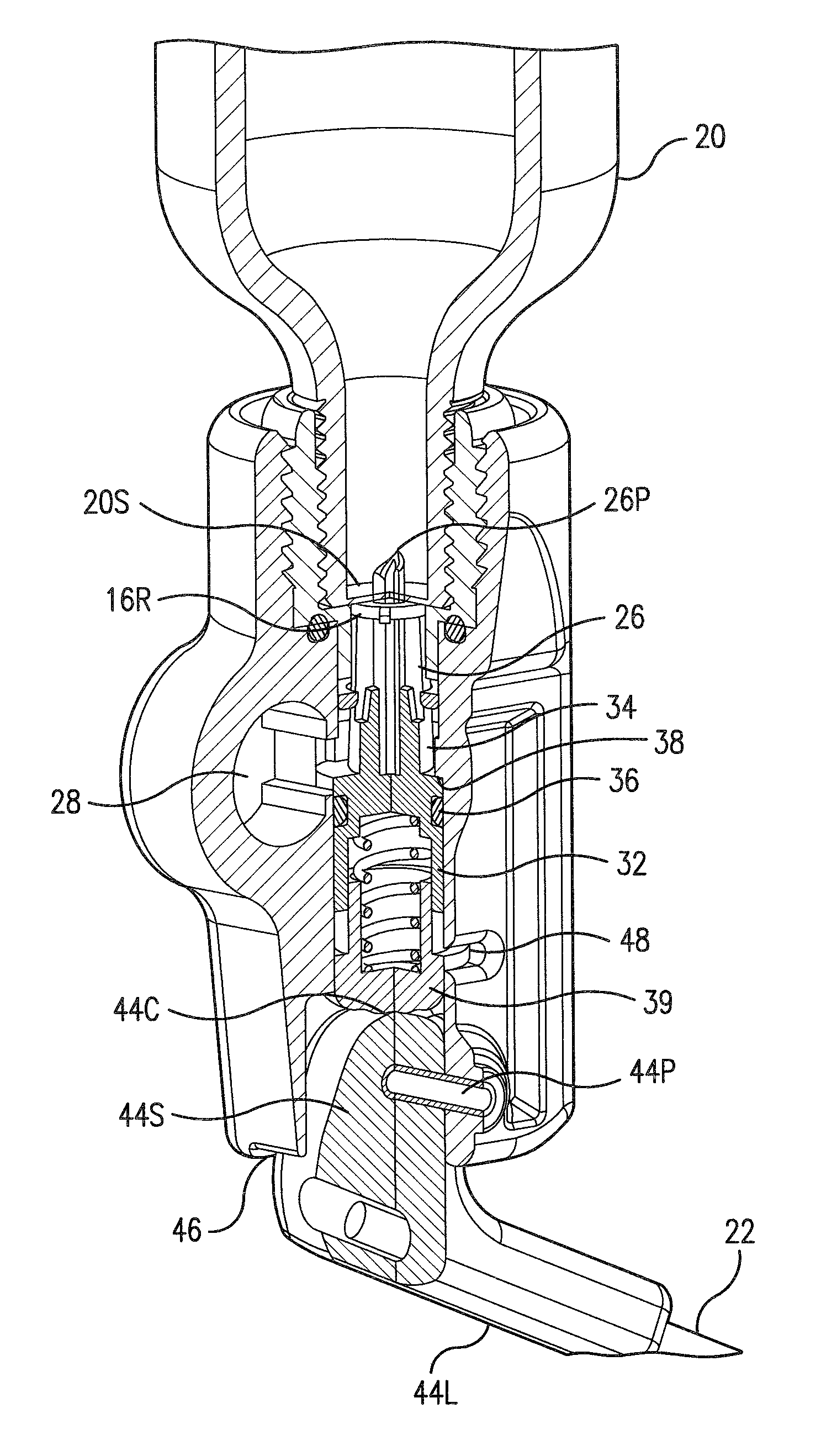

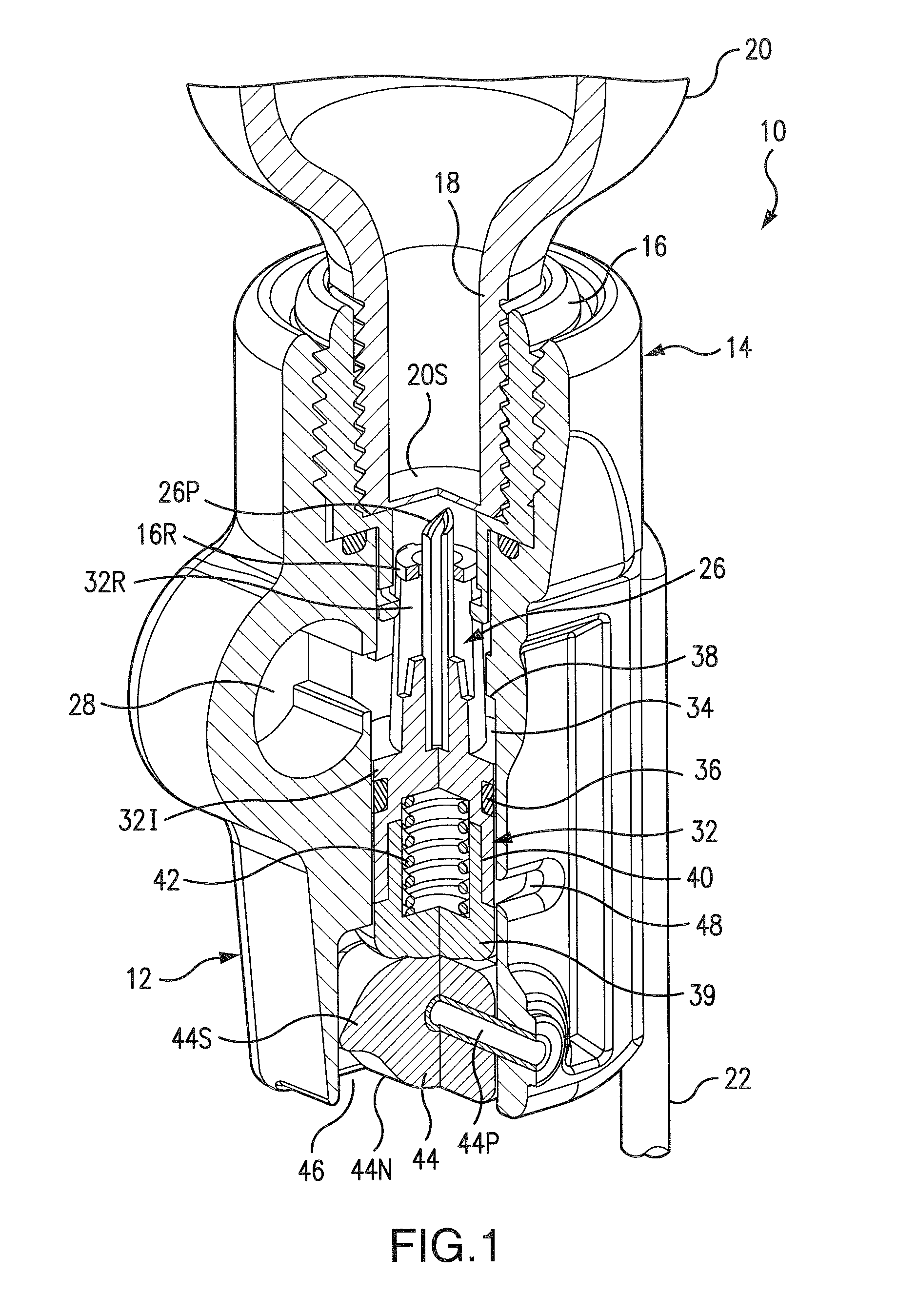

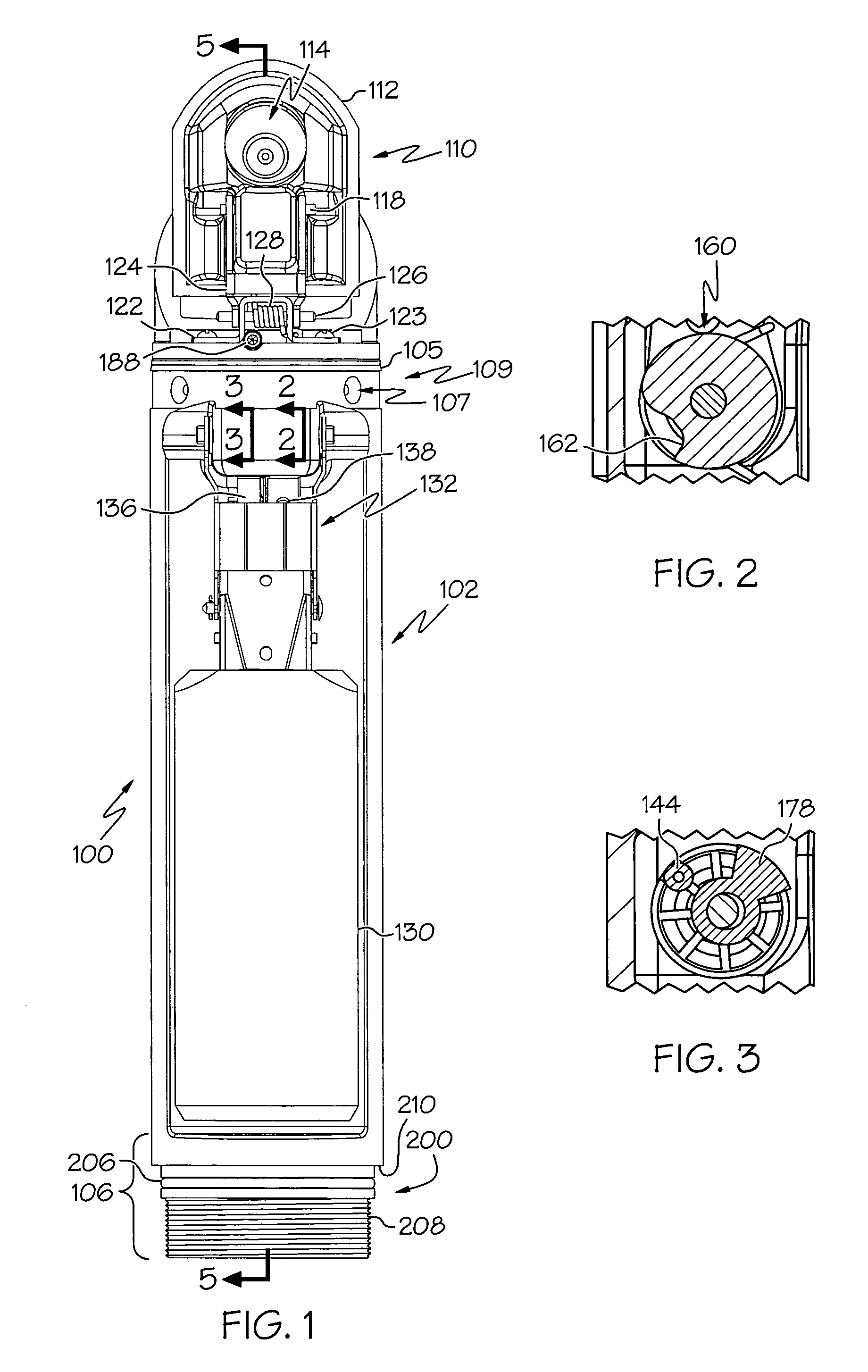

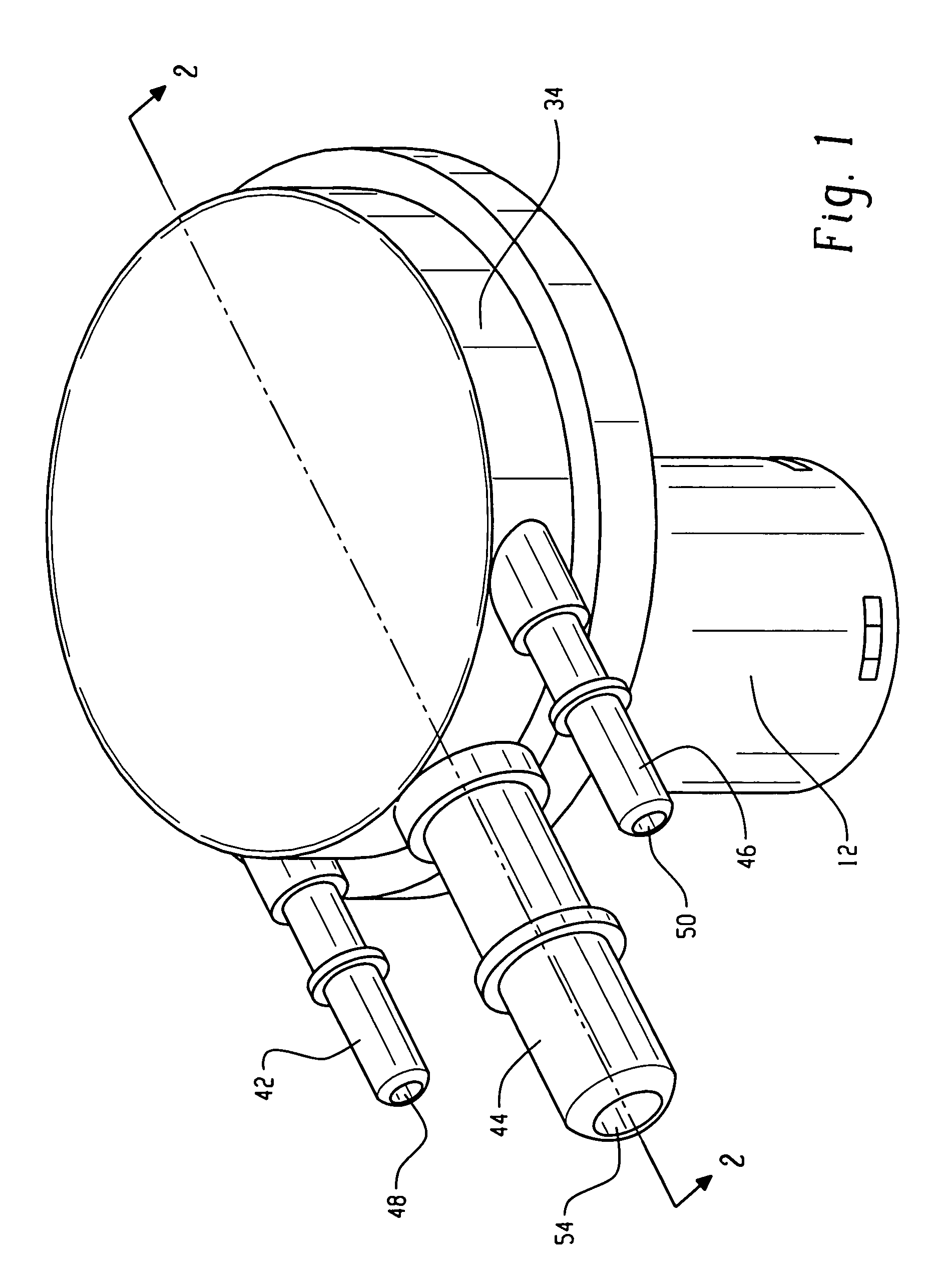

Readily demountable fill valve

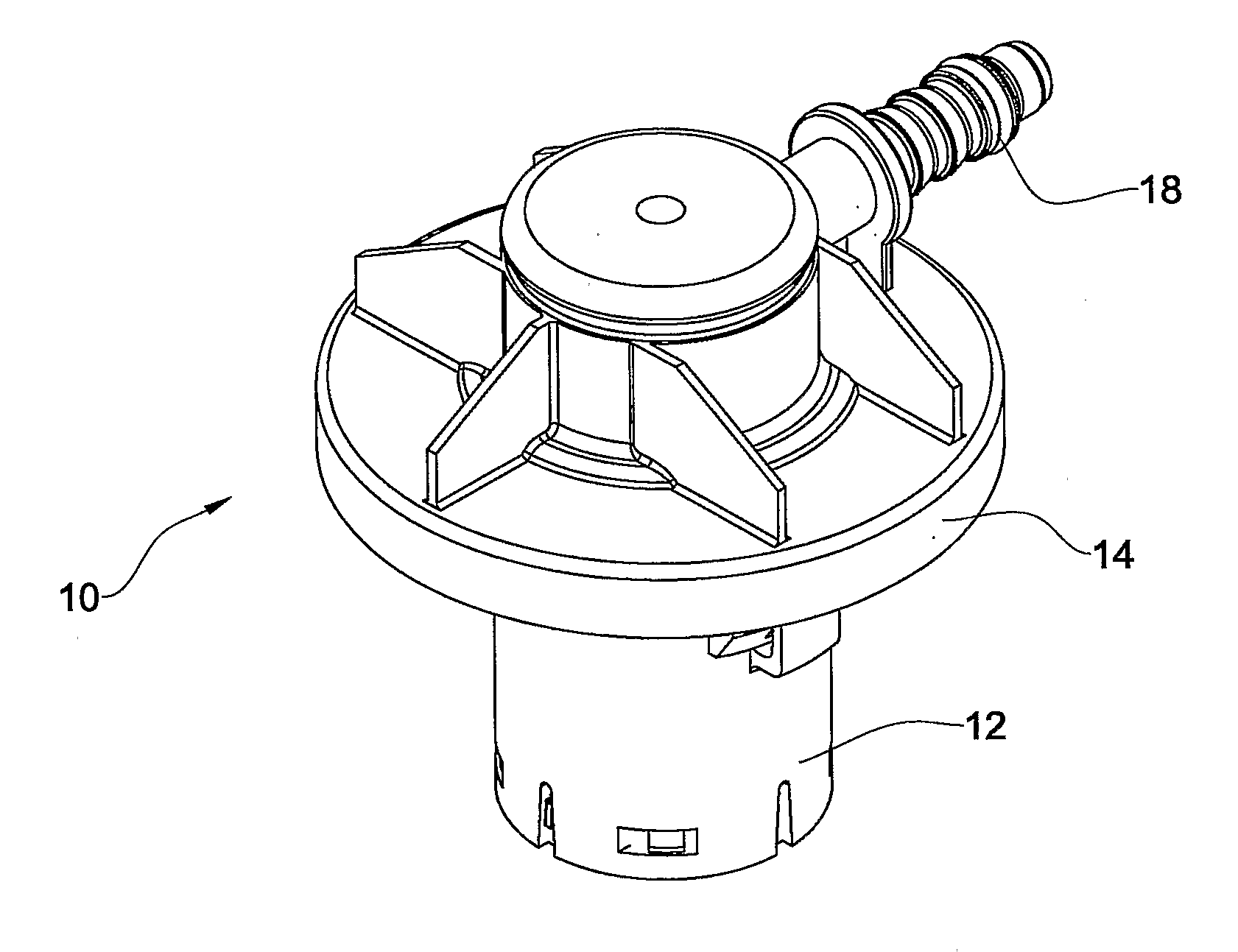

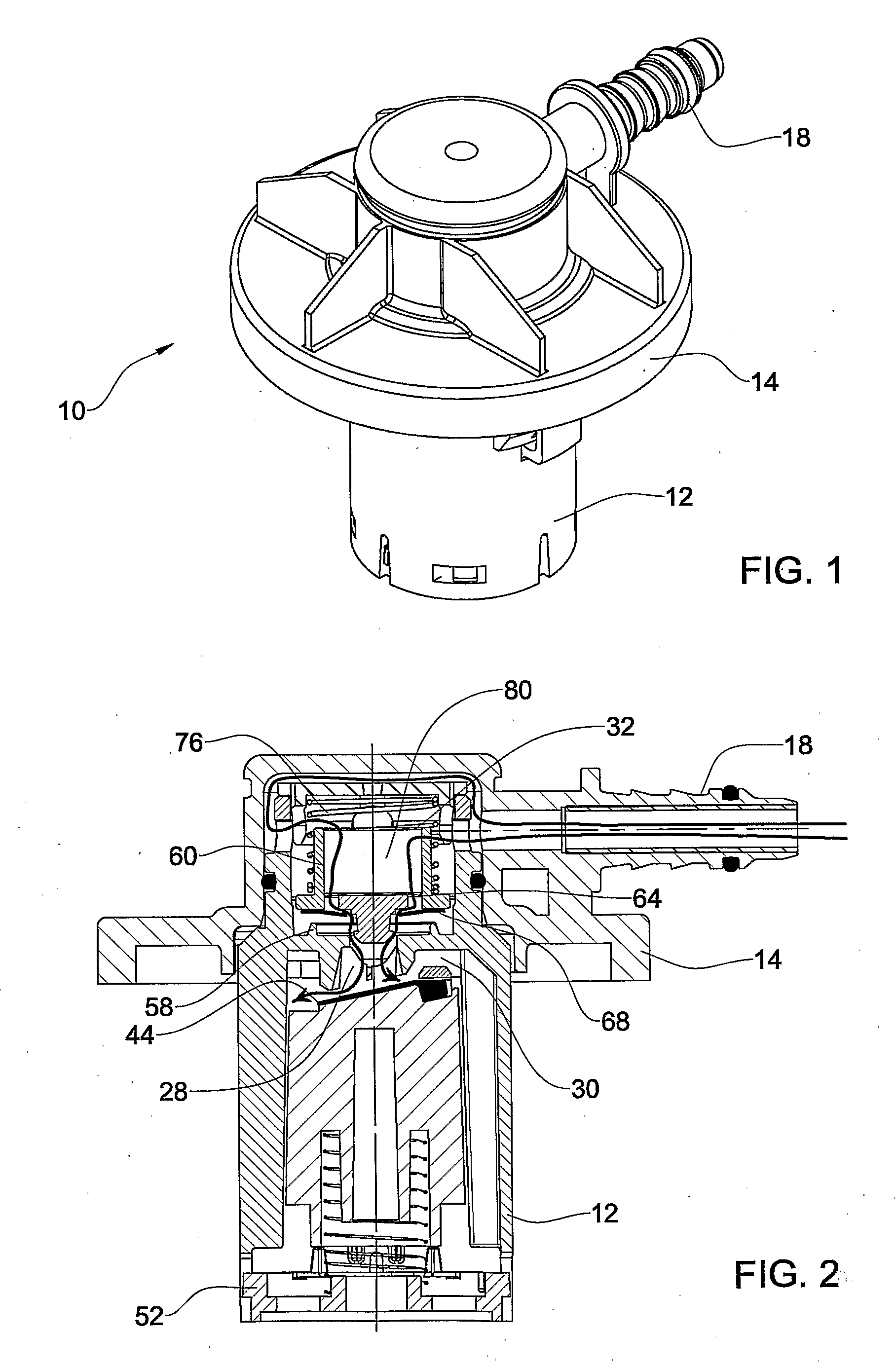

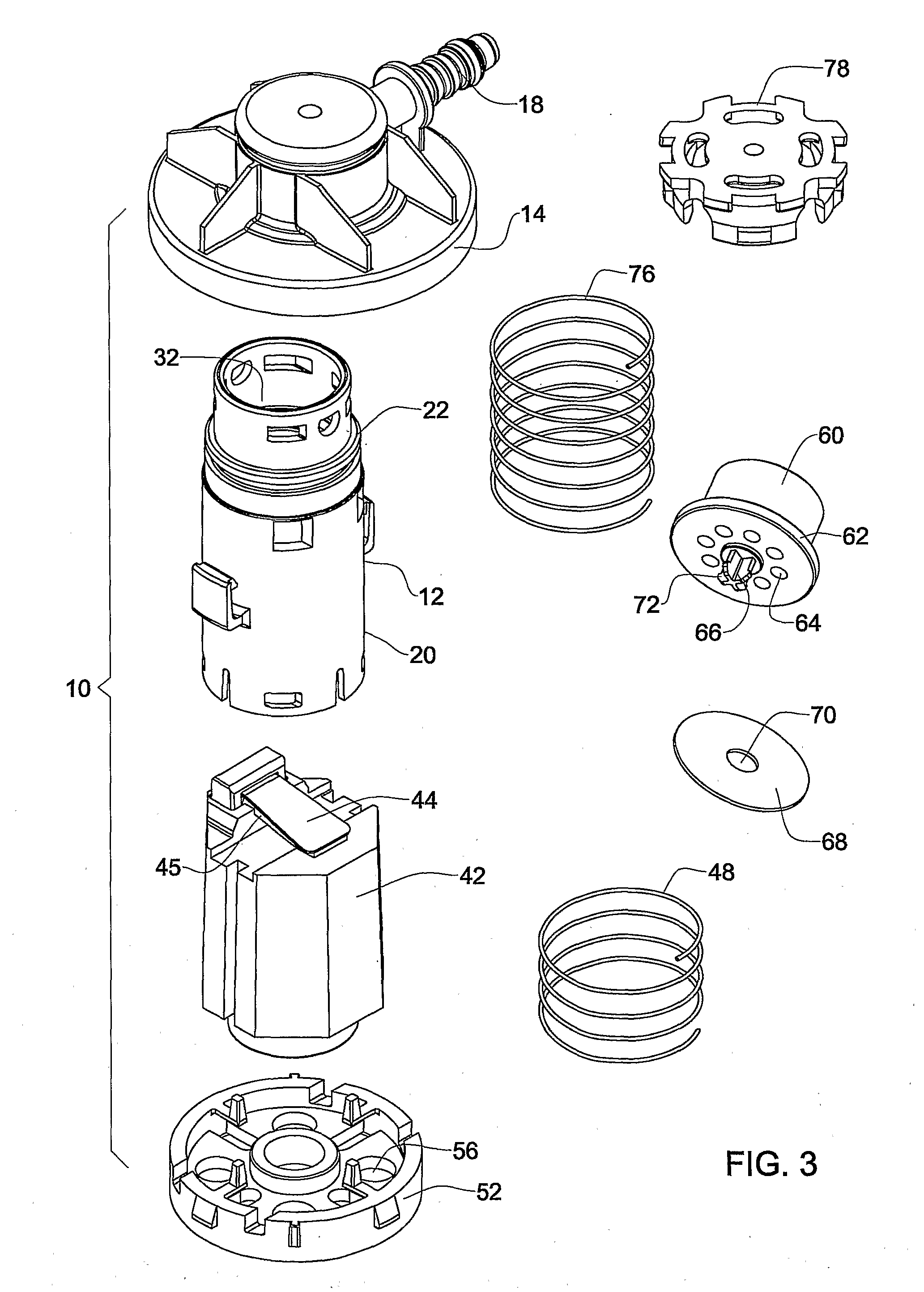

ActiveUS7647938B2Readily demountedEasy accessOperating means/releasing devices for valvesCheck valvesEngineeringInlet pressure

A fill valve assembly for controlling liquid flow into a reservoir includes a mounting adapter defining a liquid inlet passage for connection to a riser for supplying water to the valve and which renders the fill valve readily mountable and demountable for installation and maintenance. A valve body has liquid inlet and outlet openings and a pressure-responsive member is disposed within the valve body and defines a control chamber with which the liquid inlet passage communicates opposite a second side of the pressure responsive member also in communication with the liquid inlet for selectively opening and closing the inlet opening to liquid flow in response to liquid pressure in the control chamber. A biasing means acts on the pressure-responsive member together with pressure in the control chamber, against the inlet pressure acting on the opposite side of the pressure-responsive member, to hold a valve surface fixed to the pressure-responsive member against a valve seating face ion the adaptor so as to close the inlet opening to liquid flow. The valve body, pressure-responsive member and biasing means are arranged to be demountable from the adaptor as a unit in a manner so as to provide ready access to the mating valve surface and valve seating face e.g. for cleaning.

Owner:JOBE HLDG

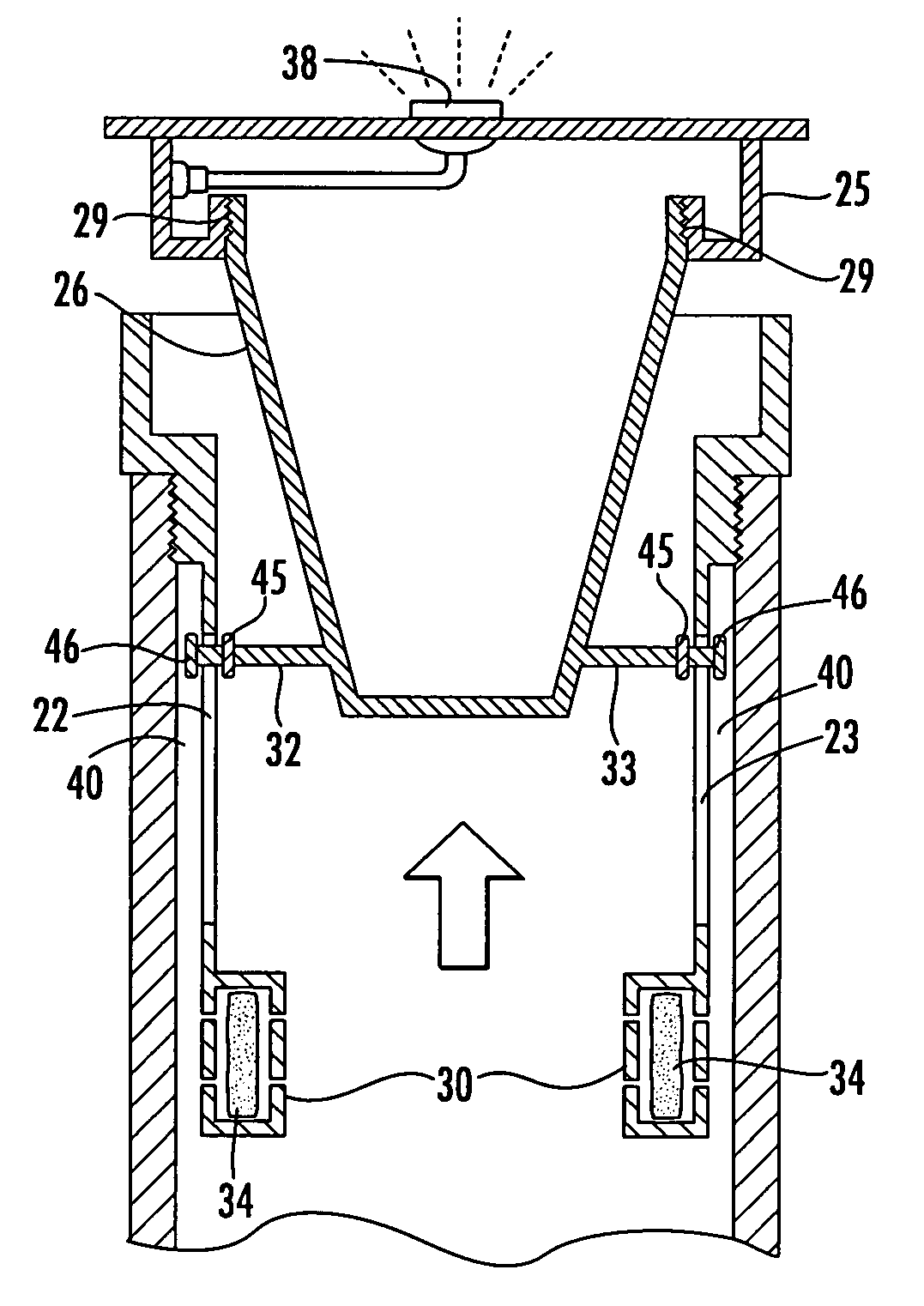

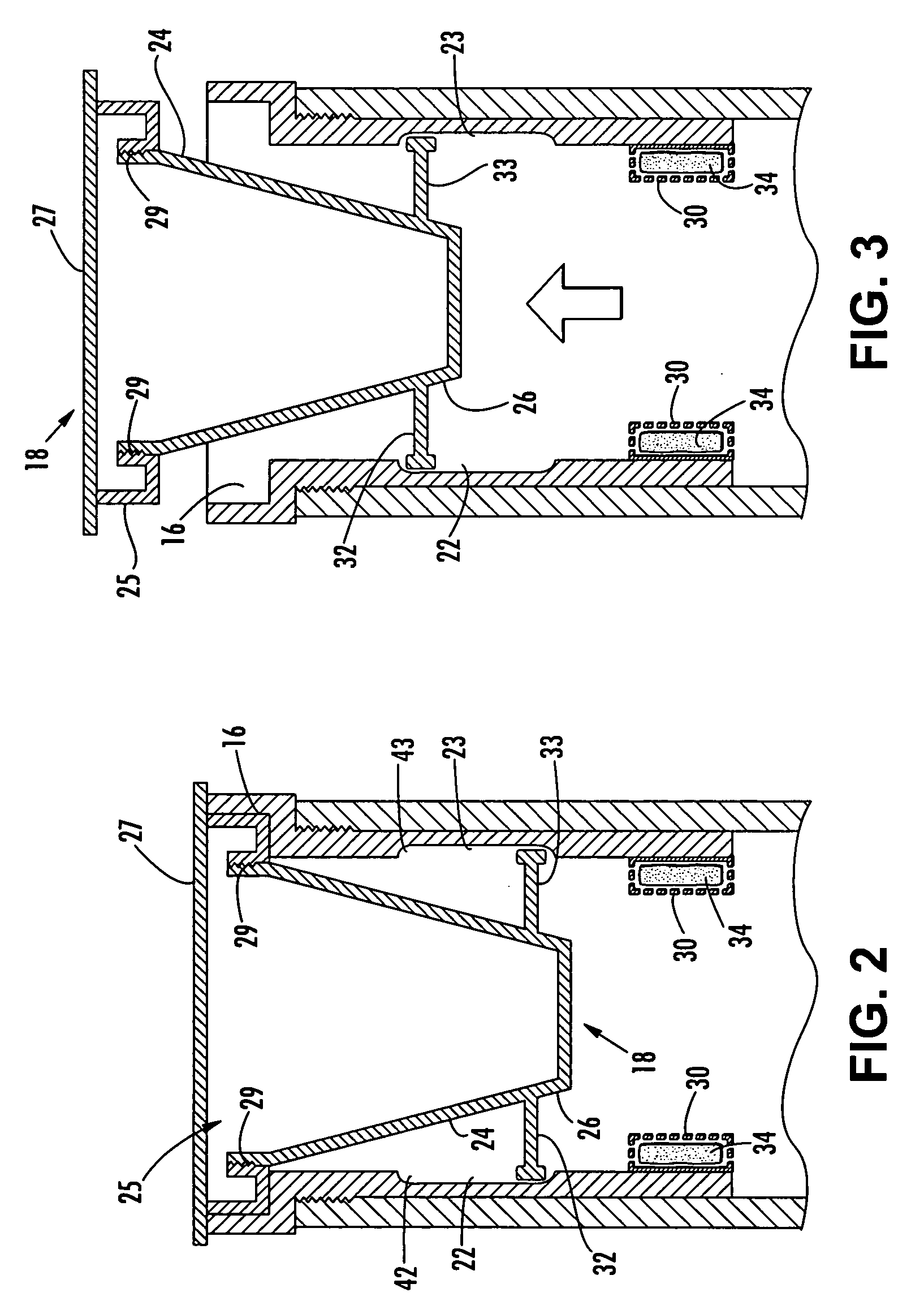

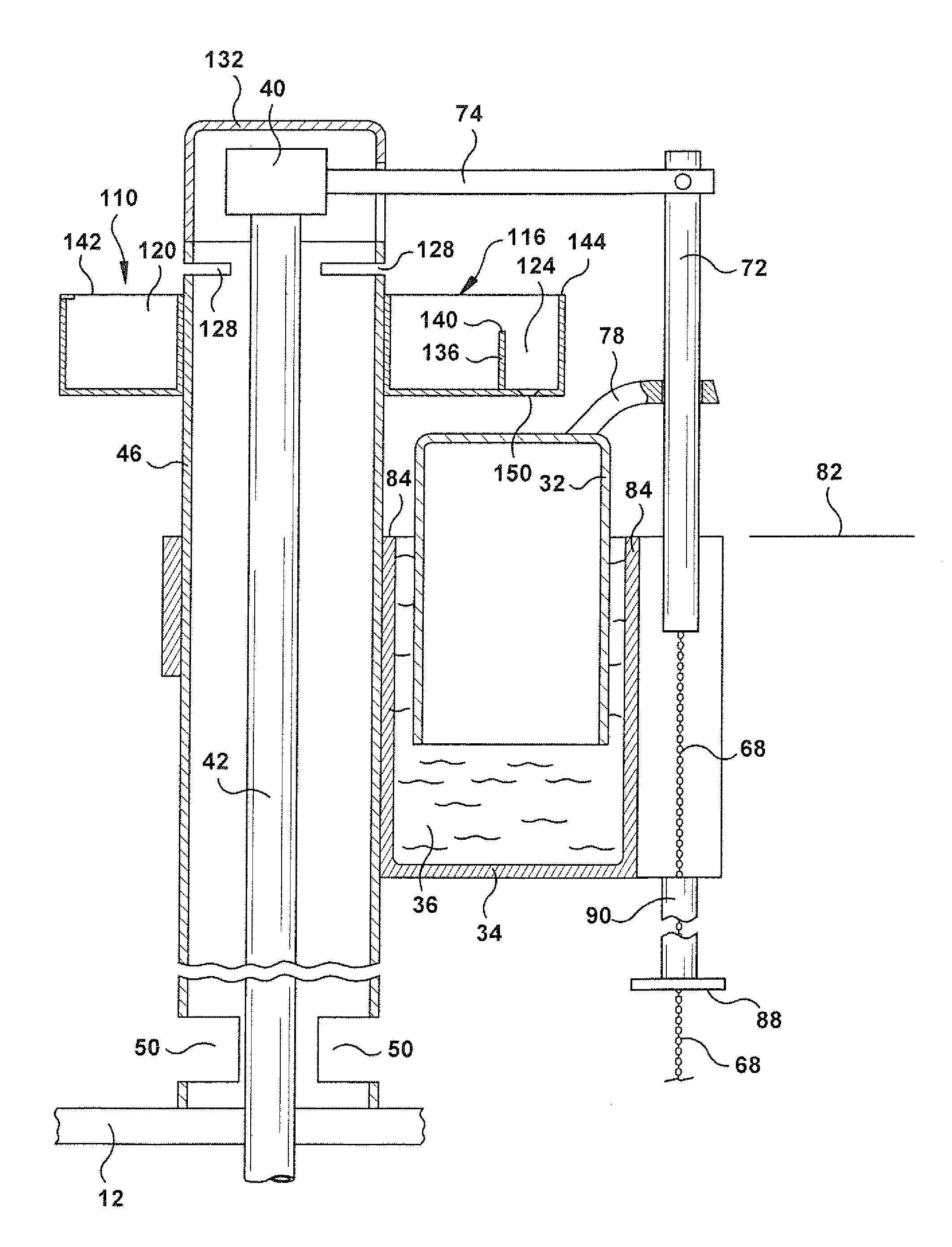

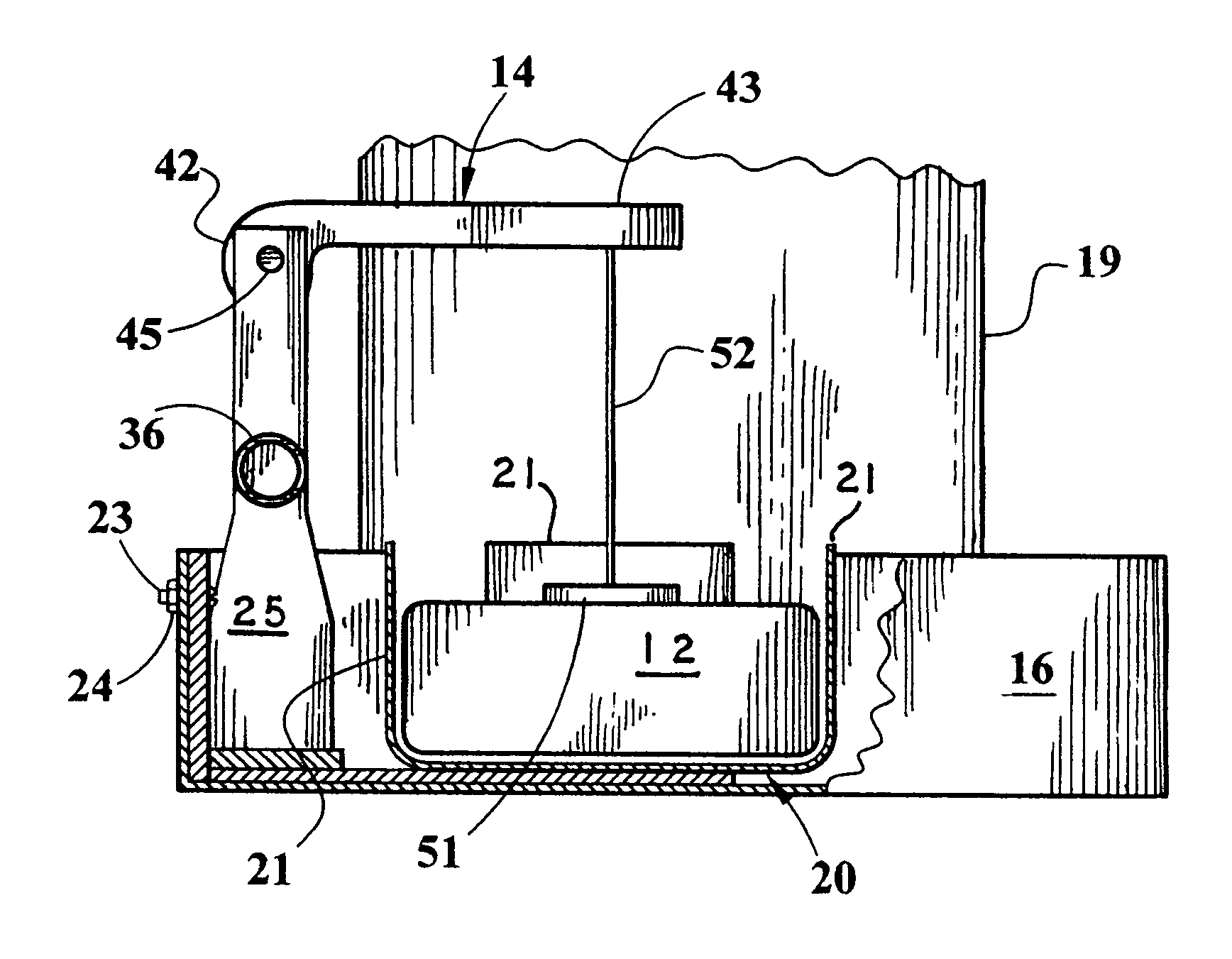

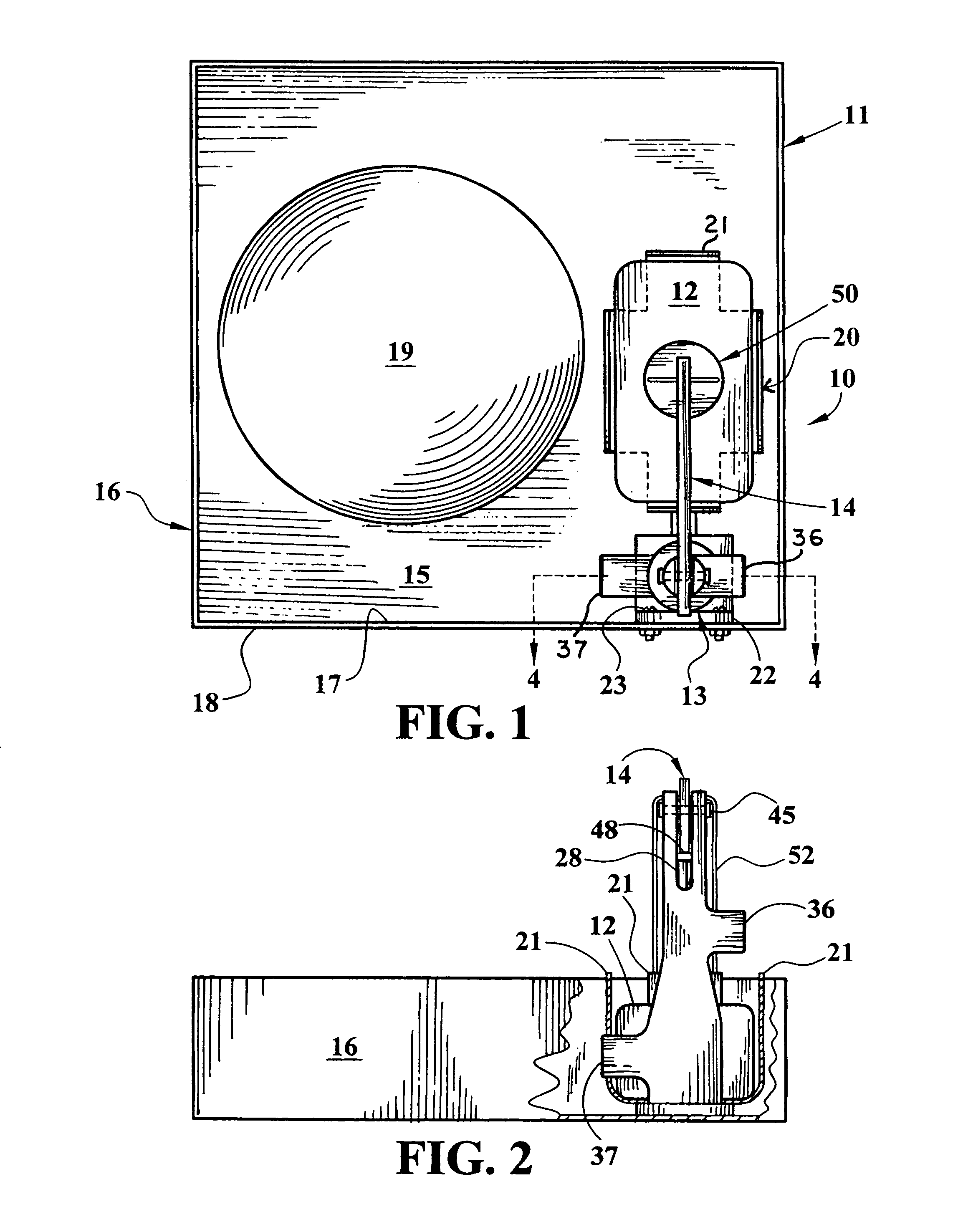

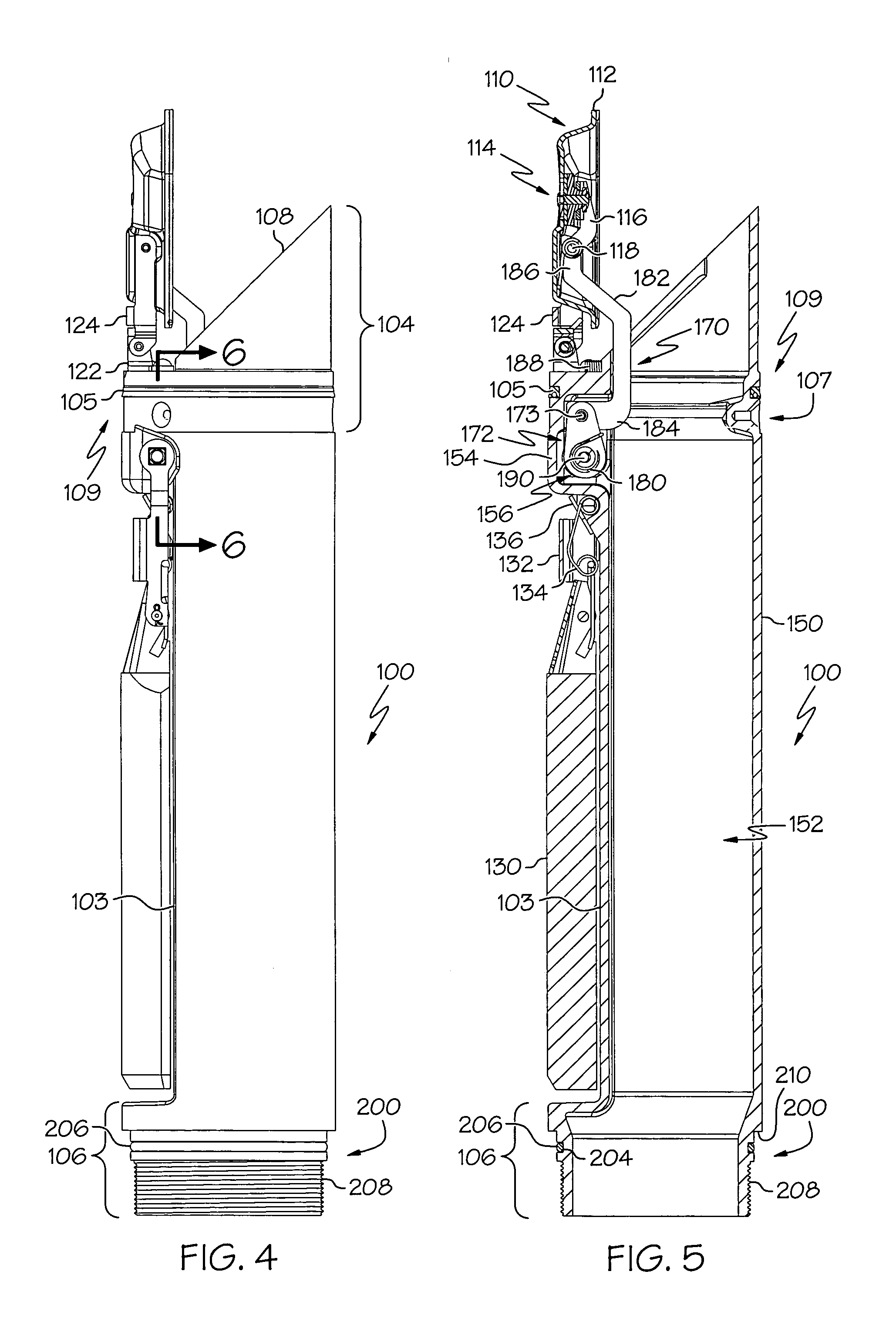

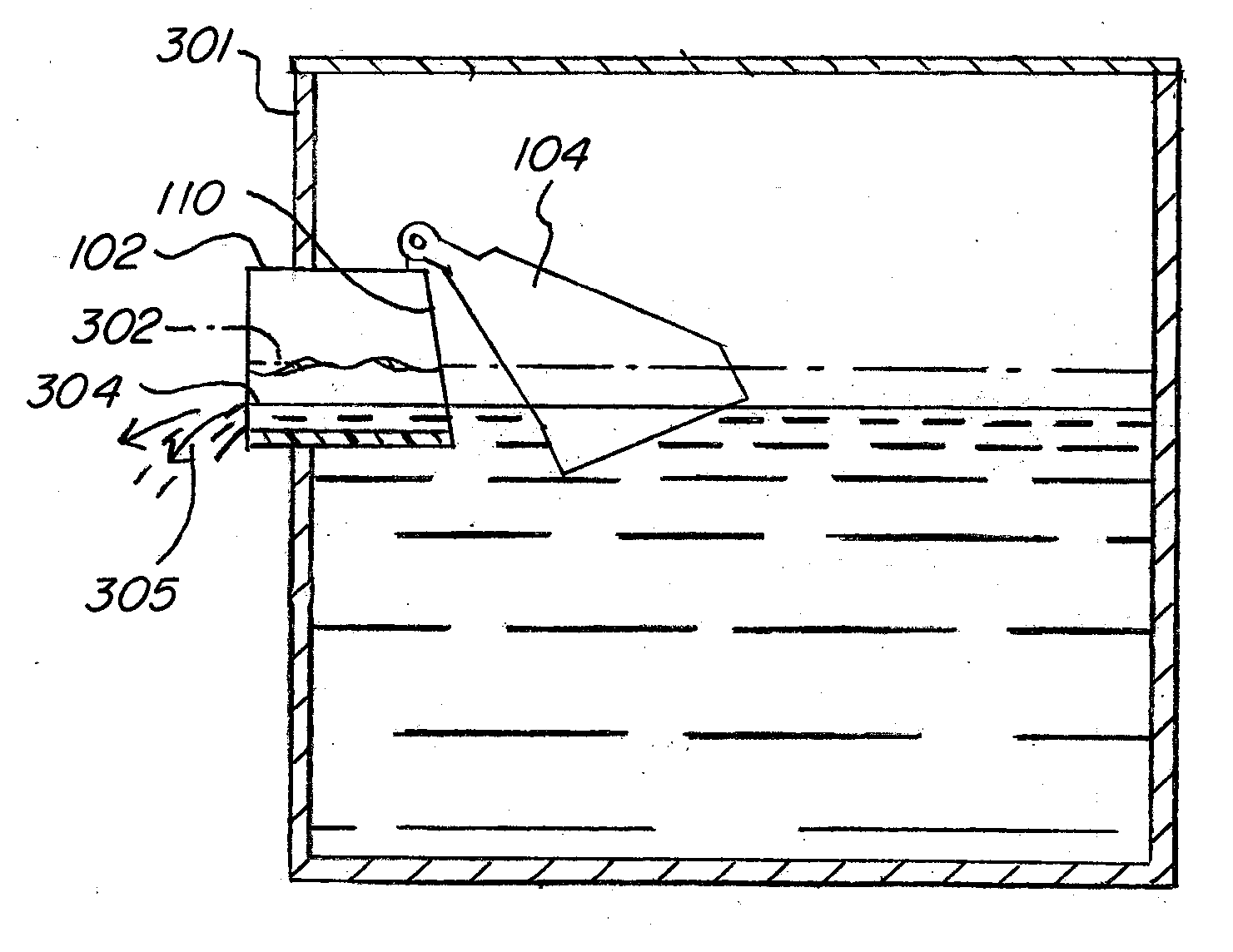

Toilet controls

ActiveUS20150074894A1Conserve waterQuantity minimizationFlushing devicesFloats for valve actuationInlet valveWater flow

Controls for use in association with the main tank of a toilet include a container which is disposed in the main tank and holds a body of water. A float is movable in the container to expel water from the container and effect operation of an inlet valve from a closed condition to an open condition. Water flows into an inlet compartment and into the main tank when the inlet valve is in the open condition. Water flows into an outlet compartment after a predetermined quantity of water has accumulated in the inlet compartment. Water flows from the outlet compartment into the container.

Owner:AQUA MIZER

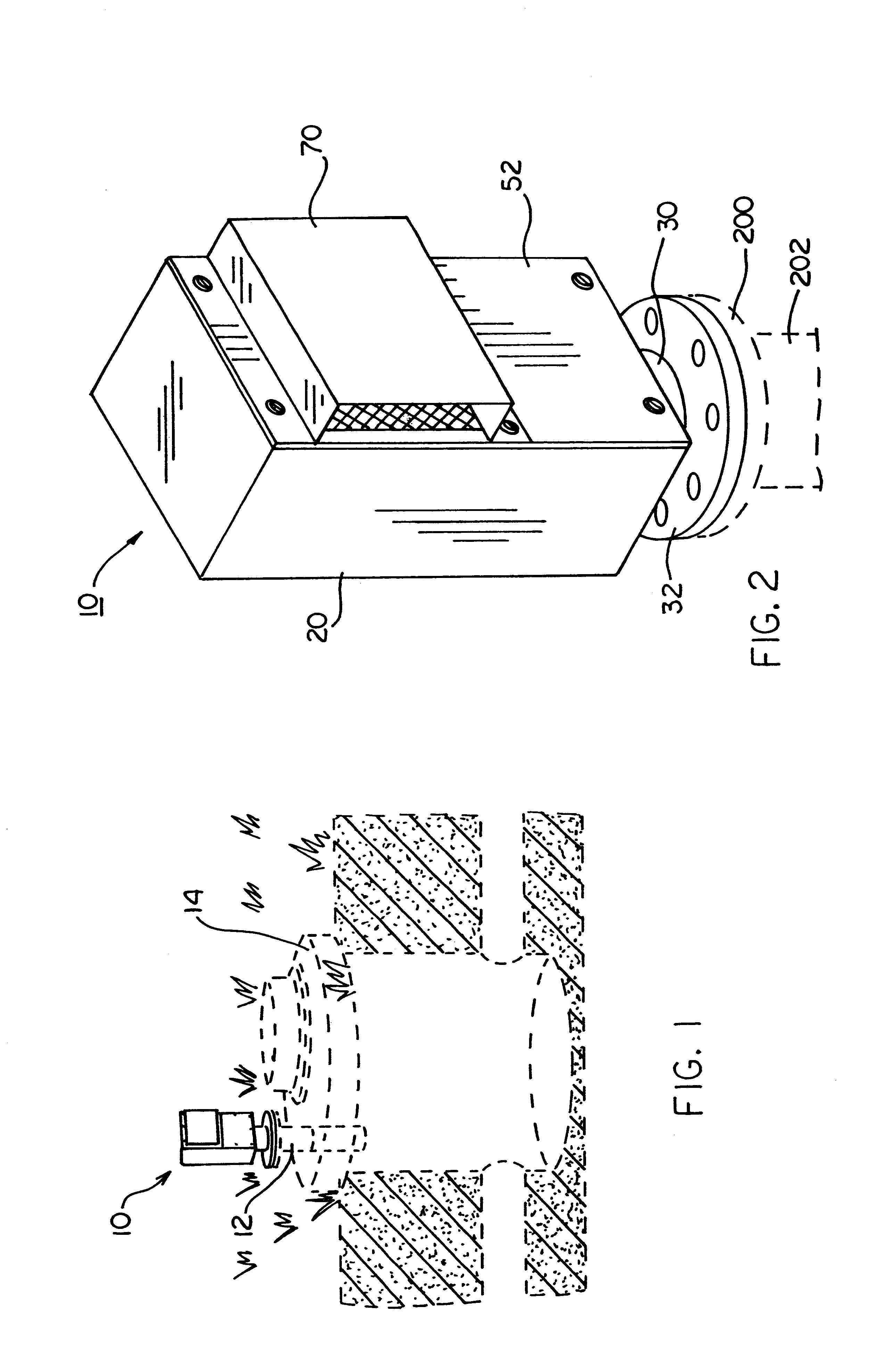

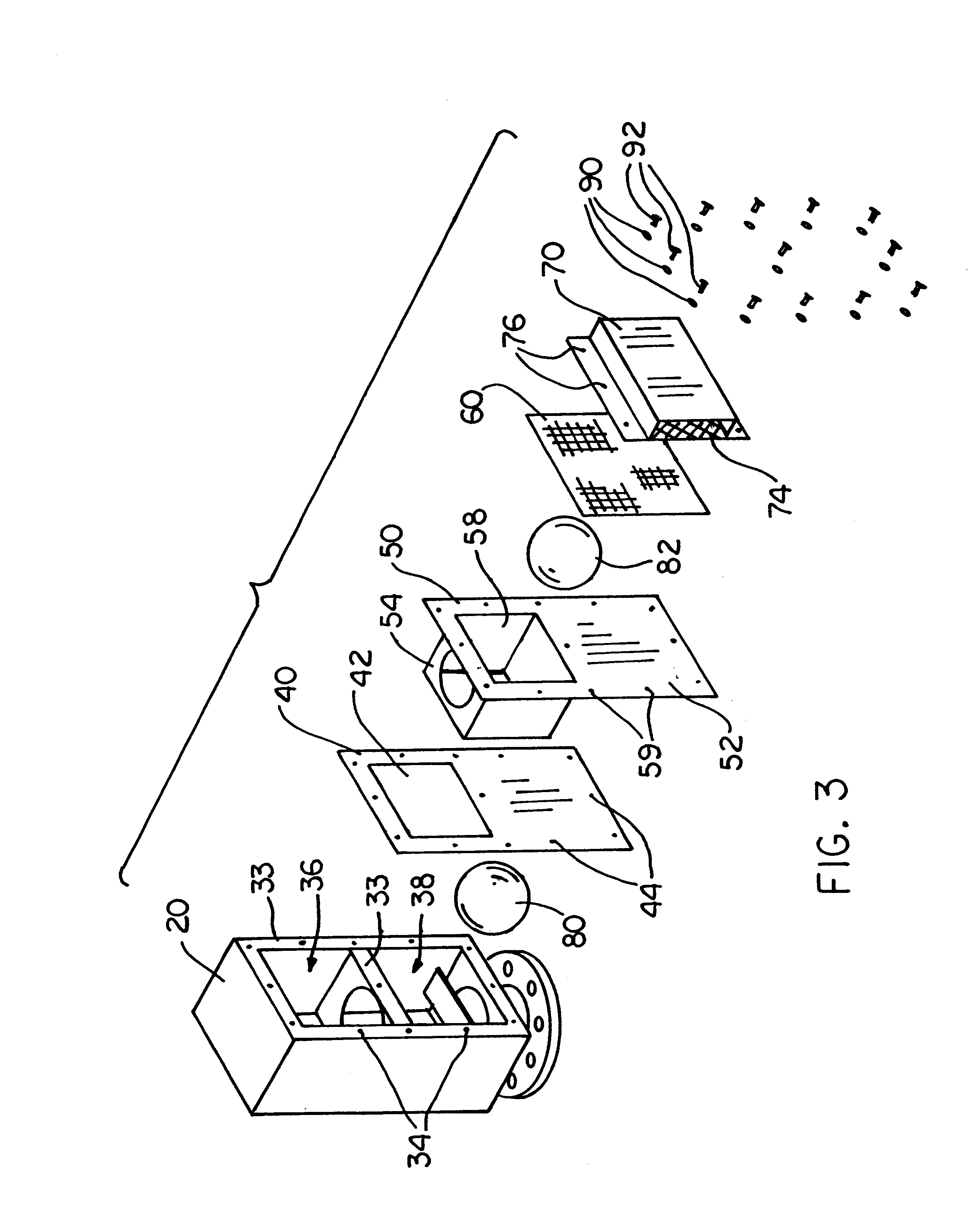

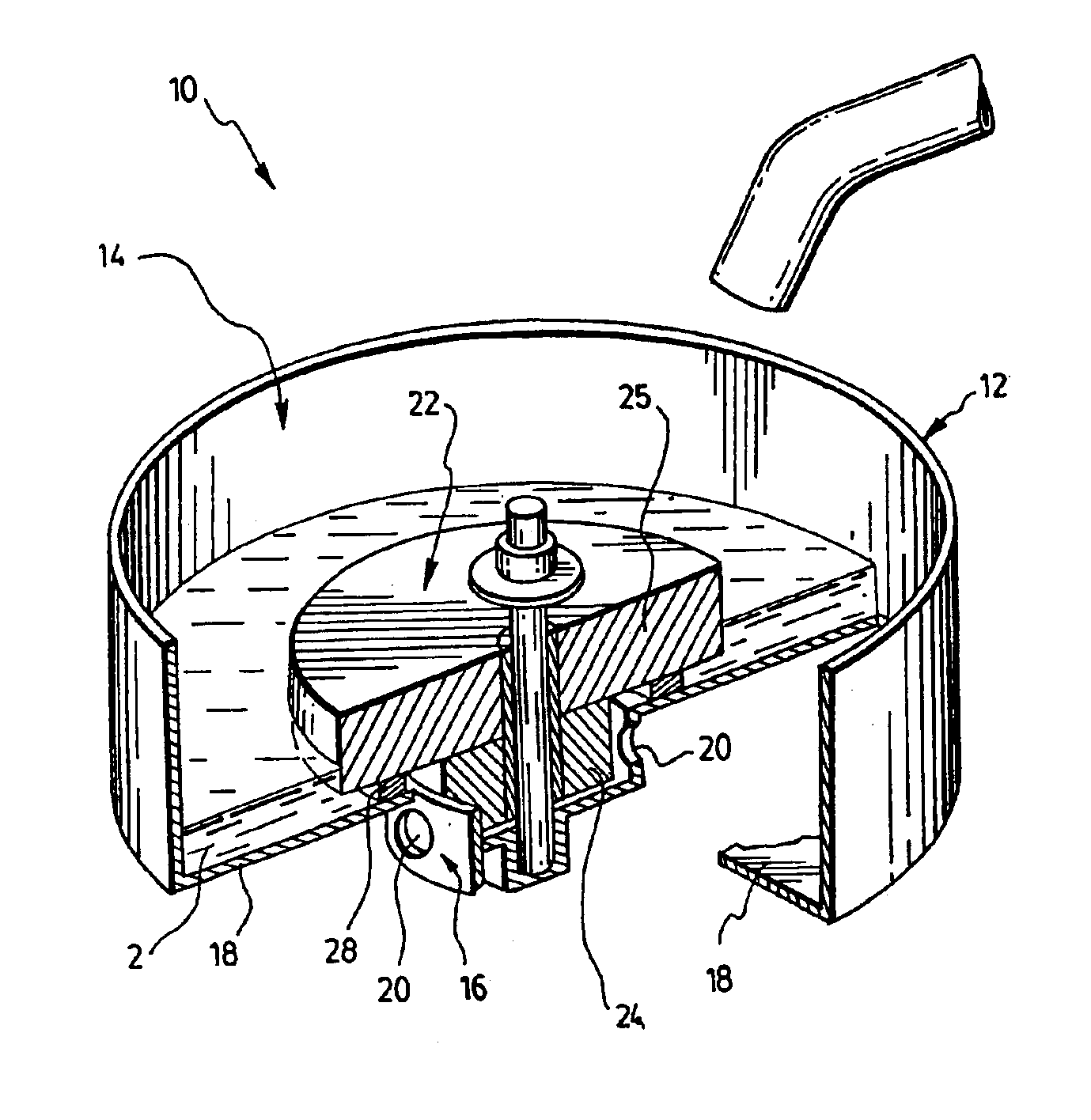

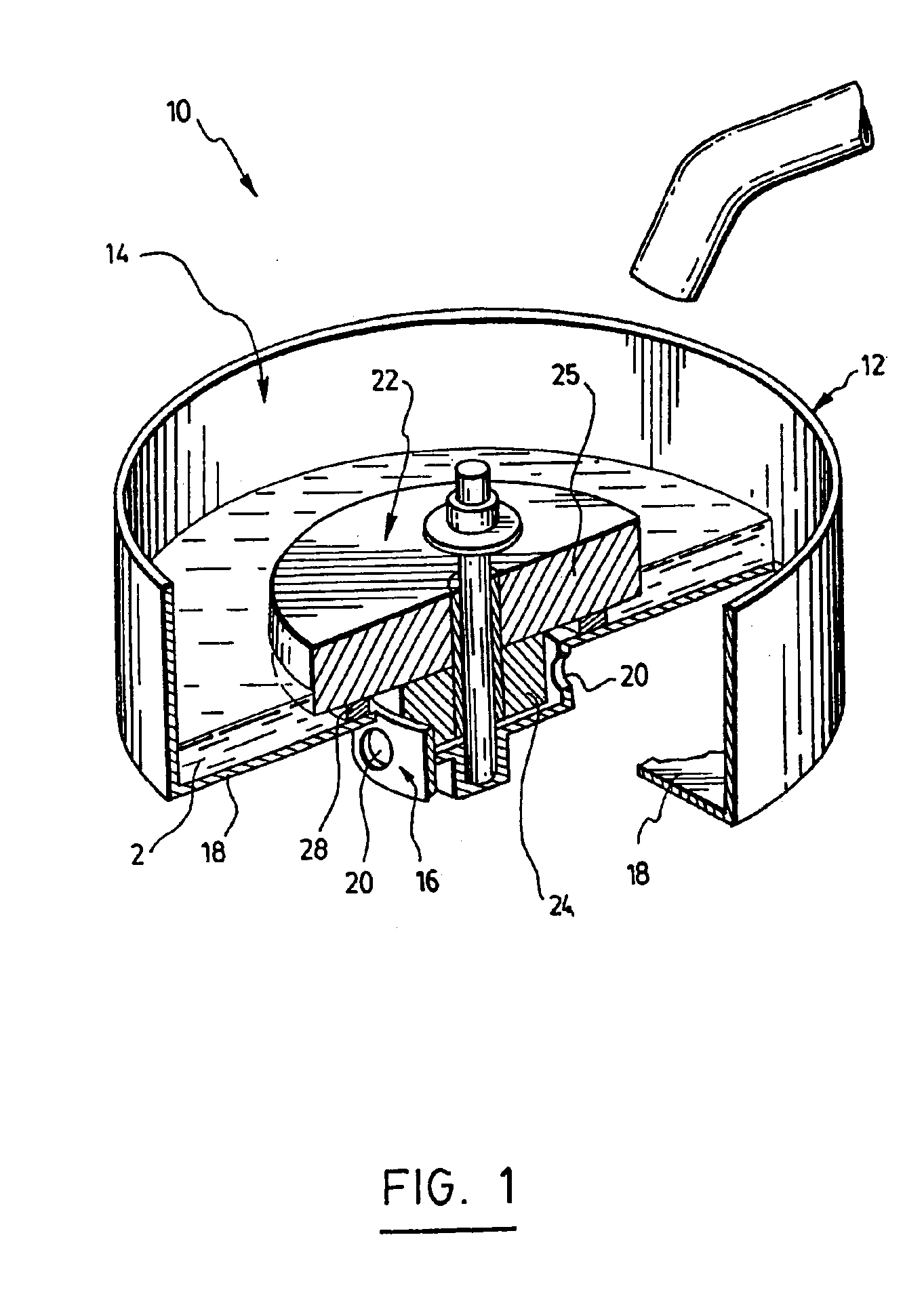

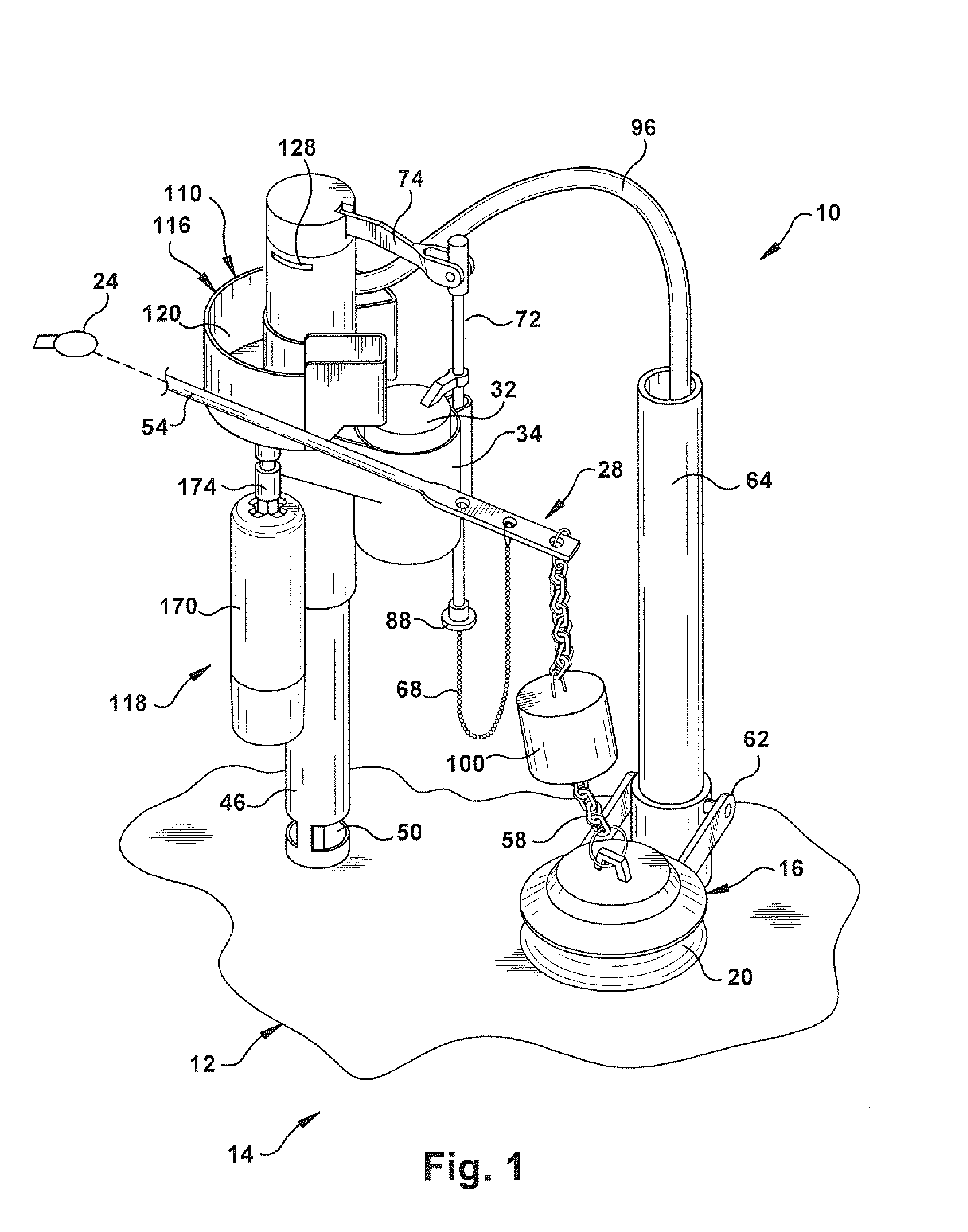

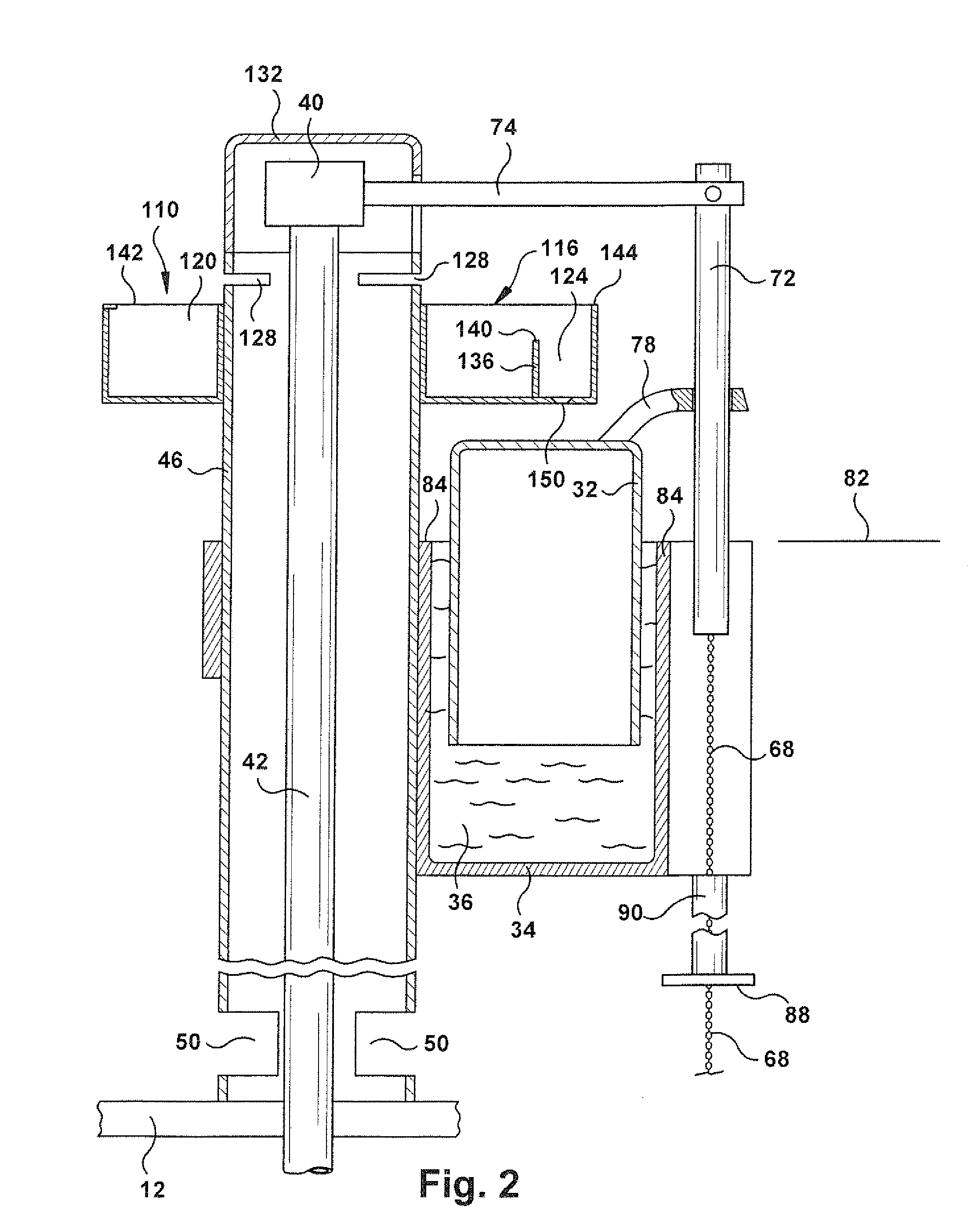

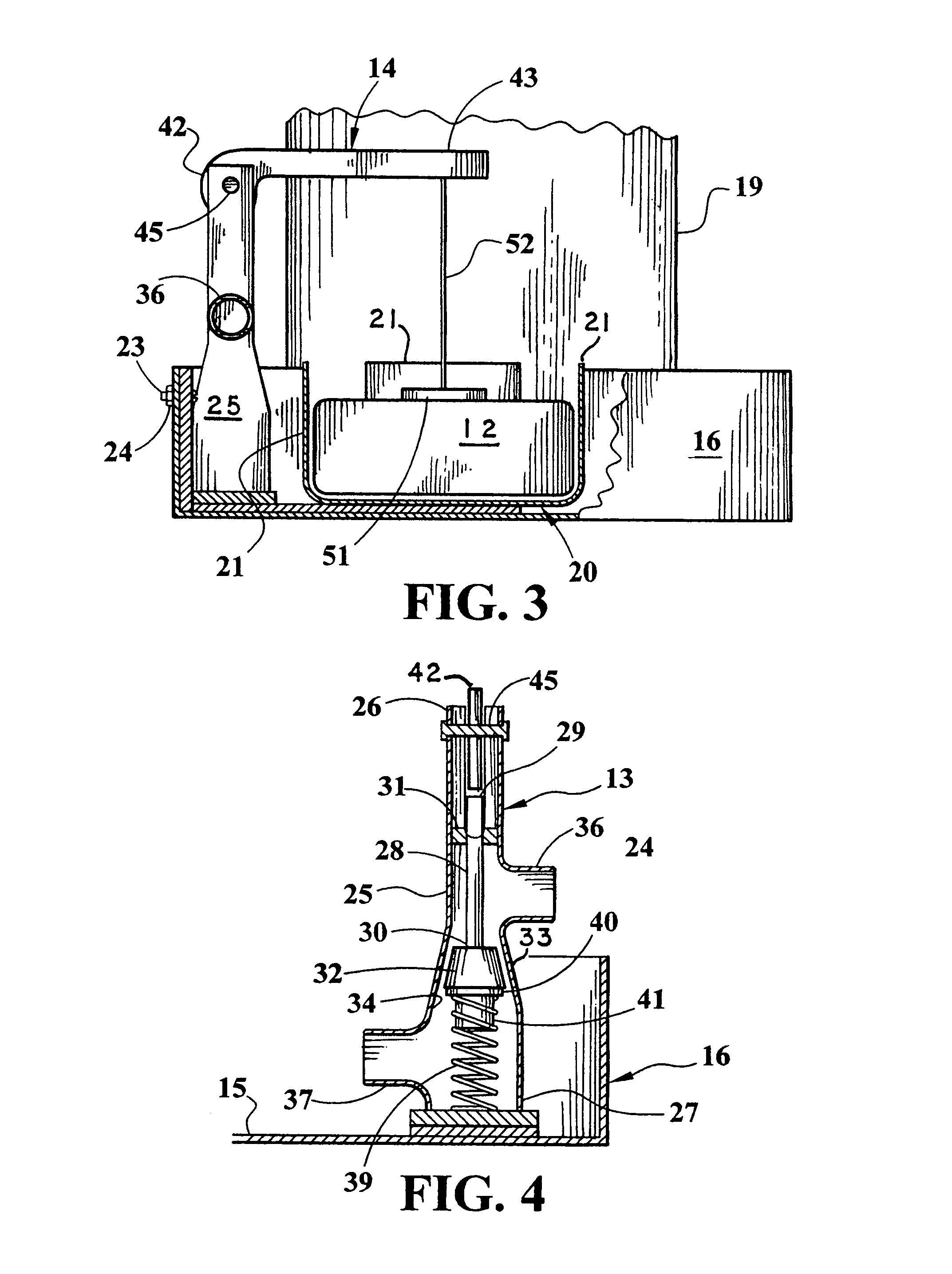

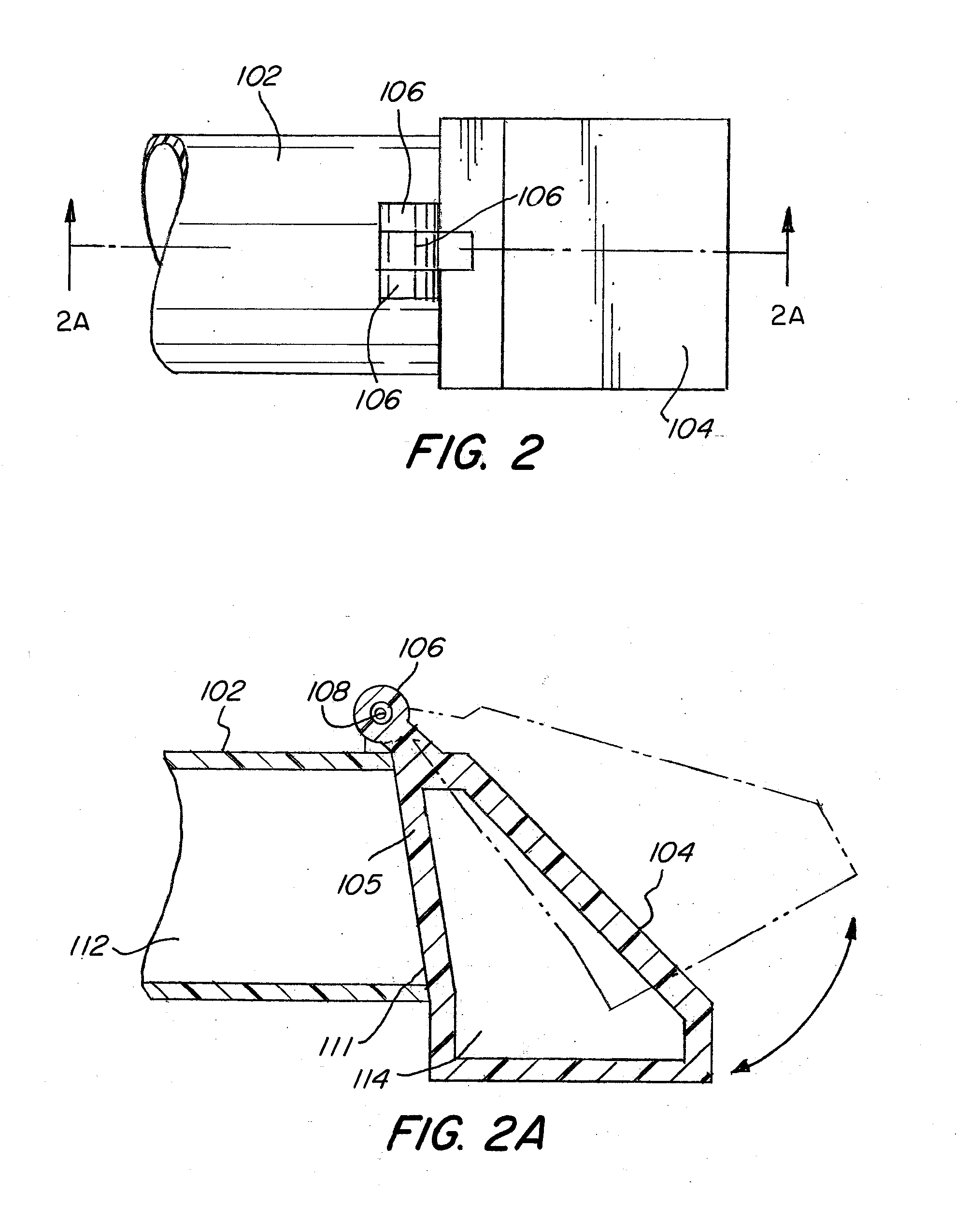

Water heater fail safe apparatus

Apparatus for automatically shutting off the water supply to a leaking water heater includes a water collecting tray positionable beneath the heater, a valve mechanism attachable to the tray, a float mechanism, and an action arm interactive between the float mechanism and valve mechanism. When water collects in the tray, the float mechanism rises, causing the action arm to trigger the release of a spring-urged component of the valve mechanism to discontinue flow of water to the heater.

Owner:CARROLL JAMES H

Drop tube segments adapted for use with a liquid reservoir

ActiveUS7243675B2Easy to adjust the positionPrevent leakageSleeve/socket jointsOperating means/releasing devices for valvesEngineeringDrop tube

A drop tube segment is adapted for use with a liquid reservoir. The drop tube segment includes a conduit with an end portion and a sidewall including a sidewall portion at least partially defining an interior housing area. The drop tube segment further includes a valve assembly comprising a valve member attached to the end portion of the conduit, a float, and a linkage device pivotally connected to the valve member. The valve assembly further includes a driver member at least partially disposed in the interior housing area. An adjustment of the float may rotate the driver member to engage the linkage device to facilitate in adjusting the position of the valve member with respect to the end portion of the conduit. The valve assembly further includes a structure adapted to inhibit, such as prevent, fluid from leaking into the interior housing area.

Owner:OPW FUELING COMPONENTS LLC

Fuel vapor vent valve float assembly and method of making same

ActiveUS20060011234A1Easy to assemblePrevent escapeOperating means/releasing devices for valvesVenting valvesValve floatEngineering

A float assembly for a multifunction fuel vapor vent valve with a float having a recess formed in the upper surface of the float with a slot formed in the side of the float and communicating with the recess. A raised surface portion is formed in the bottom of the recess and downwardly extending projections are formed in the slot at the recess. A flexible wafer like valve disk is inserted in the slot and deformed or curled to pass under the projections and over the raised surface and into the recess. When fully received in the recess the disk returns to its flat configuration; and, the downward projections prevent removal without distortion. Radially inwardly projections about the recess retain the disk for limited lost motion in the direction of float movement.

Owner:EATON INTELLIGENT POWER LTD

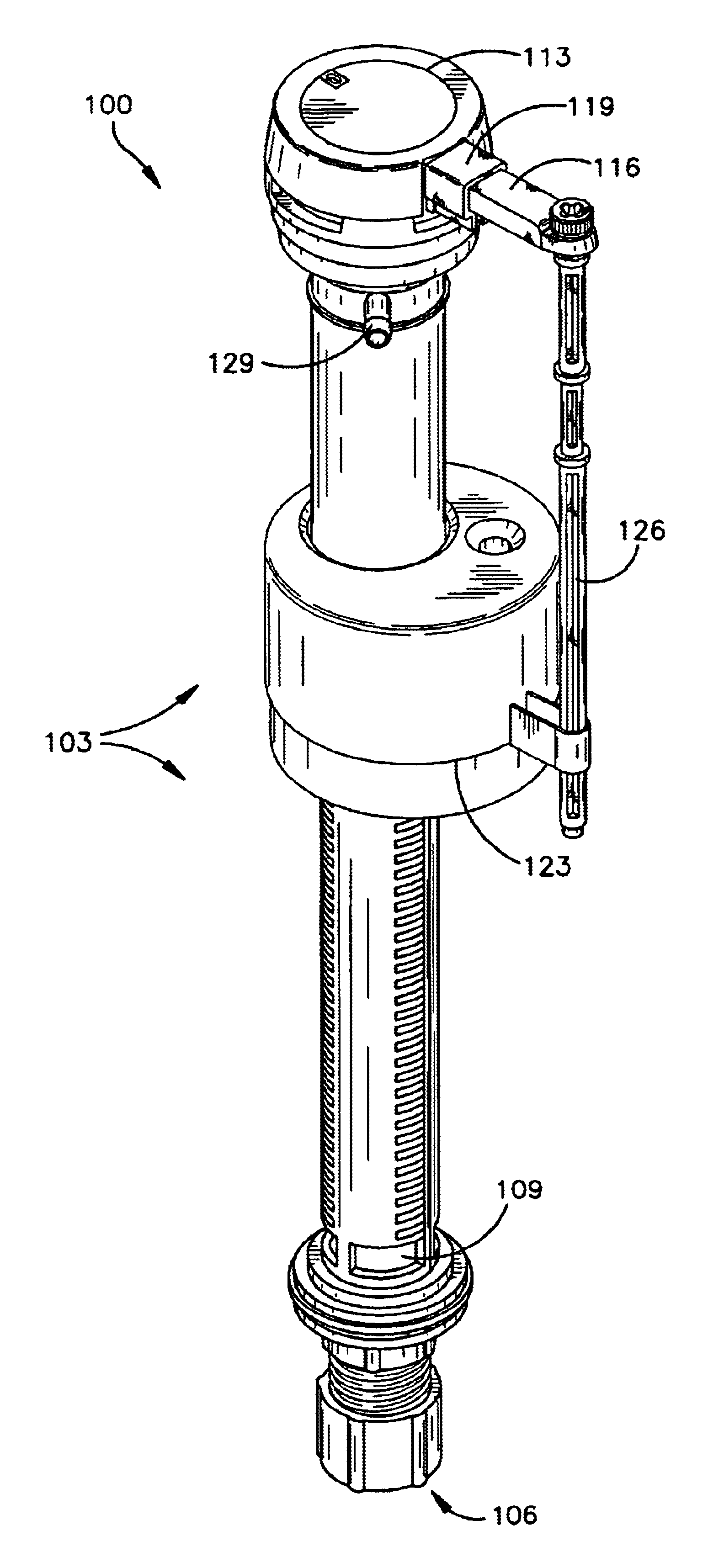

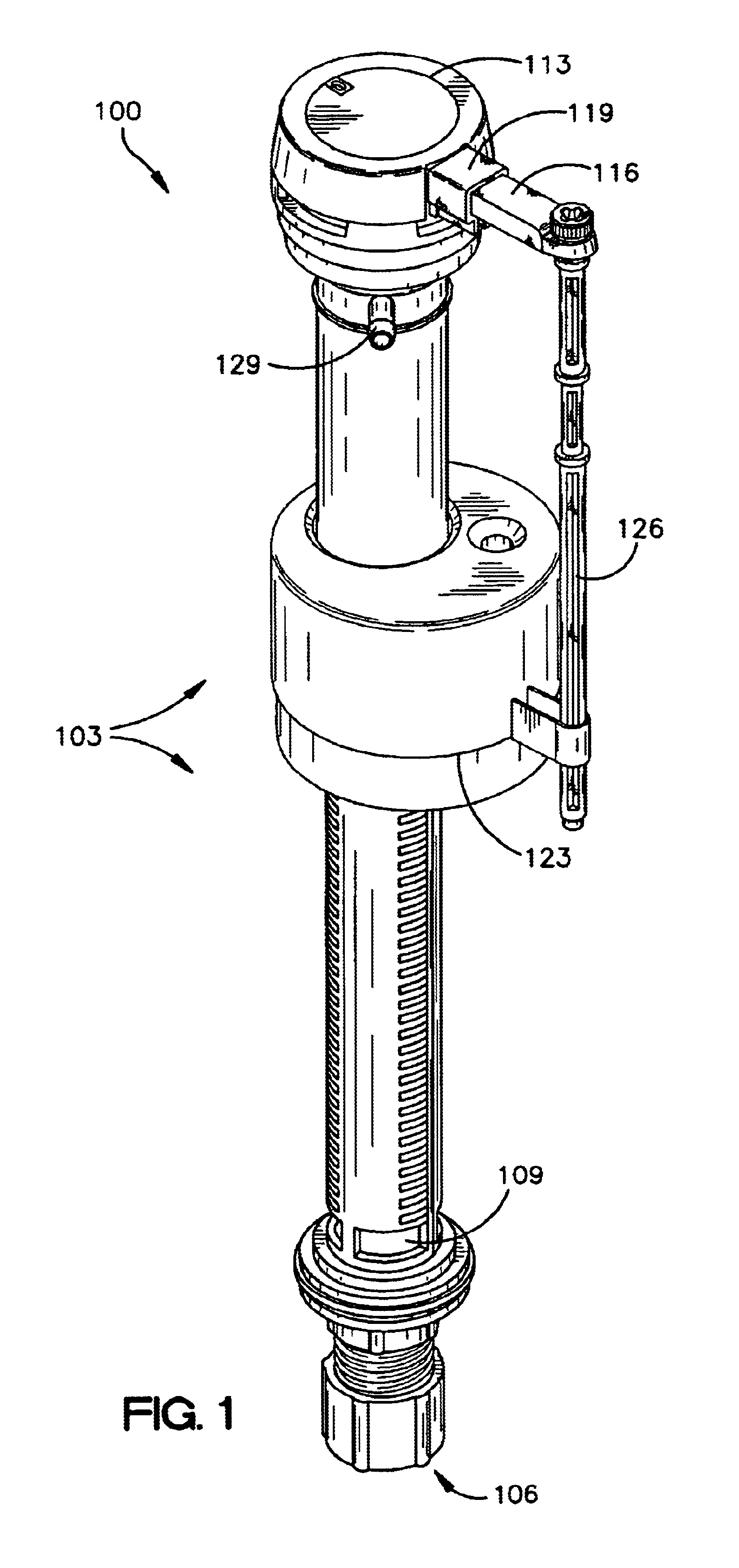

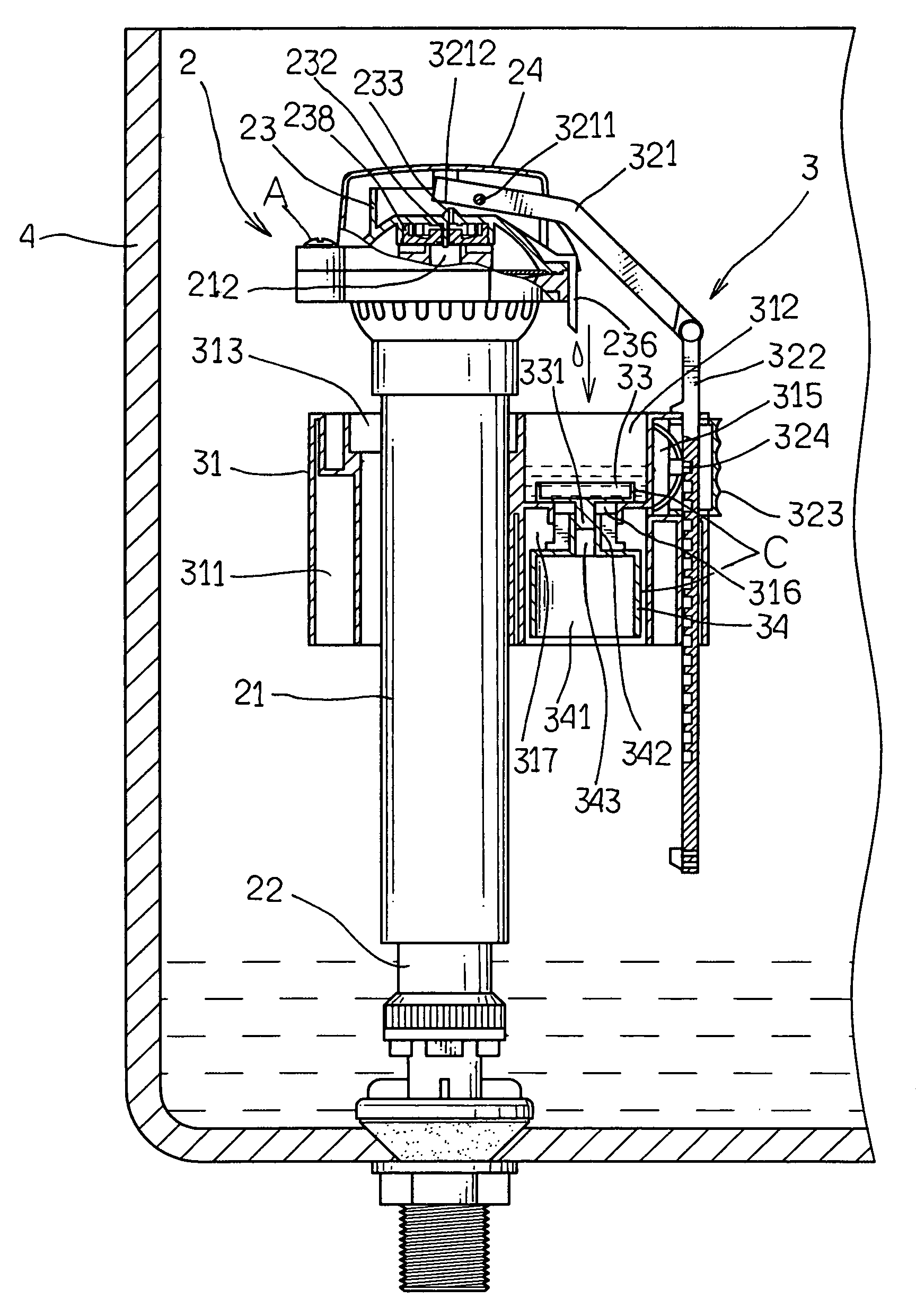

Water filler for water tank

ActiveUS20050121079A1Quick stop functionSavingOperating means/releasing devices for valvesFlushing devicesWater sourceEngineering

A water filler includes a water filling device, and a regulating device. The water filling device includes an inner filling tube, an outer filling tube, and an upper cover. The regulating device includes a floating barrel, a sliding barrel, a water support disk, and an adjusting unit. Thus, the floating barrel is lifted instantaneously and rapidly to stop the water filling action exactly and actually, thereby saving the water source. Thus, the water filler has a quick water stop function.

Owner:HUANG SO MEL

Overflow Valve For Prevention Of Water Vapor Loss

InactiveUS20120180881A1Overcomes drawbackLittle changeBarrages/weirsPipe supportsWater vaporEngineering

A system and valve for regulating the level of a fluid. The valve having a floating head member that is connected via a rotatable member to a drain member, where fluid may drain from the valve. The system having the valve and a tank, where the fluid drains from the tank once the fluid level reaches the level of the drain member of the valve.

Owner:APRICUS SOLAR

Fuel shut-off valve

ActiveUS20080236672A1Thin thicknessSecure sealabilityOperating means/releasing devices for valvesCheck valvesFuel tankEngineering

A fuel shut-off valve includes a casing, an ascendable and descendible float, and an upper valve element, which is actuated by the float to open and close connector passage that communicates the inside of fuel tank with the outside, and which includes a valve body and a ring-shaped seat member. The ring-shaped seat member makes a connector bore, which communicates with the connector passage, therein, and includes a base, a holding portion, a seating portion, a lip-shaped portion, and a thin-film-shaped portion. The seating portion opens and closes the connector passage, and defines an opening of the connector bore. The lip-shaped portion seats on and separates away from the float, and defines the other opening of the connector bore. The thin-film-shaped portion is disposed between the base and the lip-shaped portion, and is deformable elastically upon being pressed by the float when the float seats on the lip-shaped portion.

Owner:TOYODA GOSEI CO LTD

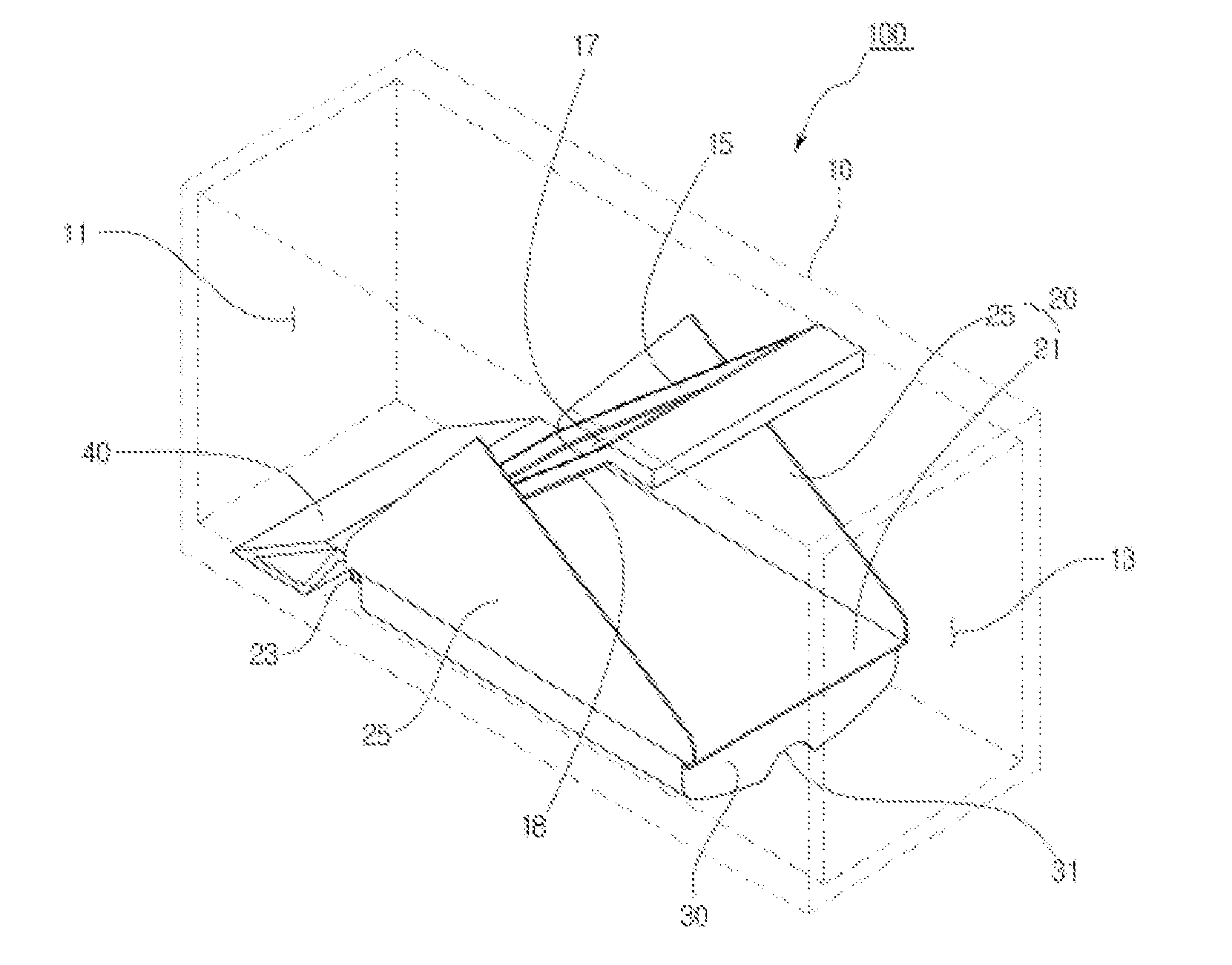

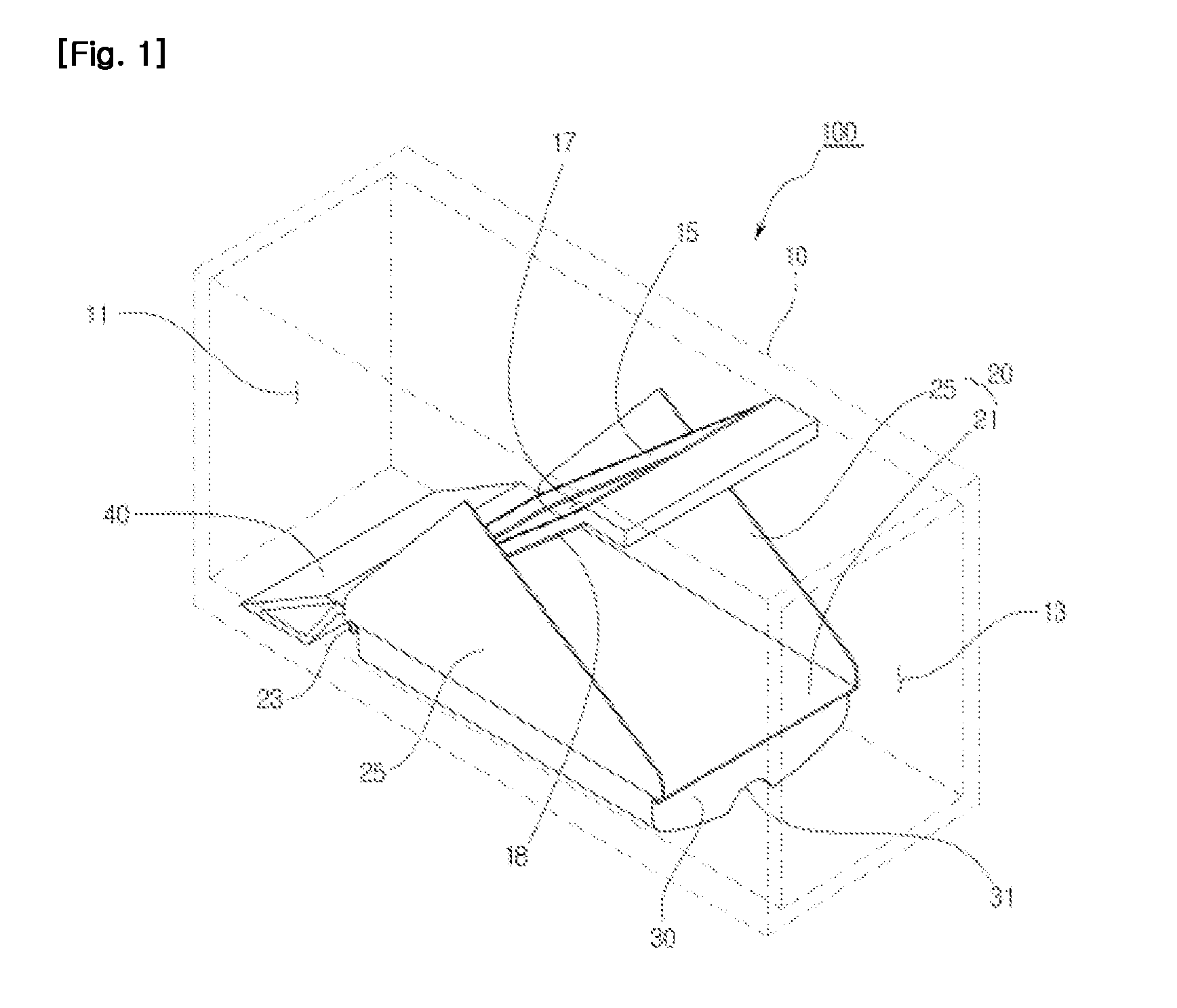

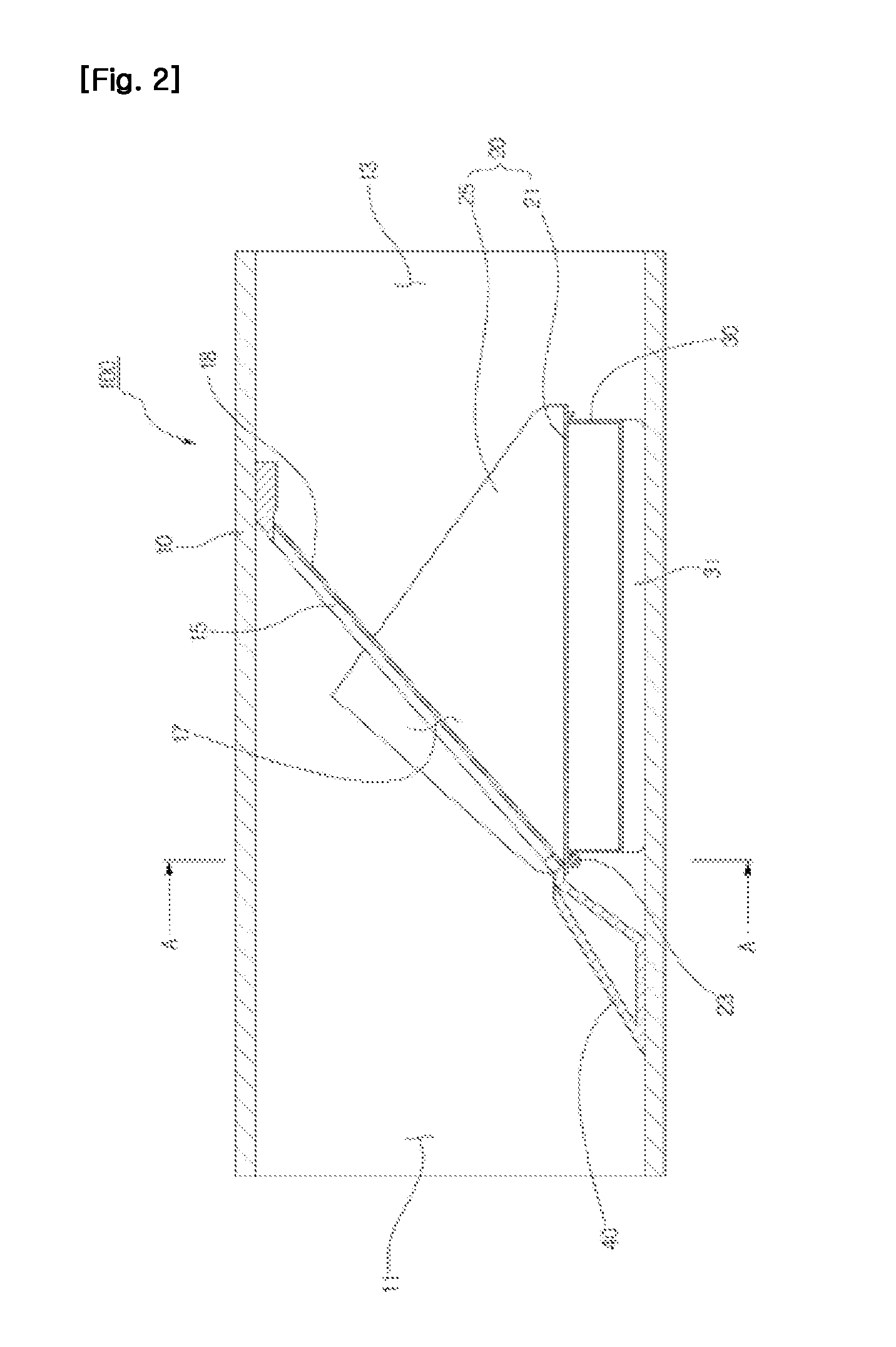

Unpowered apparatus for preventing backflow

ActiveUS20120279586A1Prevent backflowEasy to installOperating means/releasing devices for valvesSewerage structuresEngineeringSewage

The present invention relates to an unpowered apparatus for preventing backflow, comprising: a tubular main body having a stepped portion, wherein the main body has an inlet port for the inflow of sewage, an outlet port for discharging the sewage, and a communication port which is inclined toward the outlet port and which puts the inlet port and the outlet port in communication; an opening / shutting door having a door body rotatably hinged to the inside of the main body so as to open / shut the communication port, and a pair of blocking plates extending from either side of the door body so as to block the space between the stepped portion and an inner wall of the main body; a floating part which is arranged in the opening / shutting door, the interior of which is empty such that the floating part can float on a water surface, and which provides the opening / shutting door with buoyancy and operates the opening / shutting door so as to close the communication port when the sewage flows back toward the outlet port; and a guide interposed between the stepped portion and a bottom surface of the main body so as to guide the sewage introduced from the inlet port such that the sewage flows toward the outlet port via the communication port.

Owner:KIM JONG SUN

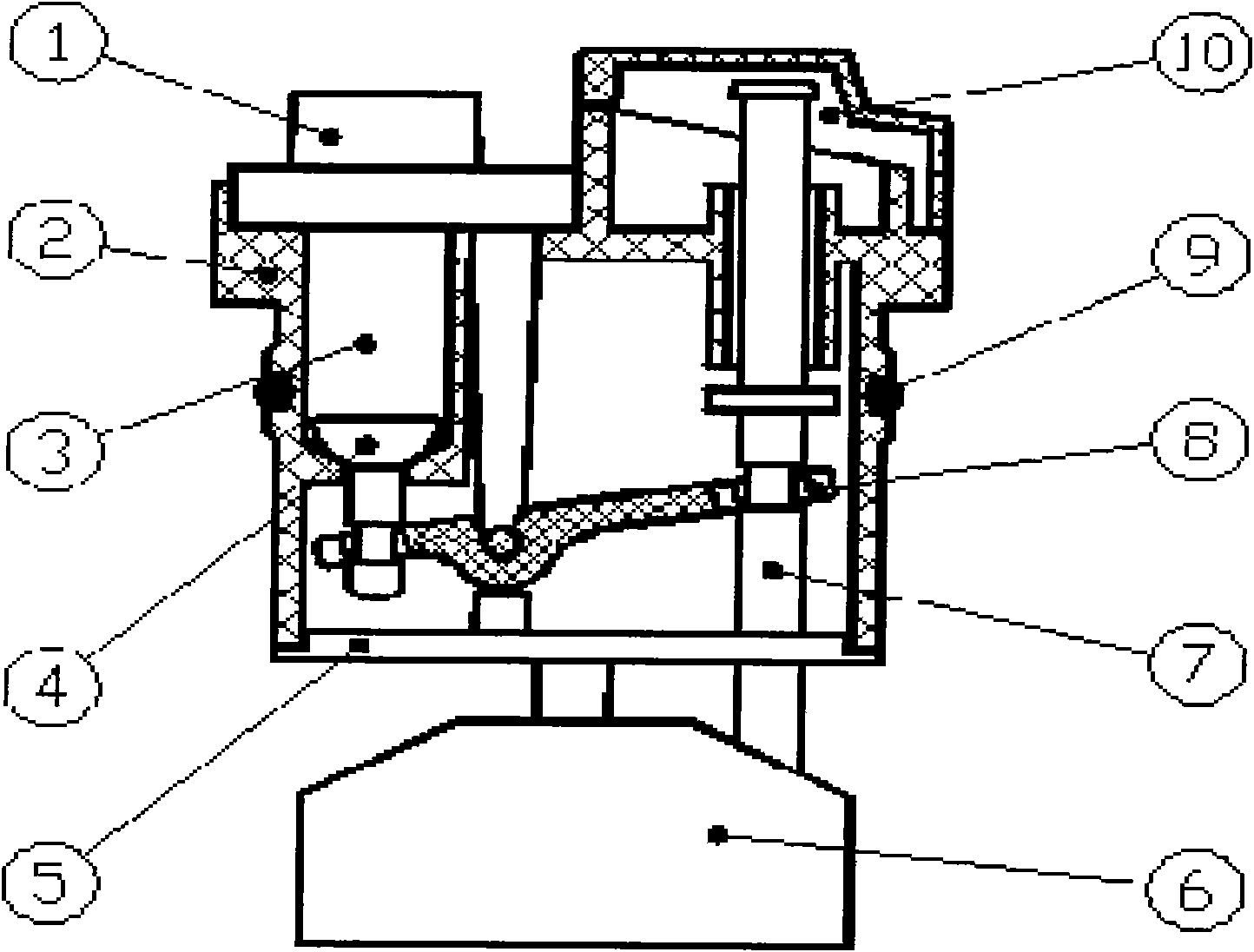

Battery liquid-filling valve

InactiveCN101847707AAvoid damageCell component detailsFluid-delivery valvesInlet channelElectrical battery

The invention discloses a battery liquid-filling valve, comprising a body, a valve core, a rotating shaft, a lever, a buoy and a water inlet channel. The battery liquid-filling valve is characterized in that the body (2) is internally provided with a fixed rotating shaft (7); the water inlet channel (3) is arranged at one axial side of the rotating shaft; the upper end of the water inlet channel is connected with a water inlet interface assembly (1); the valve core (4) is assembled at the lower end of the water inlet channel to form a valve device; the rotating shaft is provided with the lever (8) capable of rotating around the rotating shaft; one end of the lever is movably connected with the valve core; and the other end of the lever is movably connected with the body (6). By introducing a lever structure principle, the valve is controlled to be opened and closed under the action of the buoyancy provided by liquid in a storage battery to prompt a user whether the storage battery is lack of liquid or not and when to stop filling the liquid. The invention can effectively avoid the liquid lack of the battery, insufficient liquid filling, excessive liquid feeding and overflowing to damage the storage battery.

Owner:上海哈登塑料技术有限公司

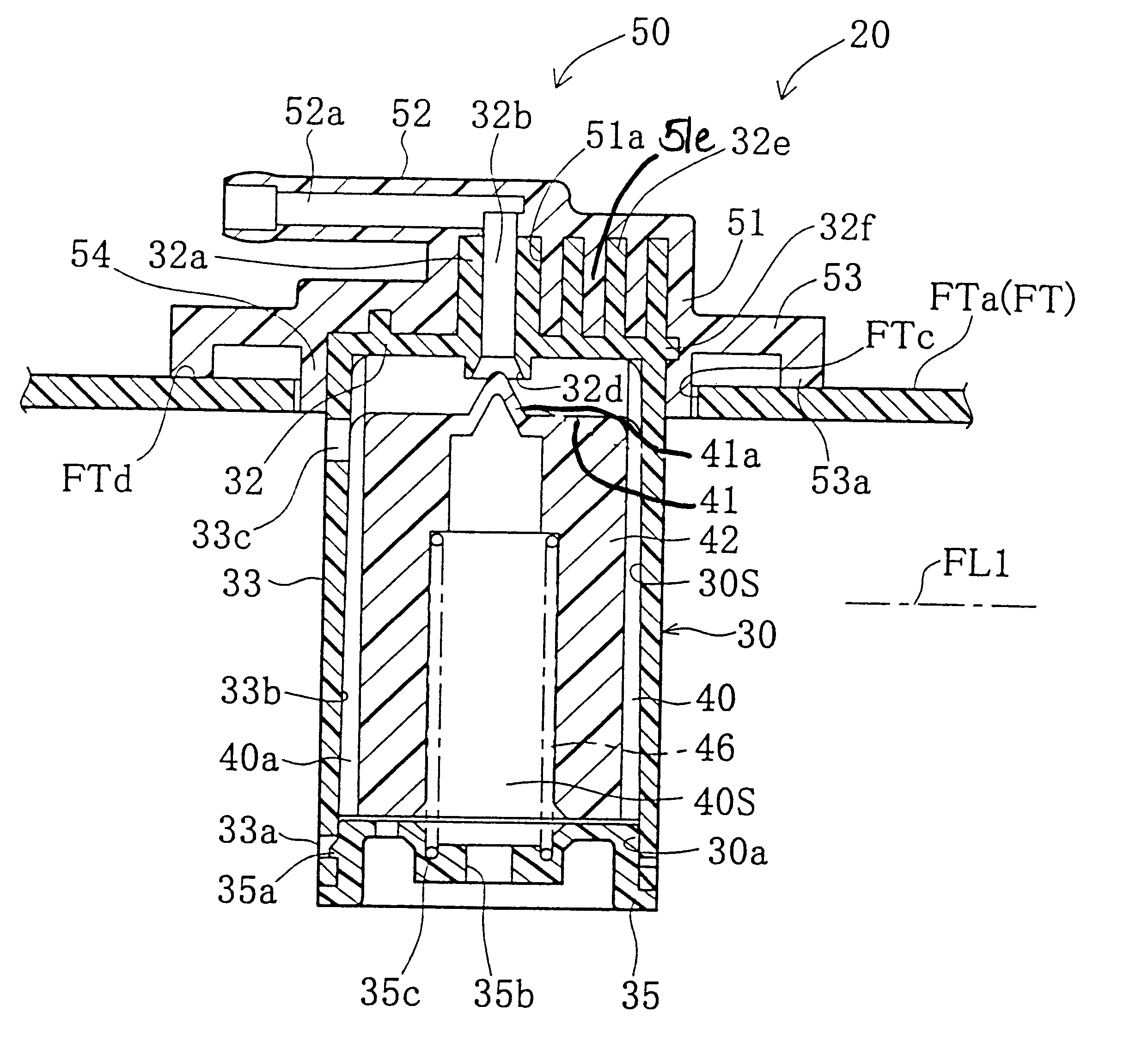

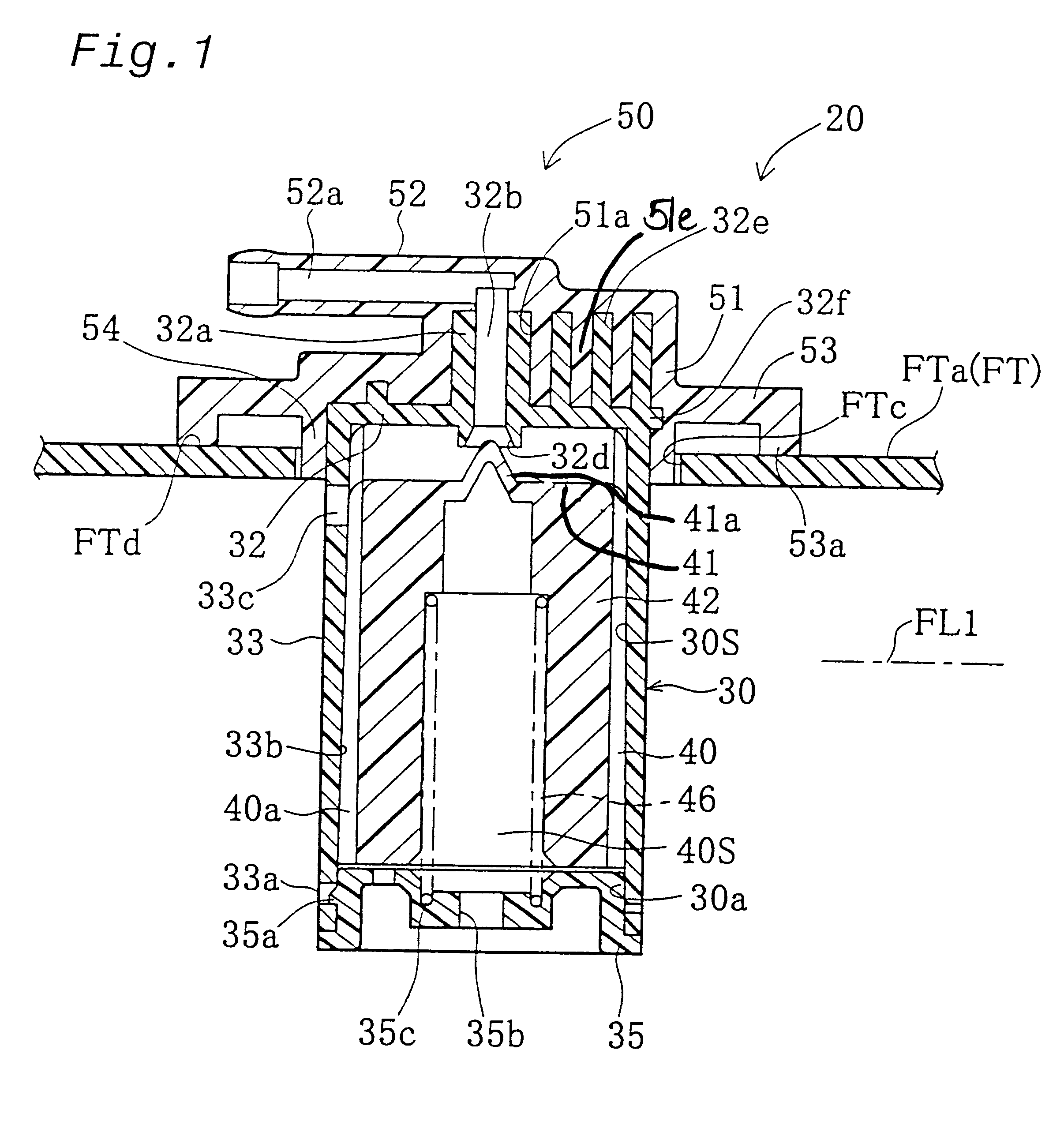

Ball tap with a water level switch

InactiveUS20030056827A1Operating means/releasing devices for valvesFlushing devicesControl signalEngineering

A compact ball tap with 1 a water level switch which comprises a guide standpipe 5 vertically arranged in a tank T, a float 6 slidably installed on the guide standpipe 5, a valve 3, a lever 4 controlling an open-close action of the valve 3 connected with the float 6, and a water level switch 29 transmitting predetermined control signals when the float 6 shifts to a predetermined water level, wherein one float 6 is shared by the ball tap 1 and the water level switch 29.

Owner:YOSHITAKE INC

Minor water leak prevention apparatus for water inlet valve

ActiveUS20170002555A1Save waterOperating means/releasing devices for valvesFlushing devicesSiphonInlet valve

Disclosed is a minor water leak prevention apparatus for a water inlet valve. A float is mounted on a regulation bar and received in a water container. The water container is mounted on a siphon tube. The siphon tube is formed with an air aperture. A counterweight buoyance switch is mounted on the water container. The counterweight buoyance switch has a counterweight water compartment having a lower end forming a water drain hole. The counterweight water compartment has an upper end to which a closure pressing plate is mounted. The closure pressing plate is opposite to the air aperture. The counterweight buoyance switch controls opening / closing of the air aperture. This arrangement allows water ingress through a water inlet valve to be stopped when minor water leakage occurs in a water tank.

Owner:LAB XIAMEN SANITARY FITTINGS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com