Structure of a floating-ball valve

a technology of floating-ball valves and structures, which is applied in the direction of valve actuation floats, valve operating means/releasing devices, transportation and packaging, etc., can solve the problem that the conventional floating-ball valves are not suitable for all industrial purposes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

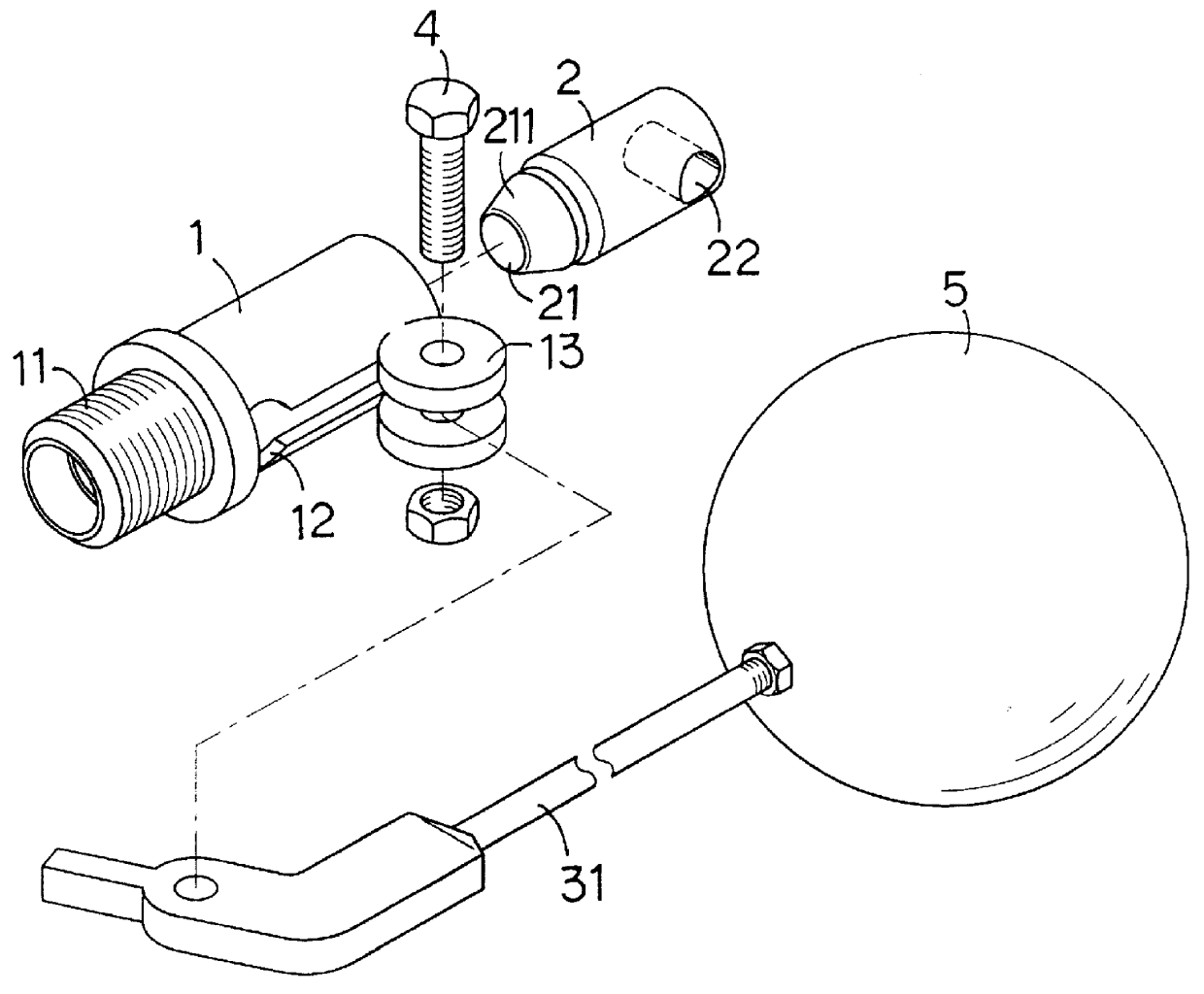

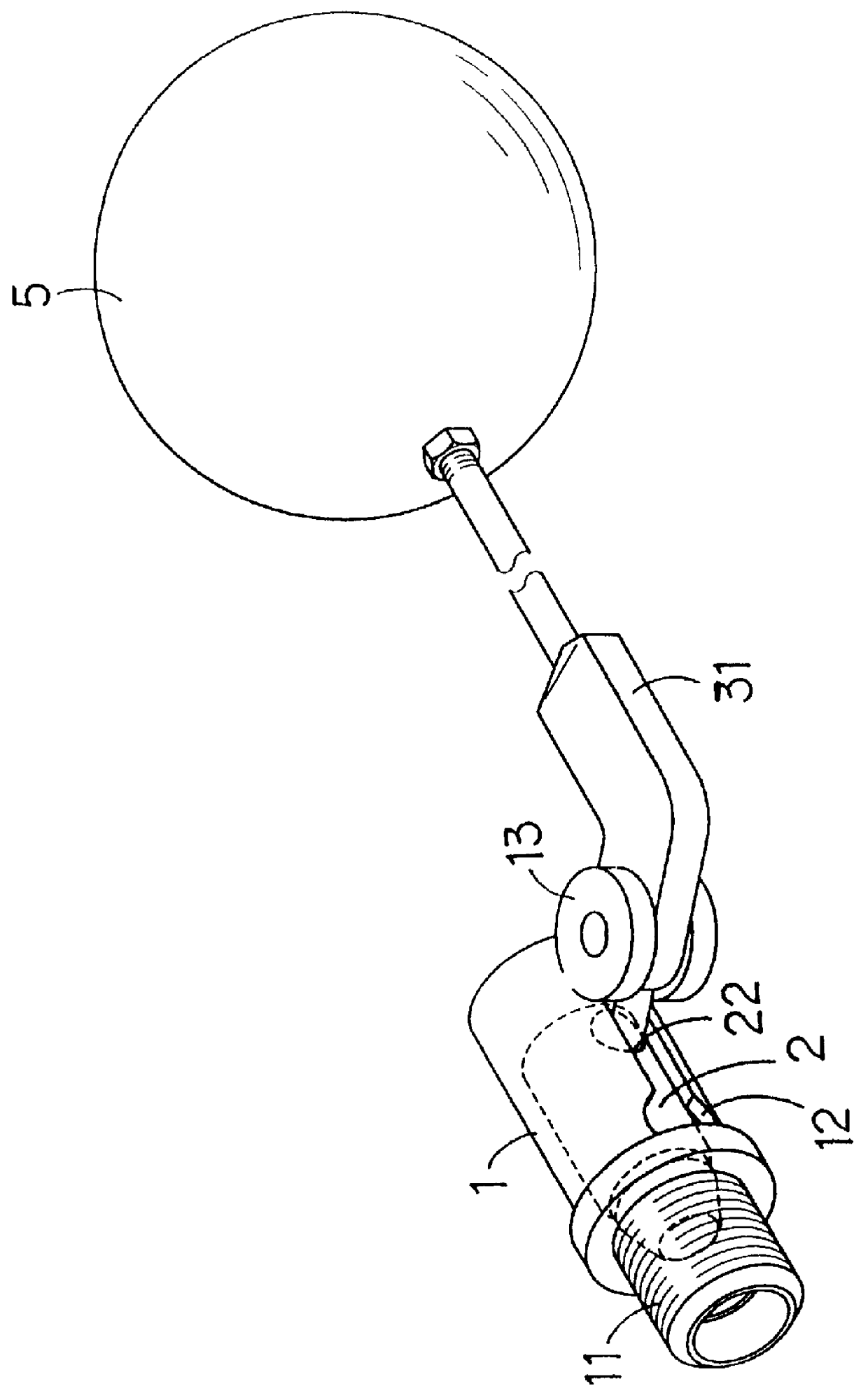

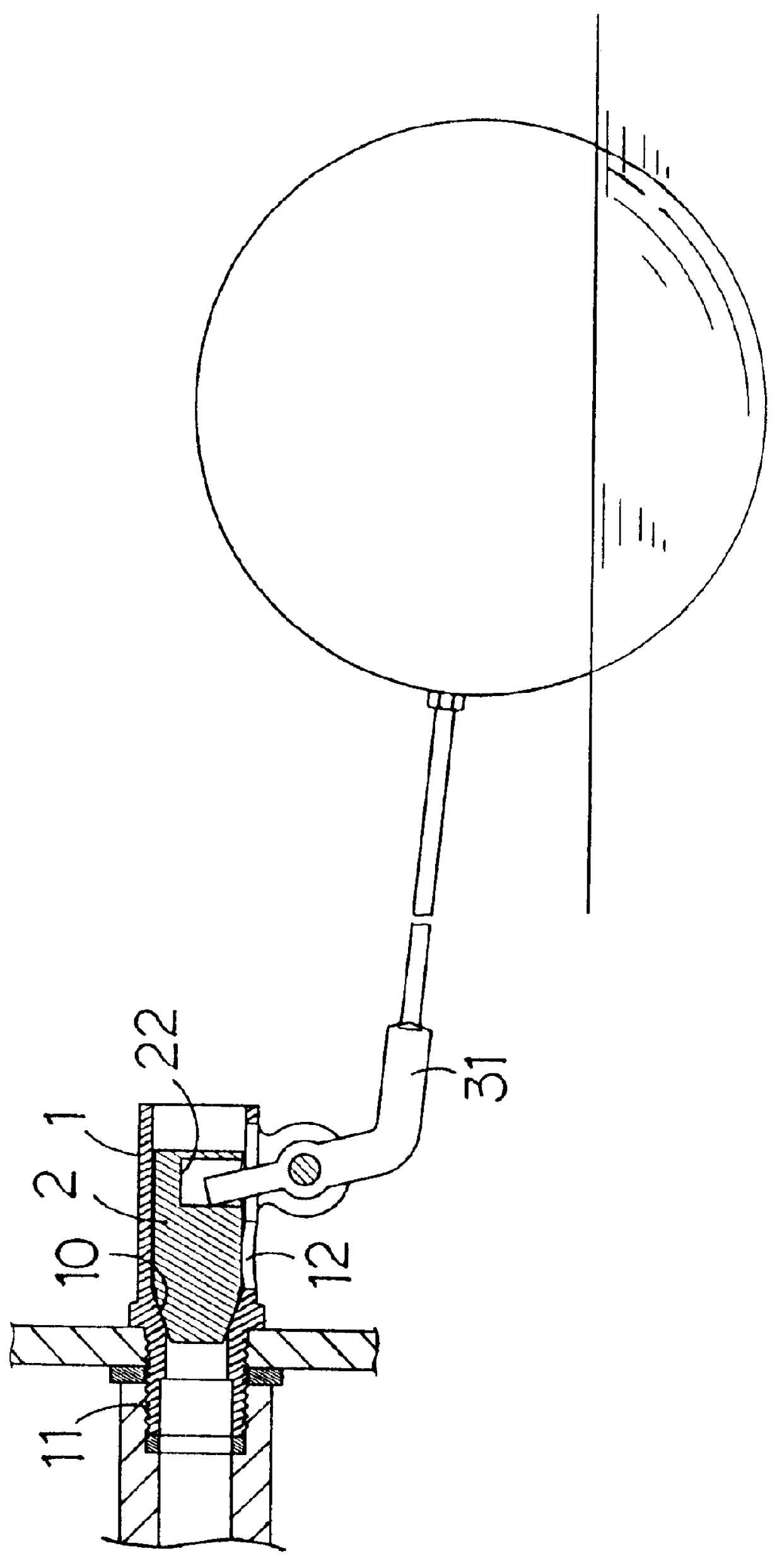

FIGS. 4 and 5 illustrate the structure of the floating-ball valve 40 comprising a valve seat 41, a valve insert 42, a cap 43, a crankshaft 44, a float 45 with a floating arm 46, wherein the front end of the valve seat 41 is provided with an outer threaded tube 416 to be fastened to the wall of a water tank (not shown) with nuts. The rear end of the valve seat 41 is also provided with an outer threaded tube 417 which can be mounted with the cap 43. A valve chamber 411, an water inlet 412 are provided to the internal of the valve seat 41, and the water inlet 412 is a pipe hole. At the bottom of the valve chamber 412, a water outlet 413 is provided and is in communication with an elongated slot 414. At the bottom of the valve seat 41, a pair of corresponding protruded members 415 are provided and one of the protruded member 415 has a threaded hole 418, and a screw 47 is used to mount the crankshaft 44 via a pore 441 thereon and the threaded hole 418 on the member 415 such that the cran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com