Hydraulic type energy recovery system for potential energy of boom of excavator

An energy recovery, hydraulic technology, applied in the direction of fluid pressure actuation system components, mechanical equipment, actuator accumulators, etc., can solve the problem of unstable outlet pressure, long response time for variable pump outlet pressure establishment, and difference in operating performance, etc. problem, to achieve the effect of improving recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

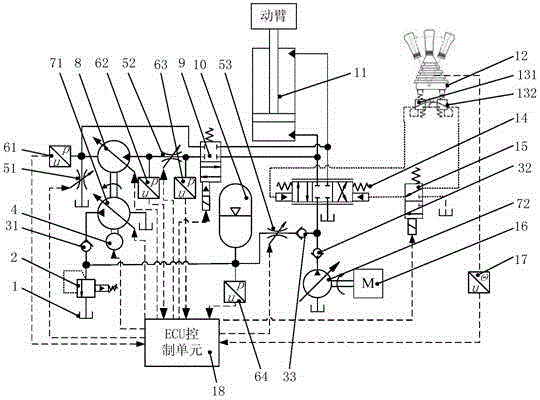

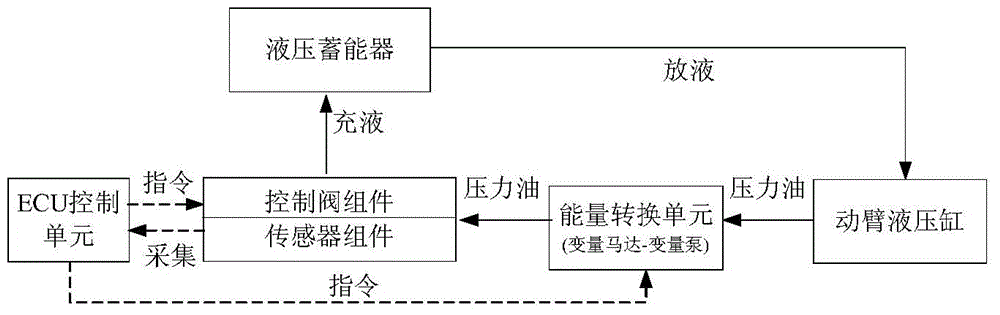

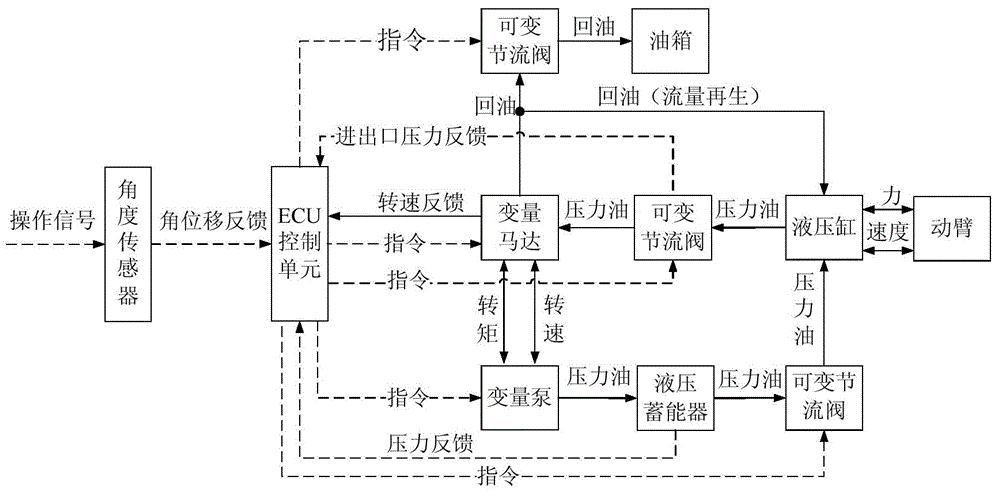

[0027] see Figure 1 to Figure 3 As shown, the excavator arm potential energy hydraulic energy recovery system includes a variable motor 8, two variable pumps 71, 72, an accumulator 10, control valves 2, 31, 32, 33, 51, 52, 53, 9, 131, 132, 14, 15, ECU control unit 18, pressure sensors 61, 62, 63, 64 speed sensor 4, hydraulic cylinder 11, fuel tank 1, engine 16;

[0028] The variable motor 8 is coaxially installed with the first variable pump 71 and the rotational speed sensor 4, the inlet of the variable motor 8 is connected in series with the throttle valve 52, and the other end of the variable motor 8 is divided into two ways to connect the throttle valve 51 and the reversing valve 9 respectively; the throttle valve 52 The other end is connected to the reversing valve 9, and the two working oil chambers of the reversing valve 9 are respectively connected to the upper and lower chambers of the hydraulic cylinder 11; the inlet of the variable pump 71 is connected to the oil t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com