Servo motor test bench and test method

A servo motor and test bench technology, applied in the field of servo motor manufacturing, can solve the problem of large torque detection error of the servo motor, and achieve the effect of satisfying torque detection and intuitive detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

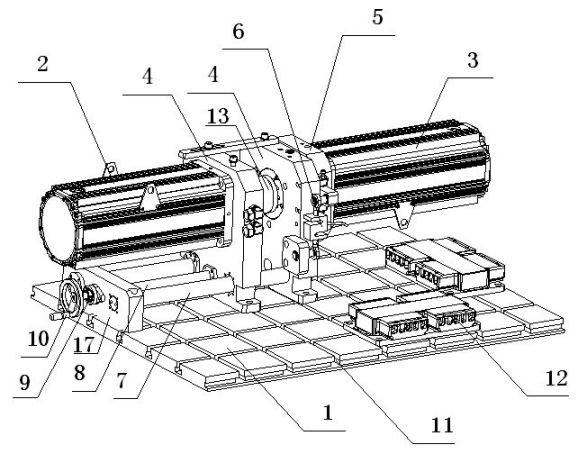

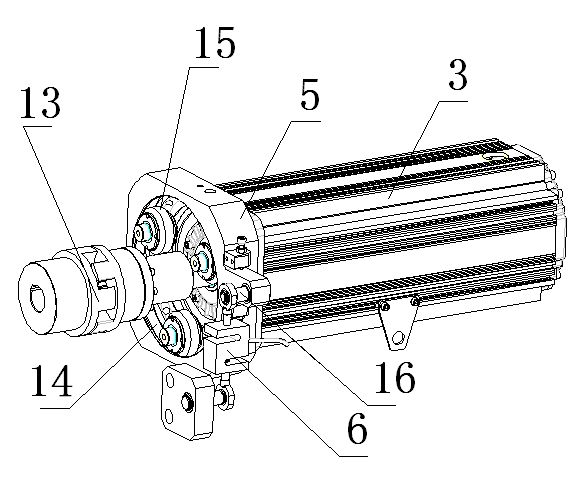

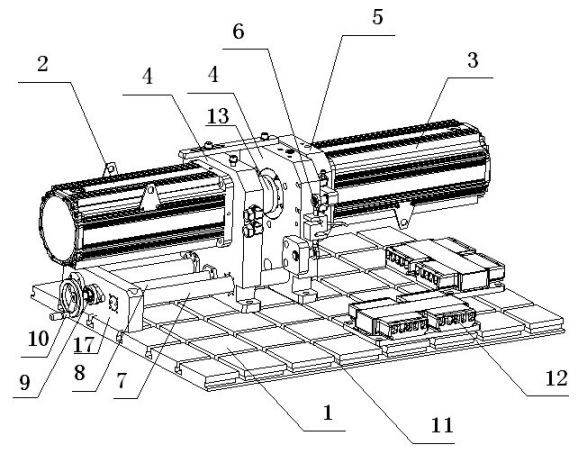

[0028] A kind of servo motor test bench of the present embodiment, see figure 1, including test bench 1, tested servo motor 2 installed on test bench 1, load motor 3, tested servo motor 2 is fixed to test bench 1 through flange 4, load motor 3 is passed through transition flange 5 and flange 4 Fixed on the test bench 1; the surface of the test bench 1 is provided with criss-crossing T-shaped small opening fixing grooves 11, the flange 4 is fixed on the fixing groove 11 by bolts, and an adjustment device is also provided on the test bench 1 to adjust The device includes a fixed plate 17, a screw nut 8, two guide rods 7, a screw mandrel 9, and an adjustment wheel 10. The bottom of the flange 4 is provided with two through holes, and the two guide rods 7 pass through the through holes. The fixed plate 17 Fixedly connected to one side of the surface of the test bench 1, one end of the guide rod 7 is fixedly connected to the fixed plate 17; the nut 8 is a tubular structure, one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com