Battery liquid-filling valve

A liquid injection valve and battery technology, applied in battery pack components, circuits, valve details, etc., can solve problems such as excessive and overflow, unable to know whether the battery is short of liquid, damage the battery, etc., to avoid the effect of battery shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

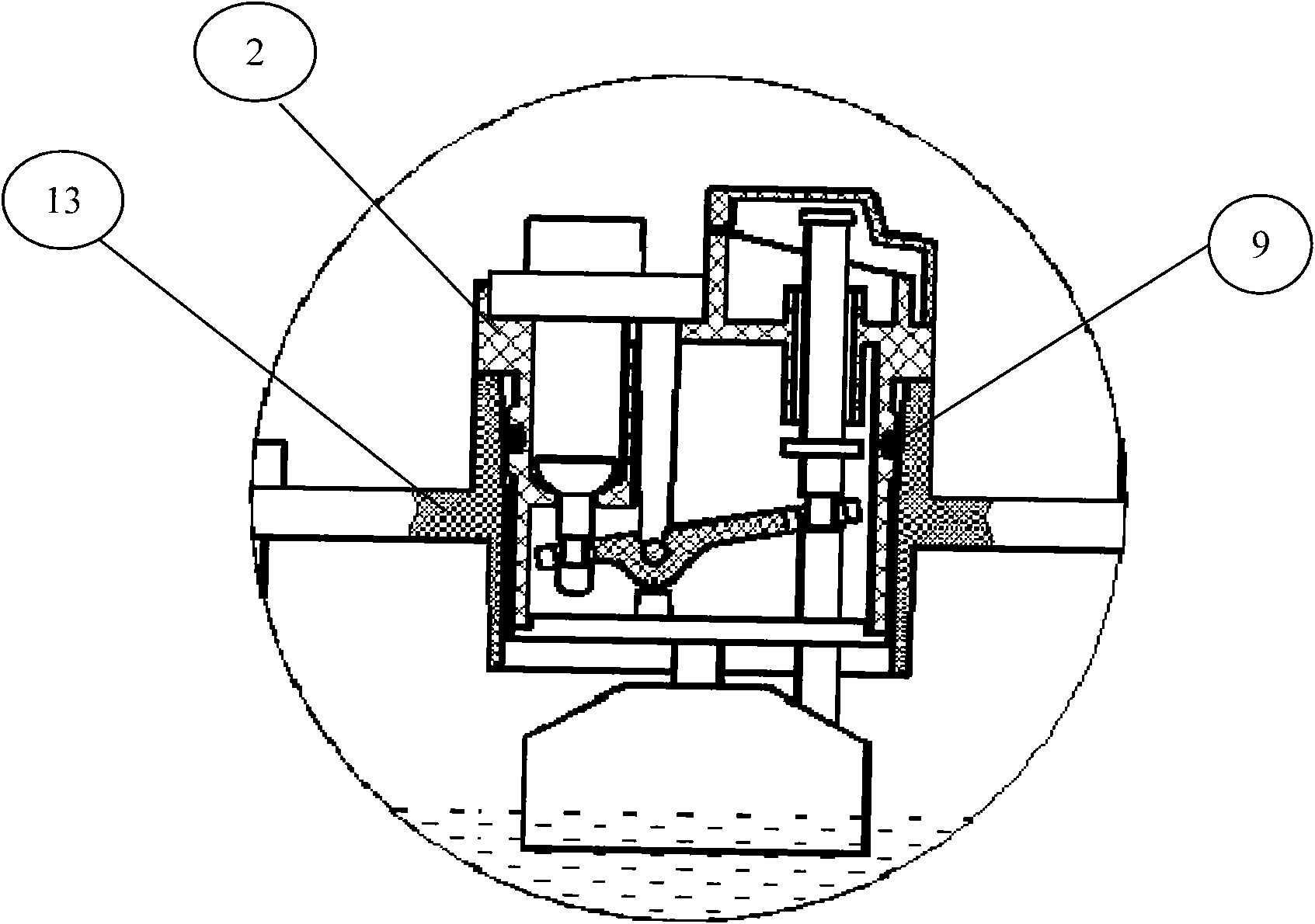

[0019] exist image 3 Among them, the liquid injection valve body 2 and the battery cover liquid filling hole 13 are fixed by mating, and the gap between the liquid injection valve body 2 and the battery cover liquid filling hole is sealed with a sealing ring 9 . The sealing ring is fixedly connected with the body in the form of a slot.

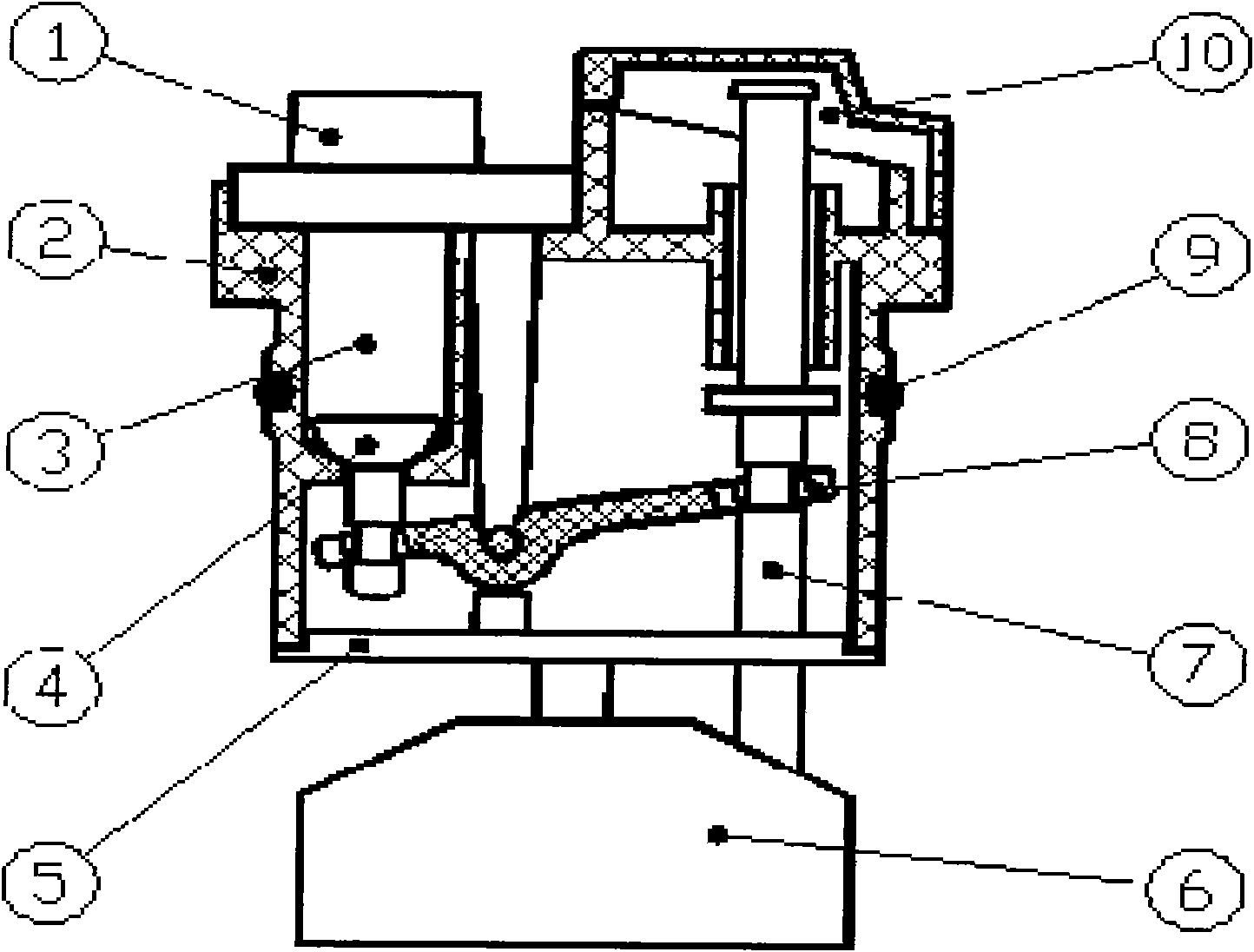

[0020] exist figure 1 Among them, a fixed rotating shaft 7 is arranged in the liquid injection valve body 2, and a water inlet channel 3 is arranged on one side of the radial direction of the rotating shaft, and a valve core 4 is provided for the water inlet channel to form a valve device. A lever 8 that the rotating shaft rotates, one end of the lever is movably connected with the spool, and the other end of the lever is movably connected with a buoy 6 . The upper end of the water inlet channel is connected to the water inlet inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com